注塑产品模具可行性分析.docx

《注塑产品模具可行性分析.docx》由会员分享,可在线阅读,更多相关《注塑产品模具可行性分析.docx(14页珍藏版)》请在冰豆网上搜索。

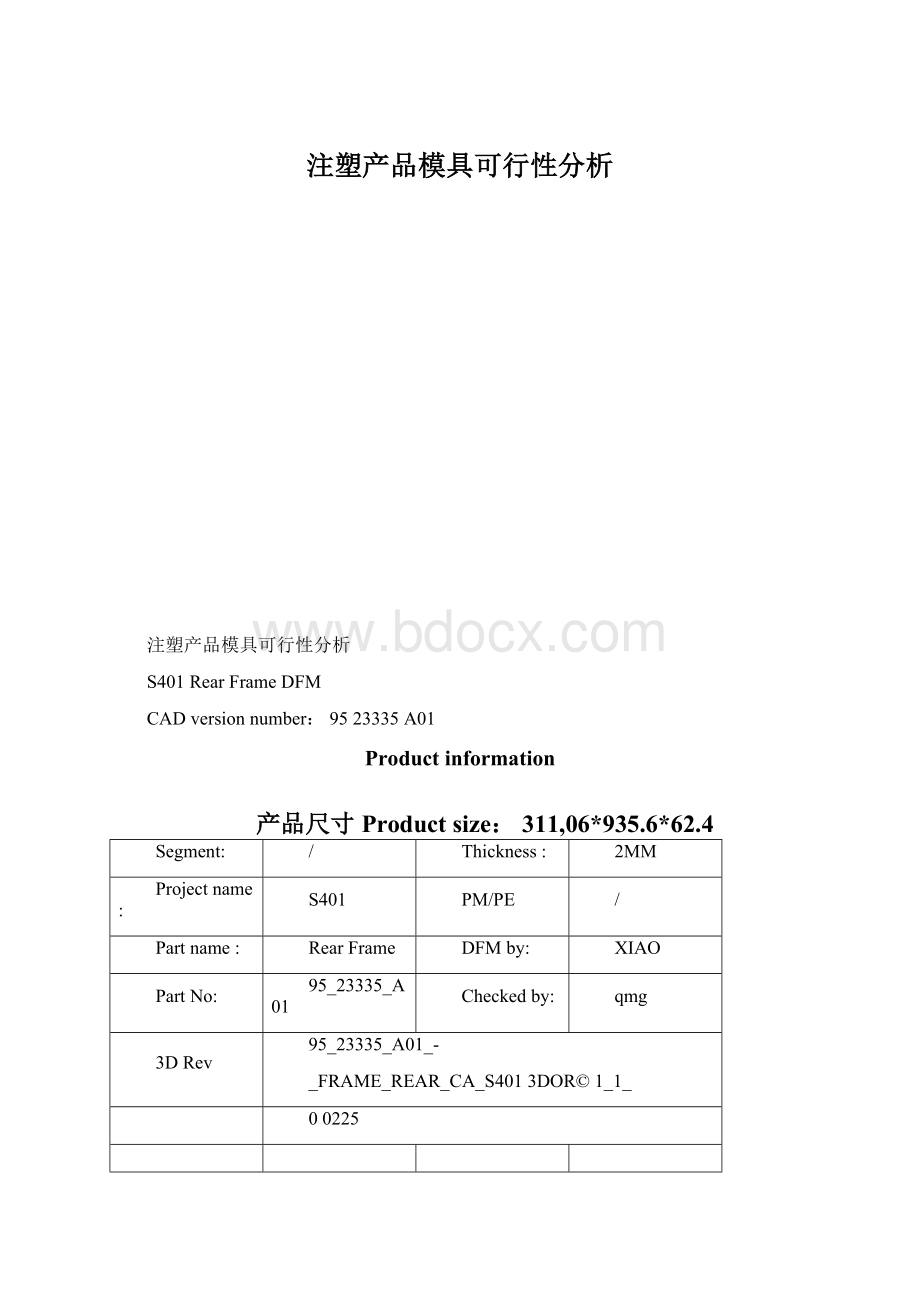

注塑产品模具可行性分析

注塑产品模具可行性分析

S401RearFrameDFM

CADversionnumber:

