Wire Bonding TechnologyWord文件下载.docx

《Wire Bonding TechnologyWord文件下载.docx》由会员分享,可在线阅读,更多相关《Wire Bonding TechnologyWord文件下载.docx(23页珍藏版)》请在冰豆网上搜索。

Grade

Brokenat

Reason

Quality

1

Balllift

Badprocess

Poor

2

Ballneck

H.A.Z

Good

3

Wire

Dependsonconditions

Verygood

4

Weld

Welddeformation

5

Stitchlift

∙Wirediameter

∙Wirelength

∙Loopheight

∙Padtoleadplanegap

∙Hooklocation

∙

Testercalibration,accuracyandvacuum

3.ballheight(thickness)

ball(1stbond)

3.Bottleneck(BTNK)CapillaryBonding

4.Bottleneck

CapillariesTolerancesTable

Family/Design

BondPadPitch

SpecRange

Tolerances(mils)

Tip

Hole

CD

OR

4149X

4849X

Above

100um

Regular

ForTip>

10�0.3

ForHole≥2.5

+0.25/-0.1

�0.2

ForOR>

3.5

�0.3

ForTip≤10�0.2

For1.8<

Hole<

2.5

+0.2/-0.1

ForOR≤3.5

ForHole≤1.8

+0.15/-0.1

High

Spec

�0.1

-0.1/-0.0

5.Loopheight

measuring

6.OpticalMeasurements

Usuallythisisthefirstsetofexaminationstobeperformed,usingaScanningElectronMicroscope(SEM)andadvancedopticalequipment.

Theseexaminationsareperformedbothpriortothebondingprocess-todeterminethebesttoolandprocessparameters-andafteritscompletion-toevaluatethebondingresults.Theseexaminationsconsistof:

∙Inspectionofthe

package/devicedimensions,whichassistsinsettingtheprocessspecifications,determiningthewiringconstraintsanddesigningthebest-suitedcapillary.

bondpadandpitch

andrelateddimensions,whichassistsindeterminingtherequiredbondpadopening,padsgap,padsizeandpadpitch.Thisalsohelpstodeterminethebondableareaandtherequiredcrosssection(accordingtopassivationlayer

andpadlayerthickness).

wiringmeasurements,whichassistindefiningtherequiredballsize,ballheight,ballplacementaccuracy,loopheightandwireswaytolerances.

∙Thepostbondinginspectionsinclude

ball(1stbond)diameter

measuring,

ballheight(thickness)measuringand

Loopheight

measuring.

7.BondPadPitch

Thebondpadpitchisadefineddistancebetweenthecentersoftwoadjacentpads.Thedesiredpadpitch,derivedfromtheapplicationconstraints,prescribesthetypeofcapillaryoneshoulduse.

Thecapillary'

sexternaldimensions(Tip,

BTNK,

CA)needtobeoptimizedinordertoavoidcontactbetweenthecapillaryandtheadjacentwirewhilemaintainingoptimalbondingperformances.

8.The1stbonddiameterisderivedfromthe

padopening.

Mostapplicationsrequirea100%bondonpad.Themostimportantcapillaryparameteraffectingthein-specaccuracyofthe1stbondisthe

IC

volume,whichconsistsofthe

Hole

diameter,the

ICA

and

CD.

Thisparameterneedstobecarefullycontrolledandoptimizedinwaysthatshallbediscussedlater.

9.WireDiameter

Thewirediameterisdefinedbytheapplication-finerprocessesnaturallyemploythinnerwires.Therefore.thecapillary

isdefinedbythedesiredwirediameter.

Generally,thickwiresarepreferableduetotheirstrengthandbetterresistancetosweepduringmolding.However,thereisadelicatebalancebetweenHoleandwirethatneedstobeobservedinordertomaintainthecriticalgapthatallowsthefreeanduninhibitedmovementofthewire.Thiscriticalgapisimperativeforthesuccessoftheprocessandeliminatingincidentsofwireswayandwirefriction.

Anotherfactorinfluencingthewirediameterselectionisthecostofthe

goldwire.

10.K&

SCapillaryDesignRecommendations

WireDiameter(mil)

RecommendedHole(mil)

Min.RecommendedHole(mil)

2.00

3.00

2.40

1.50

2.20

1.80

1.30

1.20

1.70

1.40

1.10

1.60

1.00

0.90

0.80

0.95

0.70

0.85

11.TechnicalGuide

Goodbondingresultsaretheprimarygoalofeverybondingprocess.Theseresultsarethencomparedto

thespecifications(SPEC)definedbythesemiconductormanufacturerandjudgedbytheirdeviationfromthatSPEC.

