编程题题库.docx

《编程题题库.docx》由会员分享,可在线阅读,更多相关《编程题题库.docx(26页珍藏版)》请在冰豆网上搜索。

编程题题库

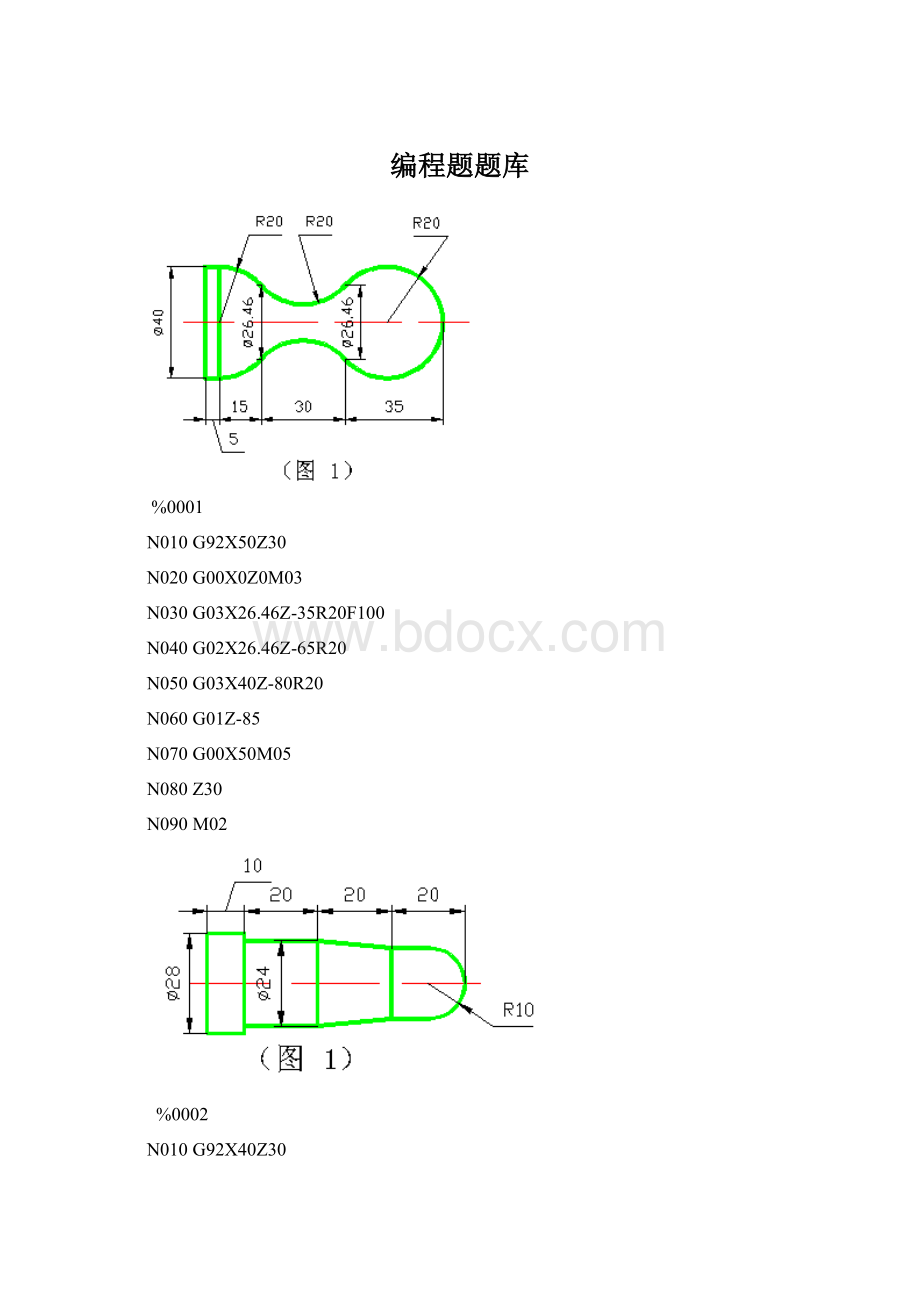

%0001

N010G92X50Z30

N020G00X0Z0M03

N030G03X26.46Z-35R20F100

N040G02X26.46Z-65R20

N050G03X40Z-80R20

N060G01Z-85

N070G00X50M05

N080Z30

N090M02

%0002

N010G92X40Z30

N020G00X0Z0M03

N030G03X20Z-10R10F200

N040G01Z-20

N050X24Z-40

N060Z-60

N070X28

N080Z-70

N090G00X40M05

N100Z30

N110M02

%0005 程序号

N010G92X40Z30 对刀点

N020M06T0101 换1号刀,粗车外圆

N030G00Z0M03

N040G73U10W5R4P100Q150X0.6Z0.3F400S500

N100G01X12.2F100

N110Z-21

N120X16.2

N130Z-29.5

N140X24.2Z-46

N150Z-72

N050G00X40

N060Z30M05

N070T0100

N200M06T0202 2号刀精车外圆

N210G00Z0M03

N220G01X10.88F100

N230X11.88Z-1

N240Z-21

N250X15

N260X16Z-22

N270Z-29.5

N280X24Z-46

N290Z-72

N300G00X40

N310Z30M05

N320T0200

N400M06T0404 4号刀切槽

N410G00Z-17

N420G81X9Z-17F100

N430G81X9Z-18

N440G01Z-16

N450X11.88

N460X10.88Z-17

N470G00X40

N480Z30M05

N490T0400

N500M06T0303 3号刀螺纹加工

N510G00Z3M03

N520G82X11.08Z-19F1.5

N530G82X10.48Z-19

N540G82X10.08Z-19

N550G82X10.02Z-19

N560G00Z30M05

N570T0300

N600M06T0404 4号刀切槽、切断

N610G00Z-51M03

N620G81X20Z-51F100

N630G81X20Z-52F100

N640G00Z-61

N650G81X20Z-61F100

N660G81X20Z-64

N670G81X20Z-67

N680G00Z-66

N690G81X13Z-66F100

N700G01Z-63F100

N710X20

N720G03X14Z-66R3

N730G01X0

N740G00X40

N750Z30M05

N760M02

六、数控车削零件如图2所示,毛坯材料为45号钢,直径为30mm,长度为100mm。

要求:

