工业工程技术培训01 Word 文档.docx

《工业工程技术培训01 Word 文档.docx》由会员分享,可在线阅读,更多相关《工业工程技术培训01 Word 文档.docx(49页珍藏版)》请在冰豆网上搜索。

工业工程技术培训01Word文档

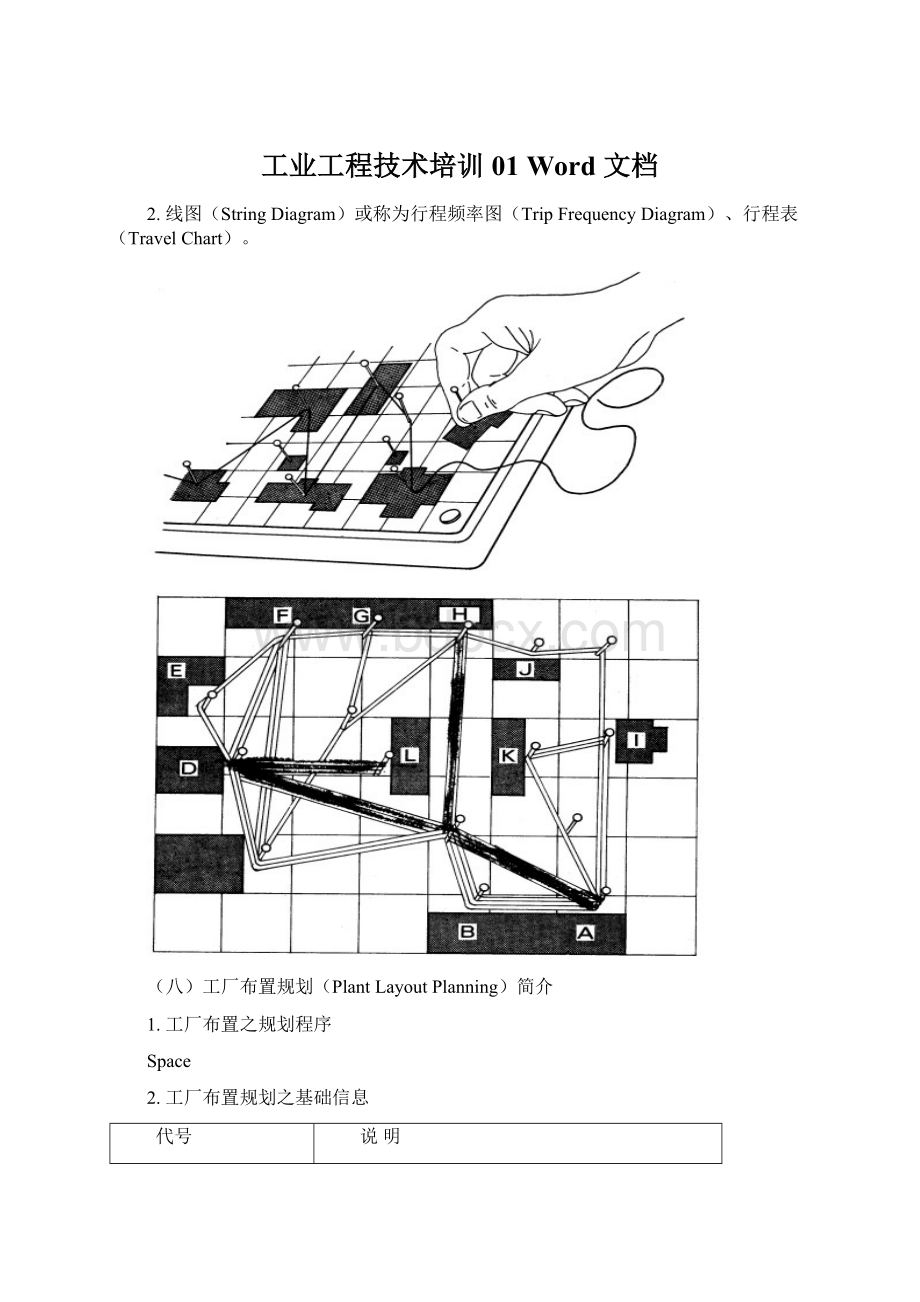

2.线图(StringDiagram)或称为行程频率图(TripFrequencyDiagram)、行程表(TravelChart)。

(八)工厂布置规划(PlantLayoutPlanning)简介

1.工厂布置之规划程序

Space

2.工厂布置规划之基础信息

代号

说明

P

ProductorMaterial

物品之特性和差异性

Q

QuantityorVolume

各单项物品之数量或体积

R

RoutingorProcess

物品之制造程序或流程

S

SupportingServices

orActivities

支持生产所必需之活动

T

Timeor

TimingConsideration

包括:

作业时间/期间、频率、

期限、季节性,…等等

3.工厂布置之型态

工厂布置之型态

4.关连图(RelationshipDiagram)

7

品管部门

1

A

2

I

2

I

3

U

U

3

A

1

A

A

3

O

O

O

1

I

1

3

4

E

3

3

I

O

A

I

5

1

E

3

U

4

I

6

4

A

4

7

MovementofMaterials

ShareofSamePersonnel

Personnel

ControlofWork

5.关连分析(RelationshipAnalysis)

2E's

2

6A’s

6I's

4O's

3U's

6.工厂布置之着眼点

◎人性化观点:

〝人、机、物〞之和谐关系

◎安全性之设计考量

◎生产性观点:

〝人、机、物〞之最适组合

‧流动程序(Flowprocess)、动线:

Ship-To-Store,

Ship-To-Line,Make-TO-Shipment,Make-To-Order,etc.

‧流动频率:

JIT-Justintime

‧Load&Unload之次数/频率

‧搬运设备之效能

(九)缩短换线换模时间之要领简介

ImprovementApproach改善的手法

☆Four(4)Steps四个步骤

☆Two

(2)Categories两种类别

☆Four(4)Stages四个阶段

4Steps(四个步骤)

☆Preparation(准备)

☆(Re)placement(更换、装置)

☆Adjustment(调整)

☆Completion(完成、善后)

Step1Preparation(准备)

*DrawingUpChange-overInstructions.

-Operations.

