Structure Design.docx

《Structure Design.docx》由会员分享,可在线阅读,更多相关《Structure Design.docx(12页珍藏版)》请在冰豆网上搜索。

StructureDesign

PlasticPartDesign

Toinsureaqualityfinalproduct,itisnecessarytostartoutwithqualitycomponents.Injectionmoldedpartscanbemoldedtoahighqualitystandardbyfocusingontheseareasofplastictechnology:

1)CorrectPartDesign

2)AccurateSelectionofMaterial

3)ProcessingPlasticProcessing

Onlybydrawingonexpertisefromthesethreeareasofplastictechnologycanaproductdesignercreatequalitymoldedpartsthatmaximizeperformanceandarecosteffective.Thepurposeofthisdesignguidedealswiththefirstofthesethreeissues-partdesign.

CorrectPartDesignGuidelines

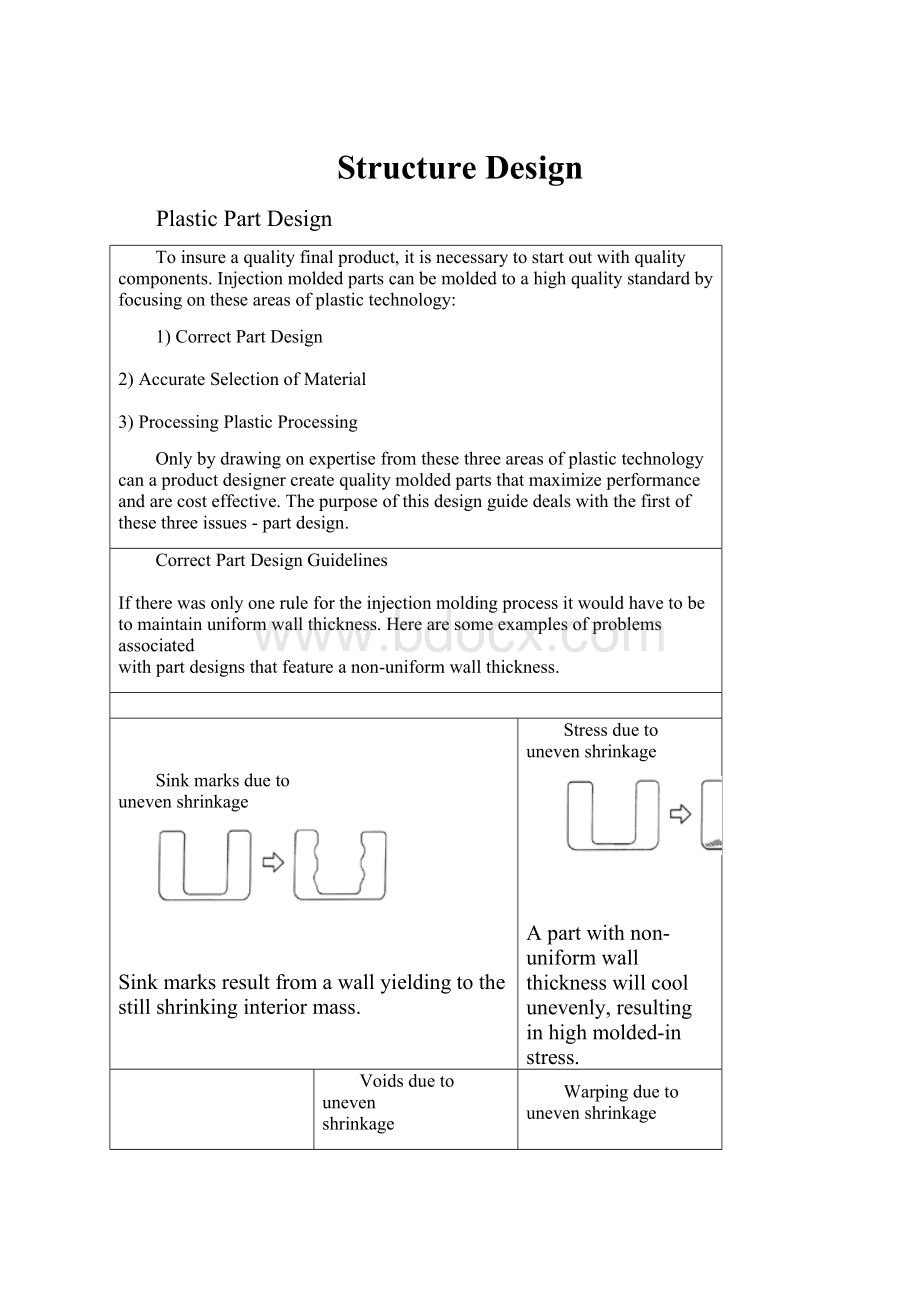

Iftherewasonlyonerulefortheinjectionmoldingprocessitwouldhavetobe

tomaintainuniformwallthickness.Herearesomeexamplesofproblemsassociated

withpartdesignsthatfeatureanon-uniformwallthickness.