使用4把车刀,1号刀为粗车90°外圆车刀,2号刀为精车90°外圆车刀,3号刀为切断刀(刀宽3mm),4号刀为三角螺纹车刀。

请编写粗、精车加工程序,并予以对应工艺说明。

(附螺纹有关参数:

牙深(半径量)0.974mm,切削深度(直径量)第1次0.8mm,第2次0.6mm,第3次0.4mm,第4次0.16mm)(18分)

%0003

N010G92X40Z30

N020M06T0101 1号刀粗车外圆

N030G00Z0M03

N040G73U8W5R3P100Q160X0.6Z0.2F400S500

N100G01X20F100

N110Z-29

N120X24.15

N130X28.15Z-48

N140Z-50

N150G02X28.15Z-70R20

N160G01Z-86

N050G00X40Z30M05

N060T0100

N070M06T0202 2号刀精车外圆

N200G00Z0M03

N210G01X18.85F100

N220X19.15Z-1

N230Z-29

N240X24

N250X28Z-48

N260Z-50

N270G02X28Z-70R20

N280G01Z-86

N290G00X40Z30M05

N300T0200

N400M06T0404 4号刀切槽

N410G00X40Z-25M03

N420G01X16F100

N430G00X40

N440Z-26

N450G01X16F100

N460G00X40

N470Z-24

N480G01X19.85F100

N490X18.85Z-25

N500G00X40

N510Z30M05

N520T0400

N600M06T0303 3号刀螺纹加工

N610G00X40Z3M03

N620G82X19.05Z-27F1.5

N630G82X18.45Z-27

N640G82X18.05Z-27

N650G82X18.05Z-27

N660G00Z30M05

N670T0300

N700M06T0404 4号刀切槽、切断

N710G00X40Z-72M03

N720G81X20Z-72F100

N730G81X20Z-75

N740G81X20Z-78

N750G81X20Z-81

N760G81X20Z-83

N770G00Z-80

N780G01X16F100

N790G00X21

N800Z-79

N810G01X20F100

N820X19Z-80

N830X0

N840G00X40

N850Z30M05

N860M02

六、数控车削零件如图2所示,毛坯材料为45号钢,直径为35mm,长度为120mm。

要求:

使用4把车刀,1号刀为粗车90°外圆车刀,2号刀为精车90°外圆车刀,3号刀为切断刀(刀宽3mm),4号刀为三角螺纹车刀。

请编写粗、精车加工程序,并予以对应工艺说明。

(附螺纹有关参数:

牙深(半径量)0.974mm,切削深度(直径量)第1次0.8mm,第2次0.6mm,第3次0.4mm,第4次0.16mm)(18分)

七、数控铣削如图3所示的零件,毛坯材料为45号钢,直径为200mm,高度为60mm。

要求:

(1)铣平上端面;

(2)铣凹槽,槽深10mm。

(说明:

可以选用多把不同半径端铣刀)(12分)

