哈工大机械原理大作业2凸轮.docx

《哈工大机械原理大作业2凸轮.docx》由会员分享,可在线阅读,更多相关《哈工大机械原理大作业2凸轮.docx(18页珍藏版)》请在冰豆网上搜索。

哈工大机械原理大作业2凸轮

HarbinInstituteofTechnology

机械原理大作业二

课程名称:

机械原理

设计题目:

凸轮结构设计

院系:

能源学院

指导教师:

唐德威赵永强

设计时间:

2013年6月27日

哈尔滨工业大学

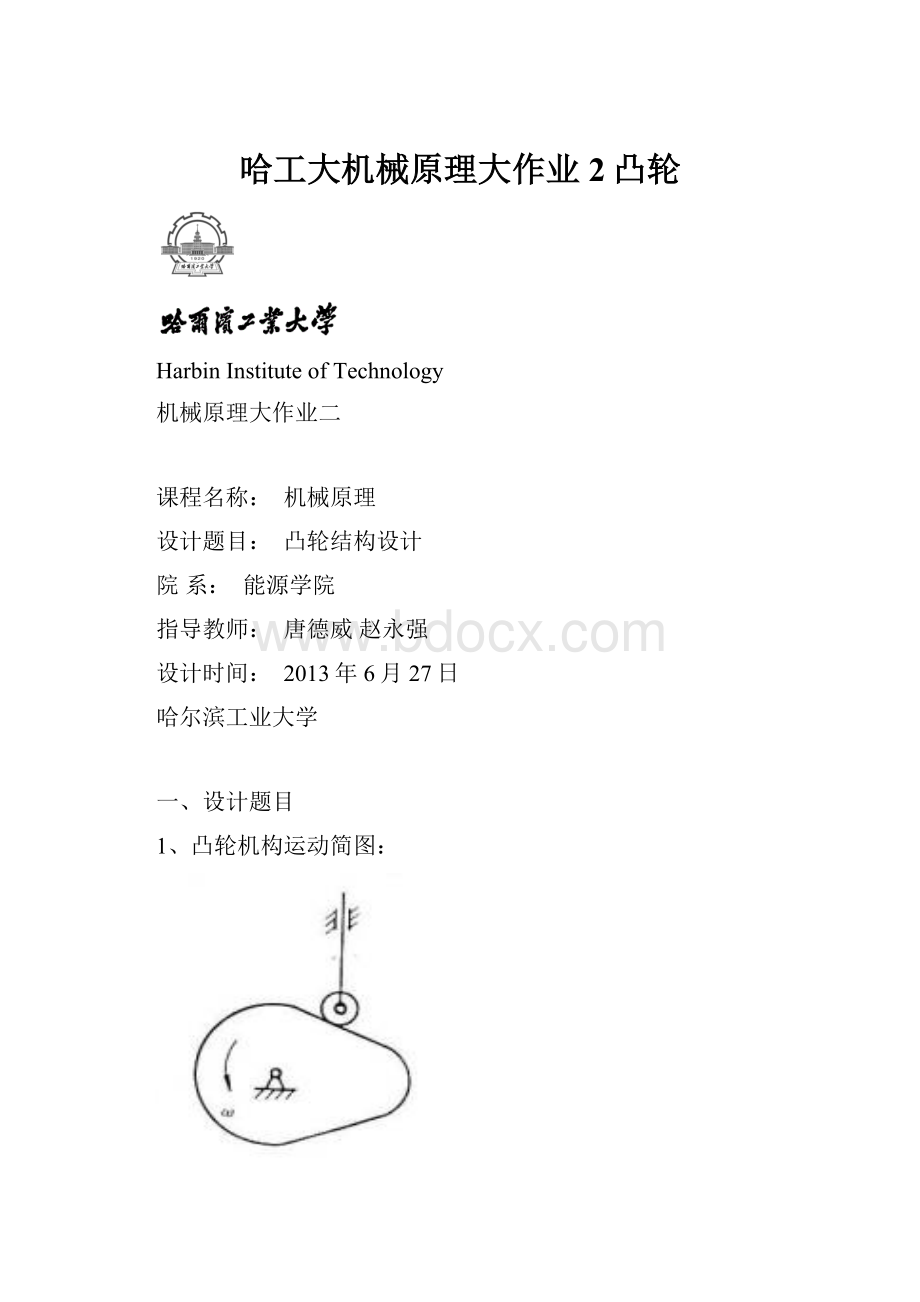

一、设计题目

1、凸轮机构运动简图:

2、凸轮机构的原始参数

序号

升程

升程运动角

升程运动规律

升程许用压力角

回程运动角

回程运动规律

回程许用压力角

远休止角

近休止角

21

110

150°

3-4-5多项式

40°

100°

3-4-5多项式

60°

45°

65°

二、凸轮推杆升程、回程运动方程及推杆位移,速度,加速度线图

1、推杆升程,回程运动方程如下:

A.推杆升程方程:

设

,

由3-4-5多项式可知:

当

时,有:

式中

H=110,

B.推杆回程方程:

当13π/12≤φ≤59π/36时,有:

式中

h=110

ϕs=5π/9

2、推杆位移,速度,加速度线图如下(用matlab编程得):

A、推杆位移线图

clear

clc

x1=linspace(0,5*pi/6,300);

x2=linspace(5*pi/6,13*pi/12,300);

x3=linspace(13*pi/12,59*pi/36,300);

x4=linspace(59*pi/36,2*pi,300);

t1=x1/(5*pi/6)

s1=110*(10*t1.^3-15*t1.^4+6*t1.^5);

s2=110;

t2=9*x3/(5*pi)-39/20;

s3=110*(1-(10*t2.^3-15*t2.^4+6*t2.^5));

s4=0;

plot(x1,s1,'k',x2,s2,'k',x3,s3,'k',x4,s4,'k');

xlabel('角度/rad');

ylabel('位移s/mm');

title('推杆位移线图');

grid;

B、推杆速度线图

clear

clc

x1=linspace(0,5*pi/6,300);

x2=linspace(5*pi/6,13*pi/12,300);

x3=linspace(13*pi/12,59*pi/36,300);

x4=linspace(59*pi/36,2*pi,300);

f1=5*pi/6;

t1=x1/f1;

f2=5*pi/9;

t2=9*x3/(5*pi)-39/20;

v1=(t1.^2-2*t1.^3+t1.^4)*3300/f1;

v2=0;

v3=-30*110*(t2.^2-2*t2.^3+t2.^4)/f2;

v4=0;

plot(x1,v1,'k',x2,v2,'k',x3,v3,'k',x4,v4,'k')

xlabel('角度/rad');

ylabel('速度v/(mm/s)');

title('推杆速度线图');

grid;

C、推杆加速度线图

clear

clc

x1=linspace(0,5*pi/6,300);

x2=linspace(5*pi/6,13*pi/12,300);

x3=linspace(13*pi/12,59*pi/36,300);

x4=linspace(59*pi/36,2*pi,300);

f1=5*pi/6;

t1=x1/f1;

f2=5*pi/9;

t2=9*x3/(5*pi)-39/20;

a1=60*110*(t1-3*t1.^2+2*t1.^3)/f1^2;

a2=0;

a3=-60*110*(t2-3*t2.^2+2*t2.^3)/f2^2;

a4=0;

plot(x1,a1,'k',x2,a2,'k',x3,a3,'k',x4,a4,'k')

xlabel('角度/rad');

ylabel('加速度a/');

title('推杆加速度线图');

grid;

三、凸轮机构的ds/dψ---s线图,并依次确定凸轮的基圆半径和偏距

1、凸轮机构的ds/dψ--s线图:

clear

clc

x1=linspace(0,5*pi/6,300);

x2=linspace(5*pi/6,13*pi/12,300);

x3=linspace(13*pi/12,59*pi/36,300);

x4=linspace(59*pi/36,2*pi,300);

f2=5*pi/9;

f1=5*pi/6;

t1=x1/(5*pi/6)

s1=110*(10*t1.^3-15*t1.^4+6*t1.^5);

s2=110;

t2=9*x3/(5*pi)-39/20;

s3=110*(1-(10*t2.^3-15*t2.^4+6*t2.^5));

s4=0;

v1=(t1.^2-2*t1.^3+t1.^4)*3300/f1;

v2=0;

v3=-30*110*(t2.^2-2*t2.^3+t2.^4)/f2;

v4=0;

plot(v1,s1,'r',v2,s2,'r',v3,s3,'r',v4,s4,'r');

xlabel('ds/dψ');

ylabel('位移s/mm');

title('ds/dψ—s曲线');

grid;

