1000TUE除锈涂装原则工艺.docx

《1000TUE除锈涂装原则工艺.docx》由会员分享,可在线阅读,更多相关《1000TUE除锈涂装原则工艺.docx(53页珍藏版)》请在冰豆网上搜索。

1000TUE除锈涂装原则工艺

江苏东方造船有限公司

除锈涂装原则工艺

第2页

共25页

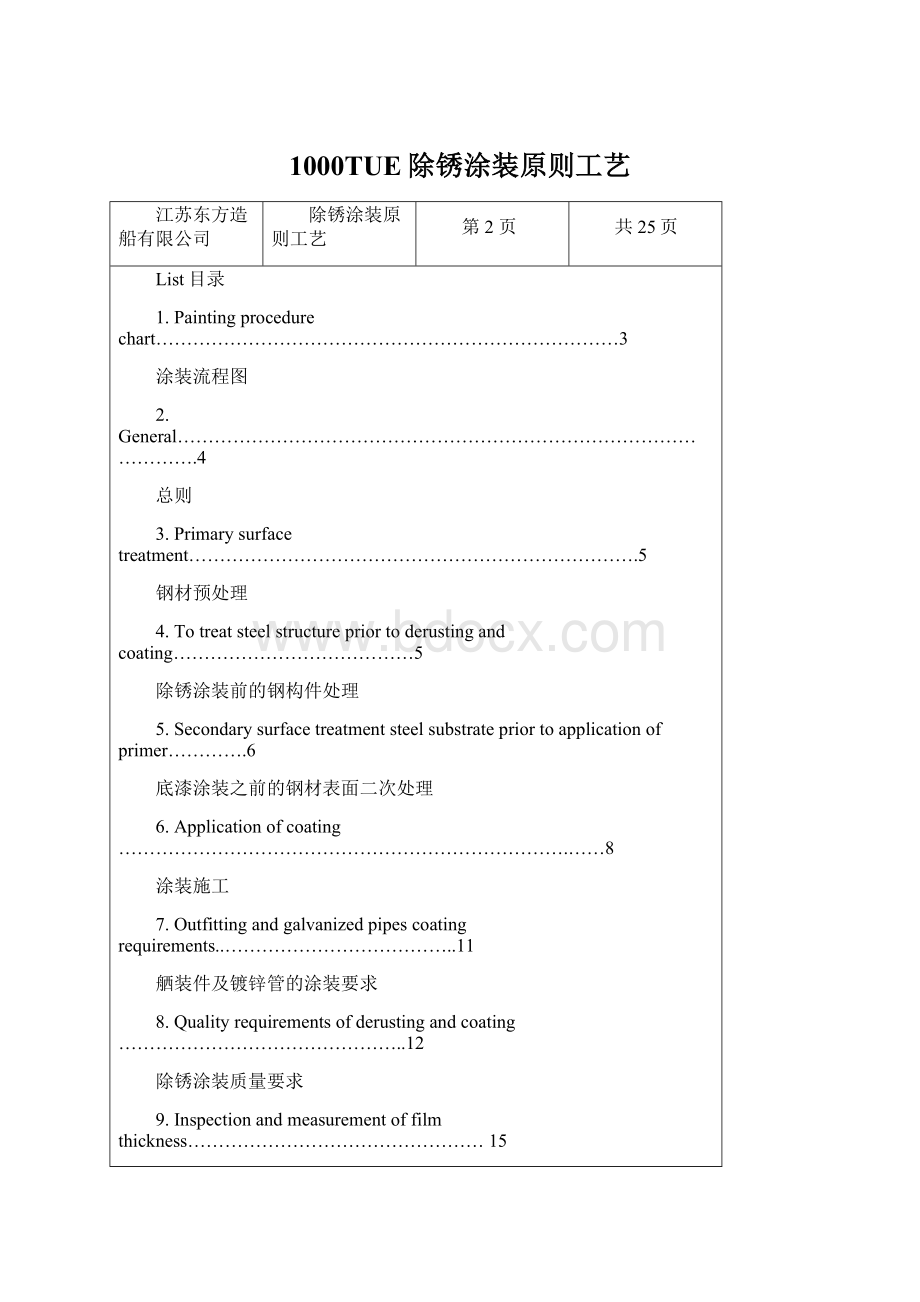

List目录

1.Paintingprocedurechart…………………………………………………………………3

涂装流程图

2.General…………………………………………………………………………………….4

总则

3.Primarysurfacetreatment……………………………………………………………….5

钢材预处理

4.Totreatsteelstructurepriortoderustingandcoating…………………………………5

除锈涂装前的钢构件处理

5.Secondarysurfacetreatmentsteelsubstratepriortoapplicationofprimer………….6

底漆涂装之前的钢材表面二次处理

6.Applicationofcoating……………………………………………………………….……8

涂装施工

7.Outfittingandgalvanizedpipescoatingrequirements..………………………………..11

舾装件及镀锌管的涂装要求

8.Qualityrequirementsofderustingandcoating………………………………………..12

除锈涂装质量要求

9.Inspectionandmeasurementoffilmthickness…………………………………………15

膜厚的检验与测量

10.Paintlist…………………………………………………………………………………...16

涂料列表

11.Paintingspecification……………………………………………………………………..17

涂装明细表

江苏东方造船有限公司

除锈涂装原则工艺

第3页

共25页

1.Paintingprocedurechart涂装流程图

Rawmaterial原材料

Primarysurfacepreparation表面预处理

Inorganiczincsilicateshop-primerwhichisTH-2approx20micronsorCuiZhutypeTH-2型或翠竹牌无机锌车间底漆约20μm

Steel-cutting,prefabricationandassembling

钢材切割、预制、组装

Blockassembly,pre-outfitting

分段组装、预舾装

Blocksecondarysurfacepreparation

分段二次表面处理

Inspection,appilicationofspecifiedcoatings

检验,涂装指定涂料

paintinginspection,touchup

油漆检验、修补

Erectiononberth,outfittingonslipway

船台合拢,船台舾装

Surfacepreparationtoerectionjoint,tightseamarea,outfitsanddamagearea

合拢焊缝、密性焊缝、舾装件及损伤处等区域表面处理

Inspection,applythesamepaintschemeassurroundingorspecifiedcoating

检验,涂与周围相同的涂料或指定的涂料

Paintinginspection,touchup油漆检验、修补

Launching,outfittingatpier下水、码头舾装

Surfacepreparationtooutfits,damageareaandremainingarea

舾装件、损伤区域及剩余区域表面处理

