钻孔灌注桩方案英文.docx

《钻孔灌注桩方案英文.docx》由会员分享,可在线阅读,更多相关《钻孔灌注桩方案英文.docx(20页珍藏版)》请在冰豆网上搜索。

钻孔灌注桩方案英文

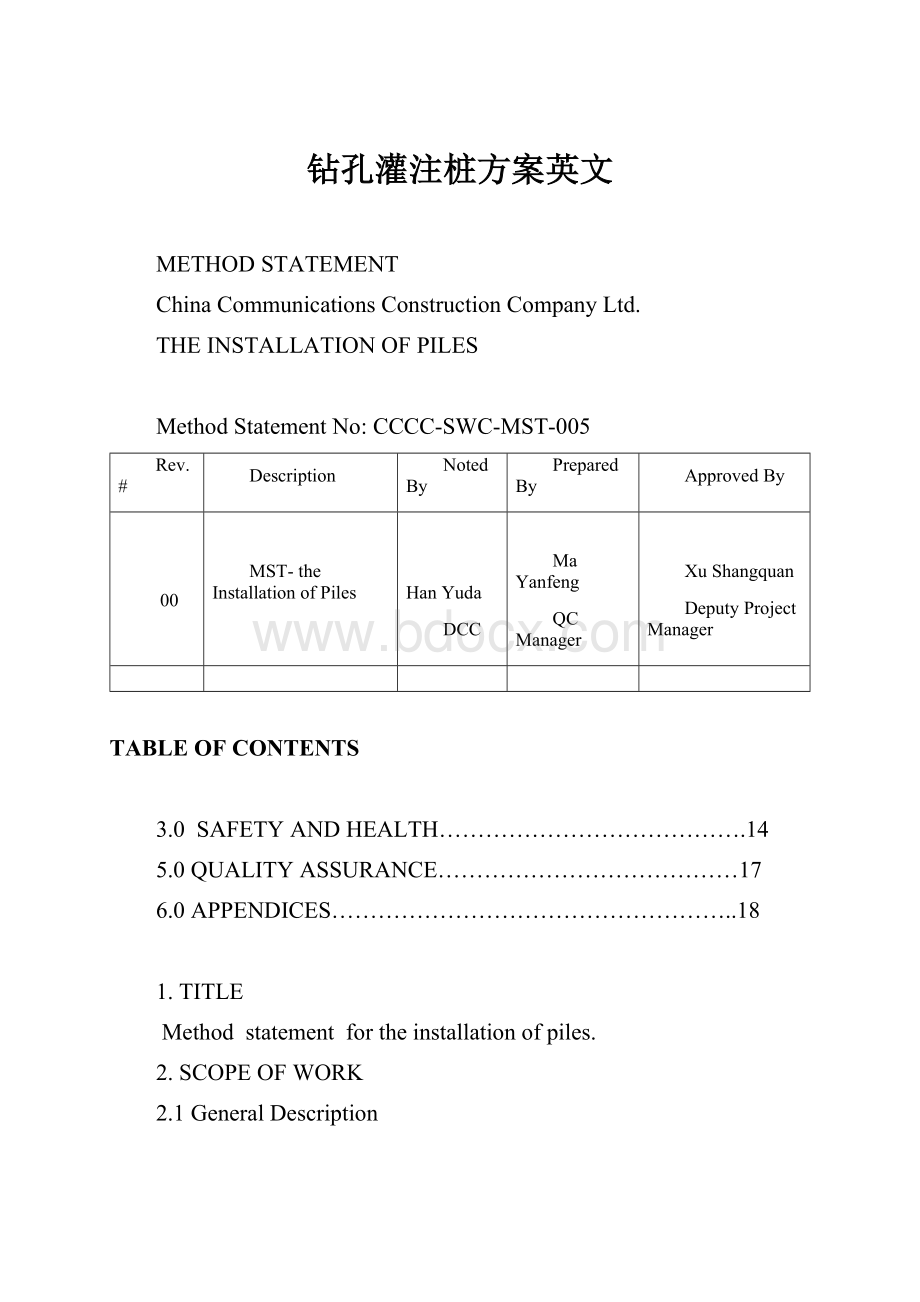

METHODSTATEMENT

ChinaCommunicationsConstructionCompanyLtd.

THEINSTALLATIONOFPILES

MethodStatementNo:

CCCC-SWC-MST-005

Rev.#

Description

NotedBy

PreparedBy

ApprovedBy

00

MST-theInstallationofPiles

HanYuda

DCC

MaYanfeng

QCManager

XuShangquan

DeputyProjectManager

TABLEOFCONTENTS

3.0SAFETYANDHEALTH………………………………….14

5.0QUALITYASSURANCE…………………………………17

6.0APPENDICES……………………………………………..18

1.TITLE

Methodstatementfortheinstallationofpiles.