2、确定凸轮的基圆半径和偏距:

clear

clc

x1=linspace(0,5*pi/6,300);

x2=linspace(5*pi/6,13*pi/12,300);

x3=linspace(13*pi/12,59*pi/36,300);

x4=linspace(59*pi/36,2*pi,300);

f2=5*pi/9;

f1=5*pi/6;

t1=x1/(5*pi/6)

s1=110*(10*t1.^3-15*t1.^4+6*t1.^5);

s2=110;

t2=9*x3/(5*pi)-39/20;

s3=110*(1-(10*t2.^3-15*t2.^4+6*t2.^5));

s4=0;

v1=(t1.^2-2*t1.^3+t1.^4)*3300/f1;

v2=0;

v3=-30*110*(t2.^2-2*t2.^3+t2.^4)/f2;

v4=0;

k1=tan(pi/2-40*pi/180);k2=-tan(pi/6);

f=sym('-k1*(2*k/f1^3-6*k^2/f1^4+4*k^3/f1^5)+k^2/f1^3-2*k^3/f1^4+k^4/f1^5=0');

k=solve(f);

t01=k/f1;

s01=110*(10*t01.^3-15*t01.^4+6*t01.^5);

v01=(t01.^2-2*t01.^3+t01.^4)*3300/f1;

c=80.5056;

d=41.7790;%求出推程切点坐标

x=-200:

1:

200;

y5=k1*(x-c)+d;

f2=5*pi/9;

k2=-tan(pi/6);

f=sym('-k2*(-2*(k*9/(5*pi)-39/20)*9/(5*pi)+6*(k*9/(5*pi)-39/20)^2*9/(5*pi)-4*(k*9/(5*pi)-39/20)^3*9/(5*pi))-(k*9/(5*pi)-39/20)^2+2*(k*9/(5*pi)-39/20)^3-(k*9/(5*pi)-39/20)^4=0');

k=solve(f);

t02=k*9/(5*pi)-39/20;

s02=110*(1-(10*t02.^3-15*t02.^4+6*t02.^5));

v02=-30*110*(t02.^2-2*t02.^3+t02.^4)/f2;

o=32.1715;

p=-112.4712;%求出回程切点坐标

y6=k2*(x-p)+o;

y7=x*-k1;

plot(v1,s1,v2,s2,v3,s3,v4,s4,x,y5,x,y6,x,y7);

xlabel('ds/dψ');

ylabel('位移s/mm');

title('ds/dψ—s曲线');

grid;

所以,由图就可以确定回转中心所在的区域,所以,可取偏距e=20mm,

mm,

所以

mm。

四、滚子半径的确定及凸轮理论轮廓和实际轮廓的绘制.

1、确定滚子半径

clear

clc

s0=80;e=20;r0=sqrt(s0^2+e^2);

forx1=0:

0.01:

5*pi/6;

t1=x1/(5*pi/6);

s1=110*(10*t1.^3-15*t1.^4+6*t1.^5);

xx1=(s0+s1)*cos(x1)-e*sin(x1);

y1=(s0+s1)*sin(x1)+e*cos(x1);

dxx1=-(s0+s1)*sin(x1)-e*cos(x1);

dy1=(s0+s1)*cos(x1)-e*sin(x1);

d2xx1=-(s0+s1)*cos(x1)+e*sin(x1);

d2y1=-(s0+s1)*sin(x1)-e*cos(x1);

p1=(dxx1^2+dy1^2)^1.5/(dxx1*d2y1-d2xx1*dy1);

plot(x1,p1);

holdon;

end

forx2=5*pi/6:

0.01:

13*pi/12;

s2=110;

xx2=(s0+s2)*cos(x2)-e*sin(x2);

y2=(s0+s2)*sin(x2)+e*cos(x2);

dxx2=-(s0+s2)*sin(x2)-e*cos(x2);

dy2=(s0+s2)*cos(x2)-e*sin(x2);

d2xx2=-(s0+s2)*cos(x2)+e*sin(x2);

d2y2=-(s0+s2)*sin(x2)-e*cos(x2);

p2=(dxx2^2+dy2^2)^1.5/(dxx2*d2y2-d2xx2*dy2);

plot(x2,p2);

holdon;

end

forx3=13*pi/12:

0.01:

59*pi/36;

t2=9*x3/(5*pi)-39/20;

s3=110*(1-(10*t2.^3-15*t2.^4+6*t2.^5));

xx3=(s0+s3)*cos(x3)-e*sin(x3);

y3=(s0+s3)*sin(x3)+e*cos(x3);

dxx3=-(s0+s3)*sin(x3)-e*cos(x3);

dy3=(s0+s3)*cos(x3)-e*sin(x3);

d2xx3=-(s0+s3)*cos(x3)+e*sin(x3);

d2y3=-(s0+s3)*sin(x3)-e*cos(x3);

p3=(dxx3^2+dy3^2)^1.5/(dxx3*d2y3-d2xx3*dy3);

plot(x3,p3);

holdon;

end

forx4=59*pi/36:

