++整理版物流思考题.docx

《++整理版物流思考题.docx》由会员分享,可在线阅读,更多相关《++整理版物流思考题.docx(11页珍藏版)》请在冰豆网上搜索。

++整理版物流思考题

testtwo

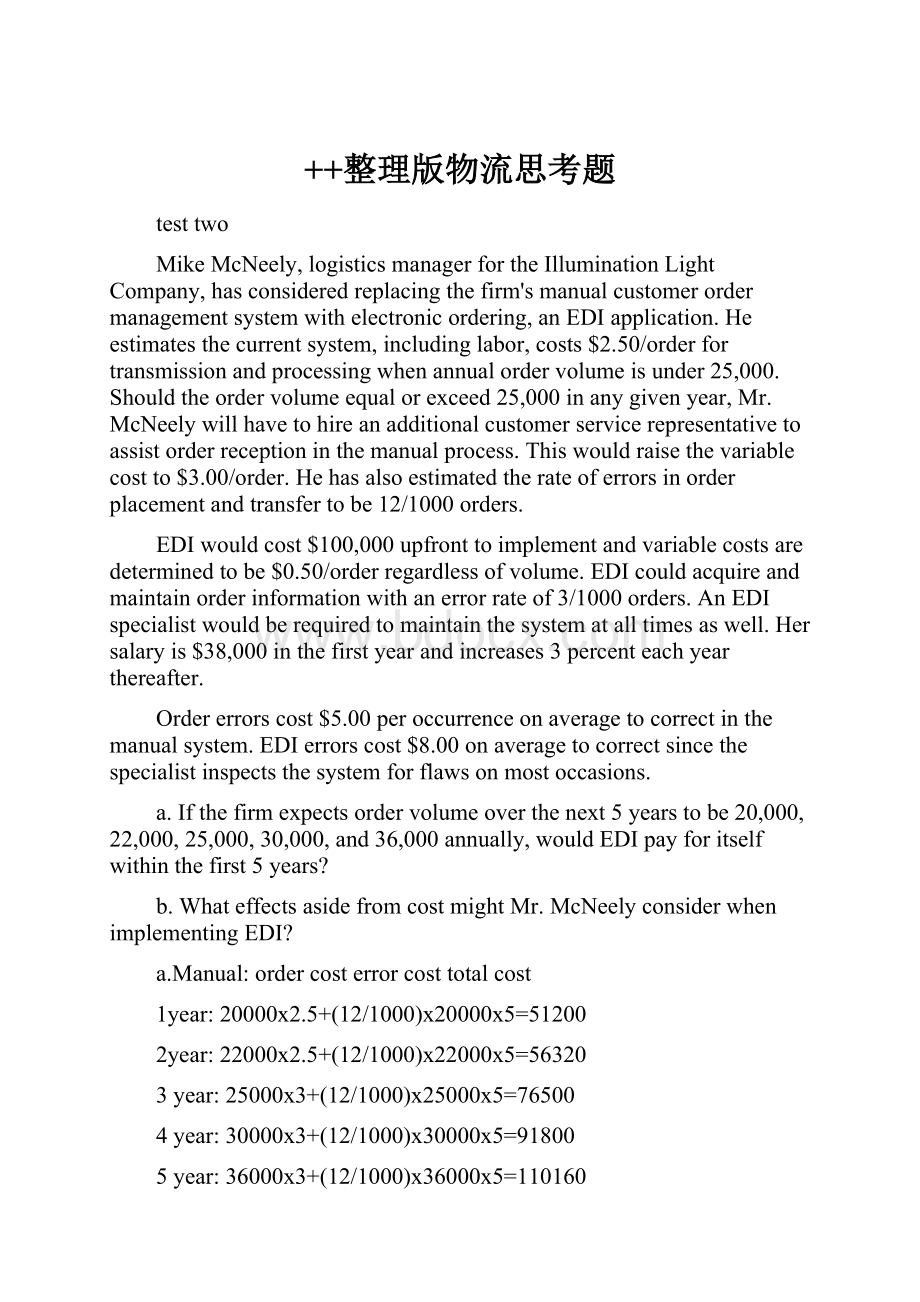

MikeMcNeely,logisticsmanagerfortheIlluminationLightCompany,hasconsideredreplacingthefirm'smanualcustomerordermanagementsystemwithelectronicordering,anEDIapplication.Heestimatesthecurrentsystem,includinglabor,costs$2.50/orderfortransmissionandprocessingwhenannualordervolumeisunder25,000.Shouldtheordervolumeequalorexceed25,000inanygivenyear,Mr.McNeelywillhavetohireanadditionalcustomerservicerepresentativetoassistorderreceptioninthemanualprocess.Thiswouldraisethevariablecostto$3.00/order.Hehasalsoestimatedtherateoferrorsinorderplacementandtransfertobe12/1000orders.

