液压挖掘机yw5572Word格式.docx

《液压挖掘机yw5572Word格式.docx》由会员分享,可在线阅读,更多相关《液压挖掘机yw5572Word格式.docx(25页珍藏版)》请在冰豆网上搜索。

100

250

500

1000

2000

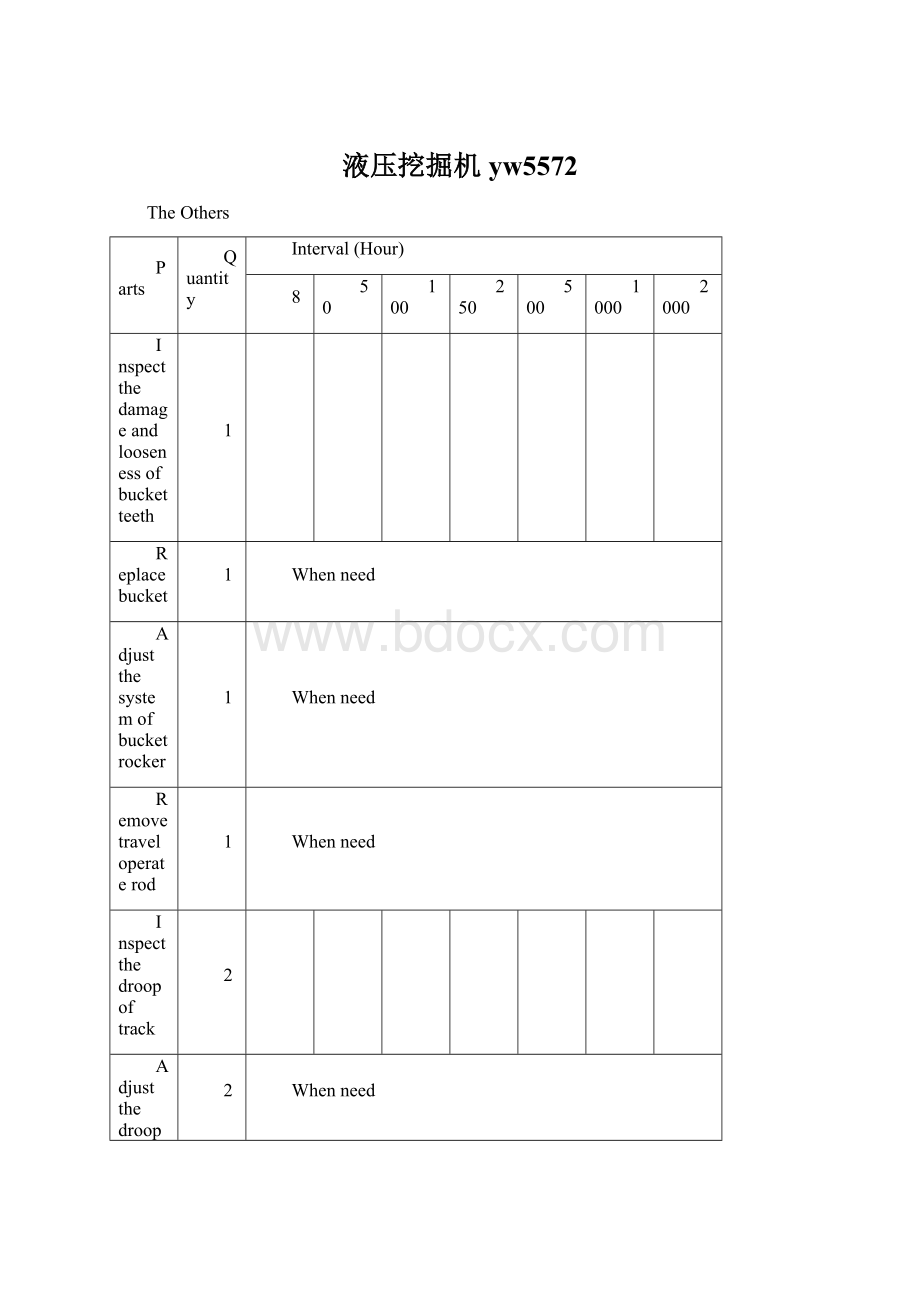

Inspectthedamageandloosenessofbucketteeth

1

Replacebucket

Whenneed

Adjustthesystemofbucketrocker

Removetraveloperaterod

Inspectthedroopoftrack

2

Adjustthedroopoftrack

Inspectthetightermo-mentofboltsandnuts

—

★★★

NOTE:

★★★Onlyinthefirstinspectionneedstomaintain.

Checkwearandtear,flabofthebucketteeth——everyday

Ifthewearandtearofteethisovermuch,replacethem.

