825 Staples Factory Audit Report QA Only.docx

《825 Staples Factory Audit Report QA Only.docx》由会员分享,可在线阅读,更多相关《825 Staples Factory Audit Report QA Only.docx(16页珍藏版)》请在冰豆网上搜索。

825StaplesFactoryAuditReportQAOnly

FactoryQualityAssessment

AuditReport

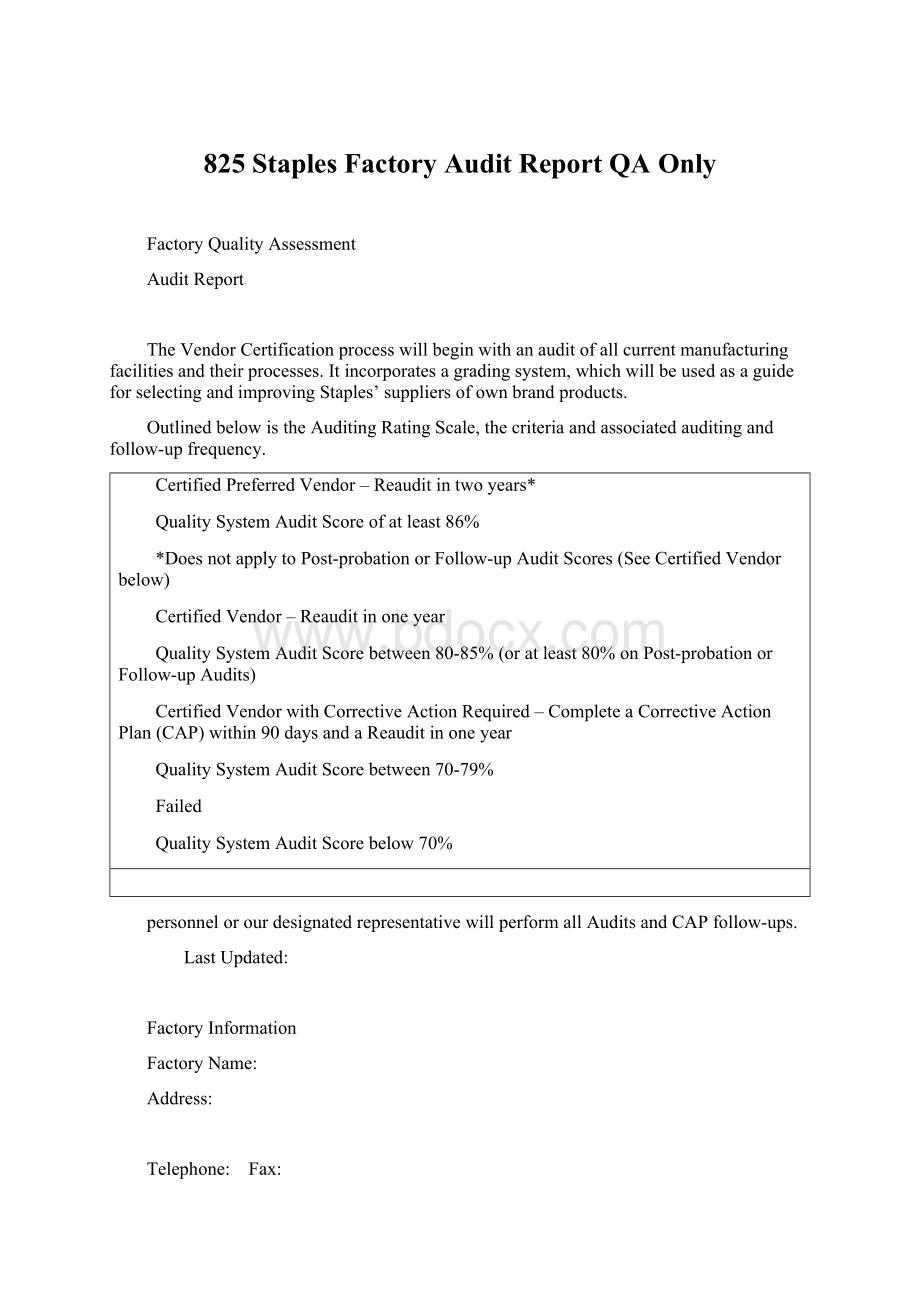

TheVendorCertificationprocesswillbeginwithanauditofallcurrentmanufacturingfacilitiesandtheirprocesses.Itincorporatesagradingsystem,whichwillbeusedasaguideforselectingandimprovingStaples’suppliersofownbrandproducts.

