CATIA线框曲面造型旋钮 knob.docx

《CATIA线框曲面造型旋钮 knob.docx》由会员分享,可在线阅读,更多相关《CATIA线框曲面造型旋钮 knob.docx(19页珍藏版)》请在冰豆网上搜索。

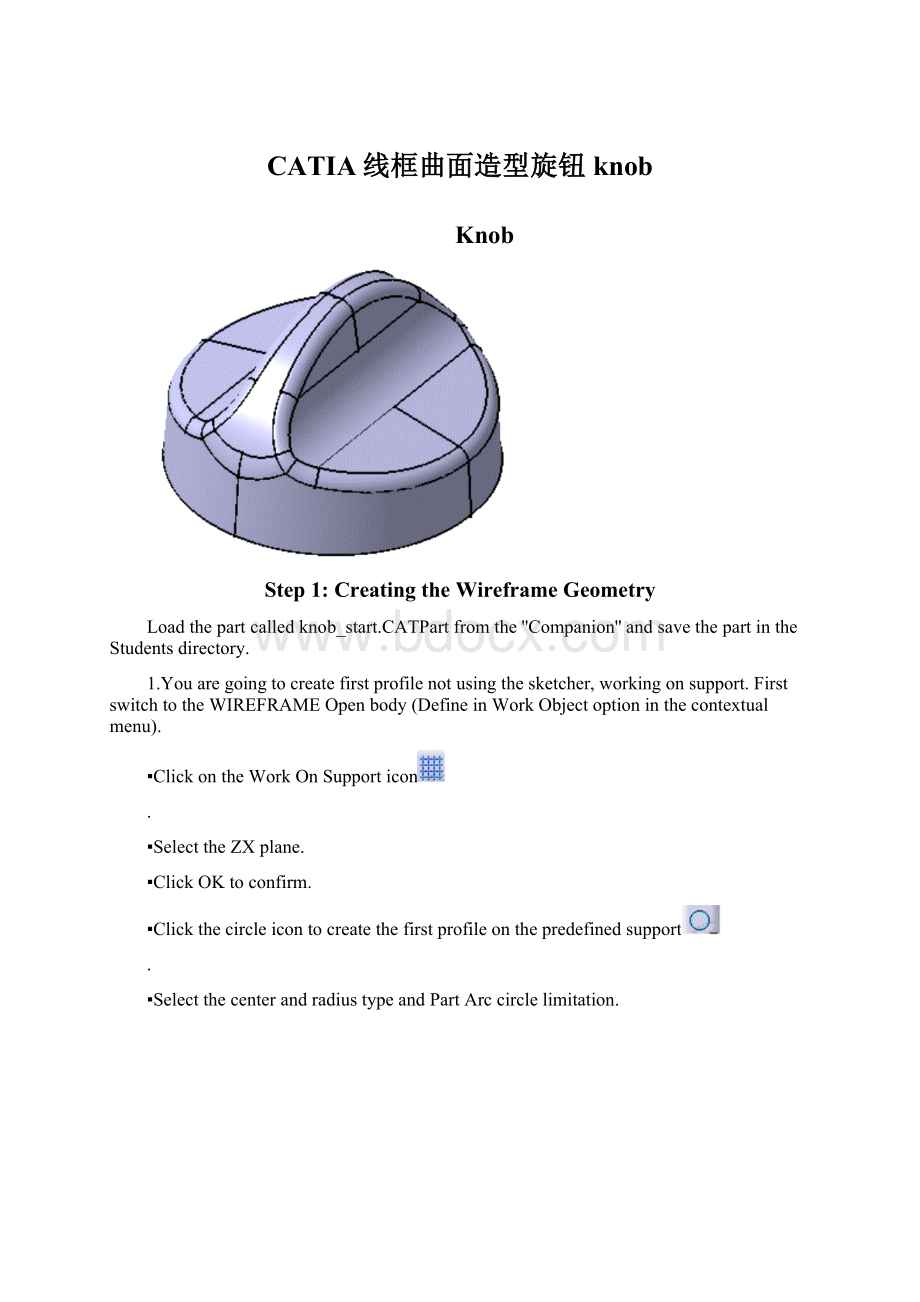

CATIA线框曲面造型旋钮knob

Knob

Step1:

CreatingtheWireframeGeometry

Loadthepartcalledknob_start.CATPartfromthe''Companion''andsavethepartintheStudentsdirectory.