%0009

N010G92X0Y0Z30

N020G00X95Y0M03 铣上端面

N030G01Z-5F200

N031G91G02X0Y0I-95J0

N032G01X-10

N033G02X0Y0I-85J0

N034G01X-10

N035G02X0Y0I-75J0

N036G01X-10

N040G02X0Y0I-65J0

N050G01X-10

N060G02X0Y0I-55J0

N070G01X-10

N080G02X0Y0I-45J0

N090G01X-10

N100G02X0Y0I-35J0

N110G01X-10

N120G02X0Y0I-25J0

N130G01X-10

N140G02X0Y0I-15J0

N150G01X-10

N160G02X0Y0I-5J0

N170G90G00Z30

N180X0Y0

N200G00X85Y0 铣凹槽

N210G01Z-15F200

N220G91G02X0Y0I-85

N250G90G00Z30

N260X0Y0

N300M98P1000

N310G68X0Y0P90

N320M98P1000

N330G69

N340G68X0Y0P-90

N350M98P1000

N360G69

N370G24X0

N380M98P1000

N390G25X0

N400M05

N410M30

%1000

N010G00X85Y0

N020G01Z-15F200

N030G91G02X0Y0I-25

N060G90G00Z30

N070X0Y0

N080M99

七、数控铣削如图3所示的零件,毛坯材料为45号钢,直径为140mm,高度为50mm。

要求:

(1)铣平上端面;

(2)铣凹槽,槽深6mm。

(说明:

可以选用多把不同半径端铣刀)(12分)

%0008

N010G92X0Y0Z30

N020G00X65Y0M03 铣端面

N030G01Z-5F200

N040G91G02X0Y0I-65J0

N050G01X-10

N060G02X0Y0I-55J0

N070G01X-10

N080G02X0Y0I-45J0

N090G01X-10

N100G02X0Y0I-35J0

N110G01X-10

N120G02X0Y0I-25J0

N130G01X-10

N140G02X0Y0I-15J0

N150G01X-10

N160G02X0Y0I-5J0

N170G90G00Z30

N180X0Y0

N190G00X17.5Y0 加工凹槽

N200G01Z-11F200

N210G91G02X0Y0I-17.5J0

N220G01X5Y0

N230G02X0Y0I-22.5J0

N231G90G00Z30

N232X0Y0

N240M98P1000

N250G68X0Y0P90

N260M98P1000

N270G69

N280G68X0Y0P-90

N290M98P1000

N300G69

N310G24X0

N320M98P1000

N330G25X0

N340G00X47.5Y0

N350G01Z-11F200

N360G91G02X0Y0I-47.5J0

N370G01X5

N380G02X0Y0I-52.5J0

N390G01X5

N400G02X0Y0I-57.5J0

N410G90G00Z30

N420X0Y0

N430M98P2000

N440G24X0

N450M98P2000

N460G25X0

N470G24X0Y0

N480M98P2000

N490G25X0Y0

N500G24Y0

N510M98P2000

N520G25Y0

N530M05

N540M30

%2000

N10G90G00X22.5Y22.5

N20G01Z-11F200

N30G91G02X0Y0I3.54J3.54

N40G01X-3.54Y-3.54

N50G02X0Y0I7.07J7.07

N60G01X-3.54Y-3.54

N70G02X0Y0I10.61J10.61

N80G90G00Z30

N90X0Y0

N100M99

%1000

N10G00X47.5Y0

N15G01Z-11F200

N20G91G02X0Y0I-12.5J0

N30G01X5

N40G02X0Y0I-17.5J0

N50G90G00Z30

N60X0Y0

N70M99

1.已编出如图所示车削零件的加工程序如下:

(1)试检查修改其中的错误。

(2)注释说明每段程序的含义。

四、编程改错

O0001程序番号

N001G92X400.0Z350

改:

N001G92X200.0Z350建立工件坐标系

N002S630M03主轴以630r/min正转

N003G90G00X44.0Z292.0M08

改:

N003G90G00X40.0Z292.0M08移到工件右端45?

斜线的延长线上,同时开启切削液

N004G01X48.0Z290.0F150

改:

N004G01X48.0Z288.0F150车45?

