无损检测工艺规程液体渗透模板.docx

《无损检测工艺规程液体渗透模板.docx》由会员分享,可在线阅读,更多相关《无损检测工艺规程液体渗透模板.docx(11页珍藏版)》请在冰豆网上搜索。

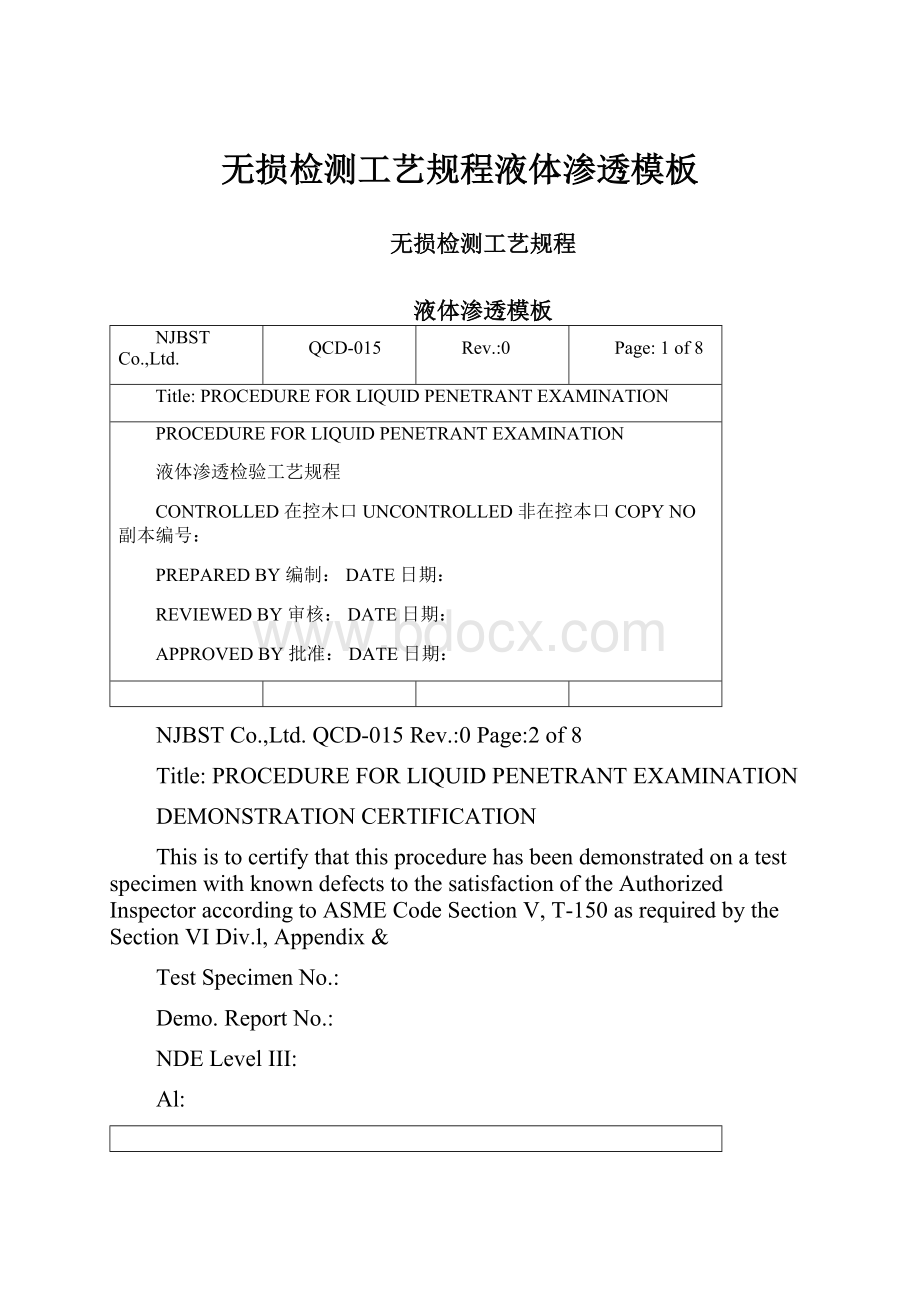

无损检测工艺规程液体渗透模板

无损检测工艺规程

液体渗透模板

NJBSTCo.,Ltd.