Sinkmarksdueto

unevenshrinkage

Sinkmarksresultfromawallyieldingtothestillshrinkinginteriormass.

Stressdueto

unevenshrinkage

Apartwithnon-uniformwallthicknesswillcoolunevenly,resultinginhighmolded-instress.

Voidsduetouneven

shrinkage

Thealreadycooledsectionwillnotyieldtotheshrinkingactionofthecoolinginteriormasscausing

voidsinthethickportionofthepart.

Warpingdueto

unevenshrinkage

Concentratedstressatthejunctionofhigh&lowshrinkageareamaycauseaparttowarp.

Draft

Plasticpartsarealwaysdesignedwithataperordraftinthedirectionofmoldmovementtoallowpartejectionorremovalfromthemold.Sinceplasticsshrinkwhencooled,itiscommonforpartstoshrink(orgriptightly)tocores.Agooddefinitionfordraftwouldbe:

thedegreeoftaperofasidewallorribneededtoallowthemoldedplasticparttoberemovedfromthemetalmold.Withoutproperdraft,plasticpartsmaybedifficulttoremovefromthemold.Adraftangleof1/2degreesisregardedasminimumformostapplications.Draftanglesof11/2to2degreespersideareconsiderednormalforplasticinjectionmolding.

Topofpage

Ribs

Manytimesthestiffnessofapartmustincreasebecauseoftheloadappliedtothepartdesign.Oneoftheeasiestwaystocurethisproblemischangethepartgeometrybyaddingribs.Theuseofribsisapracticalwayandeconomicalmeansofincreasingthestructuralstrengthofapart.Butthereareguidelinesthatgovernaddingribswithoutcausingsinkmarksorsurfaceblemishestoyourparts.

1)Ribthicknessshouldbelessthanwallthickness.Aribthicknessof60%to80%ofnominalwallthicknessisrecommended.

2)Toincreasestiffnessincreasethenumberofribsor"gussetplates",anotherfeaturedesignedtostrengthentheplasticpart.

3)Foragivenstiffness,itisbettertoincreasethenumberofribs,nottheheight.

4)Forthickribs"coreout"theribfromtheback.Thiscreatesahollowspaceunderneaththepart

andmaintainsauniformwallthickness.

Height:

Maximumheightofthreetimenominalwallthicknessofpart.

Spacing:

Minimumoftwotimesnominalwallthicknessofpartbetweenribs.

Topofpage

Holes

Holesareeasytoproduceinmoldedparts.Corepinsthatprotrudeintothemoldcavitymaketheholeswhenthepartismolded.Throughholesinthemoldedpartsareeasiertoproducethanblindholes,whichdonotgoallthewaythroughapart.Blindholesaremadebycorepinssupportedononeendonly.Thepinscanbedeflectedandpushedoffcenterbythepressuresofthemoltenplasticmaterialduringthemoldingprocess.Agoodruleofthumb:

thedepthoftheblindholeshouldbeabouttwicethediameterofcorepinsupto3/16",anduptofourtimesthediameterofcorepinsover3/16".Theguidelinesforblindandthroughholesareseenbelow.

BlindHole(shownwithdraft)

L=2DforDiametersLessthan3/16"dia.corepins

L=4DforDiametersMorethan3/16"dia.corepins

ThroughHole(shownwithdraft)

L=4DforDiameterslessthan3/16"dia.corepins

L=6DforDiametersmorethan3/16"dia.corepins

Therearedefiniterulesfortheplacementofcoredholesinamoldedpart.Iftheseminimumdistancesshownbelowarenotfollowed,theholeswillbeeggshapedorthepartwilldeformintheareasaroundtheholes.

T=wallthicknessofpart

D=diameterofhole

Asdepictedabove,thedistancefromtheedgeofaholetoaverticalsurface(i.e.rib)ortheedgeofapartshouldbetwicethepartthickness(ormore),oratleastonediameterofthehole.Thissameruleappliesbetweenholes-atleasttwopartthicknessesoroneholediametershouldbespecified.

Holes(part2)

Aseasyasitistomakeholesinmoldedpartsitdoesnotcomewithoutsomeconcernsforthestrengthofthepart.Foreverycoredormoldedholetherewillbeaweldline.Theweldlinesarecausedbytheflowofthemeltedplasticaroundthecorepins.Theseweldlinesarenotasstrongasthesurroundingplasticmaterial,andalsomaydetractfromtheoverallappearanceofthemoldedpart.Thepartdesignershouldconsiderthesepointswhendesigningholesinamoldedpart.

