材料元素含量Word文档格式.docx

《材料元素含量Word文档格式.docx》由会员分享,可在线阅读,更多相关《材料元素含量Word文档格式.docx(35页珍藏版)》请在冰豆网上搜索。

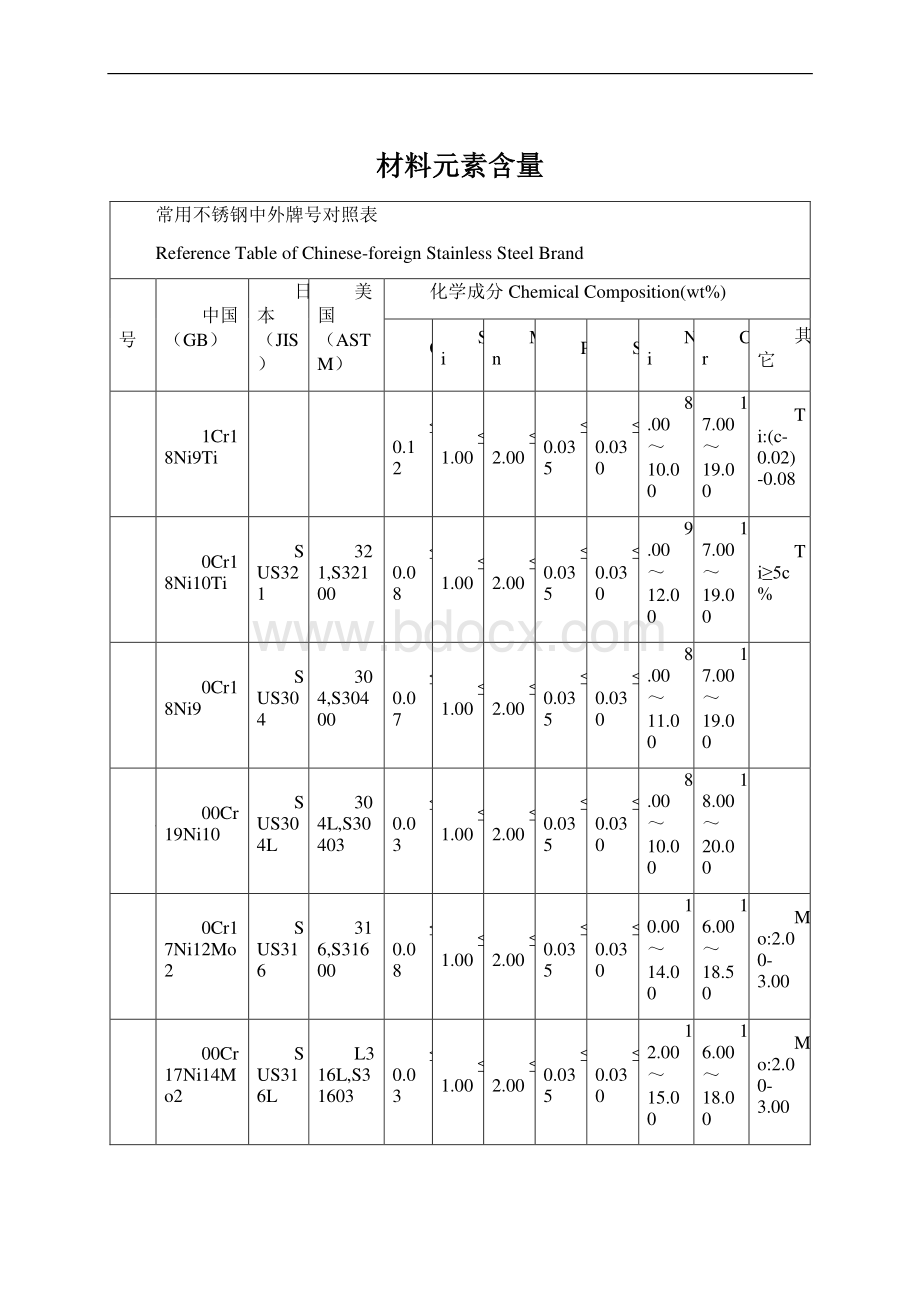

2.00-3.00600Cr17Ni14Mo2SUS316LL316L,S316030.031.002.000.0350.03012.0015.0016.0018.00Mo:

2.00-3.0070Cr18Ni12Mo2Ti0.081.002.000.0350.03011.0014.0016.0019.00Mo:

1.80-2.5080Cr25Ni20SUS310S310S,S310080.081.002.000.0350.03019.0022.0024.0026.0090Cr18Ni11NbSUS347347,S347000.081.002.000.0350.0309.0013.0017.0019.00Nb100%000Cr18Ni5Mo3Si20.031.302.001.002.000.0350.0304.505.5018.0019.50Mo:

2.50-3.00110Cr18Ni9SUS302302,S302000.151.002.000.0350.0308.0011.0017.0019.0020Cr13SUS410S410S0.081.001.000.0350.03011.5013.50国外管材、管件化学成份表序号标准号及等级CMnPSSiCuNiCrMoVAPI5LGR.B2A53GR.B0.31.20.050.050.40.40.40.153A1050.350.61.050.040.050.350.40.40.30.124A106GR.B0.30.291.060.0250.0250.10.40.40.40.155A182GR.F3040.082.00.040.03181118206A182GR.F304H0.040.12.00.040.03181118207A182GR.F10.280.60.90.0450.0450.150.350.440.658A182GR.F11CL.10.10.20.30.80.040.040.5111.50.440.659A182GR.F22CL.10.150.30.60.040.040.0522.50.871.130A234GR.WPB0.30.291.60.050.0580.11A234GR.WP10.280.30.90.0450.0450.10.50.440.652A234GR.WP11CL.10.150.30.60.030.030.5111.50.440.653A234GR.WP22CL.10.150.30.60.040.040.51.92.60.871.134A312GR.TP3040.082.00.040.030.7581118205A312GR.TP304H0.040.12.00.040.030.7581118206A333GR.10.30.41.060.050.067A333GR.30.190.310.640.050.050.150.373.183.82序号标准号及等级CMnPSSiCuNiCrMoV8A335GR.P10.10.20.30.80.0450.0450.10.50.440.659A335GR.P110.150.30.60.0250.0250.511.01.50.440.6520A335GR.P220.150.30.60.0250.0250.51.92.60.871.1321A350GR.LF20.31.350.0350.040.150.3422A350GR.LF30.20.90.0350.040.20.353.253.7523A403GR.WP3040.0820.0450.031811182024A403GR.WP304H0.040.120.0450.031811182025A420GR.WPL30.20.310.640.050.050.130.373.183.8226A420GR.WPL60.30.391.060.0480.0580.127A671GR.CC60-CL130.310.980.0350.040.130.4528A671GR.CF66-CL13-S20.20.70.0350.040.130.453.183.8229A672GR.B60CL.130.310.980.0350.040.130.4530A409GR.TP3210.0820.0450.030.0759.0137.020注:

铌-钼的含量不应小于碳含量的10倍,即大于10倍。

国外焊接材料化学成份表序号牌号CMnSiPSNiMoCrVCuTGS-51T0.11.550.820.0140.0122TGS-500.081.310.70.0130.013TGS-1N0.051.070.30.010.0090.790.124TGS-3N0.030.70.290.0080.0083.50.165TGS-M0.071.020.440.536TGS-1CM0.021.10.480.51.037TGS-2CM0.090.710.321.042.268TGS-3080.051.790.3810.1419.729TGS-3090.062.060.3513.2723.850TGS-3470.061.840.419.519.4Nb:

0.891LB-520.080.960.580.0110.0072LB-52V0.080.860.640.0120.013LB-52NS0.061.380.450.010.0080.494NB-3N0.030.940.330.010.0093.20.275CMA-760.060.790.490.0110.0060.546CMA-960.070.810.430.0110.0070.541.317CMA-1060.070.70.40.0120.0061.022.3序号牌号CMnSiPSNiMoCrVCu8NC-370.051.310.540.0210.0049.8619.41Nb:

0.89NC-380.061.660.280.0220.0049.7820.2120RNY-3080.080.92.50.40.03911182121NC-390.081.610.450.0210.00312.5123.8722ER80S-NI10.121.250.40.80.0250.0250.81.10.350.150.050.3523ER80S-B20.070.120.40.70.40.70.0250.0250.20.40.651.21.50.3524ER90S-B30.070.120.40.70.40.70.0250.0250.20.91.22.32.70.3525E7016-A10.120.90.60.030.040.40.6526E7015-C1L0.051.250.50.030.0422.7527E7015-C2L0.051.250.50.030.0433.7528E8018-B2L0.050.90.80.030.040.40.6511.529E9018-B3L0.050.90.80.030.040.91.222.5GB/T700等(基础标准)碳素结构钢板、棒、型材表2.2-1牌号等级化学成分(质量分数)/%脱氧方法CSiMnSPQ1950.060.120.300.250.50.0500.045F、b、ZQ215A0.090.150.300.250.550.0500.045F、b、ZQ215B0.090.150.300.250.550.0450.045F、b、ZQ235A0.140.220.300.300.650.0500.045F、b、ZQ235B0.060.120.300.300.700.0450.045F、b、ZQ235C0.180.300.350.800.0400.040ZQ235D0.170.300.350.800.0350.035TZQ255A0.180.280.300.400.700.0500.045ZQ255B0.180.280.300.400.700.0450.045ZQ275一0.280.380.350.500.800.0500.045Z化学成分有以下几点说明:

1沸腾钢硅含量(质量分数)不大于0.07%;

半镇静钢硅含量(质量分数)不大于0.17%;

镇静钢硅含量(质量分数)下限值为0.12%。

2D级钢应含有足够的形成细晶类结构的元素,例如钢中酸熔铝含量(质量分数)不小于0.015%或全铝含量(质量分数)不小于0.020%。

3钢中残余元素铬、镍、铜含量(质量分数)应各不大于0.30%,氧气转炉钢氮含量应不大于0.008%。

如供方能保证,均可不做分析。

4钢中砷的残余含量(质量分数)应不大于0.080%。

用含砷矿冶炼生铁所冶炼的钢,砷含量由供需双方协议规定。

如原料中没有含砷,对钢中的砷含量可以不做分析。

5在保证钢材力学性能符合本标准规定情况下,各牌号A级钢的碳、锰含量和各牌号其他等级钢碳、锰含量下限可以不做为交货条件,但其含量(熔炼分析)应在质量证明书上注明。

6在供应商品钢锭(包括连铸坯)、钢锭时,供方应保证化学成分