HP Generic Cell Qual Test SpecRev107.docx

《HP Generic Cell Qual Test SpecRev107.docx》由会员分享,可在线阅读,更多相关《HP Generic Cell Qual Test SpecRev107.docx(14页珍藏版)》请在冰豆网上搜索。

HPGenericCellQualTestSpecRev107

Lithiumion,lithiumionpolymerandthinadvancedlithiumioncellqualificationtestspecification

Revision1.07

June19,2009

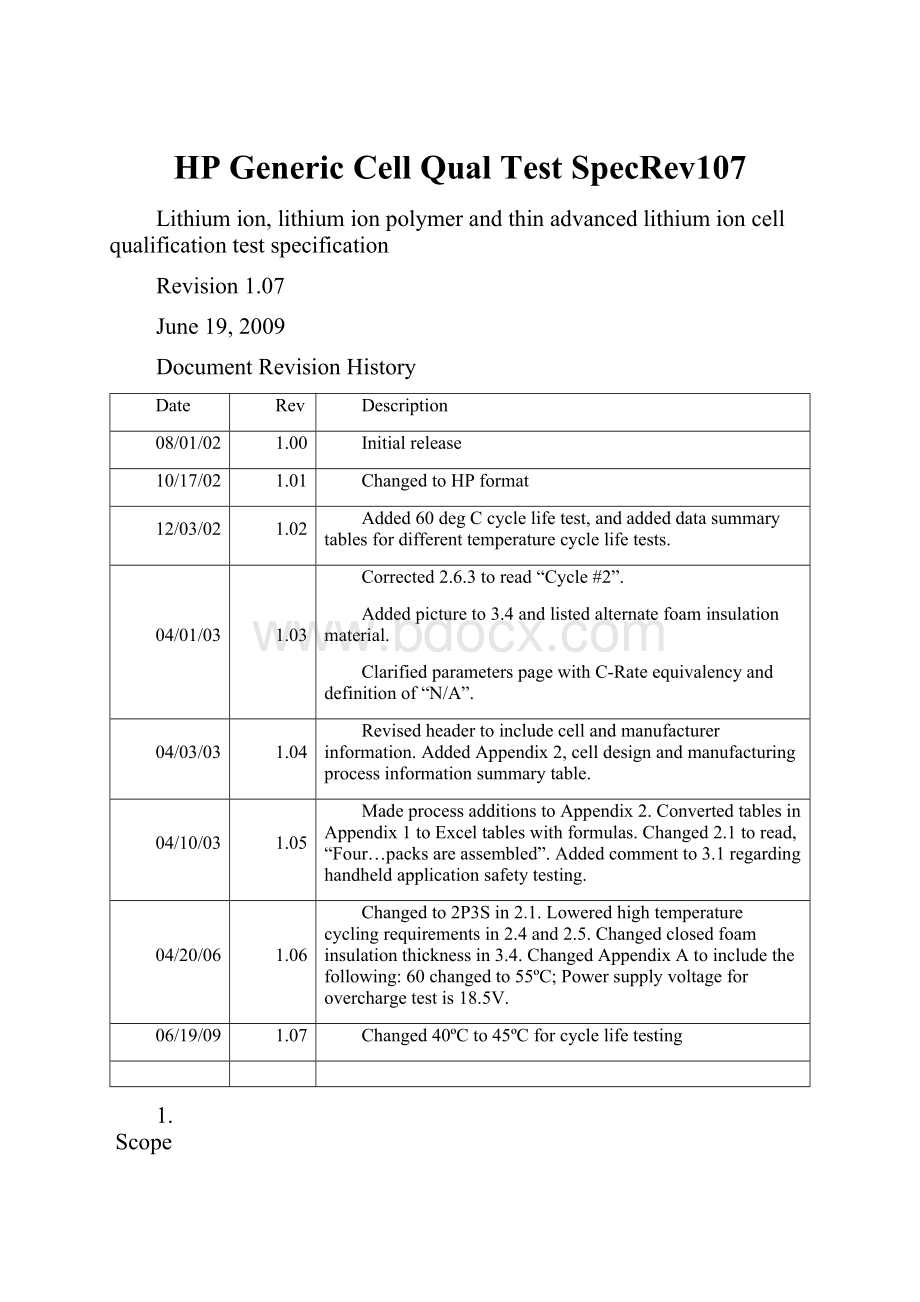

DocumentRevisionHistory

Date

Rev

Description

08/01/02

1.00

Initialrelease

10/17/02

1.01

ChangedtoHPformat

12/03/02

1.02

Added60degCcyclelifetest,andaddeddatasummarytablesfordifferenttemperaturecyclelifetests.

04/01/03

1.03

Corrected2.6.3toread“Cycle#2”.

Addedpictureto3.4andlistedalternatefoaminsulationmaterial.

ClarifiedparameterspagewithC-Rateequivalencyanddefinitionof“N/A”.

04/03/03

1.04

Revisedheadertoincludecellandmanufacturerinformation.AddedAppendix2,celldesignandmanufacturingprocessinformationsummarytable.