-Toolsneeded(jigs,dies,moulds,etc.).

-Fastenersneeded(bolts,screws,washers,nuts,clamps,clips,etc.).

*Storage,MaintenanceandInspectionofToolsandFasteners.

*GatheringandPreparationofNewToolsandFasteners.

TransportofToolsandFastenerstotheProcess.

Step2(Re)placement(更换、装置)

*UnfasteningandRemovalofOldTools.

*PlacingtheNewTools.

*CenteringtheNewTools.

Step3Adjustment(调整)

*FasteningNewTools.

*SecuringtheNewTools.

*AdjustmentoftheNewTools.

Step4Completion(完成、善后)

*TransportofOldTools.

*Cleaning,GreasingandOilingTheOldTools.

*StorageofOldTools.

2Categories(两种类别)

☆On-lineChange-over(线内更换)

Change-overactivitiesInterruptingtheprocess.

☆Off-lineChange-over(线外更换)

Change-overactivitiesalongsidetheprocess.

Producing

productB

Off-line

4

4Stages(四个阶段)

AdvancedStage改进阶段

TransferredStage移转阶段

SeparatedStage分离阶段

IntermingledStage混合阶段

◎IntermingledStage(混合阶段)

*Noseparationbetween.

*On-lineandoff-lineoperations.

*Processisstoppedduringtotalchange.

*Newtoolsarebroughtinaftertheprocesshasbeenstopped.

*Neithertoolsnorfastenersareproperlymaintained,checkedorprepared.

*Toolsandfastenersarenottidystored.

◎SeparatedStage(分离阶段)

*On-lineandoff-lineoperationsarekeptseparated.

*Processisstoppedforon-lineoperationsonly.

*Allnecessarypreparationsarecompletedwhiletheprocessisgoingon.

*Achecklistisavailableforcarryingoutoff-linework.

