管道管件等等英文缩写Word格式.docx

《管道管件等等英文缩写Word格式.docx》由会员分享,可在线阅读,更多相关《管道管件等等英文缩写Word格式.docx(13页珍藏版)》请在冰豆网上搜索。

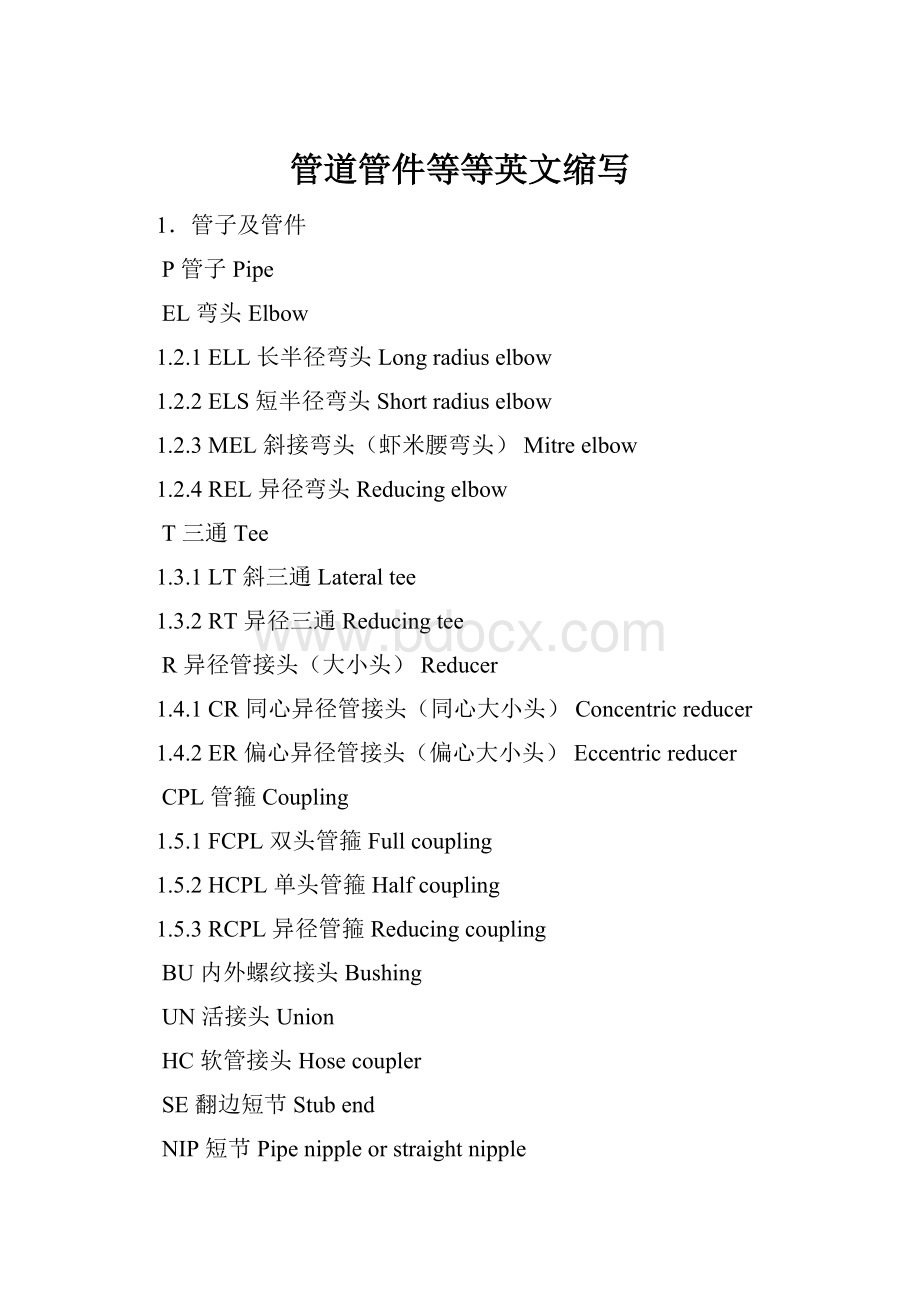

PLG法兰Flange

2.1.1WNF对焊法兰Weldingneckflange

2.1.2SOF平焊法兰Slip-onflange

2.1.3SWF承插焊法兰Socket-weldingflange

2.1.4T螺纹法兰Threadedflange

2.1.5LJ松套法兰Lappedjointflange

2.1.6REDF异径法兰Reducingflange

2.1.7BF法兰盖(日法兰)Blindflange

FSF法兰密封面Flangescalingface

2.2.1FF全平面Flatface

2.2.2RF凸台面Raisedface

2.2.3MFF凹凸面Maleandfemaleface

2.2.4LF凹面Femaleface

2.2.5LM凸面Maleface

2.2.6RJ环连接面Ringjointface

2.2.7TG榫槽面Tongueandgrooveface

2.2.8TF榫面Tongueface

2.2.9GF槽面Grooveface

3.垫片

3.1G垫片Gasket

3.1.1NMG非金属垫片Non-metallicgasket

3.1.1.1AG石棉垫片Asbestosgasket

3.1.1.2RG橡胶垫片Rubbergasket

3.1.1.3TEG聚四氟乙烯包复垫片PTFEenvelopegasket

3.1.2SMG半金属垫片Semimetallicgasket

3.1.2.1MJG金属包垫片Meta-jacketgasket

3.1.2.2SWG缠绕式垫片Spiralwoundgasket

3.1.3MG金属垫片Metallicgasket

3.1.3.1FMG金属平垫片Flatmetallicgasket

3.1.3.2SMSG齿形金属垫片Solidmetalserratedgasket

3.1.3.3LER透镜式金属环垫Lensringgasket

3.1.3.4OCR八角形金属环垫Octagonalringgasket

3.1.3.5OVR椭圆形金属环垫Ovalringgasket

3.1.3.6IR/OR内外定位环Innerringandouterring

3.1.3.7IR内定位环Innerring

3.1.3.8OR外定位环Outerring

4.坚固件

B螺栓Bolt

4.1.1SB螺柱Studbolt

NU螺母Nut

TB花蓝螺母Turnbuckle

WSR垫圈Washer

4.4.1SWSR弹簧垫圈Springwasher

5.阀门

GV闸阀Gatevalve

GLV截止阀Globevalve

CHV止回阀Checkvalve

BUV蝶阀Butterflyvalve

BAV球阀Ballvalve

PV旋塞阀Plugvalve(cock)