Thesemiconductormanufacturerseeksprocessreliabilityatlowercostsandhigheryields.Theseobviousbusinesstargetsareachievedthrougharepeatableandstablebondingprocess.Processstabilityismeasuredaccordingtothefollowingperformancespecifications:

∙FreeAirBalldiameter(min,max,std,Cpk)

∙Balldiameter&

height(min,max,std,Cpk)

∙Loopheight&

shape(min,max,std,Cpk)

∙Ballshearforce&

Strength(min,Cpk)

∙Wirepullforce(min,Cpk)

∙Ballplacementaccuracy(min,Cpk)

∙Confirmationrun(stability,numberofassists,visualinspection,

UPH)

∙Capillarydimensionstolerances(SPECs,effectonprocess,lifetime)

∙Overallprocessfeasibility(cost,demand,timetomarket)

K&

SBondingToolshasdesigned

advancedperformancetests

todeterminewhetherspecificationsweremet.

Understandingtherelationshipbetweencapillarydimensionsandbondingresultsisthekeytocontrollingthebondingprocess.Everytoolhasmorethan15differentparametersthatdeterminethebondingresults.Theseparameters,alongwithvariousotherfactorssuchasthebondingmachine,thewireandthedevicemakeupthecomplexenvironmentthatinfluencestheprocess.ThisenvironmentisanalyzedbybondingexpertsinK&

SapplicationlabsandR&

Dcenters.Thefollowingisageneraldescriptionofthecapillary-processrelationsthatbynomeansconcludethebondingresultsanalysis.

