RSF16001300泥浆泵说明书英文文档格式.docx

《RSF16001300泥浆泵说明书英文文档格式.docx》由会员分享,可在线阅读,更多相关《RSF16001300泥浆泵说明书英文文档格式.docx(43页珍藏版)》请在冰豆网上搜索。

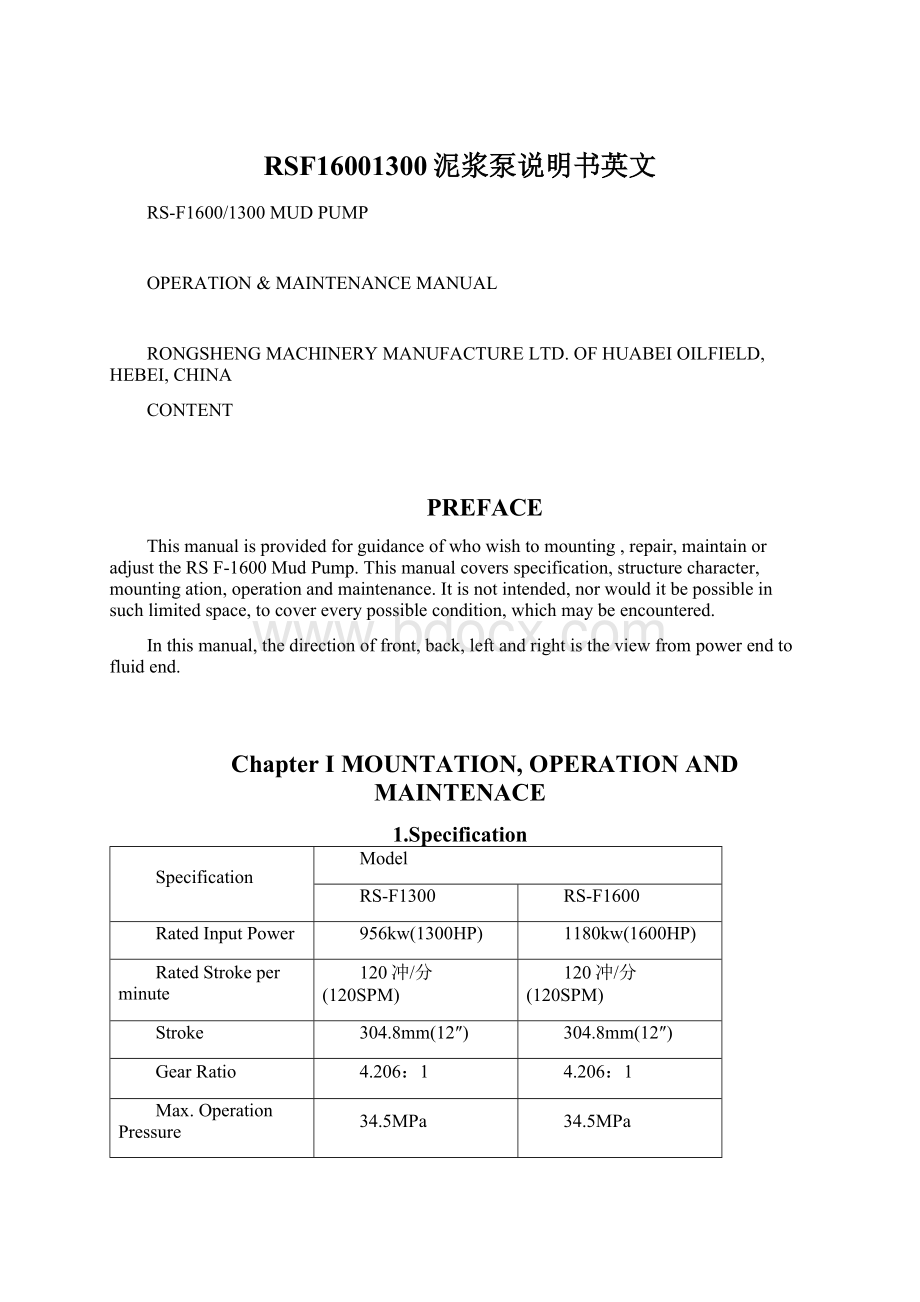

Stroke

304.8mm(12″)

GearRatio

4.206:

1

Max.OperationPressure

34.5MPa

ValveChamber

API#7

Max.LinerDia.

