紧固件各类产品名称术语中英文对照表文档格式.docx

《紧固件各类产品名称术语中英文对照表文档格式.docx》由会员分享,可在线阅读,更多相关《紧固件各类产品名称术语中英文对照表文档格式.docx(3页珍藏版)》请在冰豆网上搜索。

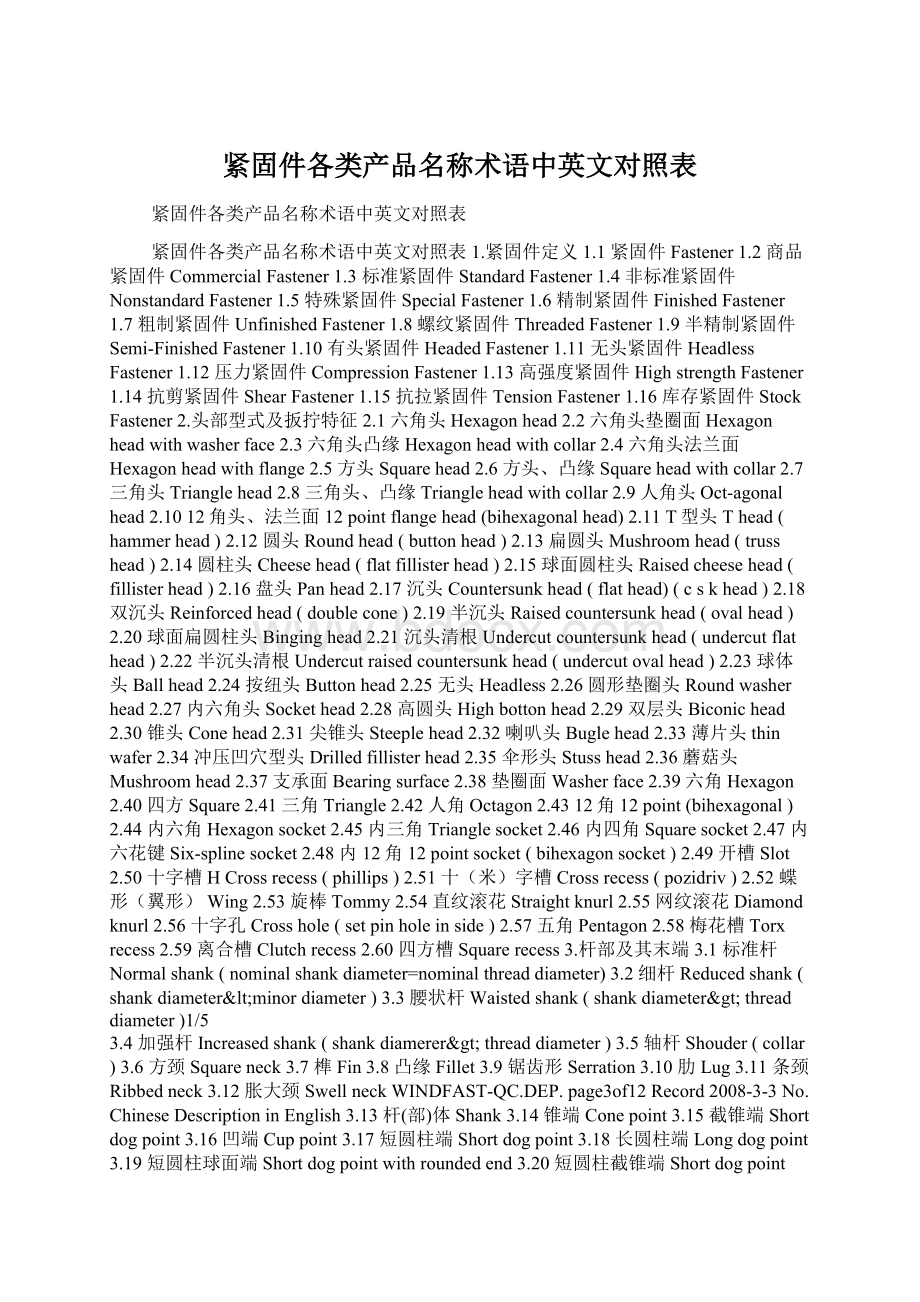

紧固件各类产品名称术语中英文对照表@#@紧固件各类产品名称术语中英文对照表@#@紧固件各类产品名称术语中英文对照表1.紧固件定义1.1紧固件Fastener1.2商品紧固件CommercialFastener1.3标准紧固件StandardFastener1.4非标准紧固件NonstandardFastener1.5特殊紧固件SpecialFastener1.6精制紧固件FinishedFastener1.7粗制紧固件UnfinishedFastener1.8螺纹紧固件ThreadedFastener1.9半精制紧固件Semi-FinishedFastener1.10有头紧固件HeadedFastener1.11无头紧固件HeadlessFastener1.12压力紧固件CompressionFastener1.13高强度紧固件HighstrengthFastener1.14抗剪紧固件ShearFastener1.15抗拉紧固件TensionFastener1.16库存紧固件StockFastener2.头部型式及扳拧特征2.1六角头Hexagonhead2.2六角头垫圈面Hexagonheadwithwasherface2.3六角头凸缘Hexagonheadwithcollar2.4六角头法兰面Hexagonheadwithflange2.5方头Squarehead2.6方头、凸缘Squareheadwithcollar2.7三角头Trianglehead2.8三角头、凸缘Triangleheadwithcollar2.9人角头Oct-agonalhead2.1012角头、法兰面12pointflangehead(bihexagonalhead)2.11T型头Thead(hammerhead)2.12圆头Roundhead(buttonhead)2.13扁圆头Mushroomhead(trusshead)2.14圆柱头Cheesehead(flatfillisterhead)2.15球面圆柱头Raisedcheesehead(fillisterhead)2.16盘头Panhead2.17沉头Countersunkhead(flathead)(cskhead)2.18双沉头Reinforcedhead(doublecone)2.19半沉头Raisedcountersunkhead(ovalhead)2.20球面扁圆柱头Binginghead2.21沉头清根Undercutcountersunkhead(undercutflathead)2.22半沉头清根Undercutraisedcountersunkhead(undercutovalhead)2.23球体头Ballhead2.24按纽头Buttonhead2.25无头Headless2.26圆形垫圈头Roundwasherhead2.27内六角头Sockethead2.28高圆头Highbottonhead2.29双层头Biconichead2.30锥头Conehead2.31尖锥头Steeplehead2.32喇叭头Buglehead2.33薄片头thinwafer2.34冲压凹穴型头Drilledfillisterhead2.35伞形头Stusshead2.36蘑菇头Mushroomhead2.37支承面Bearingsurface2.38垫圈面Washerface2.39六角Hexagon2.40四方Square2.41三角Triangle2.42人角Octagon2.4312角12point(bihexagonal)2.44内六角Hexagonsocket2.45内三角Trianglesocket2.46内四角Squaresocket2.47内六花键Six-splinesocket2.48内12角12pointsocket(bihexagonsocket)2.49开槽Slot2.50十字槽HCrossrecess(phillips)2.51十(米)字槽Crossrecess(pozidriv)2.52蝶形(翼形)Wing2.53旋棒Tommy2.54直纹滚花Straightknurl2.55网纹滚花Diamondknurl2.56十字孔Crosshole(setpinholeinside)2.57五角Pentagon2.58梅花槽Torxrecess2.59离合槽Clutchrecess2.60四方槽Squarerecess3.