不对称催化氢化Word文件下载.docx

《不对称催化氢化Word文件下载.docx》由会员分享,可在线阅读,更多相关《不对称催化氢化Word文件下载.docx(33页珍藏版)》请在冰豆网上搜索。

催化氢化都是膦配体。

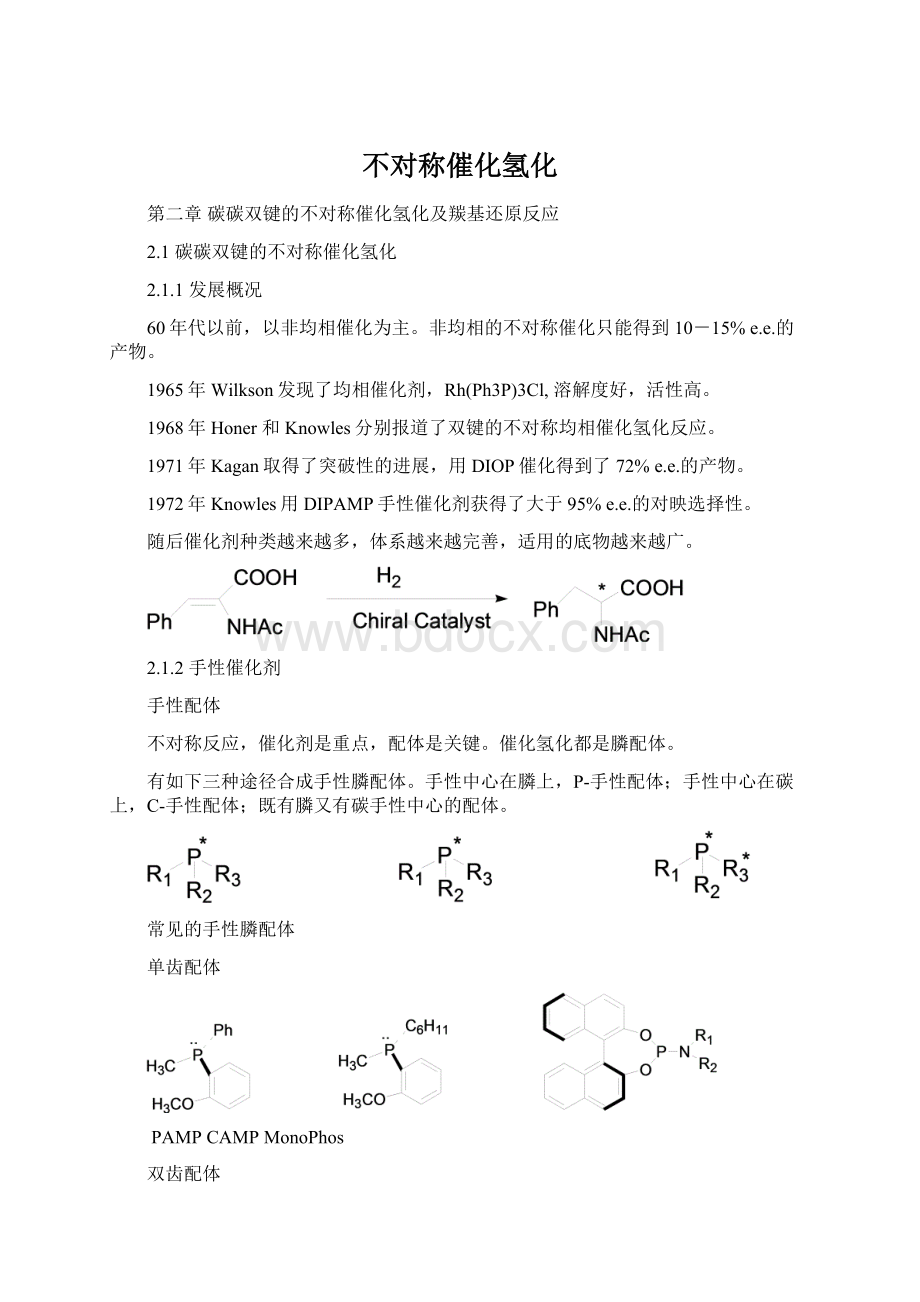

有如下三种途径合成手性膦配体。

手性中心在膦上,P-手性配体;