*Maintenance,inspectionandpreparationoftoolsandfastenersarecarriedoutoff-line.

*Acheckismadewhethertoolsandfastenersworkproperly.

◎TransferredStage(移转阶段)

*On-lineoperationsaretransferredtooff-lineasmuchaspossible.

*Heightofdies,ramsandpressblocksarestandardized.

*Allfastenersandspannersarestandardized.

*Standardizedintermediateattachmentsareintroduced.

*Adjustmentofmachinesstrokesisavoided.

◎AdvancedStage(改进阶段)

*Bothon-lineandoff-lineoperationsareminimized.

*Dimensionsofalltoolsarestandardized.

*Handlingofmoulds,jigs,diesandformsisstandardized.

*Hydraulic,pneumaticormagneticfasteningisintroduced.

*Fasteningandadjustmentworkissimplifiedoreliminatedwhereverpossible.

*Cassettesareintroduced.

◎FromIntermingledtoSeparatedStage

*Makeacleardescriptionofallchange-overoperationstobeexecutedtoday(seeworksheet).

*Prepareasummarylistof:

-alltoolsneeded(jigs,dies,moulds,etc.).

-allfastenersneeded(bolts,screws,clips,etc.).

*Classifyalloperationsinto:

-off-lineactivities.

-on-lineactivities.

◎FromSeparatedtoTransferredStage

*Transferoperationsfromon-linetooff-lineasmuchaspossible.

*Theuseoffunctionalfasteners.

*Thepreviousinstallationofintermediateattachments,bolstersandfasteners.

*Introductionoffunctionaldialorpointerreadings.

WorksheetNr.:

WorkstationNr.:

Change-overfromto

Operation

Tools&Fasteners

Location

Steps

toberemoved

tobeplaced

Preparation

(Re)placement

Adjustment

Completion

off

on

off

on

off

on

off

on

◎FromTransferredtoAdvancedStage

*Improvementofhandling,transportandstoragemethods.

*Theuseofhydraulic,pneumaticormagneticmethodsforplacingand/orfasteningtools.

*Theeliminationofcenteringandadjustmentactivitiesbystandardisationof:

-dimensionofmoulds.

-machinestrokes.

-maleandfemalejigs.

-centeringandfasteningmethods.

*Improvemeasuringandgaugingmethods.

*Eliminationoftrialruns.

(十)IE改善心法

WaysofImprovingtheWorkThroughMotionStudy

-EASIERWAY-approach

Eliminateunnecessarymotions

Avoidmovesrequiringeyedirection

Shortenmotiondistance

Improve"get"motionsbypre-positioning

Employsimplefixtures,clamps,andguides

Replacehandoperationswithfoot-operateddevices

Why?

Questioneachoperation

Adapttwo-handmethod

Yes,thereisalwaysroomforimprovement

Hey!

Youare

workingtoohard!

(三)改善之要诀:

ECRS、6W

‧删除(Elimination):

删除不必要的作业或动作

‧合并(Combination):

将数个作业或动作合并,省略转交或取放。

‧重排(Re-arrangement):

将数个作业或动作重新安排,使作业或动作能平衡顺畅。

‧简化(Simplification):

将数个作业或动作加以改善,使其简化。

StoryoftheBedauxSystem

I.StoryoftheBedauxSystem

In1911,Mr.CharlesE.Bedauxexperimentedwiththeideaofmeasuringallhumanphysicalworkintermsofacommonunit.

TheunitknownastheBedauxUnitofhumanpowermeasurementor“B”wastoconsistsofacombinationofworkandrest.

Theproportionsbetweenthesetwoitemsweredependentuponthephysicalnatureoftheworkandthesubsequentrestrequiredtocompensateforit.Astasksvaried,theratiooftheworktorestwithintheunitwastovary,buttheunititselfwastoremainconstantatatimevalueofonminute.

II.TheBedauxSystemor“E”System(UnitSystem)

The“UnitE”isthequantityofworkanexperienced,skilledworkercandoperminuteundernormalconditions,takingintoaccounttheinherentallowanceforrest,personalneeds.