QCD-015

Rev.:

0

Page:

1of8

Title:

PROCEDUREFORLIQUIDPENETRANTEXAMINATION

PROCEDUREFORLIQUIDPENETRANTEXAMINATION

液体渗透检验工艺规程

CONTROLLED在控木口UNCONTROLLED非在控本口COPYNO副本编号:

PREPAREDBY编制:

DATE日期:

REVIEWEDBY审核:

DATE日期:

APPROVEDBY批准:

DATE日期:

NJBSTCo.,Ltd.QCD-015Rev.:

0Page:

2of8

Title:

PROCEDUREFORLIQUIDPENETRANTEXAMINATION

DEMONSTRATIONCERTIFICATION

ThisistocertifythatthisprocedurehasbeendemonstratedonatestspecimenwithknowndefectstothesatisfactionoftheAuthorizedInspectoraccordingtoASMECodeSectionV,T-150asrequiredbytheSectionVIDiv.l,Appendix&

TestSpecimenNo.:

Demo.ReportNo.:

NDELevelIII:

Al:

NJBSTCo.,Ltd.

QCD-015

Rev.:

0

Page:

3of8

Title:

PROCEDUREFORLIQUIDPENETRANTEXAMINATION

制i告厂

材料

悭号

匕海沪

渗诱剂

HD-

RS

船助剂

拜像剂

HD-

XS

厂沪

洗剂

HD-B^

1•概述

1・1本规程适用于ASME规范产品金属材料和焊件着色液体渗透检验。

1.2本规程仅适用于探测材料或焊件表而开口类缺陷。

1.3本规程在执行之前,须演示至AI满意。

2.人员

2」从事液体渗透检验的人员必须是根据南京左色钛业有限公司«NDE人员培训、考试、资格认证实施细则>>(资料号:

QCD-011)进行考试和资格任命的合格人员。

3.渗透材料

1・General

1.1ThisprocedureisappliedtodyeliquidpenetrantexaminationofmetalmaterialandweldmentforASMECodeitems.

1.2Thisprocedureisonlysuitablefordetectingthedefectsthatareopentothesurfaceofmaterialorweldment・

1.3ThisprocedureshallbedemonstratedtothesatisfactionofHieAlpriortoimplementation・

2.Personnel

2.1ThepersonnelengagedinthepenetrantexaminationshallbequalifiedandcertifiedinaccordancewiththerequirementofNJBSTCo.,Ltd・,s"WrittenPracticeforNDEPersonnelTrainingExamination,QualificationandCertification^(No.:

QCD-011).

3・PenetrantMaterials

3.1Thepenetrantmaterialsisintendedtoincludeallpenetrants,solventsorcleaningagents,developers,etc,usedintheexaminationprocess・

3.2Theliquidpenetrantexaminationmaterialsshallbedesignatedandrecommended,asshowninTable32ThemateriaIntermi

SurfacePreparation

bethesametype,differentfamiliesor

differentmanufactureijsisnotpermitted・

Table—

Manu

PrecleaningandDrying

--重童■・

Shanr

PenetrantApplication

HD-XS

(ShipBrand)Deveh)per

Cleaning

Drying

nlesssteelortitanium,all

3」渗透材料包括检验过程中使用的所有渗透剂.溶剂或淸洗剂、显像剂等。

3.2液体渗透探伤材料,必须是指定的和推荐的,见表3.2。

检验使用的材料必须是同一类型的。

不允许用不同类昆合使

表而制备

表3.2

预淸洗,干燥

施加渗透剂

淸洁

33岀檢胎奧忙休不铳俶诚紘材时必干燥

3.3Mmaterialsshallbeahalyzedindividuallyforchlorineandfluorint641(b)-fluorine-TheceobtainecE_

3.4W—analyzetheprocedureshownin1-041(a)ofSectionV.Thesulphurcontentshallnotexceedl%oftheresiduebyweight・Thecertificateofcompliancefrommanufacturershallbeobtained・

DevelopmentandInspectionieprocedureshowninT-

Thetotalchlorineplusl@.oftheresiduebyweight.

1manufacturershallbe

1(b)中i和氟的

GR川1仙•H今自-木乞2超过残

显像、检验

LFJT土,J,八;I“I甲Tt*八ZTJ八"I刃勺令卡

柑应的

VAX

ylmllnefpv

EvaluationandRecord

f1

PostCleaning

allmaterialsshallbententinaccordancewith

TTffrUto

CA、1二I•人“4

角程序,对加勺材科分I别分析疏含量“硫含量「须有制

评泄、记录

»/[二1丄i・JL-i

后淸洗

NJBSTCo.,Ltd.

QCD-015

Rev.:

0

Page:

4of8

Title:

PROCEDUREFORLIQUIDPENETRANTEXAMINATION

4.检验程序

4.1检验程序流程图见图4.1

4.ExaminationProcedure

4.1ExaminationFlowChartasshowninFig.4.1.

