中外碳素结构钢对照翻译.docx

《中外碳素结构钢对照翻译.docx》由会员分享,可在线阅读,更多相关《中外碳素结构钢对照翻译.docx(17页珍藏版)》请在冰豆网上搜索。

中外碳素结构钢对照翻译

ThecomparisonofchemicalcompositionandphysicalpropertyofcarbonstructuralsteelmanufacturedinChinaandBritain

1. Generalintroduction

1.1 Manufacturingofcarbonstructuralsteelhasmorethan80yearshistoryinChina.ItwassmeltedbyMartininitiallyandthenbyconverterorelectricalfurnace,convertersteelisdevelopedfromsideblownconvertertooxidativeconverter..Ingeneral,Chinahasalreadyaccumulatedmaturesmeltingoperationexperienceandqualityoftheproductshasbeengoodenoughtocomparewithforeigncorrespondingsteelgrade.Forexample,bothphysicalpropertyandchemicalcompositionofsteelQ235(madeinChina)wassimilarwithforeignproducts,suchassteelA36(madeinUSA),steelCT-3(madeinRussia),steelSS41,SM41(madeinJapan),steel43A-C(madeinBritain),steelFe360(madeinEurope),steelST-37(madeinGermanyandAustria).

2. GeneralsituationofcarbonstructuralsteelinChina

2.1 Accordingtothedifferenceofcarboncontent,carbonstructuralsteelcanbeclassifiedintolowcarbonsteel,mediumsteelandhighcarbonsteel.Generallyspeaking,theonewith0.03%~0.25%carboncontentiscalledlowcarbonsteel;theonewith0.26%~0.60%carboncontentiscalledmediumsteel;theonewith0.60%~2%carboncontentiscalledhighcarbonsteel.Inbuildingstructure,lowcarbonsteelischieflyused.

2.2 Carbonstructuralsteelisextensivelyusedduetoitwaseasytosmelt,withlowcostandvariousgoodhandlingcharacteristics.SteelQ235hasabetterperformanceinstrength,machiningandweldingproperties.Itisfrequentlyusedinindustryandcivilarchitecture,anditisalsothelarge-tonnagesteelgrademanufacturedinChina.