Iftheteethslop,tightenthebolts,andthetighteningtorque:

451N·

m (46kgf·

m).

1.Parkingthemachineonthelevelground.Lowerthebuckettoground,andsitonthegroundwiththebucketplanepart,insurethebucketwillnotrollwhenremovethepin.

2.Removethebucketpin,anddisjoinarmandbucket.Cleanthepinandbore.Wipepropergreasetothepinandbore.

3.Adjustarm,andreplacebucket.Insurethebucketwillnotroll.

4.Mountthepin.

5.Mountlockpinandouchtothepin.

6.Adjustthejointclearanceofbucketpin.Refertothemethodofadjustbucketjointclearance.

7.Addgreasetothepin.

8.Starttheengineandrunatspeedof1200rpm,operatingbucketslowlyinthetwodirections,andcheckthebucketturninghaswhetherornotholdback.Correcttheproblemofholdback.

Adjustthelinkerofbucket

Themachinehasabucketadjustsystemtoremovelinkedshake.Whenlinkedshakeincrease,removeorfitonthetabasfollows:

1.Parkingthemachineonlevelground.Lowerthebuckettothegroundwiththeplanedownward,sothatthebucketwillnotroll.

2.Runtheengineatspeedof1200rpm.Turnthebucketwithcounter-clockwiseslowlytillthetopofthebucketleftflangecontactthearm.

3.Stopengine,andPutthegatelocklevertolocketplace.

4.Tothebestofyourabilitiesfitontabstotheclearance.

Removetravellever

Ifwish,canremovetravellever.

1.Parkingthemachineonthelevelground.

2.Lowerthebuckettotheground.

3.Reducetheenginespeedtolowidlespeed.

4.Turnthekeyinthestartertothe“OFF”positionandpulloutthekey.

5.Putthegatelocklevertothe“OFF”position.

6.Removetheleverbolts,andtakeofflever.

7.Mountboltsandtightentothetorqueof49N.m(5kgf.m).

Checkthesagoftrack——every50hours

NOTICE:

Checkthesagoftrackaftercleaningcompletelytheclayinthetrack.

Asthefigureshow,swingtheupperstructure90degreeandlowerthebuckettotheground,sothatliftthetrack.

Keeptheangleofboomandarmwithin90to110,andholdtheroundpartofbucketontheground.Placeblocksunderthetrackframetoholdupthemachine.

Swingthetrackbackwardtwowholecircles,andthenswingthetrackforwardtwocircles.

Inthemiddleoftrackframemeasurethedistance(A)betweenthebottomoftrackframeandthebackplaneofthetrackplate.Thesagoftrackprescribeswithin315to350mm(12.4to13.8in.).

Adjustthesagoftrack

Donotremovevalve,keepyourbodyandfacefarfromvalve,andpreventhighpressuregreaseshootinginjury.

Ifthelefttracksagisdifferfromtherightone,themachinewillleantothetravelingroute.

1.Cleantheareaofchainwheelorientedwheelandgreasenipple.

2.Totensionthetrack,firstlyloosenandremovetheoilplug,secondlymountthepartwithmachine04F3804(injectoiltube)totheplaceofplug,andthenconnectthegreasegun..Addgreasetillthesagwithinthecommendedlimit.Remounttheplug.

3.Toloosenthetrack,slowlywithcounter-clockwiseturnthevalve,whenvalveisloosened1to1.5circles,thegreasewillflowoutfromgreaseexport.Ifthegreasedoesnotflowoutfavorably,liftthetrackawayground,slowlyswingthetrack.

IMPORTANCE:

Ifaftercounter-clockwiseturningthevalve,thetrackisstillverytight,orafteraddinggrease,thetrackisstillveryloose,thisisexceptionalphenomena.Underthiscondition,donotdisassembletheregulatoroftrack,andimmediatelycontactmechanicalorthedealerappointedmaintenanceman.

Checkthetighteningtorqueofboltsandnuts——every250hours

Afterthefirst50hours,checkthetensionofboltsandnuts.Laterevery250hourscheckatime.Ifthereisanylooseness,tightentothetorqueshowedthat.Boltsandnutsshouldbereplacewiththesamequalityorhigherquality.

Usesthetorsionwrenchestochecktightenboltsandnuts.

1.Insurethethreadsarecleanlywhenmountingorreplacing.

2.Applylubricanttoboltsandnuts(forinstancezincisdissolvedintoaxislubricatingoil),sothattheirfrictionalcoefficientsaresteady.

3.Iftheboltsofcounterweightarealreadyloose,contactyourdealerormaintenanceman.

Thoserequestedtighteningtorqueareshowedwithkgf·

m.F