1.Youaregoingtocreatefirstprofilenotusingthesketcher,workingonsupport.FirstswitchtotheWIREFRAMEOpenbody(DefineinWorkObjectoptioninthecontextualmenu).

▪ClickontheWorkOnSupporticon

.

▪SelecttheZXplane.

▪ClickOKtoconfirm.

▪Clickthecircleicontocreatethefirstprofileonthepredefinedsupport

.

▪SelectthecenterandradiustypeandPartArccirclelimitation.

▪Createthecenterpoint“onthefly”clickingtheCenterPointfield:

▪Selectthe“coordinates”pointtypeandkeyinX=0,Y=0andZ=0.

▪Keyintheradius64mm,thestartangle–90degandtheendangle0deg:

▪ClickOKtoconfirmthefirstprofilecreation.

▪ExittheWorkOnSupportmodedeletingtheworkingsupportinthespecificationtree:

2.Youaregoingtocreatesecondprofilenotusingthesketcher,workingonsupport.

▪ClickontheWorkOnSupporticon

.

▪SelecttheYZplane.

▪ClickOKtoconfirm.

▪Clickthecircleicontocreatethefirstprofileonthepredefinedsupport

.

▪SelectthecenterandradiustypeandPartArccirclelimitation.

▪Createthecenterpoint“onthefly”clickingtheCenterPointfield:

▪Selectthe“coordinates”pointtypeandkeyinX=30,Y=50andZ=0.

▪Keyintheradius20mm,thestartangle190degandtheendangle260deg:

▪ClickOKtoconfirmthesecondprofilecreation.

▪Deletethesupportinthetree.

3.Youwillnowcreatethethirdprofileusingthesketcher.

▪SelecttheSketchericon

andselecttheYZplane.

▪Selectthelineicon

anddrawthislinewithitsconstraints:

▪Exitthesketcher.Thethirdprofileiscreated.

Step2:

CreatingtheBasicSurfaces

4.Youaregoingtocreatetwoextrudedsurfaces.

▪ClickontheExtrudeicon

.

▪Selecttheprofile1andkeyintheseparameters:

▪ClickOKtoconfirmthefirstsurfacecreation.

▪ClickontheExtrudeicon

.

▪Selecttheprofile2andkeyintheseparameters:

▪ClickOKtoconfirmthefirstsurfacecreation.

5.Youaregoingtocreatetherevolutionsurface.

▪ClickontheRevolutionicon

.

▪Selectthethirdprofileandkeyintheseparameters(axis:

verticalaxisofthesketch):

▪ClickOKtoconfirm.Allthebasicsurfacesarecreated.

Step3:

PerformingOperationstheBasicSurfaces

6.Youaregoingtotrimthefirstextrudedsurfaceandtherevolutionsurface.

▪Clickonthetrimicon

.

▪Selectthefirstextrudedsurfaceandtherevolutionsurface:

▪Usingthe“Othersideelement1”and“Othersideelement2”button,aimtoobtainthis:

▪ClickOKtoconfirmthetrimcreation.

7.Youaregoingtosplitthesecondextrudedsurfacewiththepreviouslycreatedtrim.

▪Clickonthespliticon

.

▪Selecttheextrudedsurfaceaselementtocut,andthetrimascuttingelement.

▪Playingwiththe“Otherside”button,aimtoobtainthis:

▪ClickOKtoconfirmthesplitcreation.

8.Youaregoingtoextrapolatethepreviouslycreatedsplitsurface.

▪Clickontheextrapolateicon

.

▪Selectthesplitsurfacelowerboundary.

▪Selectthesplitsurface.

▪Selectthe“uptoelement”extrapolationtype.

▪Selectthetrimsurfaceandactivatethe“Assembleresult”button:

▪ClickOKtoconfirmtheextrapolatecreation.

9.Youaregoingtoextrapolatethepreviouslycreatedextrapolatesurface.

▪Clickontheextrapolateicon

.