Inspection,applythespecifiedcoating检验,涂装指定涂料

Paintinginspection,touch-upandclosetanks

油漆检验、修补及封舱

Indrydock,cleaningandtreatmentthewholeshellandapplythesubsequentpaints

进坞,清理船壳外表,涂装完剩余涂料

Cleaningandtreatmentbeforedelivery交船前清洁或处理

江苏东方造船有限公司

除锈涂装原则工艺

第4页

共25页

2.General总则

2-1、ThewholevesselprotectivebybeingcoatedwiththeproductofSIGMA,allsteeltobuildthisvesselshouldbecoatedwithinorganiczincshopprimer(Shopprimerarebuilder’sstandard,LiYangTH-2typeandCuiZhufromJingjiang)priortobeingused.

本船采用式玛公司的油漆产品作为全船防腐保护材料;钢材投入使用前的预处理车间底漆为无机锌车间底漆(车间底漆为建造者的标准,溧阳TH-2型和靖江翠竹牌);

2-2、Theapplicationworktobeperformedinaccordancewiththebuilder’spracticeandthepaintmanufacturer’srecommendation.

防腐涂装工作的实施,按照建造方的惯例及涂料制造商的建议执行;

2-3、Thecolorsoffinalpaintaretobeinaccordancewithowner’sstandard.Thecolourofeachcoatexceptfinalpaintaretobedecidedbythebuilderinconsiderationofmanufacturer’scolorcard.

完工漆的颜色按照船东的标准,除此之外各层油漆的颜色在考虑油漆制造商标准色卡的基础上由建造方决定;

2-4、Thesurfacequalityofsteelpre-treatedshouldaccordingtostandardofISO8501-1:

1998.

本船除锈涂装前的钢材表面处理质量等级执行ISO8501-1:

1998国际标准;

2-5、Steelsurfacepre-treatmentbeforeapplication,primer,andfinishcoatafterapplicationshouldallbeinspectedandapprovedbyon-siteshipownerandtechnicalrepresentativesofSIGMA.

本船涂装前的钢材表面处理、涂装后的完工底漆和所有完工面漆均需得到船东代表和式玛公司现场技术代表的验收认可;

2-6、ThevesselshouldbecoatedaccordingtothestandardandtherequirementsofSIGMA,applicationshouldbepreformedundertheguidanceofon-sitetechnicalrepresentative.

本船防腐涂装的施工,需依照式玛公司的标准和要求,并在其现场技术代表的指导下进行;

2-7、Thewaterballasttankandvoidthatareunderlightwaterlineofthevesselshouldbefinishedbeforelaunching.

原则上该船外板轻载水线以下的压载水舱、空舱等舱室的完工涂装均需在船舶下水之前施工完毕;

2-8、Thepositionorareawhicharenotspecifiedinthe“paintscheme”ofthisspecificationshallbeappliedsameasthesurroundings.