Fig.4.1

4.2SurfacePreparation

Priortoallpenetrantexamination,thesurfacetobeexaminedandalladjacentareaswithinatleastlin・(25・4mm)shallbedryandfreeofdirt,grease,lint,scale,weldingflux,weldspatter,paint,oilandotherextraneousmatte匚Ifnecessary,surfaceshallbepreparedbygrindingormachining・

4.3Precleaning

431Theareastobeexaminedandadjacentareaswithinatleastlin.(25.4mm)shallbecleanedusingcleaningagentbeforethepenetrantisapplied・

4.3.2Aftercleaning,dryingofthesurfacetobeexaminedshallbeaccomplishedbynormalevaporationorwithforcedair,asappropriate.Theminimumdryingtimeshallensurethatthecleaningsolutionhasevaporatedpriortoapplicationofthepenetrant.

4.4PenetrantApplication

4.4.1Thepenetrantmaybeappliedonthesurface

图4」

4.2表面制备

所有渗透检验前,被检工件表而及其附近至少为1英寸(25.4mm)的区域内都应干燥淸洗干净,不得有任何脏物、纤维眉、氧化皮.焊剂、汕和其它外来物*必要时,应对表面进行打磨或机加工。

4.3预淸洗

4.3.1在施加渗透剂之前,被检区域及其附近至少为1英寸(25.4mm)的区域内均需用淸洁剂进行淸洗。

4.3.2淸洗后,经过适当的方法(自然挥发或人工通风),对被检表面进行F•燥;最少V燥的时间以保证在施加渗透剂之前淸洁剂已完全挥发为界。

4.4施加渗透剂

4.4.1能够用浸渍.涂刷或喷涂等任一合适的方法,在被检工件

NJBSTCo.,Ltd.

QCD-015

Rev.:

0

Page:

5of8

Title:

PROCEDUREFORLIQUIDPENETRANTEXAMINATION

MaterialF

)rmDwellTimes(

PenetrantDeveloper

nin)

Aluminum,magn-Cesium.steel,brassorbronze,titaniumVandhightemperaturealloysplate

astings&welds5

ioughtmaterial-・extrusions,forgings,

7

107

meCAUiunicUiOupioccuuicuimelovvci01iii^iivr

材料3

滞留时间

!

式(mil

)

渗透

剂显象齐

J

铝、離钢、黄铜青铜、钛尚温合金

铸件和焊缝

轧材-挤压件

段件.板材

57

107

足时,则按照ASME规范第V卷T-653,对提议采用的温度范帀,使用有淬火裂纹的铝试块进行验证。

temperaturerangeshallbequalifiedusingaquenchcrackedaluminumblockaccordingtoASMECodeSectionV,T-653.

4.4.3Penetrationtimeiscritical.TheminimumdwelltimeisshowninTable4.4.3・Forsuitabletemperature,theareabeingexaminedshallremainwettedbythepenetrantforthedwelltime.

Table443Recommendedminimumdwelltimes

4.5ExcessPenetrantRemoval

4.4.3严格控制渗透时间,最小滞留时间见表443。

适当的温度条件下,在滞留时间内•被检区域必须用渗透剂保持潮湿。

表4.4.3推荐的最少滞留时间

4.5多余渗透剂的淸除

多余渗透剂必须用布或吸纸擦去,剩下的痕迹必须用蘸有溶剂的布或

Excesssolventremovablepenetrantshallberemovedbywipingwithaclothorabsorbentpaper.Theremainingtracesshallberemovedbylightlywipingthesurfacewithaclothorabsorbentpapermoistenedwithsolvent.Toavoidoverremoving,flushingthesurfacewithsolventshallbeprohibited・

4.6DeveloperApplication

4.6.1Thedevelopershallbeappliedassoonaspossibleafterexcesspenetrantremovalanddryingsurface・Thesurfacemaybedriedbynormalevaporationbeforethedeveloperisapplied・Thedryingtimeshallbewithin5to20min.

4.6.2Thedevelopershallbeappliedbyspraying.Auniformthincoatingshallbeprovidedandthecoatingthicknessshallbesuitable・

4.6.3Priortoapplyingwetdevelopertothesurface,thedevelopermustbethoroughlyagitated.

4.6.4Dippingorfloodingthepartwithnon-aqueousdeveloperisprohibited,sinceitwilldissolvethepenetrantinthediscontinuitiesthroughitssolventaction.