CV调节阀Controlvalve

SV安全阀Safetyvalve

RV减压阀Pressurereducingvalve

ST蒸汽疏水阀Steamtrap

PRV泄压阀Pressurreliefvalve

BV呼吸阀Breathervalve

NV针形阀Needlevalve

AV角阀

DV隔膜阀

TWV三通阀

SGV插板阀

6.管道上用的小型设备

SPR气液分离器Separator

FA阻火器Flamearrester

SR过滤器Strainer

6.3.1SRYY型过滤器Y-typestrainer

6.3.2SRTT型过滤器T-typestrainer

6.3.3SRB桶式过滤器Buckettypestrainer

6.3.4TSR临时过滤器Temporarystrainer

SIL消声器Silencer

SG视镜Slightglass

SC取样冷却器Samplecooler

DF排液漏斗Drainfunnel

LM管道混合器Linemixer

RO限流孔板Restrictionorifice

6.9.1MO混合孔板Mixingorifice

RD爆破片(爆破膜)Rupturedisk

EJ补偿器Expansionjoint

7.隔热、伴热

INS隔热Thermalinsulation

7.1.1H保温Hotinsulation

7.1.2C保冷Coldinsulation

7.1.3P防烫伤隔热Personnelprotectioninsulation

T&

I伴热Tracingandinsulation

T管道伴热(冷)Tracing

7.3.1EST蒸汽外伴热Externalsteamtracing

7.3.2IST蒸汽内伴热Internalsteamtracing

7.3.3SJT蒸汽夹套伴热Steam-jackettracing

7.3.4ET电伴热Electrictracing

8.配管材料和等级

8.1M金属材料Metallicmaterial

8.1.1CS碳钢Carbonsteel

8.1.2CAS铸钢Caststeel

8.1.3FS锻钢Forgedsteel

8.1.4AS合金钢Alloysteel

8.1.5SS不锈钢Stainlesssteel

8.1.6AUSTSS奥氏体不锈钢Austeniticstainless-steel

8.1.7CI铸铁Castiron

8.1.8MI可锻铸铁Malleableiron

8.1.9DI球墨铸铁Ductileiron

8.1.10AL铝Aluminum

8.1.11BRS黄铜Brass

8.1.12BRZ青铜Bronze

8.1.13CU紫铜Copper

8.1.14LAS低合金钢Lowalloysteel

8.1.15FLAS低合金锻钢Forgedlowalloysteel

8.1.16CLAS低合金铸钢Castlowalloysteel

THK壁厚Thickness

8.2.1SCH表号Schedulenumber

8.2.2STD标准Standard

8.2.3XS加强Extrastrong

8.2.4XXS特强Doubleextrastrong

9.装置布置

CN建北Constructionnorth

E东East

W西West

S南South

N北North

H水平Horizontal

V竖直、铅直、直立Vertical

GRD地坪Ground

UG地下Underground

BL装置边界线Batterylimitline

ESEW事故沐浴洗眼器Emergencyshowerandeyewasher

HS软管站Hosestation

ML接续分界线Matchline

PS管道支架(管架)Pipingsupport

PR管桥Piperack

STRU构架(构筑物)Structure

BLDG建筑物Building

PD清扫设施Purgedevice

9.19PT池Pit

SHLT棚Shelter

COFF围堰Cofferdam

FL楼板Floor

PF平台Plateform

10.尺寸标注

EL标高Elevation

BOP管底Bottomofpipe

COP管中心Centerofpipe

TOP管顶Topofpipe

FOB底平Flatonbottom

FOT顶平Flatontop

CL(屯)中心线Centerline

TL切线Tangentline

SYM对称的Symmetrical

BOS支架底Bottomofsupport

TOS支架顶Topofsupport

CL净距(净空)Clearance

CTC中心至中心Centertocenter

CTF中心至面Centertoface

CTE中心至端部Centertoend

ETE端到端Endtoend

FEF法兰端面Flangeandface

FTF面到面Facetoface

D直径Diameter

DN公称直径Nominaldiameter

ID内径Insidediameter

OD外径Outsidediameter

DIM尺寸Dimension

MAX最大Maximum

MIN最小Minimum

AVG平均Average

APP约、近似Approximate

10.28PT.EL点标高Pointelevation

11.图表

PFD工艺流程图Processflowdiagram

PID管道和仪表流程图Piping&

instrumentdiagram

