ansys面与面接触分析实例doc.docx

《ansys面与面接触分析实例doc.docx》由会员分享,可在线阅读,更多相关《ansys面与面接触分析实例doc.docx(14页珍藏版)》请在冰豆网上搜索。

ansys面与面接触分析实例doc

面与面接触实例:

插销拨拉问题分析

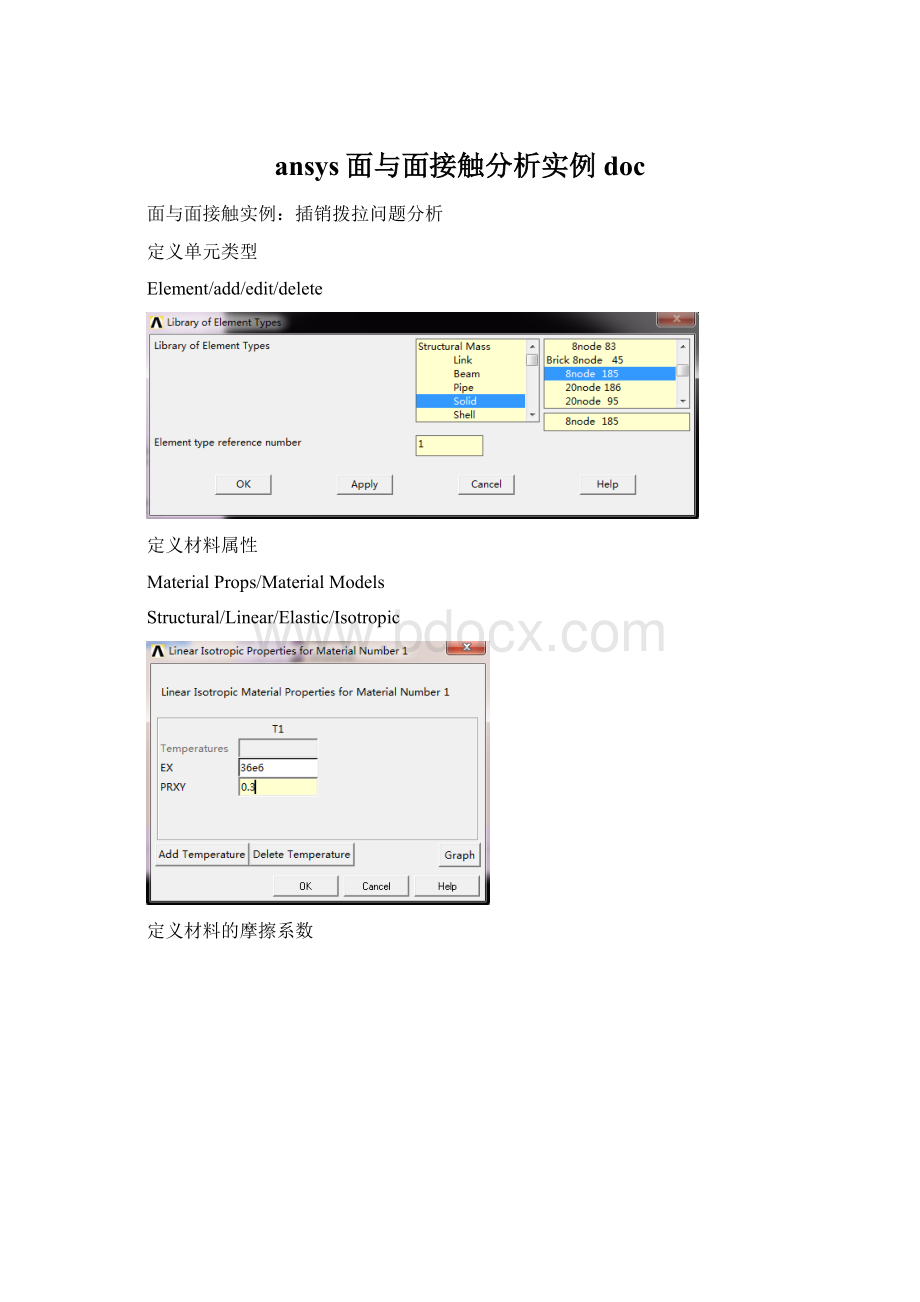

定义单元类型

Element/add/edit/delete

定义材料属性

MaterialProps/MaterialModels

Structural/Linear/Elastic/Isotropic

定义材料的摩擦系数

建立几何模型

Modeling/Create/Volumes/Block/ByDimensions

X1=Y1=0,X2=Y2=2,Z1=2.5,Z2=3.5

Modeling/Create/Volumes/Cylinder/ByDimensions

Modeling/Operate/Booleans/Subtract/Volumes

先拾取长方体,再拾取圆柱体。

Modeling/Create/Volumes/Cylinder/ByDimensions

划分掠扫网格

Meshing/SizeCntrls/ManualSize/Lines/PickedLines

拾取插销前端的水平和垂直直线,输入NDIV=3

再拾取插座前端的曲线,输入NDIV=4

PlotCtrls/Style/SizeandShape,在Facets/elementedge列表中选择2facets/edge

建立接触单元

Modeling/Create/Contactpair,弹出ContactManager对话框,如图所示。

单击最左边的按钮,启动ContactWizard(接触向导),如图所示。

单击PickTarget,选择目标面。

选择接触面

定义位移约束

施加对称约束,DefineLoads/Apply/Structural/Displacement/SymmetricB.C/OnAreas,选择对称面。

再固定插座的左侧面。

设置求解选项

AnalysisType/Sol’sControl

求解:

Solve/CurrentLS

绘制装配应力图

GeneralPostproc/PlotResults/ContourPlot/NodalSolution,选择Stress/vonMisesstress

求解拨拉过程

选择Z=4.5处的所有节点。

DefineLoads/Apply/Structural/Displacement/OnNodes,弹出ApplyU,ROTonNodes拾取框,单击PickAll按钮,选择UZ,在Displacementvalue输入1.7

Select/Everything

AnalysisType/Sol’sControl

Solve/CurrentLS

结果后处理

扩展模型:

Style/SymmetryExpansion/Priodic/CyclicSmmetry,在弹出的对话框中选择1/4DihedralSym

选择GeneralPostproc/ReadResults/Bytime/frequency,在TIME域输入120。

选择插销中与插座接触的单元,在SelectEntities中选择Element,在列表中选择ByElementname,再ElementName域输入174

Plot/Elements

GeneralPostproc/PlotResults/ContourPlot/NodalSolution,在对话框中选择Contact/ContactPressure

读入载荷步2结果。

ReadResults/ByLoadStep

绘制拨拉过程的应变变化动画

PlotCtrls/Animate/OverResults,弹出如图所示的对话框。

命令流操作:

(1)建立几何模型

/filename,bolt

/title,bolt_pullinganalysis

/PREP7

Block,-2,2,-2,2,2.5,3.5

/view,1,1,1,1

/ang,1

/rep,fast

Cylind,0.49,,2.5,3.5,0,360

Vsbv,1,2

Cylind,0.5,,2,4.5,0,360

/pnum,volu,1

Wpstyle,0.05,0.1,-1,1,0.003,0,0,,5

Wpstyle,,,,,,,,1

Wpro,,,90

Wsbw,all

Vdele,4,,,1

Vdele,6,,,1

Wpcsys,-1,0

Wpro,,90

Vsbw,all

Vdele,p51x,,,1

Wpcsys,-1,0

Wpstyle,,,,,,,,0

(2)定义单元类型、材料模型和网格划分

Et,1,solid185

Mptemp,,,,,,,,

Mptemp,1,0

Mpdata,ex,1,,36e6

Mpdata,prxy,1,,0.3

Lesize,4,,,3,,,,,0

Lesize,10,,,3,,,,,0

Lesize,18,,,4,,,,,0

Vsweep,all

/shrink,0

/eshape,0.0

/Efacet,2

/ratio,1,1,1

/cformat,32,0

(3)定义接触单元

/com,contactpaircreation-start

Cm,_nodecm,node

Cm,_elemcm,elem

Cm,_kpcm,kp

Cm,_linecm,line

Cm,_areacm,area

Cm,_volucm,volu

/gsav,cwz,gsav,,temp

Mp,mu,1,0.2

Mat,1

Mp,emis,1,7.88860905221e-031

R,3

Real,3

Et,2,170

Et,3,174

R,3,,,0.1,0.1,0

Rmore,,,1.0e20,0.0,1.0

Rmore,0.0,0,1.0,0.5

Rmore,0,1.0,1.0,0.0,,1.0

Keyopt,3,4,0

Keyopt,3,5,0

Nropt,unsym

Keyopt,3,7,0

Keyopt,3,8,0

Keyopt,3,10,1

Keyopt,3,11,0

Keyopt,3,12,0

Keyopt,3,2,0

Keyopt,3,5,0

Asel,s,,,23

Cm,_target,area

Type,2

Nsla,s,1

Esln,s,0

Esurf

Cmsel,s,_elemcm

Asel,s,,,27

Cm,_contact,area

Type,3

Nsla,s,1

Esln,s,0

Esurf

Allsel

Esel,all

Esel,s,type,,2

Esel,a,type,,3

Esel,r,real,,3

/psymb,esys,1

/pnum,type,1

/num,1

Eplot

Esel,all

Esel,s,type,,2

Esel,a,type,,3

Esel,r,real,,3

Cmsel,a,_nodecm

Cmdel,_nodecm

Cmsel,a,_elemcm

Cmdel,_elemcm

Cmsel,s,_kpcm

Cmdel,_kpcm

Cmsel,s,_linecm

Cmdel,_linecm

Cmsel,s_areacm

Cmdel,_areacm

Cmsel,s,_volucm

Cmdel,_volucm

/gres,cwz,gsav

Cmdel,_target

Cmdel,_contact

/com,contactpaircreation-end

(4)定义位移约束

Finish

aplot

/solu

Flst,2,4,5,orde,4

Fitem,2,3

Fitem,2,7

Fitem,2,11

Fitem,2,14

Da,p51x,symm

Flst,2,1,5,orde,1

Fitem,2,19

Da,p51x,all,0

(5)求解装配预应力

Antype,0

Nlgeom,1

Nsubst,1,0,0

Autots,0

Time,100

/status,solu

Solve

Finish

/post1

/efacet,1

Avprin,0

Plnsol,s,eqv,0,1.0

Save

(6)求解拨拉过程

Aplot

Nsel,s,loc,z,4.5

Finish

/sol

Antype,rest

D,all,,1.7,,,,uz,,,,,

Allsel,all

Nsrbst,100,10000,10

Outres,erase

Outres,all,all

Outots,1

Time,200

/status,solu

Solve

Finish

(7)结果后处理

/expand,4,polar,half,,90

Eplot

/post1

Set,,,1,,120

Esel,s,ename,,174

Eplot

/efacet,1

Avprin,0

Plnsol,cont,pres,0,1.0

Allsel,all

Set,2,last,1

/efacet,1

Avprin,0

Plnsol,s,eqv,0,1.0

Plns,s,eqv

Andata,0.5,,0,0,0,1,1,1

finish

/exit,all