杆部及其末端3.1标准杆Normalshank(nominalshankdiameter=nominalthreaddiameter)3.2细杆Reducedshank(shankdiameter&@#@lt;@#@minordiameter)3.3腰状杆Waistedshank(shankdiameter&@#@gt;@#@threaddiameter)1/5@#@3.4加强杆Increasedshank(shankdiamerer&@#@gt;@#@threaddiameter)3.5轴杆Shouder(collar)3.6方颈Squareneck3.7榫Fin3.8凸缘Fillet3.9锯齿形Serration3.10肋Lug3.11条颈Ribbedneck3.12胀大颈SwellneckWINDFAST-QC.DEP.page3of12Record2008-3-3No.ChineseDescriptioninEnglish3.13杆(部)体Shank3.14锥端Conepoint3.15截锥端Shortdogpoint3.16凹端Cuppoint3.17短圆柱端Shortdogpoint3.18长圆柱端Longdogpoint3.19短圆柱球面端Shortdogpointwithroundedend3.20短圆柱截锥端Shortdogpointwithtruncatedconeend3.21刮销端Scrapepoint3.22自攻螺钉的末端Endforself-tappingscrews3.23自攻锁紧螺钉的末端Endforthreadrollingscrews(threadformedbydeformation)3.24辗制末端As-rollerend3.25平端Flatpoint3.26球面端(倒圆端)Roundedend3.27倒角端Chamferedend3.28钻孔端Gimletpoint3.29顶锻端Headerpoint3.30钉子端Nailpoint3.31针端Needlepoint3.32半圆端Ovalpoint3.33导向端Pilotpoint3.34球端Sphericalpoint3.35夹断端Pinckpoint4.尺寸及形位公差4.1实际尺寸Actualsize4.2允差Allawancesize4.3基本尺寸Basicsize4.4设计尺寸Designsize4.5配合Fit4.6尺寸极限Limitsofsize4.7公称尺寸Nominalsize4.8参改尺寸Referencesize4.9公差Tolerance4.10公差位置Positiontolerance4.11对边宽度Widthacrossflats4.12对角宽度Widthacrosscorner4.13螺纹通(测量)Gothreadgauge4.14螺纹止(测量)Nogothreadgauge4.15头下圆角半径Radiusunderhead4.16开槽宽度Slotrecesswidth4.17开槽深度Slotrecessdepth4.18十字槽插入深Penetrationdepth4.19十字槽直径Recessdiameter4.20十字槽宽度Recesswidth4.21头部直径Headdiameter4.22头部高度Headheight4.23头部角度Headangle4.24无螺纹杆径Shankdiameter(unthreadeddiameter)4.25无螺纹杆长Shanklength(unthreadedlength)4.26夹紧长度Griplength4.27螺纹大径Majorthreaddiameter4.28螺纹小径Minordiameter(small)4.29肩距Unthreadedlengthunderhead4.30螺纹长度Threadlength4.31杆长Totallength4.32内六角扳拧深度Depthhexagonsocket4.33内凹槽插入深度Keyengagement4.34外径Exterdiameter(outsidediameter)4.35内径Internaldiameter(insidediameter)4.36长度Length4.37宽度Breadth4.38厚度Thickness4.39高度Hight4.40孔径Borediameter4.41法兰直径Flangediamerer4.42方径长度Squarenecklength4.43方