9523335A01

Productinformation

产品尺寸Productsize:

311,06*935.6*62.4

Segment:

/

Thickness:

2MM

Projectname:

S401

PM/PE

/

Partname:

RearFrame

DFMby:

XIAO

PartNo:

95_23335_A01

Checkedby:

qmg

3DRev

95_23335_A01_-

_FRAME_REAR_CA_S4013DOR©1_1_

00225

RE

V

Date

Updateoraddedsliders

Remark:

CavityandcoreImpression

Core

Toolinformation

Needyourinputandcorrectiontobelowinformation:

Resinmaterial:

PPLGF40

Resinsupplier:

TiconaCelstranPP-

LGF40-2

ResinGrade

Tonnage

N/A

RunnerSys:

Hotrunner

No.ofHotTip

3pointHRSOrSynventive

Tooltype:

2plate

Gatetype:

针阀式转冷流道进胶

3pointvalvegatesturntoedgegate

Automatic:

YES

No.ofGate.(Eachpart)

3

Partweight(g):

666G

Cavitysteel

S50C/1.2343

Forecastvolume

(shot)

N/A

Specialtool:

N/A

Coresteel

S50C/1.2343

No.ofCavity:

1

Cosmeticpart(Y/N):

N

Slidersteel

S50C/1.2343

Familywith:

S401

Cosmeticfinishing

N/A

Lifterandsmallnsertsteel

1.2344

3

Customercomment,(pleasegiveyourapprovalandcomments)

OKor

NG

remark

Approval

by:

date

—

Shrinkage

Notes:

aboveshrinkageisestimatedaccordingtoourunderstanding,plscorrectitifthereisanyriskofgettingrightdimension

Shrinkagewith

X

?

orientation

Y

?

Z

?

Customercomment,(pleasegiveyourapprovalandcomments)

OKorNG

remark

Approvalby:

date

Gatelayout

三点位置针阀式热嘴转搭底进胶3pointvalve

gatesturntoedgegate

GATE.PARTING.ANDEJECTO?

PINLOCATIONSMUSTBEAPPROVEDBYWE8AST0PRODUCTENGINEERINGPRIORTOTOOLSTART.

PartLayout

Needtoshowpartlayouttoavoidcustomermisunderstoodourproposal

Notes:

thisisveryroughlayout,butitisaUsefulguidanceforourtooldesigner.

BenchmarkLocation

出模方向Demoldingdirection

客户确认所有安装孔都是一个方向

Partingline—p/line

蓝色为PL线BluelineisPLline.

Core

Notes:

pleaseadviceanyconcernonproposepartingline.

Customercomment,(pleasegiveyourapprovalandcomments)

OKorNG

remark

Approvalby:

date

Partingline

P/LINE

Core

蓝色为PL线BluelineisPLline.

Customercomment,(pleasegiveyourapprovalandcomments)

参考

S301

确认是否能更改(客户不能理解此处具体意思);客户回复分型线有问题,都是放在最下面的,不会岀现插穿面,乐新下来根据客户意见重新分析

目前没有插穿角度,为简化分型面,此处做5°以上插穿(左右两侧)一Thispositiondonothaveshutoffangle.ForTosimplifythepartingline,wesuggestmake5degreeshutoffshutoffangle.(Bothsideanthesame)

OKorNG

remark

Approvalby:

date

Notes:

pleaseadviceanyconcernonproposepartingline.

to3degree.

Notes:

pleaseadviceanyconcernonproposepartingline.

、一一/

Customercomment,(pleasegiveyourapprovalandcomments)

OKorNG

remark

Approvalby:

date

Notes:

pleaseadviceanyconcernonproposepartingline.