2.3 Classificationandpropertyofcarbonstructuralsteelisshownasfollowing:

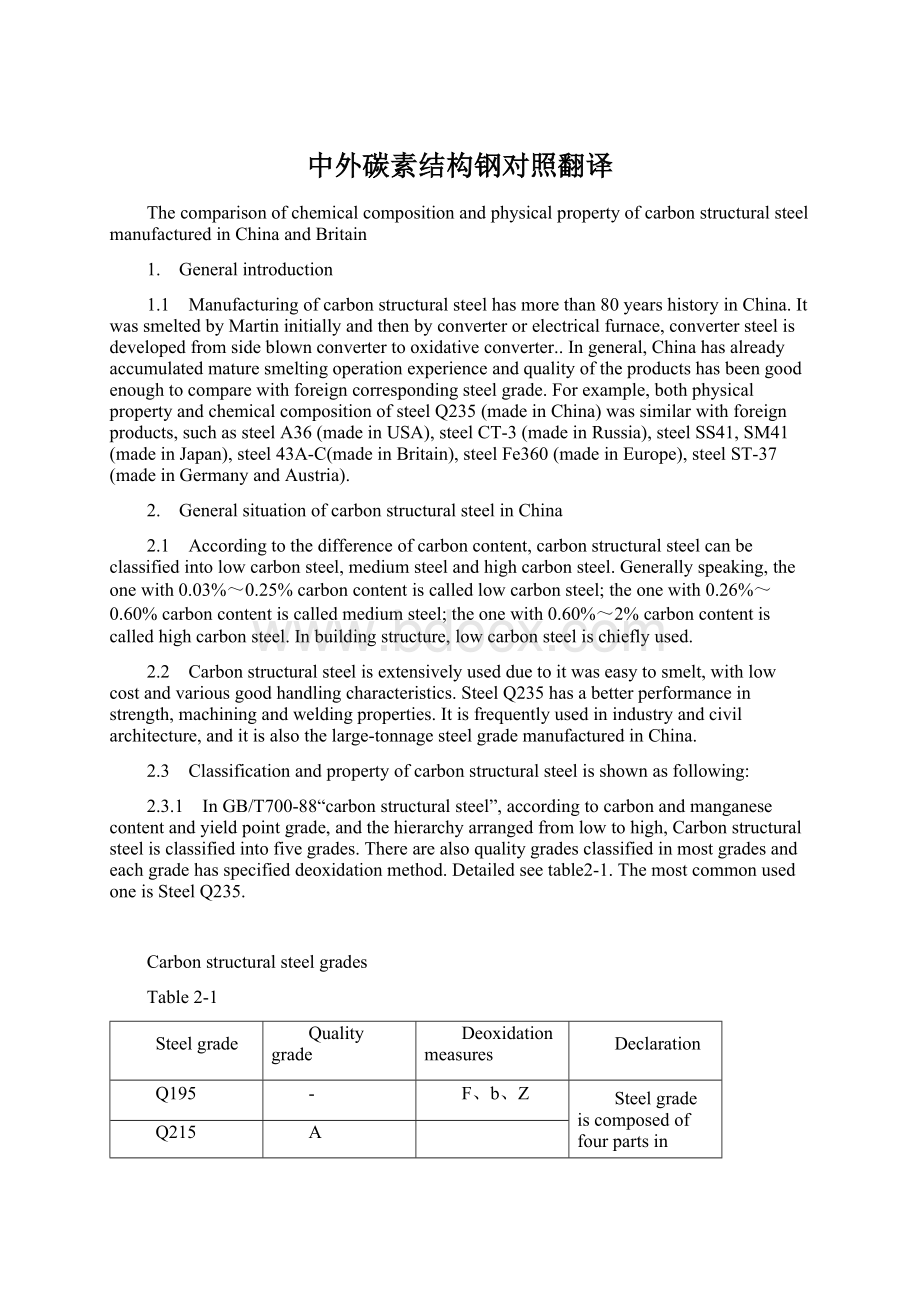

2.3.1 InGB/T700-88“carbonstructuralsteel”,accordingtocarbonandmanganesecontentandyieldpointgrade,andthehierarchyarrangedfromlowtohigh,Carbonstructuralsteelisclassifiedintofivegrades.Therearealsoqualitygradesclassifiedinmostgradesandeachgradehasspecifieddeoxidationmethod.Detailedseetable2-1.ThemostcommonusedoneisSteelQ235.

Carbonstructuralsteelgrades

Table2-1

Steelgrade

Qualitygrade

Deoxidationmeasures

Declaration

Q195

-

F、b、Z

Steelgradeiscomposedoffourpartsinsequenceas:

letterrepresentedyieldpoint,numericvalueofyieldpoint,qualitygradesymbolsanddeoxidationmethod.

Forinstance:

DefinitionofeachsymbolinQ235-B-Fis:

Q-firstletterinChinesephoneticof“yieldpoint”(屈)

A,B,C,Dindividuallyisqualitygrade

F-firstletterinChinesephoneticof“boilingsteel”(沸)

B-firstletterinChinesephoneticof“semikilledsteel”(半)

Z-firstletterinChinesephoneticof“fullkilledsteel”(镇)

TZ-twolettersinChinesephoneticof“speicalfullkilledsteel”(特镇)

Q215

A

F、b、Z

B

Q235

A

F、b、Z

B

C

Z

D

TZ

Q255

A

Z

B

Q275

-

Z

2.3.2Carbonstructuralsteelissmeltedbyoxidationoven,Martinorelectricalfurnace,unlessspecialrequirementfromdemandingparty(markedincontract),smeltingmethodisgenerallydeterminedbysupplier.

2.3.3Carbonstructuralsteelisgenerallydeliveredunderhotrolling(includingcontrollingrolling)conditionaccordingtodemandingparty’srequirement,throughagreementofbothsides,itcanalsobedeliveredundernormalizingtreatmentcondition(exceptforgradeAsteel)

2.3.4RolldownvariousgradeBsteelwithboilingsteel,itsthickness(diametral)isgenerallynotmorethan25mm

2.3.5Carbonstructuralsteel’schemicalcomposition(meltinganalysis)shouldcomplywithspecificationintable2-2.

2.3.6Carbonstructuralsteel’smechanicalpropertyshouldcomplywithspecificationintable2-3(tensileandimpacttest)andtable2-4(coldbendtest).

2.4Intensileandimpacttest,samplesofsteelplateandbandshouldadoptfromthecrosssection,elongationof1%lowerthantable2-3isallowed;samplesofstructuralsectionshouldadoptfromlongitudinaldirection.

2.5ColdbendtestofvariousgradeAsteelshouldbeproceededwhendemandingpartyrequires.Whencoldbendtestisqualified,theupperlimitoftensilestrengthisnoneedtobeasoneofthedeliveryconditions.

Carbonconformationsteel’schemicalconstitution

Table2-2

Steelgrade

Qualitygrade

Chemicalconstitution%

Deoxidationmethod

C

Mn

Si

S

P

Nogreaterthan

Q195

-

0.06~0.12

0.25~0.50

0.30

0.050

0.045

F、b、Z

Q215

A

0.09~0.15

0.25~0.55

0.30

0.050

0.045

F、b、Z

B

0.045

Q235

A

0.14~0.22

0.30~0.65

0.30

0.050

0.045

F、b、Z

B

0.12~0.20

0.30~0.70

0.045

C

≤0.18

0.35~0.80

0.040

0.040

Z

D

≤0.17

0.035

0.035

TZ

Q255

A

0.18~0.28

0.40~0.70

0.30

0.050

0.045

Z

B

0.045

Q275

-

0.28~0.38

0.50~0.80

0.35

0.050

0.045

Z

Notes:

① Theuppercontentl