径宽度Squareneckwidth4.44凸缘高度Collarheight4.45凸缘直径Collardiameter4.46对称度Symmerty4.47同轴度Concentricity(coaxiality)4.48垂直度Perpendicularity4.49平行度Parallelism4.5直度Straightriess4.51槽杆同轴度Recessconcentricity4.52头杆同轴度Headconcentricity4.53头杆垂直度Headlnclination2/5@#@4.54斜度Angularity(taper)4.55弧度或弯曲度Boworcamber4.56尾尖角Pointangle4.57镀锌层厚度Zincplatingthickness4.58跳动Run-out4.59锥度Taperratio4.60榫长Niblength4.61榫宽Nibwidth4.62倒角.圆角Chamfer4.63平面度Flatness5.机械性能5.1抗拉强度Tensilestrength5.2屈服强度Proofstrength5.3屈服点Loweryieldstress5.4扭转强度Torquestrength(torsionalstrength)5.5剪切强度Shearstrength5.6冲击韧性Impactstrength5.7延伸率Elongation5.8断面收缩率Reduction5.9拉(压)应力Tension5.10破坏(扭)力矩Breakingtorque5.11晶粒度Grahularity5.12机械性能Mechanicalproperties5.13脱碳Decarburise5.14渗碳Carburization5.15最小剩余弹力Minimumresidualspingforce5.16压负荷的百分率Percenatageofcompressionload5.17表面硬度Surfacehardness5.18芯部硬度Corehardness5.19扭矩Torque(torsion)5.20表面硬化层深度Casehardendepth5.21氢脆Hydrogenembrittlement5.22压载(负)荷Compressionload5.23硬度试验Hardnesstest5.24头部坚固性试验Headsoundnesstest5.25扭转试验Twistingtest5.26弹性试验Resiliencetest5.27保证载荷试验Proofloadingtest5.28楔负载强度试验Wedgeloadingtest5.29弯曲试验Bendingtest5.30旋入试验Screw-intest5.31最小破坏力矩试验Torsionaltestandminimumtorques5.32永久变形试验Permanentdeformationtest5.33盐雾试验Saltspraytest5.34弹性Elasticity5.35韧性Tenacity(Toughnee)5.36塑性Fiexibility5.37磁力碳伤Magneticparticleinspection6.材料-热处理-表面处理6.1碳钢Carbonsteel6.2低碳钢Lowcarbonsteel6.3中碳钢Mediumcarbonsteel6.4合金钢Alloysteel6.5热处理钢Heat-treatedsteel6.6低马钢Lowcarbonmartensitesteel6.7奥氏体不锈钢Austeniticstainlesssteel6.8马氏体不锈钢Marteniticstainlesssteel6.9铁Iron6.10铝Aluminium6.11黄铜Brass6.12紫铜Copper6.13青铜Bronze6.14塑料Plastic6.15淬火Quenched6.16回火Tempered6.17退火Annealed6.18表面硬化Casehardened6.19强度等级Class6.20氧化Oxide(anodizing)6.21金属Metal6.22非金属Metalloid6.23发黑Black6.24本色Plain(selfcolour)6.25热处理Heattreatment6.26涂层Coating6.27表面处理Finish6.28涂蜡Waxed6.29镀锌(兰白锌)Zincplated(zinc/clear)6.30镀黄锌Zincyellow(Y.Z.P.)6.31镀黑锌Zincplatedblack6.32镀镍Nickelplated6.33镀铜Brassplated6.34热浸镀锌Hotdipgalvanized(H.D.