COD接续图Continuedondrawing

DTL详图Datail

SPDWG(ISODWG)管段图Spooldrawing(eachlineisometricdrawing)

DWGNO图号Drawingnumber

DWGI所在图号Drawingidentification

LOW材料表Listofmaterial

MTO汇料Materialtake-off

APPX附录Appendix

JOB.No.工号JobNumber

BEDD基础工程设计数据Basicengineeringdesigndata

DEDD详细工程设计数据Detailengineeringdesigndata

REV.No.修改号Recisionnumber

REFDWG参考图Referencedrawing

SC采样接口Sampleconnection

12.操作方式及工作参数

AUT自动Automatic

ML手动Manualcontrol

CHOP链条操作Chainoperated

CSC铅封关Carsealclose

CSO铅封开Carsealopen

LC锁闭Lockclosed

LO锁开Lockopen

NC正常关Normallyclose

NO正常开Normallyopen

ATM大气压Atmosphere

PN公称压力Nominalpressure

12.12A绝压

12.13G表压

(T)温度Temperature

(P)压力Pressure

13.施工

W焊接Welding

13.1.1AW电弧焊Arcwelding

13.1.2GSAW气体保护电弧焊Gasshielded-acrwelding

13.1.3EFW电熔焊Elecricfusionwelding

13.1.4ERW电阻焊ElectricResistancewelding

13.1.5GW气焊Gaswelding

13.1.6LW搭接焊Lapwelding

13.1.7BW对焊Buttwelding

13.4.8TW定位焊Tackwelding

13.1.9SW承插焊Socketwelding

13.1.10CW连续焊Continuouswelding

13.1.11SEW密封焊Sealwelding

13.1.12SFG堆焊Surfacing

13.1.13FW现场焊接Fieldwelding

HT热处理Heattreatment

13.2.1PH预热Preheating

13.2.2SR应力消除Stressrelief

13.2.3PWHT焊后热处理Postweldheattreatment

EIT检查、探伤和实验Examination,inspection&

testing

13.3.1VE外观检查Visualexamination

13.3.2UI(UT)超声探伤Ultrasonicinspection(test)

13.3.3RI(RT)射线探伤Radiographicinspection(test)

13.3.4MPI(MT)磁粉探伤Magneticparticleinspection(test)

13.3.5LPI(PT)液体渗透检验Liquidpenterantinspection(test)

13.3.6HADT硬度实验Hardnesstesting

13.3.7HYDT水压实验Hydraulictesting

13.3.8PNET气压实验Pneumatictesting

13.3.9CE焊条Coveredelectrode

13.3.10WW焊丝Weldingwire

13.3.11ASSY装配、组合Assembly

13.3.12F现场Field

13.3.13F/F现场制造Fieldfabricated

13.3.14SF现场决定Suitinfield

13.3.15CSP冷紧Coldspring

13.3.16BCT螺栓冷紧Boltcoldtightening

13.3.17BHY螺栓热紧Bolthottightening

13.3.18CO清洗口Cleanout

13.3.19ANNY退火Annealed

PE平端面Plainend

BE坡口端Belelledend

THR螺纹Thread

HB布氏硬度Brinnelhardness

RC洛氏硬度

14.其他

FDN基础Foundation

INF信息(资料)Information

REF参考Reference

REV修改Revision

SEQ序号(顺序)Sequence

W/E设备带来Withequipment

W/I仪表带来Withinstrument

14.8CM色标Colourmark

CA腐蚀裕度Corrosionallowance

UTL公用系统Utility

UC公用工程接头Utilityconnection

QTY数量Quantity

WT重量Weight

MHR工时Manhour

BC螺栓分布圆Boltcircle

HP高点Highpoint

LP低点Lowpoint

SUC吸入(口)Suction

DIS排出(口)Discharge

SO蒸气吹扫(口)Steamout

NPT美国标准锥管螺纹Nationalstandardtaperpipethread

NPS美国标准直管螺纹Nationalstandardstraightpipethread

DR排液Drain

VT放气Vent

RTG(压力)等级Rating

CL等级Class

SMLS无缝Seamless