M001品质手册.docx

《M001品质手册.docx》由会员分享,可在线阅读,更多相关《M001品质手册.docx(29页珍藏版)》请在冰豆网上搜索。

M001品质手册

品質手冊

核准章

發行章

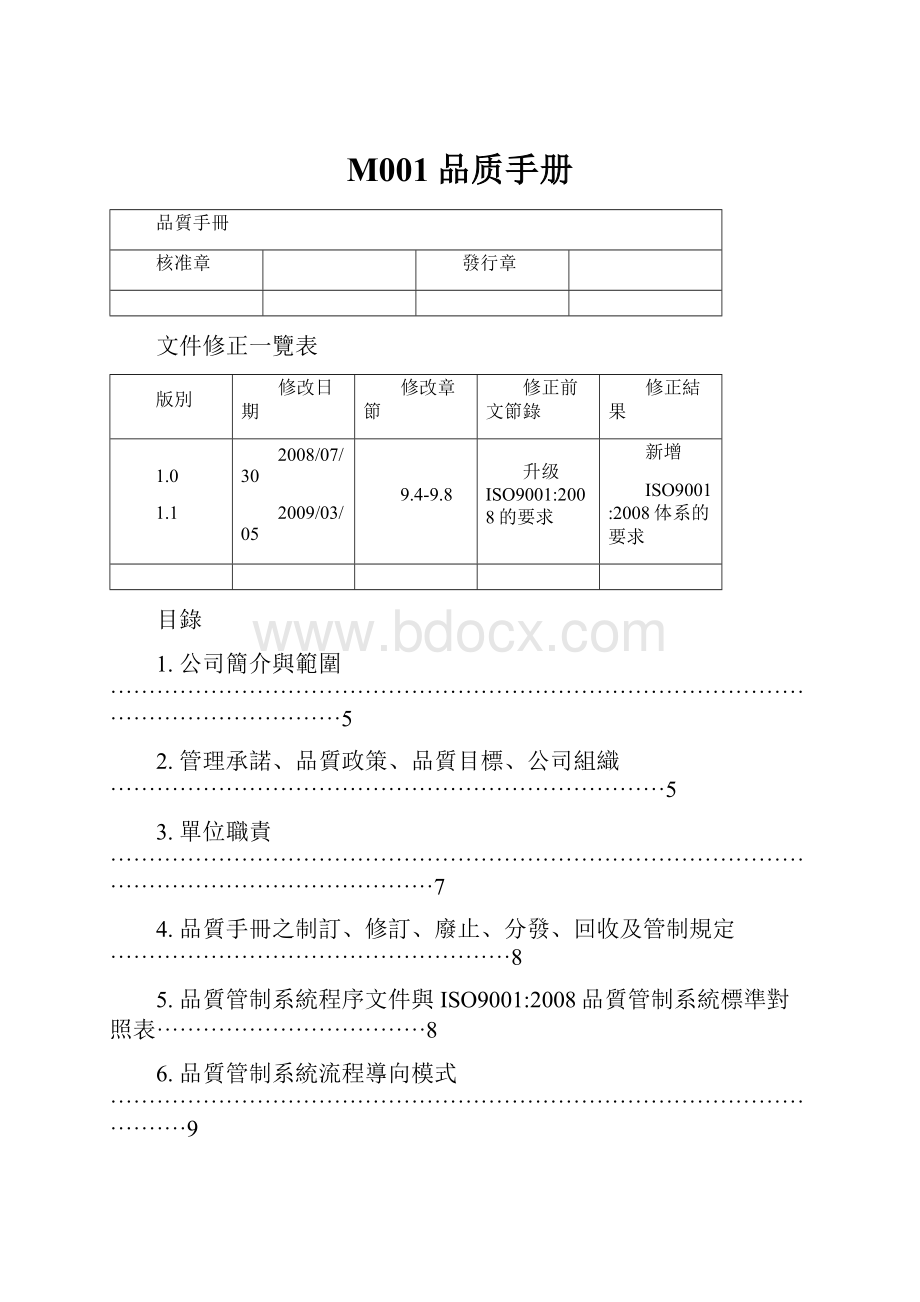

文件修正一覽表

版別

修改日期

修改章節

修正前文節錄

修正結果

1.0

1.1

2008/07/30

2009/03/05

9.4-9.8

升级ISO9001:

2008的要求

新增

ISO9001:

2008体系的要求

目錄

1.公司簡介與範圍························································································································5

2.管理承諾、品質政策、品質目標、公司組織········································································5

