22X6m磨机操作手册英文.docx

《22X6m磨机操作手册英文.docx》由会员分享,可在线阅读,更多相关《22X6m磨机操作手册英文.docx(13页珍藏版)》请在冰豆网上搜索。

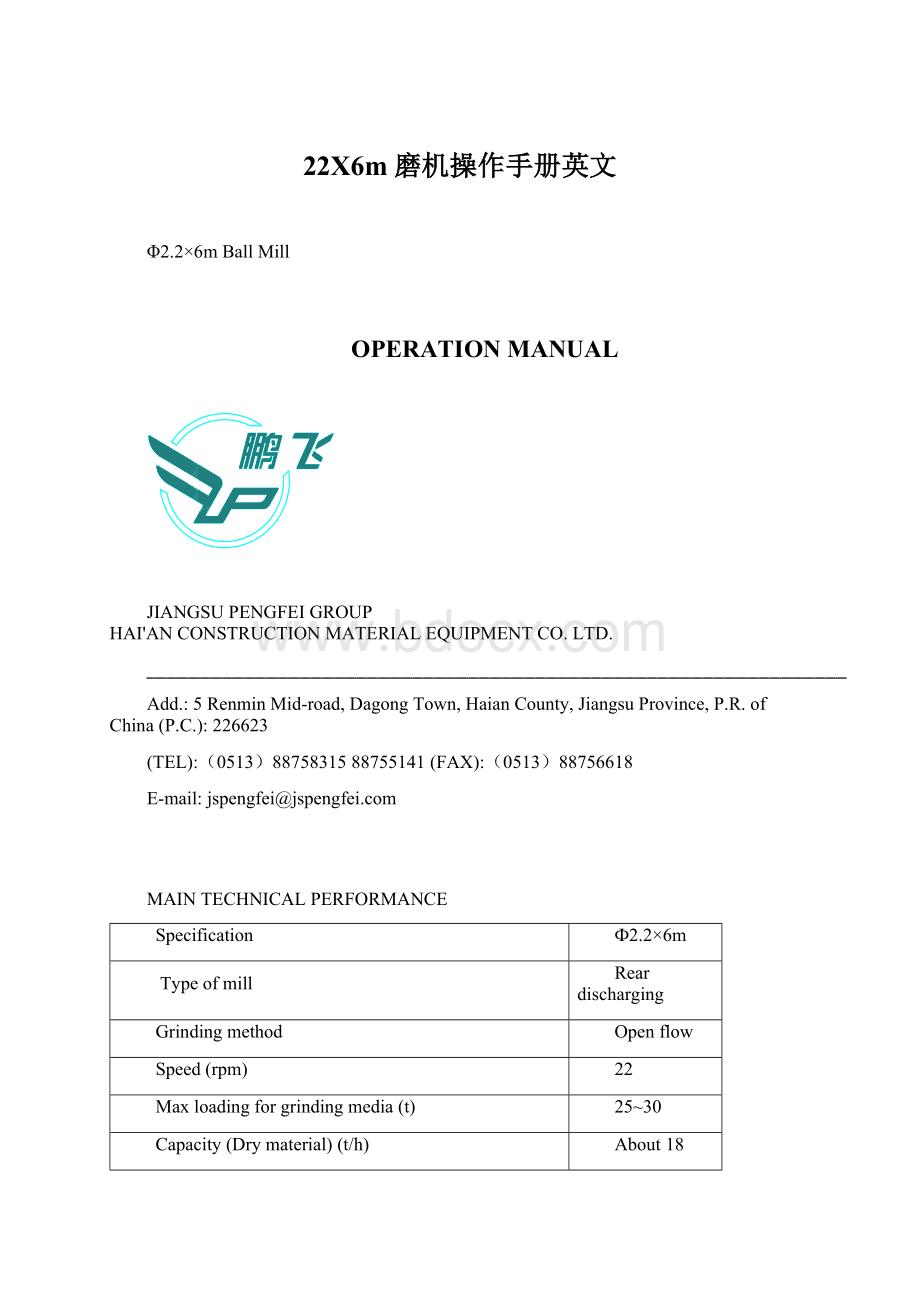

22X6m磨机操作手册英文

Φ2.2×6mBallMill

OPERATIONMANUAL

JIANGSUPENGFEIGROUP

HAI'ANCONSTRUCTIONMATERIALEQUIPMENTCO.LTD.

Add.:

5RenminMid-road,DagongTown,HaianCounty,JiangsuProvince,P.R.ofChina(P.C.):

226623

(TEL):

(0513)8875831588755141(FAX):

(0513)88756618

E-mail:

jspengfei@

MAINTECHNICALPERFORMANCE

Specification

Ф2.2×6m

Typeofmill

Reardischarging

Grindingmethod

Openflow

Speed(rpm)

22

Maxloadingforgrindingmedia(t)

25~30

Capacity(Drymaterial)(t/h)

About18

Effectvolume(m3)

19.9

Finishedproductsize4900holescreeningresidue(cm2/g)

8~10

Motor

Type

JR138-8

Power(kW)

320

Voltage(V)

380

Rotationrate(r/min)

735

Reducer

Type

JDX45

Ratio

5

Weight(t)

46.62

Thinoilstationformainbearing

1.Capacityofthemillisrelativewithfeedingsize&etc,thistableisonlytomakethereference.

