射线检测常见缺陷图.docx

《射线检测常见缺陷图.docx》由会员分享,可在线阅读,更多相关《射线检测常见缺陷图.docx(16页珍藏版)》请在冰豆网上搜索。

射线检测常见缺陷图

射线检测常见缺陷图

Thefollowingdiscontinuitiesaretypicalofalltypesofwelding.isaconditionwheretheweldfillermetaldoesnotproperlyfusewiththebase

metalorthepreviousweldpassmaterial(interpasscoldlap).Thearcdoesnotmeltthe

basemetalsufficientlyandcausestheslightlymoltenpuddletoflowintobasematerial

withoutbonding.

f二」:

D兄.「.-心门八一几

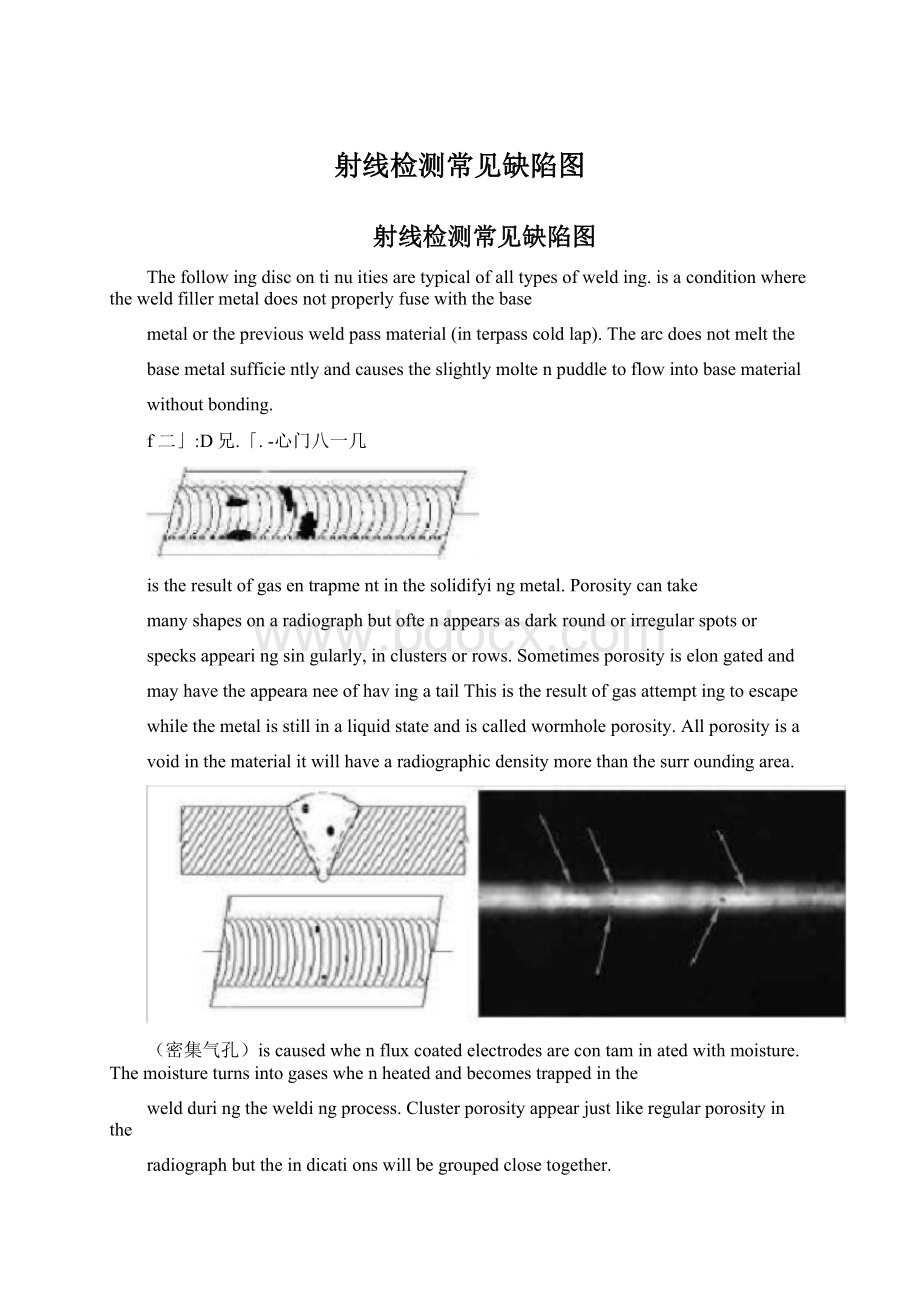

istheresultofgasentrapmentinthesolidifyingmetal.Porositycantake

manyshapesonaradiographbutoftenappearsasdarkroundorirregularspotsor

specksappearingsingularly,inclustersorrows.Sometimesporosityiselongatedand

mayhavetheappearaneeofhavingatailThisistheresultofgasattemptingtoescape

whilethemetalisstillinaliquidstateandiscalledwormholeporosity.Allporosityisa

voidinthematerialitwillhavearadiographicdensitymorethanthesurroundingarea.