3.單位職責····································································································································7

4.品質手冊之制訂、修訂、廢止、分發、回收及管制規定····················································8

5.品質管制系統程序文件與ISO9001:

2008品質管制系統標準對照表···································8

6.品質管制系統流程導向模式····································································································9

7.品質管制系統架構圖···············································································································10

8.品質系統權責矩陣圖···············································································································11

9.品質管制系統敍述

9.1範圍····································································································································12

9.2引用標準····························································································································12

9.3名詞和定義························································································································12

9.4品質管制系統····················································································································12

9.4.1.一般要求··················································································································12

9.4.2.文件要求··················································································································12

9.5管理責任

9.5.1.管理者承諾··············································································································13

9.5.2.客戶為重··················································································································13

9.5.3.品質政策··················································································································13

9.5.4.規劃··························································································································13

9.5.5.責任、職權與溝通··································································································13

9.5.6.管理審查··················································································································14

9.6資源管理

9.6.1.資源的提供··············································································································15

9.6.2.人力資源··················································································································15

9.6.3.基礎設施··················································································································16

9.6.4.工作環境··················································································································16

9.7產品實現

9.7.1.產品實現的規劃······································································································16

9.7.2.客戶相關的流程······································································································16

9.7.3.

設計和開發··············································································································17

9.7.4.採購··························································································································17

9.7.5.生產和服務提供······································································································18

9.7.6.量測和監控儀器的管制··························································································19

9.8量測、分析和改善

9.8.1.概述··························································································································19

9.8.2.量測和監控··············································································································19

9.8.3.不合格品管制··········································································································20

9.8.4.資料分析··················································································································20

9.8.5.改善··························································································································20

10.相關文件···································································································································20

11.使用表單···································································································································21

1.公司簡介與範圍

1.1公司簡介

1.1.1公司名稱:

恆進企業股份有限公司

1.1.2佳宏/柏宏工廠地址:

中國廣東省深圳市寶安區福永鎮鳳凰工業區

1.1.3負責人:

陳一明

1.1.4創立時間:

1975年09月

1.1.5資本額:

新臺幣二千萬

1.1.6公司沿革:

1975年公司成立

1984年臺灣淡水廠成立生産帳篷

1987年大陸深圳可宏廠成立

1997年開始生産背包

1999年大陸深圳佳宏廠成立

2006年大陸深圳柏宏廠成立

1.1.7主要產品:

製造各類服裝、帳篷、背包、睡袋、沙灘桌、椅、旅遊袋、攀岩帶等旅遊用品。

1.1.8主要客戶群:

日本、歐洲、美加、紐澳、南美、南非

1.2範圍:

本手冊之內容與規定事項均適用於佳宏/柏宏的產品與服務,自接受生產製令、採購、生產製造、品管至成品之包裝、送貨一直到售後服務,均依循ISO9001:

2008年版之品質管制系統之標準要求。

本公司依照客戶來樣/來圖進行產品之生產製造,無設計與開發產品之責任。

故對於ISO9001:

2008條文7.3之設計與開發部分並不適用,予以排除。

2.管理承諾、品質政策、品質目標、公司組織

2.1管理承諾:

總經理透過以下方式,以達到其對品質管制系統的發展、實施及持續改善系統有效性之承諾。

2.1.1以本手冊9.5.5.3之內部溝通方式,向本公司成員持續宣導符合客戶與法令、法規要求的重要性。

2.1.2以本手冊9.5.3之規定建立品質政策。

2.1.3以本手冊9.5.4.1之規定建立品質目標。

2.1.4以本手冊9.5.6之規定執行管理階層審查。

2.1.5確保提供必要之資源。

2.2品質政策:

總經理將本公司服務品質之理念、方向與企圖心,依以下原則發展成「品質政策」,書面化於本要項中,並簽署確認。

2.2.1適合本公司之目的。

2.2.2包含符合品質管制系統要求及持續改善系統有效性之承諾。

2.2.3提供一個建立及審查品質目標之架構。

2.2.4由管理階層透過集會或卡片等各種方式,向本公司全員溝通宣導,使其確實瞭解。

2.2.5定期透過管理審查持續審查品質政策之適切性。

品質政策

製造品質

銷售品質

秉持勤誠的理念、不斷改善創新的做法,開創公司永績成長的契機

2.3品質目標:

