聚氨酯高压发泡机PU2HFY3技术配置.docx

《聚氨酯高压发泡机PU2HFY3技术配置.docx》由会员分享,可在线阅读,更多相关《聚氨酯高压发泡机PU2HFY3技术配置.docx(16页珍藏版)》请在冰豆网上搜索。

聚氨酯高压发泡机PU2HFY3技术配置

High-pressurePolyurethaneFoamMachinePU22F-20(configuration)

Overview:

PU22F-20typehigh-pressurepolyurethanefoammachineisWenzhoudragonpolyurethaneEngineeringCo.,Ltd.inthedigestionandabsorptionofGermancompanytechnicalbasis,forthedevelopmentoftheproducts.Widelyusedinthermalinsulationpipeline,coldplateinsulationmaterialsandbuildingmaterialssuchaspolyurethanesandwichpanel.Themainequipmentofthefollowingpartsadoptimported,themachinehasthecharacteristicsofhighprecision,uniformmixing,stableperformance,simpleoperation,nocleaning,productionefficiency,energysavingandenvironmentalprotection.

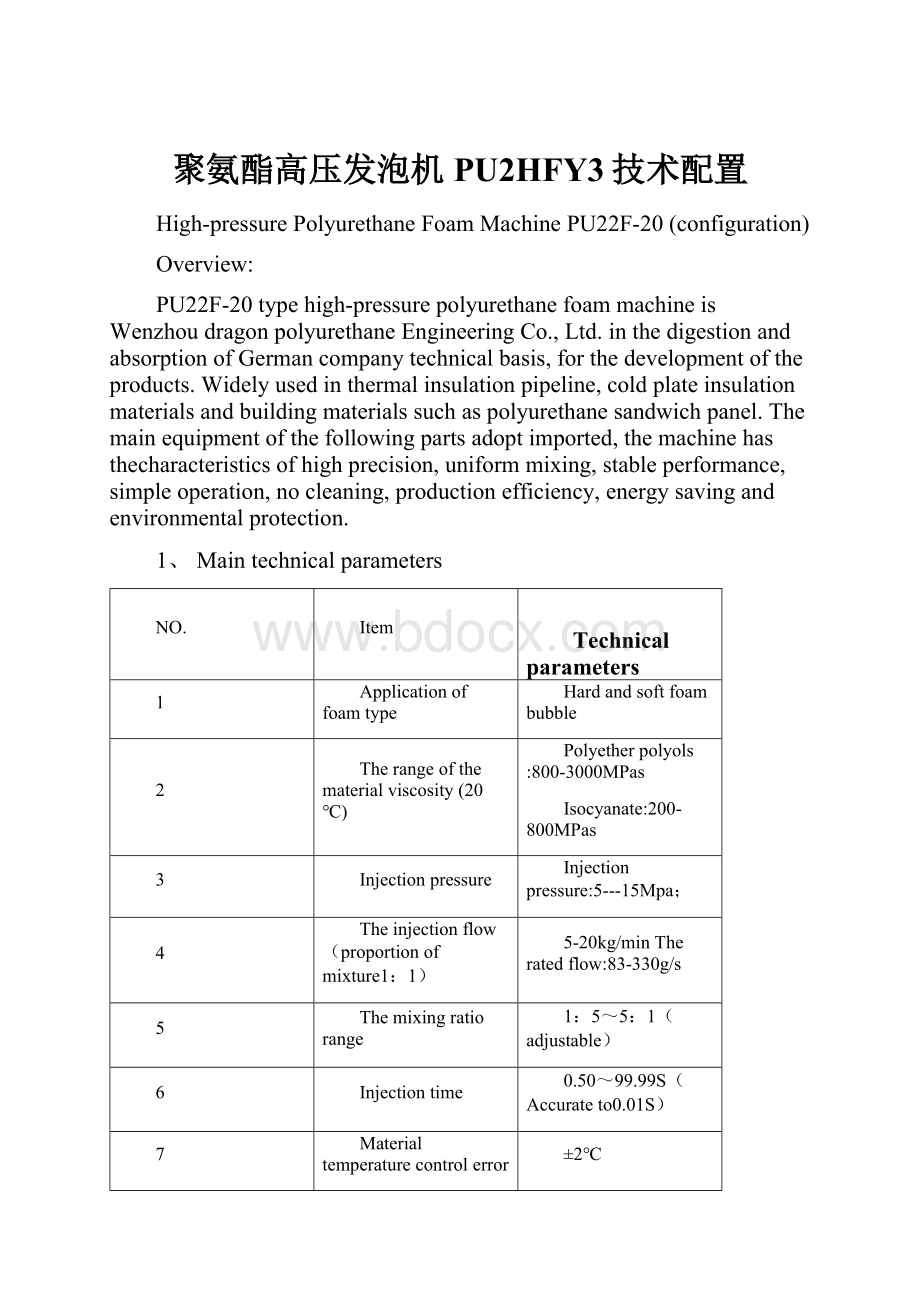

1、Maintechnicalparameters

NO.