4.7Interpretation

4.7.1Developingtimeforfinalinterpretationbegins

纸在表而轻轻地擦去。

为了防止淸洗过分,禁止用溶剂淸洗表而。

4.6施加显像剂

4.6.1多余的渗透剂被淸除且工件干燥后,必须尽快地施加显像剂。

显像剂施加之前,工件表而能够自然挥发干燥,干燥时间必须在5-20分钟以内。

4.6.2施加显像剂必须采用喷涂法,薄且均匀,涂层厚度适中。

4.6.3在施加湿型显像剂至工件表而之前,显像剂必须充分搅拌。

4.6.4禁用非水湿显像剂浸渍或灌洗工件,因非水湿显像剂会经过溶解作用将缺陷中的渗透剂溶解掉。

4.7判断

4.7.1最终判断显像时间应从施加

NJBSTCo.^Ltd.QCD-015Rev.:

0Page:

6of8

Title:

PROCEDUREFORLIQUIDPENETRANTEXAMINATION

assoonasawetdevelopercoatingisdry.Theminimumdevelopingtimeshallbe7min・

4.7.2Finalinterpretationshallbemadewithin7to60minaftertherequirementsofPara.4.7.1aresatisfied.

4.7.3Thedevelopingtracecanbeexaminedeitherbynaturallightorartificiallight.Aminumumlightintensityof50fc(500Lx)isrequiredtoensureadequatesensitivityduringtheexaminationandevaluationofindications.

4.7.4Thesurfaceshallbedividedintoseveralpartstobeexaminedifthesurfaceissolargethattheexaminationcannotbefinishedwithinthegiventime.Thedevelopingconditioncanbeobservedeitherbyeyesorbymeansofamagnifier.

4.8Post-cleaning

Thepenetrantmaterialsshallbeclearlyremovedawayfrompartsafterexamination・Thepostcleaningmustbeperformedifremainingpenetrantmaterialscanresultincorrosionbythecombinationwithothermaterialsduringtheoperation.

Thesuitablecleaningprocessshallbeadoptedforpostcleaningsuchasflushingwithwater,mechanicalcleaning,solventsoaking,etc.

Thedevelopershallbecleanedassoonaspossibleafterexaminationifthepartrequeststhepostcleaningsoastoavoiditcondensedonthepart・

5.EvaluationofIndications

5.1Broadareasofpigmentationwhichcouldmaskindications

干显像剂后或从湿显像剂涂层干燥后立即起算,不得少于7分钟。

4.7.2在满足4.7.1要求后,最终判断必须在7・60分钟内作出。

4.7.3显像痕迹能够经过自然光或人工白光进行检验,要求最小灯光强度为5Ofc(5OOLX),以保证在检验和评价显示过程中有充分的灵敏度。

4.7.4如果受检表而太大,无法在规圧时间内完成检验,则应将表而分成几个部进行检验。

显像情况能够用肉眼或放大镜进行观察。

4&后j青洗

检验后,必须完全淸除工件上的渗透材料,如果残余渗透材料在操作过程中与其它材料混合后会导致腐蚀,则必须进行后淸洗。

能够采用如用水冲洗.机械淸洁、溶剂浸泡等适当的淸洁工作,来进行后淸洗。

如果需要后淸洗,则检验后必须尽快进行,以免显像剂凝固在工件上。

5.显示评价

5」大面积颜料沉淀会掩盖缺陷显示,是不合格的,这些区域应淸洗干净并重新检验。

5.2明显的机械性不连续为其显现特

ofdiscontinuitiesareunacceptableandsuchareasshallbecleanedandreexamined・

5.2Anindicationistheevidenceofamechanicalimperfection・Onlyindicationswithmajordimensionsgreaterthan1/16in(1.6mm)shallbeconsideredrelevant.

5.3Linearindicationsarethoseindicationsinwhichthelengthismorethanthreetimesthewidth・Roundedindicationsareindicationswhicharecircularorellipsoidalwiththelengthlessthanthreetimesthewidth.

5.4Anyquestionableordoubtfulindicationsshallbereexaminedtodeterminewhetherornottheyarerelevant.Surfaceconditioningmayproceedbeforethereexamination・

5.5Theindicationofadiscontinuitymaybelargerthanthediscontinuitythatcausesit;however,thesizeoftheindicationisthebasisofacceptanceorrejection.

6.AcceptanceStandards

Thefollowingrelevantindicationsareunacceptable:

a.anycracksorrelevantlinearindications;

b.relevantroundedindicationsgreaterthan3/16in.(4.8mm);

c.fourormorerelevantroundedindicationsinalineseparatedby1/16in・(1.6mm)orless(edgetoedge);

征,只有在显示主要尺寸大于1/16英寸(1.6mm)时,才是缺陷显示。

5.3线性缺陷是指长度大于三倍宽度的缺陷。

而形缺陷是指长度小于3倍宽度的圆形或椭圆形缺陷。

5.4任何有疑问或难以判断的显示,必须重新检验以确认是否是缺陷显示,重新检验前可先作表而修整。

5.5缺陷显示可能大于缺陷本身,可是以显示的尺寸作为合格与否的依据。

6.合格标准

下列缺陷显示为不合格:

a•任一裂纹或相应的线性缺陷;

b.大于3/16英寸