04/10/03

1.05

MadeprocessadditionstoAppendix2.ConvertedtablesinAppendix1toExceltableswithformulas.Changed2.1toread,“Four…packsareassembled”.Addedcommentto3.1regardinghandheldapplicationsafetytesting.

04/20/06

1.06

Changedto2P3Sin2.1.Loweredhightemperaturecyclingrequirementsin2.4and2.5.Changedclosedfoaminsulationthicknessin3.4.ChangedAppendixAtoincludethefollowing:

60changedto55ºC;Powersupplyvoltageforoverchargetestis18.5V.

06/19/09

1.07

Changed40ºCto45ºCforcyclelifetesting

1.

Scope

Thistestspecificationdescribestheproceduresusedtoevaluatethecycleperformanceofacorepack(orsoftpack)ofcellsandthesafetyperformanceofindividualcells.Thisdocumentappliestolithiumion,lithiumionpolymerandthinadvancedlithiumioncellsusedinHPnotebookandhandheldproducts.

2.Corepackcyclelifeperformance

2.1.Packconfiguration

CellsareconnectedintoanXPbyYSmatrix,where

XP=thenumberofcellsconnectedinparallel,and

YS=thenumberofcellsinseries

Forexample;2P3S(twocellsinparalleland3cellsinseries),1P4S,2P3S,etc.

Foursuchcorepacksareassembledforcyclelifetesting.

2.2.Measuredparameters

2.2.1.Voltage

Measureandrecordthetotalvoltageofthecorepackvs.timethroughoutthecyclelifetest.

Measureandrecordthevoltageofeachbankofparallelcellsinthecorepack.Ifthetestequipmentiscapable,aback-upchargeterminationconditionissettoVov,andchargeisterminatedifanyonebankofparallelcellsexceedsthisvalue.Likewise,ifpossibleaback-updischargeterminationissetatVuvtostopdischargeifanyonebankofparallelcellsgoesbelowthisvalue.

Thecorepacksarechargedbyaconstantcurrent,constantvoltage(CCCV)method,andtheyaredischargedateitherconstantcurrentorconstantpoweraccordingtothetestprocedure.

2.2.2.Current

Measureandrecordthecurrentgoingintoandoutofthecorepackvs.timethroughoutthecyclelifetest.

2.2.3.Temperature

Measureandrecordthetemperatureofacellnearthecenterofthecorepackvs.timethroughoutthecyclelifetest.

2.3.Calculatedvalues

Calculateandrecordcapacity(Ah)goingintoandoutofthecorepackvs.time,andenergy(Wh)goingintoandoutofthecorepackvs.timethroughoutthecyclelifetest.

2.4.Chargeanddischargetemperatureconditionsforcorepackduringcyclelifetest

2.4.1.Cycleonecorepackinanenvironmentalchambersetat

10oC,+/-2oC.

2.4.2.Cycleonecorepackinanenvironmentalchambersetat

25oC,+/-2oC,orinaroomwhoseambienttemperatureremainsnearthisvalue.

2.4.3.Cycleonecorepackinanenvironmentalchambersetat

45oC,+/-2oC.

2.4.4.Cycleonecorepackinanenvironmentalchambersetat

55oC,+/-2oC.

2.5.Passcriteriaforcorepackcyclelifetest

Acorepackisconsideredtohavepassedthecyclelifeperformanceportionofthequalificationtestif:

2.5.1.Foracorepackscycledat25oC,45oC

Theenergy(Wh)deliveredatcycle#300isgreaterthanorequalto80%oftheenergy(Wh)deliveredatcycle#3

2.5.2.Foracorepackcycledat55oC

Theenergy(Wh)deliveredatcycle#300isgreaterthanorequalto70%oftheenergy(Wh)deliveredatcycle#3

Anexceptionwillbemadeforlowcapacityconsumercells.Forthesecells,60%oftheWhdeliveredatcycle#3willbeacceptable.

2.5.3.Foracorepackscycledat10oC

Theenergy(Wh)deliveredatcycle#300isgreaterthanorequalto50%oftheenergy(Wh)deliveredatcycle#3

2.6.Corepackcycletestprocedure

2.6.1.Cycle#0

DischargeatIndconstantcurrenttoVeod

Restfor15minutes

2.6.2.Cycle#1

ChargeatIncconstantcurrenttoVcl.TerminatechargewhencurrenttaperstoIct

Restfor15minutes

DischargeatIndconstantcurrenttoVeod

Restfor15minutes

2.6.3.Cycle#2

ChargeatIncconstantcurrenttoVcl.TerminatechargewhencurrenttaperstoIct

Restfor15minutes

DischargeatICconstantcurrenttoVeod

Restfor15minutes

2.6.4.Cycle#3through#300

ChargeatIscconstantcurrenttoVcl.TerminatechargewhencurrenttaperstoIct

Restfor15minutes

DischargeatPsdconstantpowertoVeod

Restfor15minutes

Repeatupto300cycles

2.6.5.Optionalperiodicdischargevariationsforcycle#3through#300.