2.SCOPEOFWORK

2.1GeneralDescription

Thescopeofworksincludesmobilizationofpilingequipment,drillingandconcretingtools,mechanicalaccessoriesandmanpowertoinstallthedrilledcast-in-placepiles.Detailsofthedrilledpilesaregivenbelow.

a.PileDiameter:

1200mm.

PileLength:

18m

Totalnos.:

48.

b.PileDiameter:

1000mm.

PileLength:

18m

Totalnos.:

76.

Twonos.preliminarytestpileshaving1000mmand1200mmdiametershallalsobeinstalledandtestedinadditiontotheabovementionedworkingpiles.Thelocationofthetwotestpileshavebeenshowninthismethodstatement,andshallbediscussedandagreedwithRCEngineer.

Thismethodstatementcoversthegeneralmethodologyfortheinstallationofthesepiles.

2.2PlantandEquipment

Toperformthenecessarytasks,thefollowingmainequipmentsshallbeavailableonsite:

a.HydraulicDrillingRig

b.CrawlerCrane50T

c.Excavator

d.Primemoversandtrailers

e.Weldinggenerators

f.Drillingandconcretingtools

g.Coaster

h.Lightvehicle

i.Liftinggears/devices

page1of18

Thenumberofthedifferenttypesofequipmentavailableonsitewilldependdirectlyontheextentofwork,andmightvaryduringdifferentphasesofthesubjecttask.Cranesandtheirrespectiveoperator’scertificatesshallbeavailableonsiteallthetime.

2.3Material

2.3.1Generalmaterial

Thematerialsneedtocompleteapilelistedbelow:

a.Steelreinforcementcagewithplasticspacersandfixing

b.ConcreteofapprovedmixDesign

c.Controlledslurry

d.Disposalofexcavatedmaterialshallbecarriedoutasnecessarytofacilitatetheworks,meetingalllegalrequirement,andasdirectedbytheRoyalCommision.

2.4SitePlanning&Preparation

2.4.1Sitelayoutandthelocationofthetestpiles

Thetestpilesshallbeinstalledinthefollowingdrawings:

page2of18

Furthermore,thetestpilesshallbewelldisposedandmakesurethetestpileswouldnotaffectthearoundutilities.

TheinternaltrafficarrangementswillbemadeinconsultationwithHSEpersonnelasspecified:

Equipmentwillbeparkedatdesignatedparkingareas.

2.4.2Permitsandcoordination

a.Permitsandcertificates:

Wewillobtainallnecessarypermitsfortheinstallationofpilesanditsrelevantactivitiesateachlocationasindicatedinmethodstatement.Allequipmentsshallhavemaintenancerecords.Recordsoftheseinspections,maintenancecertificatesanddailychecklistswillbeavailableatsitepriortostartofwork.Acopyofthesedocumentswillbekeptwithequipmentoperators.

b.Coordinationofworkswithothercontractors

Othercontractorswillbeprovidedwithadequatetrafficaccessadjacenttositeareashighlightedearlier.Incaseofanyconflict,theissuewillberaisedanddiscussedimmediatelywiththeresponsiblecontractor’srepresentativeformitigationmeasurestobetaken.

2.4.3Methodology

a.PileDesign

Thepiledesignhasbeentackledbasedonthegeotechnicalrecommendation.ThepiledetailsshallbesubmittedinshopdrawingsforRCapprovalbeforeexecution.

b.DemarcationofPileLocations

Aworkingplatformofthepilingequipmentsshallbemadewithminimumheightof1.00mabovecut-offlevel.Surveyworksestablishingthepilelocationshallbedoneontheworkingplatform.

page3of18

ThestepwouldinvolvecarefulsitesurveyanddemarcationofpilelocationsinaccordancewithapprovedIFCdrawing.Thecenterofthepileshallbefixedatsitebydrivingasteelpinasmarkwiththelengthofapproximately200mmand150mmofitshallbeunderthegroundbelowtheworkingplatformlevel.Atprotrudingsteel,aredcoloridentificationribbonshallbetiedtotopofthesteelpin,aswecanseeintheabovepicture.Subsequently,tworeferenceoffsetpointsshallbedrawninorthogonaldirection2mfromthecenterofthepilelocationformonitoringofpre-drillingholes.Theseorthogonaloffsetsshallbethereferencealsoduringtheinstallationofcasing.Fixingtworeferencesoffsetpointsandalignmentofrockaugerisshownintheillustrationphotobelow:

FixingoftwooffsetpointsAlignmentofaugertopilecenter

page4of18

Afterfixingtwoorthogonaloffsetpointsandalignmentoftherockaugerinthepilecenter,pre-drillingoftheboreshallcommenceasshowninthephotobelow.

c.InstallationofTemporaryCasing

Inordertosupporttheoverburdensoilfromcollapsingduringthepileinstallationphaseandinordertoensurethatdeviationofthepilepositionatthecut-offlevelisinlinewiththeprojectspecifications,atemporarysteelcasingapproximately3.0mlongandhavingdiameterslightlygreaterthanthepileshallbeinstalledusingahydraulicpilingrig.Acasingadaptorshallbeattachedtotherotarydrivingheadofthehydraulicpilingrigandthetemporarysteelcasingshallbedriventhroughthesoilatthedesignatedposition.