江苏东方造船有限公司

除锈涂装原则工艺

第5页

共25页

本工艺说明书的油漆配套表中未列入的部位或区域应根据周围环境的除锈和油漆要求相一致。

3.Primarysurfacetreatment钢材预处理

3-1、Allsteelandshapesteelwhosethicknessisonlessthan6㎜mustbepre-treatedandthesurfacequalityofsteelpre-treatedmustaccordwithSa2.5beforebeingused,theroughnessofsteelpre-treatedmayrangefrom40μmto70μm.

船体结构≥6mm的钢材、型材,使用前必须采用喷丸处理至Sa2.5级标准,表面粗糙度在40–70μm;

3-2、Thesteelpre-treatedshouldbecoatedwithinorganiczincshopprimerupto20μmassoonaspossible,butthehighestDFTmustbeunder25μm.

经表面预处理后的钢材,应在尽可能短的时间内喷涂20μm左右的无机锌车间底漆,最大膜厚不超过25μm;

3-3、Afterbeingcoatingwithshopprimerthehighstrengthsteelmustbemarkedwithdifferentcolorsoastobedistinguishedfromthecommonsteel.

对于高强度钢应采用不同颜色的车间底漆,以便区分于普通钢材,避免使用过程中的混淆;

3-4、Alloutfittingstructuresincapableofbeingpre–treatedshouldbesandblastedandthencoatedwithshopprimerbeforebeinginstalledtothevessel.

无法进行喷丸预处理的构件,上船安装之前需经喷砂处理并涂装车间底漆;

3-5、Thechemicalderustmethodsuchaspickleisapplicableforthesteelwhichisunsuitableforsandblasting.

对不宜冲砂处理的钢材用化学除锈方式进行处理;

3-6、Allfreeedgesofblock’soutfittingstructuresshouldbeabradedtoSt3withpowertoolsandthenbecoatedwithprimerbeforebeinginstalledtothevessel.

船体分段的结构零部件所有自由边在安装之前需以动力工具打磨处理至St3级并涂装

底漆。

4.Totreatsteelstructurepriortoderustingandcoating除锈涂装前的钢构件处理

4-1、Allsharpedgesofsteelduetogascuttingorothercuttingmethodsshouldbeedgedandabraded,Roflooseedgepolishedmayrange2㎜inengineroom,workroom,warehouse,inthehold,voidspacesandsoon.,andthatmayrangefrom2㎜to3㎜inwatertanksandexposedareas.

江苏东方造船有限公司

除锈涂装原则工艺

第6页

共25页

所有因气割或其它切割方式造成的钢材自由边的尖锐边缘都必须磨光倒角。

机舱、工作舱室、仓库、货舱、空舱部位磨光倒角等部位磨光倒角R=2mm;,饮水舱、水舱和露天区域磨光倒角R=2-3mm;

4-2、Spattersandundercutsduetoweldingshouldberemoved,thedefectssuchaspinholesandundercutsshouldberepairedbymeansofweldingandthenbeabradedifdeeperthan1㎜,sharpprominencemustbeabradeddown.

所有因焊接造成的飞溅应去除,焊缝咬边、气孔等深度≥1mm的缺陷都应补焊和磨光,焊瘤和尖锐的突出物均须磨平;

4-3、Afterdisassemblingdefectsduetoscaffoldsandtrunnionsshouldberepairedbyweldingorabrading.

拆除脚手架、吊攀后所有钢材的表面缺陷均须补焊和磨平。

5.Secondarysurfacetreatmentsteelsubstratepriortoapplicationofprimer

底漆涂装之前的钢材表面二次处理

5-1、Beforeblocksandblasting,portofallpipesthatareinstalledshouldbewrappedwithprotectivematerialtoavoidincursionbydust.Thegalvanizedpipesinvariouswatertanksshouldbeprotectedtoavoiddamagingthegalvanizedfilmduringderusting.

分段除锈之前,经预舾装的所有管道端口必须用三防布或其它材料仔细包扎好,以避免灰尘的侵入;各种水舱内部的镀锌管必须加以保护以免除锈时破坏锌层;

5-2、Ductsupports,supportfoundationsandsomesmallframeworksmustbesandblastedorabradedandthenbecoatedwithprimerandfinishcoatbeforebeinginstalled.

管系支承和支承座以及一些小的结构件,安装之前均须进行喷砂或打磨(除锈)处理和底面漆的完全涂装;

5-3、Secondarysurfacetreatmentincludingderustingandcleaningmustbecarriedoutbeforesteelsurfacebeingcoatedwiththefirstprimerofthecoatschedulesystem.