Sometimesitisdesirabletoperiodicallymonitortheenergydeliveredbyapackwhendischargedataratedifferentthanthestandarddischargerate.Ifrequired,Appendix1willlistparameterstobeappliedtothissectionofthecyclelifetestregimefromcycle#3throughcycle#300.

RepeatthefollowingchargeanddischargeeveryNcyclesasdescribedinAppendix1forthecellsundertest.

ChargeatIascconstantcurrenttoVcl.TerminatechargewhencurrenttaperstoIct

Restfor15minutes

DischargeatPasdconstantpowertoVeod

Restfor15minutes

Returntotestparameterssetinparagraph2.6.4forthenext

(N-1)cycles.RepeateveryNcycles

3.Cellsafetyperformance

3.1.Un-cycledcellsafetytestoverview

TestName

TestTemperature

(Cell)

TestCurrent

PowerSupplyVoltage

TestDuration

(Hours)

Numberofcellstested

UC1Overcharge

25oC

IOC1

Vps

ET1

3

UC2Overcharge

25oC

IOC2

Vps

ET2

3

UC3Overcharge

25oC

IOC3

Vps

ET3

3

Overchargetestsareperformedonindividualcellsfornotebookapplications.Atotalofnineoverchargetestsareperformedforagivencellmodel.

Theoverchargetestproceduresvaryslightlybetweencylindricalandprismaticlithiumioncells,andlithiumionpolymerorthinadvancedlithiumioncells.Thelithiumionpolymerandthinadvancedlithiumioncellssometimesrequirethemechanicalconstraintofthefinalbatterypacktopreventthemfromdistortingandburning.Ifsuchconstraintisrequiredtopassthetest,itshouldbenotedalongwiththeoverchargetestresults.

Overchargetestsforhandheldapplicationsshouldbeperformedoncorepacksofcells(lessprotectioncircuitry)astheywouldbeconfiguredinthefinalapplication.Thecurrent,voltageandconfigurationinformationforthesetestsshouldbenotedalongwiththeoverchargetestresults.

3.2.Measuredparameters

3.2.1.Weight

Measureandrecordcellweightbeforeandaftertheoverchargetest.

3.2.2.Voltage

Measureandrecordcellvoltagevs.timethroughouttheoverchargetest.

3.2.3.Current

Measureandrecordthecurrentgoingintothecellvs.timethroughouttheoverchargetest.

3.2.4.Temperature

Measureandrecordthecelltemperaturevs.timethroughouttheoverchargetest.

3.3.Cellstateofcharge

Thecellsthatareusedforthesesafetytestsarebroughtto100%stateofchargeunderstandardchargeconditionspriortothestartofthetest.

3.4.Cellthermalenvironment

Thesafetytestsareperformedonindividualcellsatroomtemperature.ThecellsarewrappedwithasinglelayerofFiberglasinsulation.Thisinsulationshouldbeapproximately1.0inch(25mm)thickinitsuncompressedstate.Alternatematerialisclosedcellfoamapproximately12mmthick(seephoto).

3.5.Passcriteriaforsafetytests

Acellisconsideredtohavepassedagivensafetytestifallofthefollowingconditionsaremet:

3.5.1.Nosmokeisemittedfromthecell

3.5.2.Nofireisemittedfromthecell

3.5.3.Lessthan0.2weightpercentofthecellcontentsislost

3.6.Cylindricalandprismaticlithiumionliquidelectrolytecellprocedure

3.6.1.Placethefullychargedcellinafumehoodthatprovidesadequateventilationincasethecellventsorburns.Connectthepowersupplyandoverchargethecellforthespecifiedperiodoftime.

3.7.Lithiumionpolymerandthinadvancedlithiumioncellprocedure

3.7.1.Placethefullychargedcellinafumehoodthatprovidesadequateventilationincasethecellventsorburns.Connectthepowersupplyandoverchargethecellforthespecifiedperiodoftime.Initiallyperformthistestwiththecellunconstrainedonthebench.

3.7.2.Ifthecellburns,repeatthetestwithapieceofPlexiglasorotherrigidmaterialplacedoverthecelltosimulateabatterycasethatconstrains,orrestricts,theexpansionofthecellinthethicknessdimension.Reportthisoranyotherconditionrequiredtopasstheoverchargetest.

AppendixA–CelltestparametersandTestResultsSummary

Chemistry(Anode/Cathode)

Graphite/CobaltOxide

NominalVoltageofcell(V)atC/5discharge

permanufacturer

3.7

NominalEnergyofcell(Wh)atC/5dischargepermanufacturer

Cellweight(g)

Parameter

Value

Description

XPYS

Parallelbyseriescorepackconfigurationmatrix

Vcl

4.2

Packchargeclampvoltage(V)

Veod

3.0

Packdischargecutoffvoltage(V)

Vov

4.35

Cellovervoltagecutoff(V)

Vps

18.5

Powersupplyvoltage(V)foroverchargetest

Vuv

2.75

Cellundervoltagecutoff(V)

Iasc

N/A

Alternatespecifiedpackchargecurrent(mA)

IC

PackC-Rate(mA)forthecellundertest

Ict

P