OutlinedbelowistheAuditingRatingScale,thecriteriaandassociatedauditingandfollow-upfrequency.

CertifiedPreferredVendor–Reauditintwoyears*

QualitySystemAuditScoreofatleast86%

*DoesnotapplytoPost-probationorFollow-upAuditScores(SeeCertifiedVendorbelow)

CertifiedVendor–Reauditinoneyear

QualitySystemAuditScorebetween80-85%(oratleast80%onPost-probationorFollow-upAudits)

CertifiedVendorwithCorrectiveActionRequired–CompleteaCorrectiveActionPlan(CAP)within90daysandaReauditinoneyear

QualitySystemAuditScorebetween70-79%

Failed

QualitySystemAuditScorebelow70%

personnelorourdesignatedrepresentativewillperformallAuditsandCAPfollow-ups.

LastUpdated:

FactoryInformation

FactoryName:

Address:

Telephone:

Fax:

E-mail:

Agent:

TypeofAudit:

()InitialQualification()CriticalIssueorCAPFollow-upAudit

()RecertificationAudit()Post-probationAudit

()Other(pleasespecify):

SCOREOFTHEQUALITYSYSTEMAUDIT

AuditScore

CertifiedPreferredVendorCertifiedVendorFailed

STATUSANDNEXTACTIONDUE

CertifiedPreferredVendor–Reauditintwoyears*

QualitySystemAuditScoreofatleast86%

*DoesnotapplytoPost-probationorFollow-upAuditScores(SeeCertifiedVendorbelow)

CertifiedVendor–Reauditinoneyear

QualitySystemAuditScorebetween80-85%(oratleast80%onPost-probationorFollow-upAudits)

CertifiedVendorwithCorrectiveActionRequired–CompleteCAP/Reauditinoneyear

QualitySystemAuditScorebetween70-79%

Failed

QualitySystemAuditScorebelow70%

Auditor’sName

ApprovedBy

Date

CommentsandRecommendations:

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

COMPANYORGANIZATIONMetduringAudit?

ManagingDirector/GeneralManager()Yes()No

SalesManager/MarketingManager()Yes()No

PlantManager()Yes()No

QC/QASupervisor/Manager()Yes()No

ProductionManager/FactoryManager()Yes()No

Factoryhasbeeninoperationsince

STAFFINGINFORMATION

ManufacturingPersonnel:

QualityControllers:

Engineers:

PRODUCTIONINFORMATION

MajorCustomers_________________________________________________________

MonthlyProductionCapacity___________________RequiredLeadTime____________

MainProductsProduced____________________________________________________

MajorMachinery:

ManufCalibrRemarks:

Date:

Date:

“Yes”answersscore1point.“No”answersscores0points.

A.FACILITIES

1.Doestheplantlayoutappeargenerallyacceptable?

()Yes()No

2.Doestheoverallmaintenanceofthepremises()Yes()No

appearacceptable?

3.Doesthegeneralhousekeepingappearacceptable?

()Yes()No

4.Didyouseeacompletecompanypolicymanual?

()Yes()No

5.Didyouseedocumentationthatallproduction()Yes()No

machineswereonamaintenancescheduleand

amaintenanceteamwasinplace?

6.Doesthefactoryhaveabackupgenerator?

(Ifyes,()Yes()No

providedateoflastuseanddateoflastmaintenance

below).

7.Didyouseethatallmachines/equipment/fixtures()Yes()No

weresuitabletoproducetheintendedproducts?

8.Didyouseeevidencethatthefactoryhasawell()Yes()No

organizedmaintenanceteamthatcouldimmediately

respondtoamachinerybreakdownoremergency?

9.Didthelightingandventilationconditionsappear()Yes()No

adequateintheproductionareas?

10.Didyouconfirmthatfaxandtelephonewere()Yes()No

available?

11.Didyouconfirmelectroniccommunicationsystems()Yes()No

wereinplace?

(PCswithwordprocessing,

spreadsheetande-mailcapabilities)

Rating:

Facilities:

Score1Pointforeachmarkedyes.Total:

/11

ItemNo.:

Remarks:

B.QUALITYCONTROLSYSTEM

1.Didyouseeevidencethatthefactoryhasaformal()Yes()No

internalqualitycontrolprogramforallofitsproducts?

