机组启动前的准备及联系工作英文版.docx

《机组启动前的准备及联系工作英文版.docx》由会员分享,可在线阅读,更多相关《机组启动前的准备及联系工作英文版.docx(13页珍藏版)》请在冰豆网上搜索。

机组启动前的准备及联系工作英文版

Coal–FiredPowerPlantUnit(135MW)OperationProceduresTrainingMaterial

CoalFiredPowerPlantUnitColdStartPreparationSteps:

1.SwitchOnElectricalPower

1.1Localprotectioncabinetpanel(generator-transformerprotectioncabinetA,generator-transformerprotectioncabinetC,startstandbytrnsformerprotectioncabinetC,servicestationquicktransferingdevice,circuitprotectioncabinet.

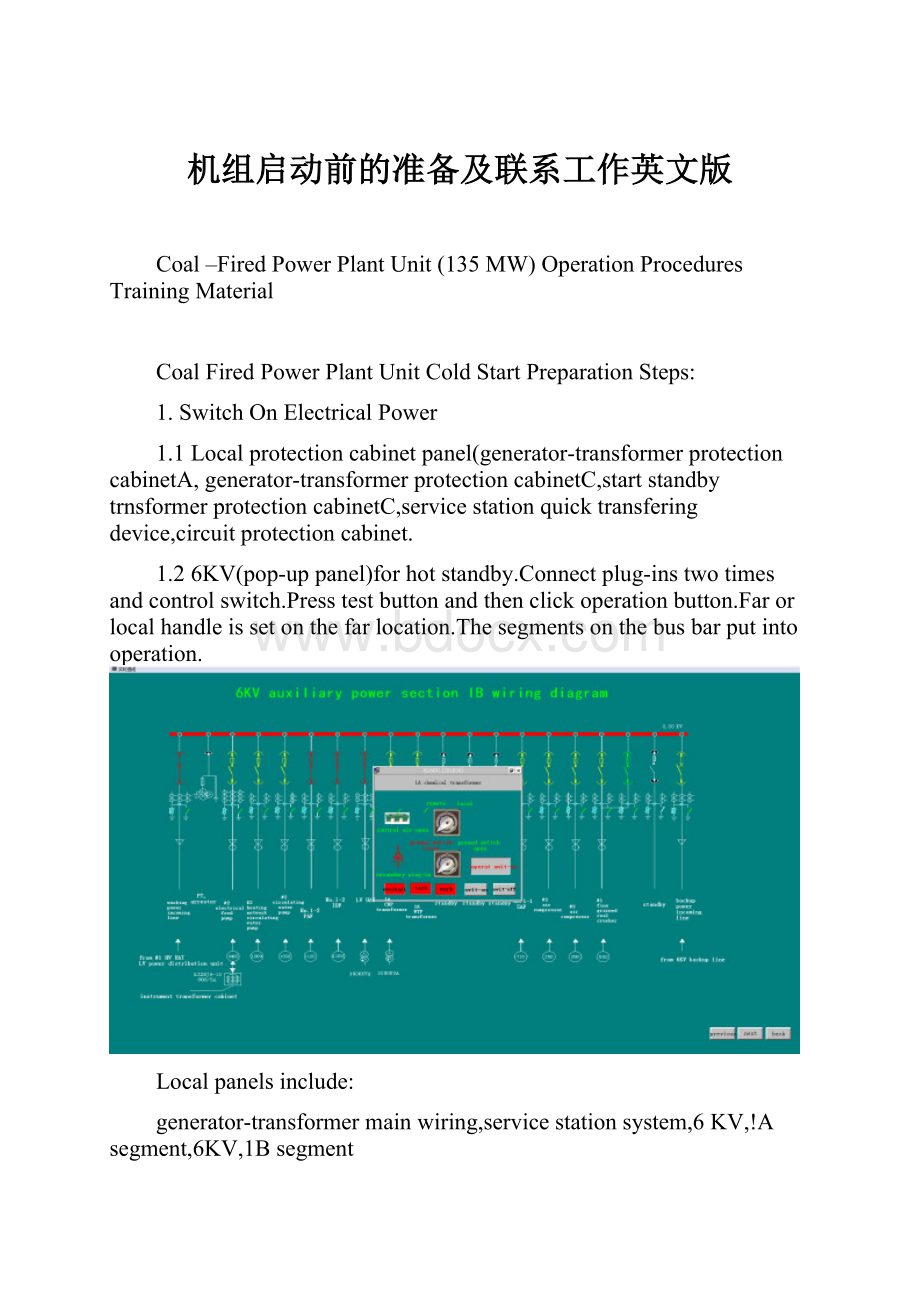

1.26KV(pop-uppanel)forhotstandby.Connectplug-instwotimesandcontrolswitch.Presstestbuttonandthenclickoperationbutton.Farorlocalhandleissetonthefarlocation.Thesegmentsonthebusbarputintooperation.

Localpanelsinclude:

generator-transformermainwiring,servicestationsystem,6KV,!