Item

Technicalparameters

1

Applicationoffoamtype

Hardandsoftfoambubble

2

Therangeofthematerialviscosity(20℃)

Polyetherpolyols:

800-3000MPas

Isocyanate:

200-800MPas

3

Injectionpressure

Injectionpressure:

5---15Mpa;

4

Theinjectionflow(proportionofmixture1:

1)

5-20kg/minTheratedflow:

83-330g/s

5

Themixingratiorange

1:

5~5:

1(adjustable)

6

Injectiontime

0.50~99.99S(Accurateto0.01S)

7

Materialtemperaturecontrolerror

±2℃

8

Repeatedinjectionprecision

±1%

9

Mixer

DHS-12R

10

Hydraulicsystem

Flow:

15L/min

Thesystempressure:

10~20MPa

11

Tankvolume

250L

12

Compressedairrequirement

Dry,withoutoilP:

0.6~0.8Mpa

Q:

400NL/min

13

Inputpower

30Kw

14

Themachineheight(mm)

(high)

〈2500

15

Wholemachineweight

About1800KG

2、Themainequipmentconfiguration

NO.

Item

Number

1

Tankunit

2

2

Meteringunit

2

3

High,lowpressurecyclingswitchunit

2

4

Componenttestunit

2

5

Self-cleaningfilter

2

6

Mixer

1

7

Hydraulicsystem

1

8

Electricalcontrolsystem

1

9

Thetemperaturecontrolunit

1

10

Plateheatexchanger

2

11

Shakingandswingarmpipingsystem

12

Meteringpumpautomaticlubrication

1

13

Compressedairrefrigerationdryer

1

14

Automaticfeedingapparatus

2

15

Enginebracket

1

16

Randomtools,spareparts

1

3、Theconfigurationandtechnicalspecificationofthesystem

3.1Tankunit

Tankvolumeis250L,threelayersofstructure,polyethertankfullaluminumalloyslowstirringdevice,eachareequippedwithsafetyvalve,pressurereducingvalve,reliefvalve,checkvalve,feedinglevelgauge,pressuregauge;including:

1).Theagitatorframe,astirringmotormodelWJ75-0.75KW;

2).Levelcontrol,theturnovertypeliquidlevelgauge,canrealizeautomaticfeedingandalarm;

3).Thetemperaturecontrol,theintegrativemachine,throughthepumpcirculationtanktemperatureconstant;

4).Materialfeedinginletisarrangedatthebottomofthetank,tankoutletisprovidedwithathreedischargevalve,tankthreelayerstructure,thestainlesssteel,themiddleclampingsleeve,theouterPUhardfoaminsulation;

3.2Meteringunit

Twosetsofhighprecisionmeteringdevice,installedonthemainbracketwithacushion,mainlyconsistsofthefollowingcomponents:

·twomotor,power7.5Kw,speed1450rpm;

·twohigh-pressuremeteringpumpwithA2VK12Beijinggelanlishi;

Pressuregauge,twosetsofexplicitprogrammable(Schneider)inGermany,pressure40mpa;

Componentmeteringpumpprepressureof5to12MPa,whenthepressureislowerthanthesetvalue,equipmentautomaticstop,alarmanddisplay"faultinformationprepressurelow".

Polyetherpolyolandisocyanategroupjobpressurecontrolinthe10~15MPa;whentheworkingpressureisbeyondthescopeofthisequipment,automaticstop,alarmanddisplay"faultinformationworkpressureistoolow"or"theworkpressureistoohigh.".

Componentsofmeteringpumppressurelimitsafetysetbytheprogramissetto25MPa,thesuperhighswitchingvalveofhighandlowpressurereliefprotectionfunction,andensurethesafeuseofmeteringpumpandsystem.

3.3Highandlowpressurebypassswitchingunit

Convertingthemachinecanbecarriedoutbetweenthehighpressure,lowpressure,prolongtheservicelifeofthemachine;

Highandlowpressurebypassswitchingunit,sothatthecomponentcanformlowenergycycle.ThePLCcontrolsystem,oneelectromagneticvalves,controlhighpressureandlowpressure,cyclicswitchingoftwocomponents.

3.4Componenttestunit

Withthehandwheeladjustmentofmeteringpump,twosetsofpneumatictestunitarerespectivelyusedforflowcomponentsandtestmixtureratio,proportion,flowofaccurateandconvenientdetermination.

Maincomponents:

test;testvalvecontrolsolenoidvalve;

3.5Self-cleaningfilter

Usedforfilteringcomponent,regularrotationfilterhandwheelorhandle,andthroughthebottomvalvedischarge.Polyethersideconfigurationofa300micronself-cleaningfilter,isocyanatesideconfigurationa200micronself-cleaningfilter.

3.6Mixer

High-pressureMixerusingselfcleandesignandhigh-voltagecollisionalmixingprinciple,thequalityMixerisrelatedtomaterialproperties(viscosity,temperature,densityetc.),injectionpressureandinjectionpressuredifferencerelatedtosize.

ThemixedbytypeLhighpressureself-cleaningMixer,nozzleneedletheadjustable,specificationsforDHSseriesproducts

TheMixermountedontherotaryhangerarm.