0.01:

2*pi;

s4=0;

xx4=(s0+s4)*cos(x4)-e*sin(x4);

y4=(s0+s4)*sin(x4)+e*cos(x4);

dxx4=-(s0+s4)*sin(x4)-e*cos(x4);

dy4=(s0+s4)*cos(x4)-e*sin(x4);

d2xx4=-(s0+s4)*cos(x4)+e*sin(x4);

d2y4=-(s0+s4)*sin(x4)-e*cos(x4);

p4=(dxx4^2+dy4^2)^1.5/(dxx4*d2y4-d2xx4*dy4);

plot(x4,p4);

holdon;

end

title('曲率半径')

grid;

所以,可知最小曲率半径为

所以,小滚子

取小滚子曲率半径

mm

2、确定凸轮理论廓线,基元及实际廓线。

clear

clc

s0=80;e=20;r0=sqrt(s0^2+e^2);

forx1=0:

0.001:

5*pi/6;

t1=x1/(5*pi/6);

s1=110*(10*t1.^3-15*t1.^4+6*t1.^5);

xx1=(s0+s1)*cos(x1)-e*sin(x1);

y1=(s0+s1)*sin(x1)+e*cos(x1);

plot(xx1,y1);

holdon;

end

forx2=5*pi/6:

0.001:

13*pi/12;

s2=110;

xx2=(s0+s2)*cos(x2)-e*sin(x2);

y2=(s0+s2)*sin(x2)+e*cos(x2);

plot(xx2,y2);

holdon;

end

forx3=13*pi/12:

0.001:

59*pi/36;

t2=9*x3/(5*pi)-39/20;

s3=110*(1-(10*t2.^3-15*t2.^4+6*t2.^5));

xx3=(s0+s3)*cos(x3)-e*sin(x3);

y3=(s0+s3)*sin(x3)+e*cos(x3);

plot(xx3,y3);

holdon;

end

forx4=59*pi/36:

0.001:

2*pi;

s4=0;

xx4=(s0+s4)*cos(x4)-e*sin(x4);

y4=(s0+s4)*sin(x4)+e*cos(x4);

plot(xx4,y4);

holdon;

end

grid;

s0=80;e=20;r0=sqrt(s0^2+e^2);

forfai=0:

0.01:

2*pi;

a=r0*cos(fai);

b=r0*sin(fai);

plot(a,b);

holdon;

end

forx1=0:

0.05:

5*pi/6;

t1=x1/(5*pi/6);

s1=110*(10*t1.^3-15*t1.^4+6*t1.^5);

xx1=(s0+s1)*cos(x1)-e*sin(x1);

y1=(s0+s1)*sin(x1)+e*cos(x1);

plot(xx1,y1);

holdon;

forfai=0:

0.1:

2*pi;

a=xx1+15*cos(fai);

b=y1+15*sin(fai);

plot(a,b);

holdon;

end

end

forx2=5*pi/6:

0.05:

13*pi/12;

s2=110;

xx2=(s0+s2)*cos(x2)-e*sin(x2);

y2=(s0+s2)*sin(x2)+e*cos(x2);

plot(xx2,y2);

holdon;

forfai=0:

0.1:

2*pi;

a=xx2+15*cos(fai);

b=y2+15*sin(fai);

plot(a,b);

holdon;

end

end

forx3=13*pi/12:

0.05:

59*pi/36;

t2=9*x3/(5*pi)-39/20;

s3=110*(1-(10*t2.^3-15*t2.^4+6*t2.^5));

xx3=(s0+s3)*cos(x3)-e*sin(x3);

y3=(s0+s3)*sin(x3)+e*cos(x3);

plot(xx3,y3);

holdon;

forfai=0:

0.1:

2*pi;

a=xx3+15*cos(fai);

b=y3+15*sin(fai);

plot(a,b);

holdon;

end

end

forx4=59*pi/36:

0.05:

2*pi;

s4=0;

xx4=(s0+s4)*cos(x4)-e*sin(x4);

y4=(s0+s4)*sin(x4)+e*cos(x4);

plot(xx4,y4);

holdon;

forfai=0:

0.1:

2*pi;

a=xx4+15*cos(fai);

b=y4+15*sin(fai);

plot(a,b);

holdon;

end

end

gridon;