在涂装涂料系统的第一道底漆之前,所有的钢材表面均须进行涂装前的二次表面处理,二次表面处理工作包括除锈和清洁工作;

5-4、Whensandblastingorgrindingisapplied,onlysweepblastingorroughingandcleantotheintactshopprimerareaofsteelsurface.

当冲砂(或打磨)时,对车间底漆未受损的钢材表面只进行扫砂(拉毛)、清洁处理;

5-5、Suchlocationasfreshwatertank,hatchcoveroutsidewithpureepoxyorzincinorganicsilicateapplicationshouldbefullysandblastedtogradeSa2.5ofentirearea.

淡水舱、舱口盖上表涂纯环氧漆或无机硅酸锌漆的全部部位冲砂等级必须达Sa2.5级;

江苏东方造船有限公司

除锈涂装原则工艺

第7页

共25页

5-6、Afterblockassembly,secondarytreatmentpriortotouchingupmustbecarriedoutby

mothodofpowertools.

分段合拢后,所有修补涂装前的钢材表面二次处理均需以动力工具打磨的方法进行;

5-7、Areaswhichareeasytobeabrasedsuchasdeck,floorshouldnotbederustedandpaintedduringpaintingatthestageofsubsection,theapplicationsafterassembly.

分段涂装时所有的甲板、地板等合拢后油漆磨损量较大的部位原则上不予以除锈涂

装,待合拢后整体除锈涂装;

5-8、Secondarysurfacepreparationforrust,weldpart,burntanddamagedpartsofshopprimershallbecarriedoutasbelowtable,

对锈蚀、焊接、灼烧及车间底漆损伤区域的二次表面处理应按下表执行:

Location

区域

Gradeofsurfacepreparation表面处理等级

Atblockphase

分段阶段

Afterassemblyontheslipway

船台合拢后阶段

Shell,topside外板、干舷

Sa2.5

Sa2.5

Ballasttanks压载舱

Sa2.5

St3

voidandcofferdams空舱、隔离舱

Sa2

St3

Deckhouse,exterior/interior甲板室内、外表

St3

St3

Holds货舱

Sa2

St3

Machineryspaceandstoreetc.

机械处所、储存室

St2

St2

Sludgeanddirtywtr.tk.油渣舱、污水舱

Sa2

St3

Hatchcoveroutside舱口盖上表

Sa2.5

Sa2.5

Hatchcoverdownside舱口盖下表

Sa2

St3

Potablewatertanks饮用水舱

Sa2.5

St3

F.O.tankandD.O.tank燃油舱、柴油舱

—

St2

Lubricationoiltank滑油舱

—

St3

Exposeddeck露天甲板

—

Sa2.5

Otherlocation其它区域

Detailsseethepaintspecification详见油漆配套表

江苏东方造船有限公司

除锈涂装原则工艺

第8页

共25页

6.Applicationofcoating涂装施工

6-1、Anyofcoatsmustbeappliedaccordingtorequirementsofsurfacetreatment,substratetemperature,temperatureofcoat,relativelyhumidityofsurroundingandcoatintervalspecifiedintheproductdataofSIGMA.

任何油漆的涂装施工,均需按照式玛油漆产品说明书有关表面处理、底材温度、油漆温度、环境相对湿度和涂装时间间隔限定的规定;

6-2、Duringapplicationrelativelyhumidityofairmustbeunder85%,andtemperatureofsteelsubstratemustbe3℃abovethedewpointofair.

涂装时环境空气相对湿度必须小于85%,底材表面温度至少要高出空气露点温度3℃;

6-3、Allapplicationareasshouldbefreefromrust,salt,oil,water,andotherpollutantsbeforeapplying.

涂装前所有被涂表面均需达到无锈、无盐份、无油、无水和无其它污染物的清洁程度;

6-4、Onprincipletoapplycoatsbyairlessspraying,butsmallersubstructuresuchasmast,pipes,anglesteel,waterholetobecoatedbymeansofbrushingorrolling.

油漆的施工原则上均采用高压无气喷涂,桅杆、管子、角钢、包角、流水孔等面积较小的部件可以刷涂,甲板的面漆允许刷涂或辊涂;

6-5、Ifitisadoptedtoairlessspray,beforeapplicationtheseareasshouldbestripecoatedsuchashand-welding,freeadges,lightingholes,areaswithin20㎜farfromedge,backpanelofshapedsubstrates,backsphericalsurfaceofflat-bulbsteel,backofpipes,cornersanddifficultofaccess.

高压无气喷涂,在每一道油漆之前,所有的手工焊缝、钢材的自由边、流水孔、减轻孔以及边缘20mm范围内和型材面板的背面、球扁钢的球头、管子背面以及喷涂难以到达的部位和喷涂回风角等部