7″

71/4″

Max.LinerMudPressure

18.5MPa

23.3MPa

Dia.OfSuctionManifold

305mm(12″)

Dia.OfDischargeManifold

51/8″flange(5000psi)

Dia.OfPinionShaft

215.9mm(8.5″)

Key

50.8x50.8mm(2x2″)

OverallDimension

4684x2413x2063mm

Weight(Mainbody)

24572kg

24751kg

RS-F1300Specification

LinerDia.in

7

63/4

61/2

61/4

6

51/2

5

DischargePressurePsi

2720

3050

3188

3440

3915

4495

5000

StrokeperMinute

InputPower

DischargeCapacity(L/S)

KW

HP

120

956

1300

45.41

42.22

39.15

36.20

33.36

28.03

23.17

110

874

1188

41.63

38.7

35.89

33.18

30.58

25.69

21.24

100

795

1081

37.84

35.18

32.63

30.17

27.8

23.36

19.31

90

715

972

34.06

31.67

29.36

27.15

25.02

21.02

13.38

50

397

540

18.92

17.59

16.31

15.08

13.9

11.68

9.65

79

107

0.3784

0.3518

0.3263

0.3017

0.278

0.2336

0.1931

RS-F1600SPECIFICATION

71/4

3146

3345

3750

3930

4235

4820

InletPower

kw

1180

1600

48.71

1078

1462

44.65

980

1329

40.59

882

1196

36.53

490

664

20.29

98

133

0.406

MechanicalEfficiencyη=90%,Fillfactorα=100%,VolumeEfficiency:

100%

2.StructureCharacter

2.1PowerEnd

2.1.1Frame

Frameisweldstructureandtransmissionshaft&

bearingseatofcrankshaftarecaststeel.Afterroughmachined,itisweldedwiththeshell.Bearingseatofcrankshaftisstrengthenedwithribs.Annealtreatmentisadoptedtoreleaseweldstresstoimproverigidityandstrength.

2.1.2Crankshaft

Crankshaftiscastalloysteel.Largegearrim,pitmenandbearingsaremountedonthecrankshaft.Geartypeoflargegearrimisintegratedherringbone.Innerholeoflargegearrimandcrankareinterferencematch,andarefastenedwithbolts&

locknuts.Largeendsofpitmenaremountedonthethreeeccentricaxilsofcrankshaftthroughsingle-rawshortcylindricalrollerbearings.Whilesmallendsaremountedonthecrossheadpinsthroughdoublerawlongcylindricalrollerbearings.Crankshaftissupportedbytwodoublerawannularballbearings.

2.1.1Pinionshaft

Pinionshaftisforgealloysteel.Thereisaherringbonegear,whichismiddlehardness.

Inordertoeasytorepair,singlerawlongcylindricalrollerbearingisadopted,whichisnobaffle.Thetwoendsofpinionshaftextendtooutsideoftheshellandpulleycanbemountedoneachendofit.

2.1.2Crosshead

Crossheadissphericalgraphitecastironandhasgoodwearresistanceperformanceto

realizelongerusagelife.Topandbottomguideplateareadoptedinmudpump,andconcentricitycanbeadjustedthroughbottomplateplusspacer.Connectionbetweencrossheadandcentralpullrodisflangedwhichispinmatchedhole.Thisrigidconnectioncanensureconcentricitybetweencentralrodandcrosshead.Thecentralrodisconnectedwithpistonrodthroughhubandthislighthubcanensurereliableconnectionbetweenthem.

2.2FluidEnd

2.2.1Cylinder

Cylinderisforgedbyalloysteelandthethreecylindersonmudpumpcanbeexchanged.Thoroughstructuredesign,whichisvalveonvalve,canreducecylindervolumeandtoimprovevolumeefficiency.Cylindersurfacecancoatednickeltoimproveitscorrosionresistanceperformanceifclientsrequire.Dischargecompressor,shearpinsafetyvalveanddischargefilterscreenaremountedoneachdischargeoutletofthreecylinders.Dischargeoutletis51/8″5000psiflange

2.2.2ValveAssy.

API7#valveisusedbothforF-1600&

F-1300mudpump.Suctionvalveanddischargevalvecanalsobeexchanged.

2.2.2Liner

Linercanbeprocessedwithdoublemetallayerwhichinnerlayeriswearresistancecast

ironwithhardnessHRC60~65,alsohasgoodcorrosionresistanceperformanceandfinish。

2.2.3Pistonandpistonrod

Pistonandpistonrodissealedthroughcylindersurfaceandrubberring.Locknutsareusedtopreventpistonloosenandseal.

2.2.5SpraySystem

Spraysystemincludesspraypump,cooldownwatertankandspraypipe.Itisusedtocoolandwashlinerandpistontoimprovetheirusagelife.