page5of18

Installationoftemporarysteelcasingwithahydraulicpilingrig

Duringdrivingofthecasing,ahandlevelandwoodenframesextendingfromthereferencecontrolpointsshallbeusedtoensurethat(a)thecasingisdrivenverticallyineachofthetwoorthogonaldirectionsandthecenterofthecasingisalignedwiththepilecenter.

d.Drillingtodesigndepthandcleaningofpilebasewithcleaningbucket

Oncethetemporarysteelcasinghasbeeninstalleduptotherequiredlevel,

drillingofthepileboreshallbeundertakenusingdrillingbucketanddrillingaugermountedonthepilingrig.Drillingbelowthetemporarycasingshallbecarriedoutusinggroundwaterasdrillingfluidorbentonitewhicheversuitsthein-situgroundconditions.Trialboresshallbedrilledusingwaterasdrillingfluid.Incasesomeboreinstabilityisobservedusingthissystem,drillingfluidshallbechangedtothebentoniteslurry.Duringdrilling,itshallbeensuredthattheboreremainsfullofwaterorbentoniteslurrytopreventcollapseoftheborewalls.Incaseofbentonitesystem,thebentoniteshallbemixedandstoredinsteeltanksinaccordancewiththeprojectspecificationsfromwhereitshallbepumpedtothepileboreasdrillingproceeds.BentonitepropertiesshallbecontrolledwithinthespecifiedlimitsgiveninTable-A.

page6of18

TABLE-A.

PROPERTYTOBEMONITORED

TESTINGAPPARATUS

VALUESDURINGDRILLING

VALUESPRIORTOLOWERINGOFSTEELCAGE

DENSITY

MUDBALANCE

LESSTHAN1.20g/ml

LESSTHAN1.10g/ml

VISCOSITY

MARSHCONE

30–70SECONDS

LESSTHAN45SECONDS

SANDCONTENT

SANDCONTENTKIT

NOLIMIT

LESSTHAN6%

pH

pHStrips

7TO12

7TO12

Thedrillingprocessshallcontinueuntiltherequireddepthisachievedasindicatedinapproveddrawings.Thepicturebelowshowsthehydraulicrigperformingthepiledrillingoperation

Drillingofpilebore

page7of18

Subsequently,theboreshallbecleanedwithaflatbottomcleaningbucket(seephotobelow)toremoveallloosematerialsdepositedduringthedrillingoperation.Duringcleaning,QCengineerandPilingIn-chargeshallmonitorifthereisnoexcessivematerialremovedduringcleaningprocess.

Cleantheboreuntilthatitisclearandwithoutanyloosematerialsaround.Cleanlinessoftheborecanbefeltduringthesoundingofthefinaldepth.Duringpullingofmeasuringtapewithweightattheend,itismovingfreelyandnoresistancefeltduringsuchexercises.

Cleaningofborewithflatbottombucket

Withagraduatedtape,thefinaldepthoftheborewillbemeasuredaftercleaning.Thedepthsofthepileshallbemeasuredfromthetopofthecasingwithknownelevationdowntothetoeofthepile.Afterinspection,thecasingshallbecoveredwitha25mmsteelmeshandtiedtothecasingholetoprotecttheworkerfromfallingintothebore.Depthmeasurementisshowninthephotoontherightside

Soundingoffinaldepthaftercleaning

page8of18

e.ToleranceofPilePosition

Pilepositionatworkingplatformshallnotdeviatelaterallyfromtheirdesignpositionbymorethan75mm.Casingverticalityshallnotbemorethan1:

100.

f.PlacementofSteelCages

Reinforcingsteelbarsshallbedeformed,grade60,andshallbeassembledbysteelfixercomplywiththedrawings.Allreinforcingsteelingtobeembeddedinthepilesandextendingfromthepilestobeembeddedinpilecapsandotherfoundationelementsshallbefusionbondedepoxy-coated.Allspacerrollers,supportbars,spreaderbars,sideformspacers,tiewire,andaccessoriesnecessarytoholdthereinforcingbarssecurelyandaccuratelyinpositionshallbeshownandscheduledwithinthereinforcingsubmittals.

Onceithasbeenverifiedthattheborehasbeendrilledtotherequireddepthandthebottomoftheborehasbeenproperlycleaned,steelcagefabricatedaccordingtoapprovedshopdrawings.Sufficientnumberofweldedinnerringsforrigidityandadequateconcretespacersforcover(allinaccordancewithapprovedshopdrawings)shallsubsequentlybeloweredintothebore.Oncethereinforcementcagehasbeenlowered,thecageshallbefirmlyhungfromthetemporarysteelcasingusingsteelwireropesuchthatthereisaminimum100mmgapbetweenthetip