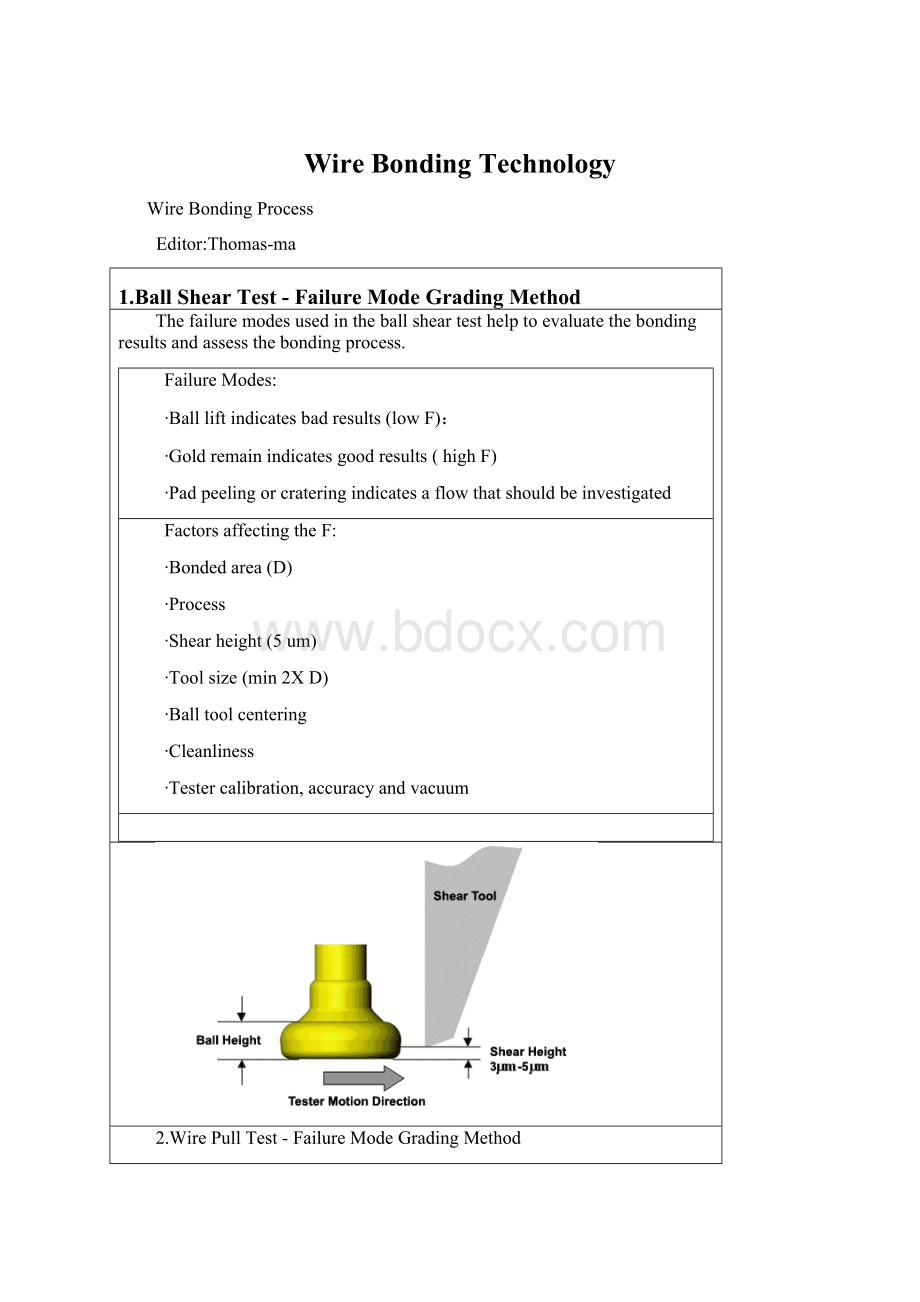

12.BallShearTest

TheballsheartestisperformedusingaShearTester(BT-24,BT-2400PC,DAGE4000)andaShearTool.

Thetestisconsistentwiththefollowingmethodology:

1.Measureballdiameter(D)andballheight(H),andthencalculatethe"

bondedarea"

(S).

S=[(D^2)/4]*p

in[mil]^2or[um]^2.

2.Fixshearheightaccordingtoballheightandpassivationthickness.

3.PerformShearforcetest.TheShearforce(F)ismeasuredin[gr.].

4.Theforcevalueobtainediscalculatedasfollows:

S/u_a(Shearperunitarea)=Shear/[pD2/4].

Reasonablestrengthrange=5.5andabove[gr.]/[mil]2

13.TheEffectonthe1stBond

The1stbondisprimarilyaffectedbythe

IC.TheICcentersthe

FAB

priortotheformationofthebond,transmitsultrasonicpowertotheball,andhelpstocontrolthesizeofthebond.The

CD

andthe

ICAdeterminetheICvolume,whichinturndeterminestheshape,diameterandstrengthofthe1stbond.

Therearetwomainfactorsaffectingthestrengthofthe1stbond:

1.TheforcevectorsappliedbytheICAand

Tip

face.

2.TheultrasonicvibrationsappliedtotheFAB,whichiscapturedintheICvolume.

TheICAalsoaffectstheforcevectorappliedonthegoldsquash.InmostcasesthelargertheICA,thehigherthepressureappliedonthesquash.

K&

SBondingToolsoffersvariousICAsfordifferentapplicationrequirements,rangingfrom60°

to130°

.ThemostcommonICAdimensionsare90°

and120°

.The120°

ICAisusuallyappliedtostandardapplicationswherealargersquashispermitted.The120°

ICAallowsmoregoldtoflowoutsidetheIC,thusutilizingthetipfaceforastronger1stbond.

InFinePitchapplications,wheresmallersquashesarerequired,enlargedICvolumeisneededtocapturemoregold.Intheseinstances,90°

ICAisappropriate.Inthiscase,theICvolumeisofmoreimportancethantheTipfaceasameansoftransmittingtheforceandultrasonicvibrationsneededtostrengthenthe1stbond.

14.TheEffectonLooping

Themaincapillaryparametersaffectingloopingarethe

ICtypeandthe

Hole.Toensurestablelooping,itiscriticaltoreduceoccurrencesoffrictionbetweenthewireandthecapillary.

Duringlooping,thewirecomesincontactwiththecapillaryalongtheHole,whentouchingthecorneroftheHoleandICandwhengoingthroughthecorneroftheICandthe

face.Whenexcessfrictionoccurs,thesecontactscanresultinwiredamageandloopsways.

ToavoidthesesetbacksinloopingoneneedstodefineanappropriategapbetweentheHoleandthewire,determinethebest

ICA,andselectadditionalfeaturessuchas

D/IC

or

IR.

Theminimumhole-wireclearanceisusuallysetat0.2milforFinePitchapplications;

whenfinerclearancesarerequired,thereisdifficultyinreducinggapswithoutdamaginglooping.

Kulicke&

Soffaindustry-leadingtolerancesallowsuchreductionswhilemaintainingastableprocess.

InStandardcapillarydesign,theloopheightdeterminestheCA,whileinFinePitchcapillarydesign,theloopheightdeterminesthe

BTNKheight,

BTNKangle

andBTNKradius.

Forlongandhighlooping,aD/ICwitha90°

or120°

angleisusuallyrecommended.Forlongandlowlooping,anIRandICAof120°

areadvisable.Naturally,theserecommendationsaresubjecttoapplicationconstraintsandoptimizationconsiderations.

15.TheEffectonthe2ndBond

Thecapillaryaffectsthe2ndbondintwomainaspects:

∙Thestitchbond-thisbondpermanentlyconnectsthewiretothelead.(Moreaboutthestitchbond)

∙Thetailbond-thisbondtemporarilyconnectsthewiretothelead.Itenablesthecapillarytorisetothetailposition,t