成品批退率<5%顧客滿意度>98%

經總經理核示後公告,透過本手冊9.5.6之管理階層審查定期檢討及修訂品質目標。

2.4公司組織圖

3.單位職責

總經理

⏹樹立公司之經營方針,並要求貫徹。

⏹制定各部門職掌,復核各級幹部工作管理績效,並予適當之獎懲。

⏹編製公司未來之經營計畫。

⏹分析各項經營管理或技術層面問題,並協助解決。

管理代表

⏹執行總經理所編制之經營計劃及交付之任務。

⏹督導本公司品質管理系統之建立、執行及維持。

⏹直接向最高主管報告系統運作的績效和改善需要。

⏹協助各部門設定成長目標。

⏹控制與稽核各項經營管理工作及成果。

⏹確保本公司全盤掌控對客戶需求的認知。

文控中心

⏹負責公司各類文件的發行和回收廢除管制作業。

生管

⏹每週訂單生產排程表之製作。

⏹生產與加工間工作進度之跟催與溝通協調。

⏹產前樣追蹤。

⏹物料追蹤。

⏹排定出貨表與客戶溝通。

採購部

⏹尋找、評估、選擇和評鑑供應商。

⏹議價、詢價、比價與採購下單。

⏹跟催物料進廠進度。

倉庫

⏹物料分類、存放管理。

⏹供應商貨品來料點收。

⏹發料管理。

⏹倉庫存貨計數帳之登錄。

⏹每月存貨量報表之製作。

裁剪課

⏹裁片裁剪。

⏹裁片貼合。

⏹網印加工。

⏹刺繡外發。

鐵管部

⏹金屬材料前加工。

⏹金屬材料後加工。

生產課

⏹產前樣製作。

⏹成品車縫

⏹理貨包裝。

⏹生產計畫之達成。

研發課

⏹樣品之製作與修正。

⏹技術文件與圖面之管理。

品保部

⏹建立產品品質規格、檢驗方法及標準。

⏹進料檢驗及報告。

⏹成品檢驗及報告。

⏹品質異常處理和協助客戶抱怨處理。

行政管理處

行政管理處下設人事、總務、出納、船務、報關、保安,分別負責該業務。

⏹工廠各項制度之建立。

⏹工作說明、職能資格、業務之分析落實、推行、督導與修訂。

⏹部門員工業務之督導、訓練與考核。

⏹廠內保全、水電力、電器、設備之維護。

4.品質手冊之制訂、修訂、廢止、分發、回收及管制規定

4.1品質手冊之制訂、修訂與廢止流程

4.1.1制訂、修訂或廢止擬案:

管理代表。

本手冊採紙本發行,如需制訂、修訂或廢止,依「文件管制作業程序」辦理。

4.1.2審查:

各單位主管。

4.1.3核准:

總經理。

4.2品質手冊之分發、回收及管制規定

4.2.1由文控中心依「文件管制作業程序」規定執行。

4.2.2分發與回收:

本手冊以紙本方式發行,並進行紙本分發及回收工作。

4.2.3文件保存:

由文控中心保留紙本核准原稿一份。

4.2.4影印管制:

本手冊不得任意影印。

4.2.5版本管制:

依據「文件管制作業程序」之規定執行。

4.2.6因業務需要,對外發行之手冊為非管制文件,需保留適當記錄,但不予以更新回收舊版本。

5.品質管制系統程序文件與ISO9001:

2008品質管制系統標準對照表

條 文

程序文件

文件編號

負責部門

4.品質管制系統

4.1一般要求

4.2文件要求

品質手冊(一階)

文件管制作業程序

記錄管制作業程序

M-001

P-001

P-002

管理代表

文控中心

文控中心

5.管理階層責任

5.1管理階層的承諾

5.2客戶為重

5.3品質政策

5.4規劃

5.5責任、職權與溝通

5.6管理審查

品質手冊

品質手冊

品質手冊

品質手冊

品質手冊

品質手冊

M-001

M-001

M-001

M-001

M-001

M-001

管理代表

管理代表

總經理

管理代表

管理代表

管理代表

6.資源管理

6.1資源的提供

6.2人力資源

6.3基礎設施

6.4工作環境

品質手冊

品質手冊

品質手冊

品質手冊

M-001

M-001

M-001

M-001

管理代表

管理代表

管理代表

管理代表

7.產品實現

7.1產品實現規劃

7.2客戶相關流程

7.4採購

7.5生產和服務提供

7.6量測與監控儀器管制

品質手冊

品質手冊

品質手冊

生產及服務提供流程管理作業程序

品質手冊

M-001

M-001

M-001

P-006

M-001

管理代表

管理代表

管理代表

生產課

管理代表

8.量測、分析及改善

8.1規劃

8.2量測與監督

8.3不合格品管制

8.4資料分析

8.5改善

品質手冊

品質手冊

內部稽核管理作業程序

不合格品管制作業程序

品質手冊

矯正與預防措施作業程序

M-001

M-001

P-003

P-004

M-001

P-005

管理代表

管理代表

管理代表

品保部

管理代表

品保部

6.品質管制系統流程導向模式

7.