3.7Hydraulicsystem

Witha10Lhighpressureaccumulator,theoverflowvalve,DanXiangfa,unloadingvalve,pressurerelaysandconfiguretheoilfilter,oilfilterbacktostandardhydraulicstation;

Aninstallationofhydrauliccontrolcomponentsoftheoiltank,thevolumeis100L;

·hydraulicpumpanddrivingmotor,coupling,motor5.5Kw,speed1450rpm;

·accumulator10liters,pressure31.5MPa;

·oilcooler,usedinhydraulicoilcooling,toensurethehydraulicsystemincontinuousworknottoohightemperaturerise(≤60℃);

·hydraulicintegratedblock,thepressurevalvewithintegratedblock,safetyvalve,pressureswitch,manualunloadingvalve;

Apressuregaugetodisplaytheworkpressureofhydraulicsystem,programmablepressuregaugeSchneiderdechina;

·anon-returnvalvewithreturnfilter;

·feedingelectromagneticvalvetwopositionfiveway2B36W24V;

ThecleaningrodelectromagneticdoorC2LW24V;

ANG10twopositionfourwayelectromagneticvalveisusedtocontroltheopeningorclosingofmixer;

3.8Electricalcontrolsystem

3.8.1usesa10InchTouchscreenman-machineinterface,setthedisplayprocessdatamachineinjectiontime,testtime,pressuretime.

3.8.2usesPLCmodulecontrol,automaticcontrolofthefoamingmachine,sothatthemeteringunit,hydraulicunit,temperaturecontrolsystem,tankmixing,themixingheadinjectionpartaccordingtoprogramcoordination,ensurereliableperformance.

3.8.3usesthematerialtemperatureofrefrigerationandheatingintegratedmachinetanksetaccordingtoprocessrequirements,totemperaturecontrolsystemofcoldwaterorhotwaterasthemedium,automaticmaterialtemperatureconstantcontrol.

3.8.4mixingheadisarrangedontheinjectionprogrambuttonbox,programnumberbuttonboxcanbesetaccordingtouserrequirements,thegeneralprocedureforsixtymonths.

3.8.5inordertoensuretheperformanceofthecontrolsystemisstable,reliable,durable,programmablecontroller,10InchTouchscreenman-machineinterfacealluseBrandName,otherdevicessuchasbutton,indicatorlight,contactors,relaysareselectedSchneiderIncproducts.

3.8.6devicewithmanual,automaticfunction,thedry/wetinjectionselectionfunction,automaticcycle.Equipmentmanualfunctionandsteminjectionfunctionismainlyusedforequipmentdebugging,undernormalworkingconditions,choosewetinjectioncondition,automaticfunction;automaticcycleismainlyappliedtotheequipmentlongtimenoproductioninordertokeepthesysteminnormalconditionsoftheoccasion,theautomaticcycleparameterscanbesettodisplaythemenu,thesystemfunctionparameterscanbeoperatedinthemenu,thecontrolsystemhasstrongfaultalarmfunction,theinformationpointoffaultdetectionineachdisplaycontroller,andsoundalarm,automaticshutdown,whentroubleshootingcanrestartthedevice.

3.8.7Thecontrollerincludes:

·programmablecontrolleranda10InchTouchscreenman-machineinterface

·variousrelay(Schneider);

Avarietyofcontactor(Schneider);

Andallkindsofbuttons(Schneider);

·themixingheadcontrolelement;

·testunitcontrolelement;

Thesystemsoftwareandcontrolprogram;

·controlcabinet

3.8.8Electricalparameters

NO.

Item

Parameters

Note

1

Injectionprogram

180

Accordingtouserrequir-ementscanbeextended

2

Injectiontimeadjustingrange

0.5~99.99S

OPisadjustable

3

Materialtemperatureadjustmentrange

20~30℃

Temperaturemodule

4

Hydraulicmotorpower

5.5KW

5

Meteringpumpmotor

(2)

7.5KW

6

Thestirringmotorpower

(2)

everyoen0.75KW

7

Chillerpower

About8KW

8

Moldtemperaturemachine

2×4.5KW

9

Programmablecontroller

PLC

10

TheOPoperator

10InchTouchscreenman-machineinterface

12

Feedingway

Thefeedpumpfeed

13

Totalpower

About30KW

3.9Thetemperaturecontrolunit

Thetemperaturecontrolunitismainlyusedformaterialtemperaturecontrolofthetworawmaterials,including:

Anda5Pcryocooler(Manufacturing),usedtosupplycoolingwaterheating/coolingunit,coolingcapacityof25000Kcal/h;

·closedsteelshell,withmovablewheel;

·thermostat;

Automaticdisplayandfaultcontrol;

·refrigerantpressuregauge;

3.10Plateheatexchanger

Twostainlesssteelplateheatexchangerarerespectivelyarrangedinthetwocomponentofthereturnpiping,exchangertemperaturecontrolmedium(water)andotherconfigurationofthemachinetemperaturecontrolsystem(heating/coolingunit)withconnectiontoregulatethematerialtemperature.

3.11Pipelinerockingarm

Fromtheracktothepipea