EDIwouldcost$100,000upfronttoimplementandvariablecostsaredeterminedtobe$0.50/orderregardlessofvolume.EDIcouldacquireandmaintainorderinformationwithanerrorrateof3/1000orders.AnEDIspecialistwouldberequiredtomaintainthesystematalltimesaswell.Hersalaryis$38,000inthefirstyearandincreases3percenteachyearthereafter.

Ordererrorscost$5.00peroccurrenceonaveragetocorrectinthemanualsystem.EDIerrorscost$8.00onaveragetocorrectsincethespecialistinspectsthesystemforflawsonmostoccasions.

a.Ifthefirmexpectsordervolumeoverthenext5yearstobe20,000,22,000,25,000,30,000,and36,000annually,wouldEDIpayforitselfwithinthefirst5years?

b.WhateffectsasidefromcostmightMr.McNeelyconsiderwhenimplementingEDI?

a.Manual:

ordercosterrorcosttotalcost

1year:

20000x2.5+(12/1000)x20000x5=51200

2year:

22000x2.5+(12/1000)x22000x5=56320

3year:

25000x3+(12/1000)x25000x5=76500

4year:

30000x3+(12/1000)x30000x5=91800

5year:

36000x3+(12/1000)x36000x5=110160

b.EDI:

devicecostsalaryerrorcostordercosttotalcost

1year:

100000+38000+20000x(3/1000)x8+0.5x20000=148480

2year:

38000x(1+3%)+22000x(3/1000)x8+0.5x22000=50668

3year:

38000x(1+3%)^2+25000x(3/1000)x8+0.5x25000=53414

4year:

38000x(1+3%)^3+30000x(3/1000)x8+0.5x30000=57243.6

5year:

38000x(1+3%)^4+36000x(3/1000)x8+0.5x36000=61633.3

testthree

1.Mr.StanBusfield,distributioncentermanagerforHoganKitchenwares,mustdeterminewhentoresupplyhisstockofspatulas.TheDCexperiencesadailydemandof400spatulas.Theaveragelengthoftheperformancecycleforspatulasis14days.Mr.Busfieldrequiresthat500spatulasberetainedassafetystocktodealwithdemanduncertainty.

a.Usesimplereorderpointlogictodeterminetheorderquantityforspatulas.

b.Basedonyouranswertopart(a),findMr.Busfield’saverageinventorylevelofspatulas.

a.Usethereorderpointtofindtheorderquantity:

R=DxT+SS

=400x14+500=6,100spatulas

reorderpointis6100,Orderquantityismorethanorequalto5600.

b.Theaverageinventorisone-halftheorderquantity+safetysock:

IfOrderquantityisequalto5600,then

Averageinventory=5600/2+500=3,300spatulas

4.Mr.JohnEastesoverseesthedistributionofTasteeSancksproductsfromtheplantwarehousetoitstwodistributioncentersintheUnitedStates.Theplantwarehousecurrentlyhas42,000unitsofthecompany’smostpopularproduct,ChocolateChewies.Mr.Estesretains7000unitsoftheproductatthewarehouseasabuffer.TheCincinnatiDChasaninventoryof12500unitsanddailyrequirementsof2500units.ThePhoenixDChasaninventoryof6000unitsanddailyrequirementsof2000units.

a.Determinethecommondays’supplyofChocolateChewiesateachDC.

b.Giventheaboveinformationandyouranswertopart(a),usefairshareallocationlogictodeterminethenumberofChocolateChewiestobeallocatedtoeachDC.

a.Commondays’supplyofchocolatechewies:

DS=[(42,000-7,000)+18,500]/4500=11.89days(around)

b.FairShareAllocationLogic:

Allocation=(Days’SupplyxDailyRequirements)-Inventory

ACincinnati=(11.89x2,500)-12,500=17,225units

APhoenix=(11.89x2,000)-6,000=17,780units

Attention:

Together,theallocationsequal35,005units(17,225+17,780)whichis5morethantheplantwarehouse’sallocationsupply.Thedifferencerestswiththeroundingofthedays’supplyfigure.

2.Mr.Busfieldrecentlycompletedacourseinlogisticsmanagementandnowrealizesthattherearesignificantcostsassociatedwithorderingandmaintaininginventoryathisdistributioncenter.Mr.BusfieldhaslearnedthattheEOQisthereplenishmentlogicthatminimizesthesecosts.InanefforttofindtheEOQformeasuringcups,Mr.Busfieldhasgatheredrelevantdata.Mr.Busfieldexpectstosell44,000measuringcupsthisyear.Hoganacquiresthemeasuringcupsfor75centseachfromShatterIndustries.Shattercharges$8forprocessingeachorder.Inaddition,Mr.Busfieldestimateshiscompany'sinventorycarryingcosttobe12percentannually.

a.FindMr.Busfield'sEOQformeasuringcups.AssumethatMr.BusfieldacceptsownershipofproductsuponarrivalathisDC.

b.NowassumeMr.BusfieldmustarrangeforinboundtransportationofthemeasuringcupssinceHoganacceptsownershipofproductsatthesupplier'sshippingpoint.Quantitiesoffewerthan4000measuringcupscost5centsperunittoship.Quantitiesof4000andabovecost4centsperunittoship.DeterminethedifferenceintotalcostsassociatedwithanEOQof4000unitsandtheEOQlevelfoundinpart(a)whentransportationcostsmustbeconsidered.