III.The“M”System(UnitSystem)

TheUnit(M)istheamountofworkthatcanbecarriedoutinoneminutebyatrainedworker,undernormalcircumstance,andatnormalspeed,includingallowancesforinterruptionsasrestandpersonalcare.

TheUnit(M)doesnotrepresenttimeinthesenseofaclocktime,butitisratherameasureof“workquantity”or“laborcontent”.

IV.Expression

WorkQuantityorLaborContent=Work+Rest(Bedauxdefinition)or

=Work+TotalAllowance(Philipsdefinition)

Example:

LaborContent1M

TAF-totalallowancefactor:

1.14/1.18/1.2

LaborContentWork(NormalTime)TAF

1M(60seconds)=52.6seconds+7.4seconds(14%)

1M(60seconds)=50.8seconds+9.2seconds(18%)

1M(60seconds)=50.0seconds+10.0seconds(20%)

VIII.PerformanceRating

Performanceratingisexpressingnumericallythespeedandeffectivenesswithwhichanoperationisdone,inrelationtowhathasbeendefinedasnormalperformance.

Tempomeanstheintensityofworking.

InBedauxtime-studysystem:

Speedofthemovements

Tempo

Skillofthemovements(i.e.proficiency,usefuleffect,dexterity,efficiency).

IX.NormalPerformance

Normalperformanceistheperformanceofanaverageskilledworkerdoingajobundernormalconditionswithoutbeingstimulatedbyanincentivescheme.

Itmustbepossibletokeepthisperformancefromdaytodaywithoutexcessivephysicalormentalstrain.

Asareferencefornormalperformancecanbetaken,asteadydeliberateandunhurriedaverageperformanceofaperson,whowalksaround4.8Km(3miles)perhourordeals52playing-cardsin30seconds.

X.Remarks

-Unit(English)

-Einheit(German)

-Eenheid(Dutch)

-单位(Chinese)

-Esystem:

forPerformanceorTempo(60E,75E,80E)

-Msystem:

forLaborContentorWorkQuantity(5M’s,60.5M’s)

EffectsofWorkingConditionsondeterminingAllowance

Allowance

Value

Constantallowance

C-1

Personalallowance

5%

C-2

Basicfatigueallowance

4%

Variableallowance

V-1

Standingallowance

1%

V-2

Abnormalpositionallowance

Slightlyawkward

0

Awkward(Bending)

2%

Veryawkward(Lying,Stretching)

7%

V-3

Useofforceormuscularenergy(Lifting,pulling,orpushing)

Weightlifted:

5Pounds(2.3Kg)

0

10Pounds(4.5Kg)

1%

15Pounds(6.8Kg)

2%

20Pounds(9.1Kg)

3%

25Pounds(11.4Kg)

4%

30Pounds(13.6Kg)

5%

35Pounds(15.9Kg)

7%

40Pounds(18.2Kg)

9%

45Pounds(20.4Kg)

11%

50Pounds(22.7Kg)

13%

60Pounds(27.3Kg)

17%

70Pounds(31.8Kg)

22%

V-4

Badlight

Slightlybelowrecommended

0

Wellbelow

2%

Quiteinadequate

5%

V-5

Atmosphericconditions(HeatandHumidity)

0~10%

V-6

Closeattention

Fairlyfinework

0

Fineorexacting

2%

Veryfineorveryexacting

5%

V-7

Noiselevel

Continuous

0

Intermittent–loud

2%

Intermittent–veryloud

5%

High–pitched–loud

5%

V-8

Mentalstrain

Fairlycomplexprocess

1%

Complexorwidespanofattention

4%

Verycomplex

8%

V-9

Monotony

Low

0

Median

1%

High

4%

V-10

Tediousness

Rathertedious

0

Tedious

2%

Verytedious

5%

(CourtesyofInternationalLaborOffice,GenevaSwitzerland)

PHILIPS

动作分析表页次:

/

作业名称:

产品型号:

作业区域:

分析人:

分析日期:

LH

RH

LH

RH

LH

RH

LH

RH

50

50

50

50

10

10