手性中心在碳上,C-手性配体;

既有膦又有碳手性中心的配体。

常见的手性膦配体

单齿配体

PAMPCAMPMonoPhos

双齿配体

DEGPHOSDuPHOSPNNP

RROPHOSNORPHOSBPPFA

CYCPHOS(R,R)-DIPAMP(S,S)-CHIRAPHOS

(R)-BINAP(S,S)-BPPMDIOP

(R,R)-DPCP(+)-DIPMC(2R,3R)-NORPHOS

(-)-MENO

BIPHEMPSpirOPBICP

中心金属

主要限于铑(Rh)和钌(Ru)两种贵金属,另外铱(Ir)有少量的应用。

手性铑(Rh)膦催化剂只对α-酰氨基丙烯酸衍生物的催化氢化有很好的结果,对其它底物对映体选择性很低。

手性钌(Ru)膦催化剂底物适用范围广,尤其是Noyori等发展的[Ru(BINAP)(OCOR)2]催化剂能用于C=C,C=O,C=N等的不对称氢化,得到特别优异的对映体选择性。

2.1.3不对称催化机理

手性铑(Rh)膦催化剂对α-酰氨基丙烯酸衍生物的氢化催化结果如下:

PhosphineLigand

%e.e.oftheproduct

R=C6H5

R=H

(R,R)-DIPAMP

96(S)

94(S)

(S,S)-CHIRAPHOS

99(R)

91(R)

(S,S)-NORPHOS

95(S)

90(R)

(R,R)-DIOP

85(R)

73(R)

(S)-BINAP

98.5(R)a

(S,S)-BPPM

100(R)a

98(R)

(S)-BPPFA

93(S)

(S,S)-SKEWPHOS

92(R)

(S,S)-CYCPHOS

88(R)

(S,S)-Et-DuPHOS

99(S)

a.hydrogenateonofN-benzoylderivative

Halpern等人以及Brown等人对手性铑(Rh)膦催化剂的机理进行了详尽的研究。

烯烃能用Re面或者Si面与手性催化剂配位生成两个非对映体,氧化加成(K2)是速率控制步骤。

手性钌(Ru)膦催化剂催化机理

Ru(II)的配位数比Rh(I)大,可形成六配位数的八面体结构,后者只形成四面体结构。

机理更加复杂,形成单氢形式的活性中间体。

Halpern提出了机理如下

OrganicSyntheses,CV9,169

ASYMMETRICHYDROGENATIONOFALLYLICALCOHOLSUSINGBINAP-RUTHENIUMCOMPLEXES:

(S)-(−)-CITRONELLOL

[6-Octen-1-ol,3,7-dimethyl,(S)-]

SubmittedbyHidemasaTakaya1,TetsuoOhta1,Shin-ichiInoue2,MakotoTokunaga2,MasatoKitamura2,andRyojiNoyori2.

CheckedbyAndrewMadinandLarryE.Overman.

1.Procedure

Caution!

BINAP-Rucomplexesarerapidlyoxidizedinsolutioninthepresenceofair,andallproceduresshouldbecarriedoutunderanaerobicconditionsusingdegassedsolvents.

A.[(R)-2,2'

-Bis(diphenylphosphino)-1,1'

-binaphthyl]rutheniumdiacetate,Ru(OCOCH3)2[(R)-BINAP].Adry,150-mLSchlenktube(Note1)connectedtoasupplyofargon(Note2)isequippedwithaTeflon-coatedmagneticstirringbarandaglassstopper.Thevesselischargedwithbenzeneruthenium(II)chloridedimer,[RuCl2(benzene)]2,(800mg,1.60mmol)(Note3)and(R)-BINAP(1.89g,3.04mmol)(Note4),evacuated,andthenfilledwithargon.N,N-Dimethylformamide(DMF)(30mL)(Note5)isintroducedwithahypodermicsyringeunderthestreamofargon.Thereddishbrownsuspensionisstirredat100°

Cfor10min(Note6)andtheresultingclearreddishbrownsolution(Note7)iscooled.Anotherdry,60-mLSchlenktubeischargedwithsodiumacetate(5.20g,63.4mmol)andmethanol(50mL)(Note8)andthesolutionisdegassedbythreefreeze-thawcycles.ItistransferredintotheDMFsolutionofBINAP-Ru(II)complexpreparedaboveviacannulaandthesolutionisstirredat25°