倒角,进给速度150

N005Z275.0

改:

N005Z270.0车右端Φ48的外圆柱面

N006X62.0Z200.0车长70的锥面

N007G91Z30.0

改:

N007G91Z-30.0车Φ62的圆柱面,增量编程方式

N008X80.0Z-25.0

改:

N008X80.0车端面(阶梯面)

Z-25.0车右方Φ80的外圆此应分两步走

N009G03Z60.0R70.0

改:

N009G02Z-60.0R70.0顺时针方向车圆弧成形面

N010G90Z65.0

改:

N010G90G01Z65.0回到绝对编程方式,直线插补,车左方Φ80的外圆

N011X85.0车端面(阶梯面)

N012G00X400.0Z350

改:

N012G00X200.0Z350M09快速返回到起刀点处,关闭切削液

N013M05主轴停转

N014M30程序结束,并复位。

O0001

N001G92X400.0Z350

N002S630M03

N003G90G00X44.0Z292.0M08

N004G01X48.0Z290.0F150

N005Z275.0

N006X62.0Z200.0

N007G91Z30.0

N008X80.0Z-25.0

N009G03Z60.0R70.0

N010G90Z65.0

N011X85.0

N012G00X400.0Z350

N013M05N014M30

(1)以工件上表面为Z零平面,试编出如图所示铣削零件轮廓的加工程序。

(深度方向采用分层铣切,粗铣2次,精铣1次,精铣量2mm。

要求用主、子程序调用方式,并考虑刀径补偿。

)

主程序

子程序

%0001

G92X0Y0Z100

G90G00X-20

S1000M03

G01Z-14F100M08

M98P0010

Z-28

M98P0010

Z-32

M98P0010

G00Z100M09

X0Y0M05

M30

%0010

G42G01X5Y0D01

G01X20

G02X40Y20R20

G03X10Y50R30

G03X0Y40R10

G01Y5

X5Y0

G40X20Y-10

X-20Y0

M99

1.以工件上表面为Z零平面,试编出如图所示铣削零件轮廓的加工程序。

(深度方向采用分层铣切,粗铣2次,精铣1次,精铣量2mm。

要求用主、子程序调用方式,并考虑刀径补偿。

)

1.在立式加工中心上加工如图所示零件,以上表面为Z零平面,用刀座对刀,试填表并按表中加工工艺参数编出对其上部进行轮廓铣削和钻2孔的加工程序(含自动换刀动作)。

(铣轮廓时,深度方向采用分层铣切,粗铣2次,精铣1次,要求采用主、子程序调用方式,并考虑刀径和刀长补偿。

)

工序号

工序内容

刀具号

刀具规格

刀径补偿

刀长补偿

主轴转速

进给速度

切削深度

粗1

-7

1

铣四周轮廓

T01

Φ8平底立铣刀

(D01=4)

(H01=55)

1000

100

粗2

-14

精1

-15

2

钻2-φ6孔

T02

Φ6钻头

(H02=70)

800

30

-35

3

锪2-φ10孔

T03

Φ10沉孔钻

(H01=65)

500

80

-10

%0002

G92X0Y0Z100

G90G00X-20Y50

S1000M03

G01Z-12F100M08

M98P0020

Z-23

M98P0020

Z-27

M98P0020

G00Z100M09

X0Y0M05

M30

子程序

%0020

G42G01X-20Y30D01

G02X-30Y20R10

G03Y-20R20

G01X0

G03X17.321Y10R20

G01X8.66Y25

G03X0Y30R10

G01X-20

G40X-40

X-20Y50

M99

试编出如图所示车削零件的精车、切槽、车螺纹的带换刀的加工程序,假设毛坯已车成图中点划线所示。

O0002

G92X120Z150;

T0101;

G90G00X0.0Z105.0M03;

G01X0.0Z100.0F30;

G03X20.0Z90.0R10;

G01X48.0;

Z20.0;

X65.0;

G00X120.0Z150.0T0100;

M05M00;

T0202;

G00X55.0Z40.0M03;

G01X43.0F20;

G04X2.0;

G00X55.0;

G00X120.0Z150.0T0200;

M05M00;

T0303;

G00X55.0Z92.0M03;

G82X47.1Z42.0F2.0;

G82X46.5Z42.0;

G82X45.9Z42.0;

G82X45.5Z42.0;

G82X45.4Z42.0;

G00X120.0Z150.0T0300;

M05M02;

1.加工下图所示零件,要求自己确定加工顺序、设定加工参数、选调刀具、编制填写数控工艺卡片和手工编写数控程序,输入程序代码、装夹工件和刀具、对刀并操作机床进行切削加工。

O0001

G92X60Z120;

T0101;

G90G00X35Z5

M03S600

G71U1R2P100Q200X0.2Z0.2F100

G00X0

Z0

N100G01X16C2F40

Z-17

X24Z-20

Z-30

X26

G03X30Z-32R2

N200Z-40

G00X60Z120T0100

M05M00

T0202

G00X35Z-17M03

G01X14F30

G04X2

G00X35

G00X60Z120T0200

T0303

G00X30Z3

M03S300

G82X15.2Z-15F1.5

G82X14.6Z-15F1.5

G82X14.2Z-15F1.5

G82X14.04Z-15F1.5

G00X60Z120T0300

M05M02