Thecoringofholesiseasywhentheaxisisparalleltothepartingline.Butwhenholesandotherfeaturesrunperpendiculartothepartinglinethenretractablecores(orcams)arerequired.Splitpinsandcores(calledpassingsteelshutoffs)canbeusedtocreatesomeofthefeatures.Thedesignerneedstobeawareoftheproblemsofsideactioncoresandtheaddedexpensesassociatedwiththesetypesofmolds.Withalittleunderstandingofhowthemoldopensandwherethepartinglinewillexist,thesecostlyfeaturescanbemodified.Ruleofthumb:

wheneverpossiblealldesignfeaturesshouldbeincorporatedinthesamedirectionofthemoldopeningsothatcamactioncanbeavoided.

Topofpage

Bosses

Bossesareusedforlocating,mounting,andassemblypurposes.Therearebossdesignguidelinesthatmustbefollowedtoinsurethehighestqualityinmoldedparts.Again,oneofthemainpointstoconsiderisnominalwallthickness.Toomanytimesbossesaredesignedwiththickwallsectionsthatcanaffecttheappearanceoftheplasticpartandthefinalproduct.

Ruleofthumb:

thewallthicknessaroundabossdesignfeature(t)shouldbe60%ofthenominalpartthickness(T)ifthatthicknessislessthan1/8".Ifthenominalpartthicknessisgreaterthan1/8"thebosswallthicknessshouldbe40%ofthenominalwall.

Bossdiameter,wallthickness,andheightdesignparameters.Whilebossheightsvarybydesign,thefollowingguidelineswillhelpavoidsurfaceimperfectionslikesinkmarksandvoids:

theheightofthebossshouldbenomorethan21/2timesthediameteroftheholeintheboss.

Pleaseobservethe"60/40"rule(seeabove)forthewallthicknessatthebottomoftheboss.

Topofpage

Radii

Inthedesignofinjectionmoldedparts,sharpcornersshouldbeavoided.Sharp

cornersactasstressrisersorconcentrators,reducingpartstrengthandcausing

prematurefailures.Sharpcornersmayalsoeffectplasticflow,producingpartswith

objectionablesurfaceflowpatterns.

Bosses&Ribs

Nominalradiusshouldbeonequarterofthenominalpartthickness,withaminimumradiusof.015(i.e..100wall,025r)

T=wallthicknessofpartRadius-T

Corners

Theinsideradiusshouldbeatleasthalfthepartwallthickness.

Theoutsideradiusshouldequaltheinsideradiusplusthepartthicknessi.e..100wallandinsideradiusof.050equalsoutsideradiusof.150)

InsertMoldingTips

Anotherproblemconcerninghighstressoccurswithmolded-ininserts.Theplasticmeltheatsthemetaloftheinserts.Duringthecoolingstageofinjectionmolding,theplasticpartcools,buttheplasticbosssurroundingthemetalinsertisreheatedbytheheatfromtheinsert.Thisallowstheplastictocontinuetoshrinkaroundtheinsert,causingexcessivehoopstress*thatwilleventuallycausethebosstocrack.Thebetterdesignandprocesswouldbetouseultrasonicinsertionorahotprobe(suchasaheatstakingunit)afterthemoldedparthascooledthroughout.

Hoopstress:

stresswithinthecircumferenceoftheboss

Topofpage

ReplacingMetalwithPlastics

Therearenumerousreasonswhyreplacingmetalpartswithplasticmakessense.PlasticsOne,Inc.hasworkedwithmanycompaniesonmetal-to-plasticconversions.Hereiswhyplasticmaybethebestoptionforyourparts.

1.DECREASEPIECEPARTPRICES

Apennysavedisapennyearned.Afterinitialtoolingcostsarepaid,thepiecepartpricingisusuallymuchlessthanthesamepartproducedinmetal,whetheritbeastamping,casting,oradiecastpartThiscostsavingsisrealizedbecausetheinjectionmoldingprocesshasfastercycletimes(morepartsmadepermachinehour)andthesepartsareidenticalfromonetotheotherwhicheliminatessecondarymachining.

2.ELIMINATETIME-CONSUMINGANDCOSTLYSECONDARYOPERATIONS

Eliminatingsecondaryoperationsfurtherreducescosts.Plasticmaterialcanbecoloredwithcolorconcentratesbeforemolding-eliminatingsecondarypaintingoperations.Injectionmoldscanbetexturedorgivenvariouslevelsofpolishedsurfacesbeforemolding.Thecostlyassemblyofseveralmetalstampingsorcastingsfastenedtogethercanoftenbereplacedbyasingleinjectionmoldedpartincorporatingthefeaturesofthetotalassembly.Ifmultipleassembliesarerequired,theplasticpartscanhavesnap-togetherfeaturestoeliminateanyfasteners.Eliminatingsub-assemblytoolingorfixturesbyusinginjectionmoldedpartscanquickendeliveryinnewproductdevelopmentprograms.

3.REDUCEPRODUCTWEIGHTANDIMPROVEUSEREASE

Oneprimaryadvantageofusingplasticsinsteado