Cfor5min.Tothesolutionareaddedwater(50mL)andtoluene(25mL)underargonandtheresultingtwolayersaremixedbyvigorousstirring.Theupperorganiclayeristransferredintoanother200-mLSchlenktube(Note9)usingacannula.Theaqueouslayerisvigorouslymixedwithtoluene(25mL)andtheupperorganiclayerisagaintransferredintotheSchlenktube.Thisprocedureisrepeatedoncemore.Thecombinedorganiclayersarewashedwithfour10-mLportionsofwater(Note10).Removalofthesolventat1mmand40°

Cfor30minwithvigorousstirring(Note11)andevacuationat0.1mmand25°

Cfor12hrgives2.54–2.67gofsolidRu(OCOCH3)2[(R)-BINAP](99–104%crudeyieldbasedonBINAP)(Note12).Itisdissolvedintoluene(20–25mL)withheating.Hexane(80–100mL)isaddedverycarefullytothesolutiondownthesideoftheflasktoformtwolayers.Thesolutionisleftat25°

Cfor12hrandthenat4°

Cfor3daystogivesolidmaterial.Removalofthemotherliquorisfollowedbywashingwithhexane(20mL)anddryingunderreducedpressuretoafford1.8–2.2g(71–85%yield)ofpureRu(OCOCH3)2[(R)-BINAP]asfineyellowneedlesorpowderycrystals;

mp188–190°

Cdec(Note13).

B.(S)-(−)-Citronellol.Geraniol(12.9mL,74mmol)(Note14)and95%methanol(15mL)(Note15)areplacedinadry,80-mLSchlenktubeandthemixtureisdegassedbyfivefreeze-thawcycles.Anotherdry,80-mLSchlenktube,equippedwitharubberseptumandamagneticstirringbarandfilledwithargon,ischargedwithRu(OCOCH3)2[(R)-BINAP](45mg,53μmol)(Note16).Thesystemisevacuatedandrefilledwithargonthreetimes.Byuseofacannula,thesolutionofgeraniolinmethanolisintroducedintotheSchlenktubecontainingtherutheniumcomplexunderargon.Theresultinglightyellowsolution(Note17)isthentransferredwithacannulaintoa100-mL,stainlesssteelautoclaveequippedwithaglassvessel(Note18)andamagneticstirringbarbyuseofaslightpositivepressureofargon.Theautoclaveisconnectedtoahydrogensource(Note19)usingthearrangementshowninFigure1,andtheairoriginallypresentinthegas-inlettubeisreplacedbyhydrogen(Note20).ValveAisopenedandhydrogenisintroduceduntilpressuregaugeBindicates100atm.Thesolutionisstirredat20°

Cfor8–16hr(Note21).Duringhydrogenation,thehydrogenpressureiskeptabove90atmbytheoccasionalintroductionofhydrogenfromthecylinder(Note22).Whenconsumptionofhydrogenceases,thegas-inlettubeisdisconnected.ExcesshydrogeniscarefullyreleasedbyopeningvalveAandthentheapparatusisdisassembled.Theyellowishbrowncontents(Note23)aretransferredtoa50-mLflaskandthesolventisremovedbyarotaryevaporator.Theresidue(Note24)isdistilledunderreducedpressuretogive10.7–11.2g(93–97%yield)of(S)-(−)-citronellolin98%ee(Note25)and(Note26);

bp58–62°

C/0.01mm.

Figure1

2.Notes

1.Beforeuse,allapparatusisdriedovernightina120°

Coven.

2.Argon(99.998%)ispurifiedbypassingthroughaBASFcatalystRC-11columnat80°

Candthenthrough4Å

molecularsieves.

3.[RuCl2(benzene)]2,availablefromAldrichChemicalCompany,Inc.,isusedwithoutpurification.

4.BINAP[2,2'

-bis(diphenylphosphino)-1,1'

-binaphthyl]iscommerciallyavailableorcanbepreparedaccordingtoaliteratureprocedure.3Thediphosphineisslowlyoxidizedinairtogivethecorrespondingmono-anddiphosphineoxidesthatcanberemovedbycolumnchromatography(silicagel,benzene)underaninertatmosphere.