Customercomment,(pleasegiveyourapprovalandcomments)

OKorNG

remark

Approvalby:

date

InsertlinesofCavityside—p/LINE

前模镶件结构如示Cavitysidemaininsertslayout

软硬模前模镶件分型一样SofttoolandHardtoolarethesame

Customercomment,(pleasegiveyourapprovalandcomments)

OKorNG

remarkApprovalby:

date

Notes:

pleaseadviceanyconcernonproposepartingline.

P/LINE

InsertlinesofCoreside

后模镶件结构如示Cavitysidemaininsertslayout

软硬模后模分3件

SofttoolandHardtoolarethesame

Customercomment,(pleasegiveyourapprovalandcomments)

OKorNG

remark

Approvalby:

date

CoreLifter&Slider

]=Lifter

]=Slide

倒扣问题,PPT说明不清楚,乐新重新更新

Notes:

pleaseadviceanyconcernonwitnesslineformbylifter.

Coresideslider1,2andsliderinsertline(bothsidearethesame)后模行位1和2(左右两侧)

Customercomment,(pleasegiveyourapprovalandcomments)

OKorNG

remark

Approvalby:

date

4

CoreLifter&Slider

的东西都要提出来是否需要客户确认,确认何种问题

乐新重新更新PPT,需要客户确认

]=Slide

□

Notes:

pleaseadviceanyconcernonwitnesslineformbylifter.

后模行位3Coresideslider3positionandsliderinsertlines

Customercomment,(pleasegiveyourapprovalandcomments)

OKorNG

remark

Approvalby:

date

(shrinkage/strength/sink

4.000

even

产品整体胶厚均匀

Overallthepartthickness

0.057

3.333

3.000

2.667

2.335

2.000

1.56T

1.000

0.866,

Customercomment,(pleasegiveyourapprovalandcomments)

OKorNG

remark

Approvalby:

date

DraftangleinformationCavity

PartIssueone

前模此处位獸扣,需修改

Thesepositionhaveundercut

needtomodify

Coreside

+3.00

+2.00

产品周圈无出模斜度,建议减胶拔模岀后模

ThispositionaroundthePartsdonothavedemoldingdraftangle,needtomodify

+1.0000

-2-00

-3.0000

Cavityside

morethenonedegree.

avityside

客户确认更改

Coreside

CavityLifter&Slider

PartIssuethree

㈣

9

PPT乐新更新得更详细,

]=Lifter]=Slide

位

为简化】生产稳定,修改。

UndercutDsitionneedtomodify

建议修改成这种枕位可以成型的特征(左右两侧)Suggestmodifylikethis(botharethesame)

Notes:

pleaseadviceanyconcernonwitnesslineformbylifter.

Customercomment,(pleasegiveyourapprovalandcomments)

OKorNG

remark

Approvalby:

date

2

■

查看K4的数据,并反馈客户

产生薄钢,建议取消,加宽枕位封胶位置2MM以上Thispositionisplastictoothin,thatwillleadtomoldsharpsteel.Wesuggestincreasethedistancemorethen2mm.

0.1mm系剑

产品此处所有类似特征建议移动到

0.5MM左右。

避免后续生产披锋Suggestforthechainholdmoveto0.5mm.Toavoidflashinthemass

production.

产品此处位置倒扌口,需像下侧特征开通Thesepositionhaveundercut,needmodifyasthispictures.

EngravingPositionlayout

根据2D图纸

晒字位置,需以最终模具图位置为准

OKorNG

Remark

Approvalby:

date

Customercomment,(pleasegiveyourapprovalandcomments)

WeneedcosmeticspecificationtomakethisDetailedsurfacefinishing.Pleasehighlightit.

WeneedcosmeticspecificationtomakethisDetailedsurfacefinishing.Pleasehighlightit.

Rectorpinpositionlayout

螺丝孔周围不能有顶针

蓝色为顶针,具体位置以最终模具图为准Needaccordingtothefinalmold3D

Customercomment,(pleasegiveyourapprovalandcomments)

WeneedcosmeticspecificationtomakethisDetailedsurfacefinishing.Pleasehighlightit.

OKorNG

remark

Approvalby:

date

THANKS