Asegment,6KV,1Bsegment

1.3InthemainelectricalwiringofDCSscreen,connect1915-Eastor1915-West,1915-B,522,52141,52142,52146toggle,1915,3620,1621A,1622A,1622B,1621B,1661266A,467A,463A,463B,467B,464B,465B,466B,1666,1664,1667,1663,3660,267,2664,1667,1663,3660,2666,2664,2665,266B,465B,466B,461A,461B,421A,421switch,andfurnaceMCC,machineMCC,coalfeedMCClinepowersupply.

1.4connectmainplanthouse380Vsectionsoftheloadswitch,boilerMCC,turbineMCC,coalfeederMCCloadswitch(bothdirectpointswitch)

2localelectricvalvestatusmaintainremotebyturbineandboileroperators,openandmanualvalve

3.Ifcirculatingmake-upwatersystemisnormal,startthecirculatingpump,circulatingwaterflowstothecondenserconnectsto,andcoolingwaterflowstotherelevantequipment.

4.Startopencirculatingwaterpump,putopencoolingwatersystemintooperation,startclosedcirculatingwaterpump,putclosedwatersystemintooperaion."interlock"switchisintroducedandwatercoolingwaterflowstotheauxiliaryequipment.

5.contactthechemicalwaterdepartmen.Condensatewatertankaddssalinewatertothenormalwaterlevel.Thecondensersteamsideadddstothewaterlevelgauge1200mm

6.Coalisfeededtothenormallevel,andbedmaterialaddingtothefurnaceisnotlessthan62t.

7.airpressureofcheckinstrumentisnotlessthan0.6MPa

8.Opentheboilersidesteamwatersystemtoreleasetheairvalveanddrainagevalve.

BoilerIgnitionOperation

1.Theoldpowerplantopenstheplantauxiliarysteam,andifplantauxiliarysteampressureisnormal,puttheplantauxiliarypipeintooperation.

2.Checkthemaintankoillevelisnormal.Ifoiltemperatureis35℃,starttheexhaustfan,DClubricatingoilpumpandputjackingoilpumpintooperation.

3.Checkthetopshaftpumpinletoilpressurenormal,startthetopshaftpump,putthetopshaftpumpsystem

4.Checkthebearingshaftoillevelisnormal,starttheturninggear.

5.StarttheEHoilpumpforoilcirculation

6.opencondensatewaterrecyclingvalve,startthecondensatepumptofeedwatertothedeaerator.Putcondensatepumpintointerlockingprotectionandfeedwaterto2000mmorso.Deaeratorboilandheattomaintainwatertemperatureof70~80℃

7.Checkthenormalwatersupplypump.Ifwatersupplysystemisnormal,startwaterpumpifrequiredbyboiler.Putwaterpumpinto"interlock"operation.

8.Puthighpressureheaterwatersideintooperation,openhighpressuredrainagewater,andputhighpressureheaterprotectionintooperation.

9.Beforefeedingthewatertoaboiler,opentheairexhaust,saturated,overheatedairvalve;openoverheating,andreheatingdrainagevalve.

10.Boilerfeedingwater:

turnofftheeconomizerrecycling,usewaterbypasssystemtocontrolthefeedingwaterspeed,checkthetemperaturedifferenceofupperandbelowwallofsteamdrumisnotmorethan40℃anddeaeratorwatertemperatureisbetween50-100℃

11.Drumwaterlevelis-100mm,stopthefeedingwater,opentheeconomizerrecyclingvalve;

12.Puttheboilerbottomheatingdeviceintooperationtocontrolthatthesteamdrumwalltemperaturechangerateis<1.67℃/min,drumtemperaturedifferencebetweentheupperandlowerwallis<40℃

13.Furnacewater100~120℃,stopheatingdeviceofthebottomofboiler

14.Turnoffavalvewhichkeepsvacuum,startvacuumpumpandcondenserisinthevacuumstate.Vacuumpumpputinto"interlock"operaton.

15.Ifcondenservacuumisgreaterthan-40KPa,theboilerisreadytoignite.

16.Ifcondenservacuumisgreaterthan-70KPa,openthefollowingdrainagetotheexpansioncontainer,andputintoautomationoperation:

1)#1,2frontandbackdrainageofelectricmainvalve

2)#1,2middleconnectingvalvedrainage

17.Putintotheboilerinterlockandfan-relatedinterlockintooperation

18.Starttheairfluesystem:

1)startNo.1,2IDF,keepthefurnacenegativepressureat-50~-100Pa

2)starthighpressurefluidizationfan,putintointerlockingoperation

3)startNo1,2secondaryfan,andadjustthesecondaryairisabout36000Nm3/h

4)startNo.1,2primaryairfan.Atotalamountofairfortheminimumcriticalfluidflowisabout120000Nm3/h

5)startthelimestonefanrunning

19.Afterfurnacecompletespurge,MFTresetsafterpurging

20.Adjusttheprimaryandsecondaryairsystemrelatedmanualvalvedegree

21.Afterfurnacecompletespurge,MFTresetsafterpurging

22.Accordingtotheboilerneed,putthebypasssystemintooperation,andtheboilerisignited

23Putthelow-pressurecylinderwaterspraydeviceintooperationandcast"automation"status.