G.)6.35电镀Electplating6.36机械镀锌Mechanicalgalvaizing6.37表面热处理Surfaceheattreatment7、加工方法7.1冷镦Coldheading7.2冷锻Coldforging7.3热锻Hotforging7.4成型Forming7.5切削(断)Cutting3/5@#@7.6缩径Shrinkdiameter7.7搓(攻)丝Threading7.8滚丝Threadrolling7.9拔丝Drawing7.10酸洗Pickling7.11钝化Passirating7.12废水处理Wastewatertreatment7.13研磨Grinding7.14镦粗Upsetting7.15开槽Soltting7.16刮削Sharing7.17滚花Kunrling7.18抛光Polishing7.19冲压Punching7.20滚动Tumbling7.21精整Trimming7.22铣削Milled7.23挤压Extruding7.24钻孔Drilling7.25模压Embossing7.26沉孔Countersinking7.27压印Coining7.28扩孔Counterboring7.29控削Broaching7.30辊光Burnishing7.31锻造Forging7.32剪切Shear7.33焊接Welded7.34喷砂Sandblasting8.表面缺陷8.1裂缝Cracks8.2淬火裂缝Quenchcracks8.3锻造裂缝Forgingcracks8.4锻造爆裂Forgingbursts8.5剪切爆裂Shearbursts8.6条痕Laps8.7凹痕Voids8.8皱纹Folds(pits)(laps)8.9切痕Toolmarks8.10损伤Damages8.11毛刺Burr8.12碎屑Chip8.13夹杂Inclusions8.14锈皮Sharing8.15飞边Flash8.16开裂Cracks8.17锈、锈斑Rust9.螺纹9.1普通螺纹Screwthread9.2锥螺纹Taperscrewsthread9.3自攻螺纹(宽牙螺纹)Tappingscrewsthread(spacedthread)9.4木螺钉螺纹Woodscrewsthread9.5米制螺纹Metricthread9.6ISO米制螺纹ISOMetricthread9.7米制细牙螺纹Metricfinepitchthread9.8ISO米制细牙螺纹ISOMetricfinepitchthread9.9寸制螺纹Inchthread9.10统一螺纹(ISO寸制)Unifiedscrewthread(ISOinch)9.11惠氏螺纹Whitworththread9.12管螺纹Pipethread9.13惠氏管螺纹Whitworthpipethread9.14螺旋线Helix9.15螺旋面Helicalsurface9.16外螺纹Externalthread9.17内螺纹Inernalthread9.18牙侧Flank9.19沟槽Groove9.20凸起Ridge9.21牙顶Crest9.22牙底Root9.23螺纹牙型Threadprofile9.24螺纹线Thread9.25单线螺纹Single--start--thread9.26多线螺纹Multi--start--thread9.27右旋螺纹Right--start--thread9.28左旋螺纹Left--start--thread9.29工作牙侧Pressure(load)flank9.30非工作牙侧Clearing(clearance)flank9.31牙底的圆角半径Rootradius9.32牙型高度Height(ordepth)ofthread9.33牙型角Includedangle9.34牙型半角Flanklead9.35中径线Pitchline9.36螺纹轴线Axisofthread9.37导程Flanklead9.38双牙导程Dualflanklead9.39螺距Flankpitch9.40双牙螺距Dualflanklead9.41大径Majordiameter9.42小径Minordiameter9.43中径Pitchdiameter4/5@#@9.449.459.469.479.489.499.50单一中径Simplepitchdiameter作用中径Virtualpitchdiameter螺纹升角Leadangle基本牙型Basicprofile伞状螺纹Umbrellathread粗牙螺纹Coarsethread细牙螺纹Finethread5/5@#@