c.GiventheinformationaboveandthelowcostEOQalternativedeterminedinpart(b),useperiod-order-quantitylogictodeterminethenumberofordersHoganwouldplaceeachyearformeasuringcupsandthetimeintervalbetweenorders.

a.Theeconomicorderquantity(EOQ)isthesquarerootoftheproductofthenumerator(twotimesordercostanddemand)dividedbytheproductofthedenominator(inventorycarryingcosttimesunitcost):

EOQ=2,797cups

Annualtotalcostwithorderquantitiesof2,797cups(calculatedinpart(a)):

InventoryCarryingCosts=(2,797/2)x0.75x12%=$125.87

todetermineOrderCosts,thenumberofwholeorders/yrshallfirstlybedetermined:

(44,000/2797)=15.73->roundupto16wholeorders/yr.

Oordercosts=16ordersx$8/order=$128.00

TransportationCosts=44,000unitsx$0.05/unit=$2,200

TotalCost(EOQ=2,797units)$2,453.87/year

Annualtotalcostwithorderquantitiesof4,000cups:

InventoryCarryingCosts=(4,000/2)x0.75x0.12=$180

OrderCosts:

determinethenumberofwholeorders/yr.

44,000/4,000=11wholeorders/yr

11ordersx$8/order=$88

TransportationCosts=44,000unitsx($0.04/unit)=$1,760.00

TotalCost(EOQ'=4,000units)$2,028

Theorderquantityof4,000unitscosts($2,453.87–2,028.00)$425.87lessannuallythan2,797orderquantityfoundinpart(a)whentransportationcostsareconsidered.

Test4:

1.SuperPerformanceParts(SPP)producesbrakingdevicesexclusivelyfortheAceMotorcompany,anautomotivemanufacturer.SPPhasbeenleasingwarehousespaceatapublicfacility20milesfromthecompany'splant.SPPhasbeenapproachedbyagroupoffourotherAcesupplierswiththeideaofbuildingaconsolidatedwarehousetogaintransportationandmaterialshandlingeconomies.Aninvestmentof$200,000wouldberequiredbyeachofthefivecompaniestoacquirethewarehouse.PaymentoftheinitialinvestmentsecuresI0yearsofparticipationintheagreement.Annualoperatingexpensesareanticipatedtobe$48,000foreachparty.SPPiscurrentlycharged$6000permonthforuseofthepublicwarehousefacilities.

SPP'soutboundtransportationfromthepublicwarehouseoftenconsistsofLTLquantities.Itsannualoutboundtransportationbilliscurrently$300,000.SPPexpectsconsolidatedwarehousingtomorefullyutilizetruckloadquantitieswithtransportationexpensessharedamongthesupplierpool.SPP'sannualoutboundbillwouldbereducedby25percentintheconsolidatedplan.Differencesininboundtransportationcostsareassumednegligibleinthiscase.

a.ComparethestorageandshippingcostsassociatedwithconsolidatedwarehousingasopposedtoSPP'scurrent,directshippingplan.Areanyefficienciesapparentthroughconsolidation?

b.Asidefrompotentiallyreducingcosts,howelsemightSPPbenetitbyparticipatingintheconsolidatedwarehouse?

c.Whatdisadvantagesmightexistinaconsolidatedwarehouseasopposedtoadirectshippingsituation?

a.DirectShippingPlan(annualcosts)

Storagecosts:

$6,000/monthx12months=$72,000

Shippingcosts:

=$300,000

Annualtotalcosts:

$372,000

Consolidatedwarehousing(annualcosts)

Storagecosts:

fixed$200,000/10years=$20,000/year

Operationscost=$48,000

Shippingcosts:

($300,000)x(1-25%)=$225,000

Annualtotalcosts:

$293,000

b.Theconsolidatedwarehousecanbeoperatedfor$79,000lessperyearovertheagreement’stenyearlife.

Thisisacreativethinkingquestionforthepurposeofdiscussion.Keypointsmayincludebutarenotlimitedto:

bettercustomerservice(invariousforms)toAce,synergythroughcoordinationwithpartners,SPPmaybeabletoutilize/shareassetsnotfinanciallyfeasibleontheirown.

c.Thistooisacreativethinkingquestion.Keypointsmightbe:

addedriskthroughownership(part-ownership),potentialdifficultieswithcoordinationacrosspartners,incongruentobjectivesmayleadtotribulations,andpossiblecashflowdifficultiesduetofixedinvestmentexpenditures

2.Assumeyouarethelogisticsmanagerforaluggagecompany.AllbagsareproducedatthemanufacturingfacilityinGuangzhou.Thebags,valuedat¥30each,arestoredinawarehousenearthefactorypriortodistributiontoDClocationsinShanghai,andtheDCexperiencesanannualdemandof700,000bags.Nowtheproductsaretransportedbyrailandtheaverageinventoryf