品質管制系統架構圖

8.品質系統權責矩陣圖

部門

條文

總經理

管理代表

品保部

採購部

人事

總務

生產課

生管

研發課

4品質管制系統

4.1

一般要求

◎

△

△

△

△

△

△

△

△

4.2

文件要求

△

◎

△

△

△

△

△

△

△

5管理責任

5.1

管理承諾

◎

△

△

△

△

△

△

△

△

5.2

客戶為重

◎

△

△

△

△

△

△

△

△

5.3

品質政策

◎

△

△

△

△

△

△

△

△

5.4

規劃

◎

△

△

△

△

△

△

△

△

5.5

責任、許可權與溝通

◎

△

△

△

△

△

△

△

△

5.6

管理階層審查

◎

△

△

△

△

△

△

△

△

6資源管理

6.1

資源的提供

◎

△

△

△

△

△

△

△

△

6.2

人力資源

△

△

△

△

◎

△

△

△

△

6.3

基礎設施

△

△

△

△

△

◎

△

△

△

6.4

工作環境

△

△

△

△

△

△

◎

△

△

7產品實現

7.1

實現流程的規劃

△

◎

△

△

△

△

△

△

△

7.2

客戶相關的流程

△

△

△

△

△

△

△

◎

△

7.3

設計和開發

△

△

△

△

△

△

△

△

◎

7.4

採購

△

△

△

◎

△

△

△

△

△

7.5

生產和服務供應

△

△

△

△

△

△

◎

△

△

7.6

監督和量測裝置的管制

△

△

◎

△

△

△

△

△

△

8量測、分析及改善

8.1

概述

△

△

◎

△

△

△

△

△

△

8.2

監督和量測

△

△

◎

△

△

△

△

△

△

8.3

不合格品的管制

△

△

◎

△

△

△

△

△

△

8.4

資料分析

△

△

◎

△

△

△

△

△

△

8.5

改善

△

△

◎

△

△

△

△

△

△

◎責任單位△配合單位

9.品質管制系統敍述

9.1範圍

9.1.1概述:

本公司所制定之品質管制系統,依據國際標準ISO9001:

2008品質管制系統(Qualitymanagementsystem)所訂定之要求,以證明在此系統下能有能力穩定地提供符合客戶期望和適用法規要求的產品,且透過該系統的有效實施,達到提高客戶滿意程度的目的。

9.1.2實施:

本公司之品質管制系統系依據ISO9001:

2008國際標準之條文所訂定,本公司依品質管制系統之要求,實施並執行相關作業。

9.2引用標準:

ISO9001:

2000品質管制系統-基本原理和辭彙。

9.3名詞和定義

9.3.1依ISO9001標準,後續用以描述供應鏈的用詞如下:

供應商→本公司→客戶

9.3.2在本公司品質管制系統全文中,無論何處使用到的用詞「產品」,亦包含「服務」。

9.4品質管制系統

9.4.1一般要求

9.4.1.1本公司應依據ISO9001:

2008之要求制訂「品質管制系統」,並規劃、制訂、實施、維持、量測、監督、分析和持續地改善「品質管制系統」。

9.4.1.2「品質管制系統」包含各相關主流程與子流程在內。

9.4.1.3本公司制訂「品質管制系統架構圖」(如本手冊第7條)以界定各部門流程間的順序和相互作用。

9.4.1.4本公司有刺繡,電鍍倆生產工序進行外發,針對公司生產負荷過重,無法滿足客戶交期時,會選擇全制程外發加工,針對外發加工部分,對其生產過程及產品進行管制,具體依據9.7.4的要求,按供應商管理要求執行。

9.4.2文件要求

9.4.2.1概述:

本公司制訂「品質管制系統」及所需之相關流程,相關文件包含

9.4.2.1.1品質政策。

9.4.2.1.2品質目標。

9.4.2.1.3品質手冊。

9.4.2.1.4ISO9001:

2008品質管制系統所要求的各相關書面程序。

9.4.2.1.5本公司用以確保系統流程有效的規劃、作業和管制所要求的文件。

9.4.2.1.6ISO9001:

2008品質管制系統要