(密集气孔)iscausedwhenfluxcoatedelectrodesarecontaminatedwithmoisture.Themoistureturnsintogaseswhenheatedandbecomestrappedinthe

weldduringtheweldingprocess.Clusterporosityappearjustlikeregularporosityinthe

radiographbuttheindicationswillbegroupedclosetogether.

arenonmetallicsolidmaterialentrappedinweldmetalorbetweenweldandbasemetal.Inaradiograph,dark,jaggedasymmetricalshapeswithintheweld

oralongtheweldjointareasareindicativeofslaginclusions.

occurswhentheweld

metalfailstopenetratethejoint.Itisoneofthemost

objectionablewelddiscontinuities.

Lackofpenetrationallowsanaturalstressriserfromwhichacrack

maypropagate.The

appearanceonaradiographisadarkareawithwell-defined,straightedgesthatfollows

thelandorrootfacedownthecenteroftheweldment.

(未融合)isaconditionwheretheweldfillermetaldoesnot

properlyfusewiththebasemetal.Appearanceonradiograph:

usuallyappearsasadarklineor

linesorientedinthedirectionoftheweldseamalongtheweldpreparationorjoining

area.

isconditionwheretheweldmetalhascontractedasitcoolsandhasbeendrawnupintotherootoftheweld.Onaradiographitlooks

similartolackofpenetrationbutthelinehasirregularedgesand

itisoftenquitewidein

isanerosionofthebasemetalnexttotherootoftheweld.Inthe

radiographicimageitappearsasadarkirregularlineoffsetfromthecenterlineoftheweldment.UndercuttingisnotasstraightedgedasLOPbecauseit

isanerosionofthebasemetalnexttothecrown

oftheweld.Intheradiograph,itappearsasadarkirregularline

alongtheoutsideedge

aretermsassociatedwithaconditionwheretwopiecesbeingweldedtogetherarenotproperlyaligned.Theradiographicimageisanoticeable

differeneeindensitybetweenthetwopieces.Thediffereneeindensityiscausedbythe

differenceinmaterialthickness.Thedark,straightlineiscaused

byfailureoftheweld

metaltofusewiththelandarea.

isanareaofaweldwherethethicknessofweldmetaldepositedislessthanthethicknessofthebasematerial.Itisveryeasyto

determinebyradiographiftheweldhasinadequatereinforcement,becausetheimage

densityintheareaofsuspectedinadequacywillbemore(darker)thantheimagedensity

ofthesurroundingbasematerial.

isanareaofaweldthathasweldmetaladdedinexcessofthatspecifiedbyengineeringdrawingsandcodes.Theappearaneeonaradiographisalocalized,lighterareaintheweld.Avisualinspectionwilleasily

determineiftheweldreinforcementisinexcessofthatspecifiedbytheengineering

requirements.

canbedetectedinaradiographonlywhentheyarepropagatinginadirectionthatproducesachangeinthicknessthatisparalleltothex-raybeam.Cracks

willappearasjaggedandoftenveryfaintirregularlines.Crackscansometimesappear

as"tails"oninclusionsorporosity.

ThefollowingdiscontinuitiesarepeculiartotheTIGweldingprocess.These

discontinuitiesoccurinmostmetalsweldedbytheprocessincludingaluminumand

stainlesssteels.TheTIGmethodofweldingproducesacleanhomogeneousweldwhich

whenradiographediseasilyinterpreted.

Tungstenisabrittleandinherentlydensematerialusedin

theelectrodeintungsteninertgaswelding.Ifimproperweldingproceduresareused,

tungstenmaybeentrappedintheweld.Radiographically,tungstenismoredensethan

aluminumorsteel;therefore,itshowsasalighterareawithadistinetoutlineonthe

radiograph.

areusuallyvisibleonthesurfaceofmaterialbeingwelded

(especiallyaluminum).Oxideinclusionsarelessdensethanthesurroundingmaterialsand,

therefore,appearasdarkirregularlyshapeddiscontinuitiesinthe

radiograph.

ThefollowingdiscontinuitiesaremostcommonlyfoundinGMAWwelds.

areshortlengthsofweldelectrodewire,visibleonthetoporbottomsurfaceoftheweldorcontainedwithintheweld.Onaradiographtheyappearaslight,"wirelike"

indications.

resultswhentoomuchheatcausesexcessiveweldmetalto

penetratetheweldzone.Oftenlumpsofmetalsagthroughtheweldcreatingathick

globularconditiononthebackoftheweld.Theseglobsofmetalarereferredtoasicicles.