▪Selecttheextrapolatedsurfacehigherboundary.

▪Selectthesplitsurface.

▪Selectthe“uptoelement”extrapolationtype.

▪Selectthetrimsurfaceandactivatethe“Assembleresult”button:

▪ClickOKtoconfirmthesecondextrapolatedsurfacecreation.

10.Youaregoingtotrimthepreviouslycreatedextrapolatesurfacewiththefirstcreatedtrimsurface.

▪Clickonthetrimicon

.

▪Selectthelastcreatedextrapolatedsurfaceandthefirstcreatedtrim.

▪Usingthe“Othersideelement1”and“Othersideelement2”button,aimtoobtainthis:

▪ClickOKtoconfirm.

11.Youaregoingtocreateavariablefiletonthepreviouslycreatedtrim.

▪Clickonthevariableradiusfilleticon

.

▪Selectthisedgeandkeyintheradius10mm:

▪Double-clickontheleftradiusvalueandkeyin20mm:

▪ClickOKtoconfirm.Yougetthis:

▪ClickOKtoconfirmthefilletcreation:

12.Youaregoingtocreateanedgefiletonthepreviouslycreatedsurface.

▪Clickontheedgefilleticon

.

▪Selectthisedgeandkeyintheradius5mm:

▪ClickOKtoconfirmthefilletcreation:

13.Youaregoingtocreatethesymmetricsurfaceandjointhetwosurfaces.

▪Clickonthesymmetryicon

.

▪SelectthepreviouslycreatedsurfaceaselementtosymmetrizeandtheYZplaneasreference:

▪ClickOKtoconfirm.

▪Clickonthejoinicon

.

▪SelecttheEdgeFillet.2surfaceandtheSymmetry.1surface.

▪ClickOKtoconfirmthejoinoperation.

14.Youaregoingtocreatethesymmetricsurfacefromthepreviousjoinandjointhetwosurfaces.

▪Clickonthesymmetryicon

.

▪SelectthepreviouslycreatedjoinaselementtosymmetrizeandtheZXplaneasreference:

▪ClickOKtoconfirm.

▪Clickonthejoinicon

andselecttheJoin.1surfaceandtheSymmetry.2surface.

▪ClickOKtoconfirmthejoincreation.

Theoperationsonthesurfacesareallperformed.Youshouldgetthis:

Step4:

AnalyzingandModifyingthedraftangle

15.Youaregoingtoanalyzethedraft.

▪ClickontheDraftAnalysisicon.

▪

Changetothecustomizedviewmode:

▪SelecttheJoin.2.

▪Changethedraftvaluestoobtain:

▪Closethedraftanalysiscolorbar.

16.Thenmodifythedraftangle.

▪DoubleclickontheSketch.1inthetree:

yougetinthesketch.

▪Modifythelineinclinationfrom90deginto86deg:

▪Exitthesketch.Thepartisautomaticallyupdated:

Step5:

Offsettingasolid

17.Youaregoingtocreateasolidfromthepreviouslycreatedsurface.

▪SelectStart/MechanicalDesign/PartDesign.

▪SelecttheJoin.2.

▪SelecttheThickSurfaceicon

.

▪VerifytheThickarrowspointinginwardasshownbelow:

▪Keyin4mmintheFirstOffsetValuefield.

▪ClickOKtoconfirmthesolidcreation.

▪HidetheOpenBodycontainingallthesurfaceelements.

18.Thenyouaregoingtosplitthesolidtomakeitsbottomfaceplane.

▪ChangethevisualizationmodetoWireframe:

▪Selecttheleftviewicon:

▪Zoomontheleftbottomtocheckthatthebottomofthepartisnomoreplane.

▪ComebacktoaShadingvisualizationmode.

▪PuttheXYplaneina‘’Show’’mode.

▪Selectthespliticon.

▪SelecttheXYplaneasSplittingelement.

▪ClickOKtoconfirmthesplitcreation.

19.Now,applyamaterialonthethicksurface:

▪SelecttheApplyMaterialicon.

▪SelecttheRubbermaterialunderthe‘‘other’’tabofthemateriallibrary.

▪Draganddropitontheknob,clickonOKtoconfirm.