Spraypumpiscentrifugepumpandcanbedriventhroughbeltwhichpulleyismountedontheextendendoftheinletshaftorelectricalmotordirectly.Waterisadoptedtocoolandlubricateit.

Spraypipeismountedonthehubwhichconnectsmiddlepullrodandpistonrod,andcanmovereciprocallytogetherwithpiston.Coolfluidcanalwaysspraythecontactsurfacebetweenpistonandcylinderbecausenozzleisverynearpiston.Stationaryspraypipecanalsobeadoptedandhaslongusagelife.

2.2.6LubricationSystem

Pressurelubricationcombiningsplashlubricationisadoptedforpowerend.Pressureoilpumpedbygearoilpumpintheoiltankistransmittedtocrosshead,middlepullrod,crossheadguideandbearingsthroughlubricationpipeline.Workingconditionofgearoilpumpcanbewatchedfrompressuregaugeinthebackoftheshell.

2.2.7SuctionSystem

Suctionsystemisusedforpreventingairblockduetolowairpressureofpumpinlet.Suctionsystemiscomposedbybase,butterflyvalveandmanifold.Suctionpumponthesuctionmanifoldcanbedrivenbyelectricalmotororbybeltontheinletshaftofmudpumptoreducepowerconsumption.

3.Mountationofnewpump

3.1Mountationofpump

Inordertosavetimeandpower,beforemountingthispump,youshouldgivethecorrectprogramforlocatingthedrillingpump,spraypump,suctionpipeanddischargepipeline,includingtheredirection.

Theboxtypeconstructionofthepowerframehashighresistancetobendingbutrelativelylessresistanceagainsttwist.Therefore,thesupportunderthepumpmustbelevelandadequatetosupporttheweightandoperatingforcesexertedbythepump.Youshouldplacethepumponthelevelconcretefoundation,soastogetthecorrectlubricatingforpowerendandpreventpossibilityoftwistinganddistortingofpowerframe.

Onpermanentmountationsoronbarge,youmustlevelthepump,ensurethebaseofpumpbeinguniformsupported.Pleasedonottightthefoundationboltsunevenly,orunnecessarydistortionwillberesultedinthebaseofpump,andthatwilleffecttheoperatingofthepump.Ifyouusev-belttodrive,youshouldtofixthepumpbysteelboardandsupportrod,preventthepumpbeingmovedbytheforceexertedwiththev-belt.

3.1.1Mountationofthedrive

Thedrivebetweenthemudpumpsandthepowersource,whetherV-beltsormultiwidthchains,shouldbemountedwiththegreatestcaretoassuremaximumoperatinglifewithminimumofunexpectedorundesirableshutdownsduetodrivefailures.

Thesheavecanbemountedontheleftorrightsideaccordingtotherequirement.Therefore,wecanmountthesheaveusedfordrivingspraypumpontheothersideofthedrivingshaft.

Whenmountingthedrivesheave,makesureallgreaseofrustpreventativeisremovedfromtheshaftandtheboreofthedrive.Removeallburrsorroughspotsfromtheshaftend,key,andkeyway.Fitkeytothekeywaysintheshaftandthenmountingkeyintoshaftkeyway.

Coatdrivepinionshaftendwithlightoiloranti-seizecompoundandmountingthedrivesheavehub,thentightenthehubbolts,ThetighteningtorqueforRS-F1600/1300pumpisintableI.Whenmountingthehub,thetighteningforceontheboltsismultipliedmanytimesbythewedgingactionofthetaperedsurface.Thisactioncompressesthehubforasnugfitontheshaft.Ifthetightenboltsforceistoolarge,theburstingpressureiscreatedinthehubofthemountedpulleyandthispressuremaycausethepulleytocrack.Thehubboltsshouldalwaysbetightenedalternatelyandprogressively.

ChartI

Tighteningtorque

N.m

Wrenchlengthmm

Force

N

F-1600/1300

813

900

Notice:

1N=0.1kg

3.1.2Checkbeforemountation

1)Checksheavegroovecondition.

Beforemountingthev-beltssheave,checksheavegroovesforwear.Wormorroundedgrooveswilldestroyv-beltsrapidly.Thesidewallsmustbestraight.Sheavegroovesmustbefreeofdirt,rustorotherextrusions,whichcoulddamagethev-belts.

2)Checksheavealignment.

Thefinalalignmentofthev-beltsheavesshouldbecheckedafterthev-beltshavebeenmountedandadjustedtotheiroperatingtension.Ifthesidesofthesheavesareofequaldistancefromthecenterlineofthegroove,checkalignmentbystretchingtwostrings(fishlineorpianowire