Onaradiograph,burnthroughappearsasdarkspots,whichareoftensurroundedby

lightglobularareas(icicles).

RadiographInterpretation—Castings

Themajorobjectiveofradiographictestingofcastingsisthedisclosureofdefectsthatadverselyaffectthestrengthoftheproduct.

Castingareaproductformthatoftenreceiveradiographicinspectionsincemanyofthedefectsproducedbythecastingprocessarevolumetricinnatureand,thus,relativelyeasytodetectwiththismethod.Thesediscontinuitiesofcourse,arerelatedtocastingprocessdeficiencies,which,ifproperlyunderstood,canleadtoaccurateaccept-rejectdecisionsaswellastosuitablecorrectivemeasures.Sincedifferenttypesandsizesofdefectshavedifferenteffectsoftheperformanceofthecasting,itisimportantthattheradiographerisabletoidentifythetypeandsizeofthedefects.ASTME155,StandardforRadiographsofcastingshasbeenproducedtohelptheradiographermakeabetterassessmentofthedefectsfoundcomponents.Thecastingsusedtoproducethestandardradiographshavebeendestructivelyanalyzedtoconfirmthesizeandtypeofdiscontinuitiespresent.Thefollowingisabriefdescriptionofthemostcommondiscontinuitytypesincludedinexistingreferenceradiographdocuments(ingradedtypesorassingleillustrations).

Gasporosityorblowholesarecausedbyaccumulatedgasorairwhichistrappedbythemetal.Thesediscontinuitiesareusuallysmoothwalledroundedcavitiesofaspherical,elongatedorflattenedshape.Ifthe

sprueisnothighenoughtoprovidethenecessaryheattransferneededtoforcethegasorairoutofthemold,

thegasorairwillbetrappedasthemoltenmetalbeginstosolidify.Blowscanalsobecausedbysandthatis

toofine,toowet,orbysandthathasalowpermeabilitysothatgascan'tescape.Toohighamoisturecontentin

thesandmakesitdifficulttocarrytheexcessivevolumesofwatervaporawayfromthecasting.Anothercause

ofblowscanbeattributedtousinggreenladles,rustyordampchillsand

chaplets.

Sandinclusionsanddrossarenonmetallicoxides,appearingontheradiographasirregular,darkblotches.Thesecomefromdisintegratedportionsofmoldorcorewallsand/orfromoxides(formedinthemelt)which

havenotbeenskimmedoffpriortointroductionofthemetalintothemoldgates.Carefulcontrolofthemelt,

properholdingtimeintheladleandskimmingofthemeltduringpouringwillminimizeorobviatethissource

oftrouble.

Shrinkageisaformofdiscontinuitythatappearsasdarkspotsontheradiograph.Shrinkageassumesvarious

formsbutinallcasesitoccursbecausemoltenmetalshrinksasitsolidifies,inallportionsofthefinalcasting.

Shrinkageisavoidedbymakingsurethatthevolumeofthecastingisadequatelyfedbyriserswhich

sacrificiallyretaintheshrinkage.Shrinkagecanberecognizedinanumberofcharacteristicbyvarying

appearancesonradiographs.Thereareatleastfourtypes:

(1)cavity;

(2)dendritic;(3)filamentary;and(4)

spongetypes.Somedocumentsdesignatethesetypesbynumbers,withoutactualnames,toavoidpossible

misunderstanding.

Cavityshrinkageappearsasareaswithdistinctjaggedboundaries.

Itmaybeproducedwhenmetalsolidifies

betweentwooriginalstreamsofmelt,comingfromopposite

directionstojoinacommonfront;cavity

shrinkageusuallyoccursatatimewhenthemelthasalmostreached

solidificationtemperatureandthereisno

sourceofsupplementaryliquidtofeedpossiblecavities.

isadistributenofveryfinelinesorsmallelongatedcavitiesthatmayvaryindensityandareusuallyunconnected.

usuallyoccursasacontinuousstructureofconnectedlinesorbranchesofvariablelength,widthanddensity,oroccasionallyasa

network.

showsitselfasareasoflacytexturewithdiffuseoutlines,

generallytowardthemid-thicknessofheaviercastingsections.Spongeshrinkagemaybe

dendriticorfilamentaryshrinkage;filamentaryspongeshrinkageappearsmoreblurred

becauseitisprojectedthroughtherelativelythickcoatingbetweenthediscontinuities

andthefilmsurface.

arethin(straightorjagged)linearlydisposeddiscontinuitiesthatoccurafterthemelthassolidified.Theygenerallyappearsinglyandoriginateatcastingsurfa