5.GuaranteedgradeDMF,availablefromNACALAITESQUE,Inc.,isdistilledover4Å

molecularsievesunderargonbeforeuseandstoredina100-mLSchlenktube.Itisdegassedbythreefreeze-thawcycles.

6.Reactionatahighertemperatureforalongerperiodleadstoformationoftherutheniumcarbonylcomplex[IR(KBr)1964cm−1].

7.ThesolutionmaybeacrudemixtureofcationicBINAP-Ru(II)complexessuchas[RuCl(BINAP)(DMF)3]Cland[Ru(BINAP)(DMF)4]Cl2.Physicalpropertiesincludeconductivity,27Scm2/mol(DMF);

31PNMR(4:

1DMF-CDCl3)δ:

60.6(d,J=46),61.4(d,J=46),61.8(s).The(R)-BINAP-Ru(II)complexobtainedbyremovalofthesolventcancatalyzehydrogenationofgeraniol(98.7%purecommercialgeraniolcontaining1.3%ofnerol,distilledfrom4Å

molecularsieves).However,inadditionto(S)-citronellolin95–96%ee,dihydrocitronellol,anoverreductionproduct,isobtainedin3–7%yield(1.1Msubstratein95%aqueousmethanol,1.7mMcatalyst,100atmofH2,20°

C,8hr).

8.Guaranteedgrademethanolisdistilledunderargon.

9.Thediameterisabout4cm.

10.Theextractionproceduremustbecarriedoutunderanargonatmosphere.

11.Underreducedpressure,thesolutionsometimesfoams.ThiscanbeavoidedbyheatingthetoppartoftheSchlenktubewithahotairgun.

12.CrudeBINAP-Rucomplexwithconsistentspectralcharacteristicscanbeusedforhydrogenationofgeraniol(98.7%purecommercialgeraniolcontaining1.3%ofnerol,distilledfrom4Å

molecularsieves,4.7Msubstratein95%aqueousmethanol,2.8mMRu(OCOCH3)2[(R)-BINAP],100atmofH2,20°

C,8hr),togive(S)-citronellolin96%ee,97%isolatedyield.

13.Theproducthasthefollowingspectralproperties:

1HNMR(CDCl3)δ:

1.80(s,2OCOCH3),6.47–7.84(m,aromaticprotons);

31PNMR(CDCl3)δ:

65.13(s);

13CNMR(CDCl3)δ:

23.50,125.2–138.3,188.1;

IR(CH2Cl2)cm−1:

1452,1518.Ananalyticalsampleispreparedbydryingat110°

Cand0.01mmfor12hr:

CalcdforC48H38O4P2Ru:

C,68.5;

H,4.6.Found:

C,68.4;

H,4.5.

14.Puregeraniolisobtainedbyfractionaldistillationusinga1000theoreticalplatecolumn.Thecheckersobtainedgeraniol,>

99.5%puritybyGCanalysis,fromFlukaChemicalCompanyanduseditdirectly.

15.The95%methanolispreparedbymixingdistilled,guaranteedmethanol(95mL)andwater(5mL).Ifabsolutemethanolor90%aqueousmethanolisusedassolvent,somewhatlongerreactiontimesareneeded.

16.Thecomplexcanbestoredunderargonwithoutnoticeablelossofcatalyticactivity.Itisweighedunderanargonatmosphere.

17.Therutheniumcomplexismoderatelysolubleinmethanol.Ultrasonicstirringisemployedforcompletesolution.

18.Aglassvesselisusedforkeepingthereactionmixtureawayfromthestainlesssteelwall.Thereactionsystemisevacuatedandfilledwithargonthreetimesbeforeuse.

19.Thepurityofhydrogen(NipponSansoCo.)usedbythesubmittersis99.99999%.Thecheckersusedhydrogenof99.99%purity.

20.Thegas-inlettubeisattachedtotheautoclaveandthenthemainvalveofthecylinderisopened.Afterclosingthemainvalveofthecylinder,theconnectorofthegas-inlettubeisloosenedtoreleasehydrogenpressureandtightenedimmediately.Thisprocedureisrepeatedfivetimes.

21.To