BoilerIgnition

1.Confirmtheburnercontrolmodeisinthe"programstart"mode,andigniteburner

2.PutFSSSsystemrelatedprotectionreoperation.

3.Burnthebedburner,accordingtothetemperaturerisecurve,adjusttheburningrateofbedburner,controlthefollowingparametersandthenwithinthescopeof:

Bedtemperatureriserate≯100℃/h

Steamdrum,thelowerwalltemperature≤40℃

Saturationtemperaturechangerateis≤56℃/hsteamflowisbelow10%.Theoutlettemperatureofcyclingseparatorshouldnotexceed482℃.

4.Accordingtothebedtemperaturechanges,puttheburnerintoopearation

5.Whenthesteampressureexceeds125℃,closetherelevanthydrophobicdoor,starttheshaftandfanoperation,themainsteampressureof0.98Mpa,themainsteamtemperatureof250℃,beforetheturbineintheforward.Firstputinthelow-pressurecylinder,sendtothehigh-pressurecylinderseal.

6.Ifdrumpressureis0.1~0.2MPa,thefollowingworkshouldbedown:

1)Turnoffthesuperheaterairexhaustvalve

2)checkthedrainagevalveintheswitching-onposition,openthehydrophobicexpansiontankattempetatortomaintainthetemperaturewhin80℃

7.Whenthedrumpressurerisesto0.2~0.3MPa,thefollowingworkshouldbedone:

1)Turnoffallairvalveintheboiler

2)Accordingtothedrumlevel,withthebypasstotheboilercontinuouswater,putwaterautomaticallyintooperation

8.Fullyopen#1,2electricmaingate,closeitsbypassvalve

9.Whenthedrumpressurereaches0.5MPa,thefollowingworkshouldbedone:

thewatertankunderthejointboxandthedownfalltoconductacomprehensivesewage

10.Whendrumpressurerisesto1.0MPa,thefollowingworkshouldbedown:

Closethefurnacesideofthesuperheatedsteamsystemdrainagevalve

11.Whenthedrumpressurerisesto1.5MPa,closethereheatersystem

12.PutintotheturbineETSsystemoperation

Rollingtofixedspeed

1.rollingcondition:

1)sidemainsteampressureis0.98MPa

2)sidemainsteamtemperatureis250℃

3)Thedifferencebetweenthemainsteamandthereheatsteamtemperatureisnotmorethan50℃

4)Condenservacuumis41~48KPa

5)oilcooleroutletoiltemperatureis40~45℃

6)Lubricatingoilpressureis0.098+0.02MPa

7)Adjusttheoilpressure:

anti-fueloilis14+0.2MPa,turbineoil:

1.96+0.1MPa

8)thebearingreturnoiltemperatureandthetopshaftoilpressureisnormal

9)turninggearrunsnormallyandcontinuousturninggeartimeisnotlessthan4hours

10)Theabsolutevalueofthelargeaxisdoesnotexceed0.05mm

11)Temperaturedifferenceofhighandmediumpressurecylinderislessthan50℃

12)Theexpansionandaxialdisplacementiswithinthequalifiedrange

13)ETSinputisnormal,withoutanyalarmsignal

2.Thefollowingupperlimitsshouldbecontrolledduringtheacceleration(load)process:

1)Themainsteamtemperaturerisingrateof2.5℃/min

2)Reheatsteamtemperaturerisingrate3.5℃/min

3)themainsteampipe,reheatsteampipewalltemperaturerisingrateof7℃/min

4)Therelativeexpansionofthehighpressurecylindershallnotexceed+8.5~-3.0mm

5)Therelativeexpansionofthelowpressurecylindershallnotexceed+8.0~-4.5mm

3.Turbinerollingoperation:

Ifclicklatch-offswitchonthemainDEHandsolenoidvalveindicatorislitstartindicator;clickstart-up/shut-downbuttonandclickpressuremainsteamvalve,DEHcontrolhighpressureandmainvalvefullopen.MainscreenTV1,TV2,RSV1,RSV2indicatestofullposition

4.Ifthemainvalveisturnedon,clickthebutton.Iftheredindicatorbuttonontherightsideoftheredlightislit,andtheredbuttonontherightsideoftheshutdownbuttonisoff;

5.Clickonthemainscreeninthe"check"button,checkthelightslit,thesteamengineto100r/minratebegantoincreasethespeed,whenthespeed>4.3rpm,checkthecarautomaticallytrip,

4.Whentherotatingspeedreaches500r/min,executeshutdownoperation,shutdownthehighpressurecontrolvalve,motorrotatingspeedcoastingandfrictiontest.

5.Clickthebutton“cancel”whileendingthefrictiontest,theprocesswillbeovertillitsindicatorlightrunout.

6.Ensureitworksnormallyafterfrictiontest,pressspeed-upcontrolbuttononthemainframe,choosemanualspeed-upmethod.

7.3000r/min100r/minClickrotatingspeed/speed-u