2.Didyouseeevidencethatthereisaformalinternal()Yes()No

trainingprogramforallqualitycontrol(QC)personnel?

3.DidyouseeformaltrainingrecordsforallQCpersonnel?

()Yes()No

4.WereallQCpersonnelcertifiedbeforetheywereallowed()Yes()No

toperformtheirjobs?

5.AretheQCpersonnelindependentoftheproductionstaff?

()Yes()No

6.DidyouseeacompleteQualityManual?

()Yes()No

7.Didyouseethatthefactoryisusinginternational,national,()Yes()No

client’s,and/oritsownapprovedstandardstoperform

in-housequalitycontrol?

8.Didyouseedetailedwrittenplansdemonstratinghow()Yes()No

safetyrequirementsofproductsarecheckedin-house?

9.DidyouseedetailedQCreportsthatreflectallproducts()Yes()No

arebeingproperlychecked/inspected?

10.DidyouseeevidencethattherewasadequateQC()Yes()No

supervisiononallshifts?

11.WasthereevidencethatallQCpersonnelfully()Yes()No

understandqualitypolicy,qualityconsciousnessand

theimportanceofthequalityassuranceconcept?

12.DoesQChaveadequatebasicknowledgeandexpertise()Yes()No

onproductsandgeneralmanufacturingtechnology?

13.Didyouseedocumentationthatthefactoryhadall()Yes()No

relevantinternational/nationalsafetystandardsandwas

incompliance?

Rating:

QualityControlSystems:

Score1Pointforeach“Yes”response.Total:

/13

ItemNo.:

Remarks:

C.INCOMINGMATERIALSINSPECTIONS

1.Wasthereevidencethatthefactorytakesadequate()Yes()No

measurestoassurerawmaterialsconformanceto

requiredspecificationsbeforeuse?

2.Arerawmaterialsproperlylabeled,storedandtraceable?

()Yes()No

3.Arerawmaterialskeptincontrolledstoreroomstoavoid()Yes()No

theft,lossandanydeteriorationofquality?

4.Ifrawmaterialsneedinspectionbeforeputtinginto()Yes()No

production,aretheyproperlyinspectedandarerecords

traceable?

5.Dorecordsshowthatrejectedlotsarewellidentified,()Yes()No

segregatedfromacceptablelotsandeventuallyreturned

tothesupplier?

6.Istheinspectionsamplingscheduleadequateandcanthe()Yes()No

qualityoftheproductbeguaranteedwithconfidence?

7.Areadequateinspectionrecordsmaintainedtoprove()Yes()No

productsarecheckedandmeetallrequirements?

8.Arethereadequatewritteninspectioninstructions()Yes()No

withproperaccept/rejectcriteriaavailableasguidelines

toinspectors?

9.Iftestingequipmentisneededduringinspection,isit()Yes()No

sufficient,ingoodconditionandcalibrated?

10.Isthereasystematiccontrolonthenon-conforming()Yes()No

rawmaterialsandisitefficient?

11.Doesthefactoryhaveaformalprocessforselectingand()Yes()No

qualifyingnewsuppliers?

12.Doesthefactoryhaveaformalprocessforcontinuously()Yes()No

monitoringasupplier’sperformance?

Rating:

IncomingInspections:

Score1Pointforeachmarkedyes.Total:

/12

ItemNo.:

Remarks:

D.INPROCESSQUALITYCONTROL

1.Didyoureviewanoutlineofthevariousstepsof()Yes()No

themanufacturingprocess?

2.Aresamplesofpilotrunscarefullyreviewedby()Yes()No

engineersandqualitystafftoseeallqualityandsafety

aspectsarebeingmet?

3.IstheresufficientwelltrainedIn-ProcessQCstaff()Yes()No

toprepareformassproduction?

4.Istheredocumentationfromeitherengineering,the()Yes()No

QCdepartment,ortopmanagementtoauthorize

massproduction?

5.AretheproductionlinescheckedbyQC(orbyother()Yes()No

means)tomonitorthecomplianceoftheproductto

meetqualityandsafetyrequirements?

6.Doesthefactoryuseinternational(orotherapproved()Yes()No

standards)tocarryoutin-processinspectionandare

thererecords?

7.Dorecordsreflecttheactiontakenontherejected()Yes()No

lots?

8.Dorecordsshowrejectedlotsare