2.Equipmentweightisn’tincludethemotorandreducer.

I.PRINCIPLEOFOPERATIONANDUSESOFMILL

Tubemillisahorizontalrotarycylinder,loadinabrasivemediums(generaltheyaresteelgrindingballs,clypeus).Tocrushthematerialsmainlybypercussionenergyoftheabrasivebodieswhentheshellrotarytoliftandfallthem,andthematerialstobecrushed.Duringtheoperationalprogress,byrollandsliderepeatedly,thematerialsweregotslidegrindingandpercussivecrushing.Somassivematerialbecomepowder.

Thismachineismainlyusedingrindingforcementrawmealsandcementclinkers.

II.SUMMARYFORSTRUCTURE

(I)Transmissionsystem

Transmissionsystemiscomprisedofmotor,reductionunit,transmissionshaft,girthgearandpinion(centraldrivemilldon’tusegirthgearandpinion),couplingetc.Thereductionunitisconnectedtothemotorbyspringcoupling,andthepinionisconnectedtothereductionunitbyspringcouplingwhichhasagooddampingcapacityandmayreducetheshockandvibrationinfluenceofmillshellonthereductionunitandincreasetheserviceliftoftheequipmentandconvenienttomaintain,Girthgearisfixedontheflangeofshellbody,shellbodyisrotatedbymotorpassingreducertransmissionshaftpinionandgirthgearrim.Inordertoincreaseserviceliftoftransmissiongears,themillusesthe“largemodified”gear.

(II)Feeddevice

Feeddevicemainlyconsistsofcharginghopper,supports,observationdoor,etc.Linerisfixedinthecharginghopper.Butitalsousesmaterialsaslinertoreduceitswearingforcharginghopper.Thespacersareusedbetweenthehopperandthesupporttoadjustthecentralheightofthehopperbyincreasingordecreasingthespacerpieces.

(III)Rotatingpart

Rotatingparthascharginganddischargingscrew,charginganddischargingTrunnionshafts,girthgear(centraldrivehasn’tgirthgear)shellbody,linersandcompartmentseparators,etc.

Shellbodyismadeofsteelplates,whicharerolledupandwelded.Theplain-endcoversofthesamekindofsteelplatesareweldedontheshellbodyends.Therearemanholesonshellbodywitheachonehasastrengthenedge.Themillhasacoarsegrindingcompartmentandafinegrindingcompartment.ThecircularlinersofZGMn13manganesecastingsteelareboltedontheshellbodyinthecoarsegrindingcompartment.Theshapeofboltsholeisovaltopreventthestressconcentration.Linersareusedinthefinegrindingcompartmentbybolt.ThecompartmentseparatorsofZGMn13manganesecastingsteelaresinglelayer.Thetwomainbearingssupportthewholerotatingpartbytwoquillshafts.Quillshaftsareconnectedwithplain-endcoversbybolts.

(Ⅳ)Mainbearing

Mainbearingsarecomprisedofglobebearings,bearingseatsanduppercovers,etc.Theglobesbearingsareusedforpurposesofautomaticalignmentshaftlinesoftrunnionshafteachother,andmakeregularoillubricationformainbearings.

Thefixedoilrings(beltoilrings)areinstalledonthetrunnionshaftsforlubrication,topreventoilleakage.Smalloilbrushesareinstalledonthebothsidesofmainbearingandoilscrapersareinstalledonthesideofnearshellbody.(Thinoilstationisusedaccordingtocustom’srequirement).

Becausethegrindingproducesalargeamountofheat,themainbearingsarecooledbywatertokeepthenormaloperationofthemainbearings.Heat-insulatingmaterialisfilledintothegapbetweenthescrewtubeandtrunnionshafttopreventheattransfer.

Dischargingdeviceconsistsofdischargingcover,supports,dischargingscreen,etc.Thedischargingscreenisconnectedwithdischargingscrewtubebybolts.Thegroundmaterialdropsintodischargingcoverthroughthescreen.Someobjects(suchasironpieces,bolts,etc.)willberemovedfromexit.Thepipelineconnectedwithdustcollectorisinstalledonthedischargingcover.Airlockdeviceisinstalledonthelowerpartofdischargingcoverwhichisconnectedwithconveyingequipmentinordertoavoidairleak.

III.INSTALLATION

(I)Foundation

1.1Foundationcheckandaccept

(1)Beforeinstallingthemill,thefoundationshouldbeclearedupandcheckedoverforquality,itsstrengthshouldconformtorequirementsofrelevantcommunications.

(2)Arrangementanddimensionofeyeletboltholesoffoundationshouldbeappropriatetoallowmachinerybasedriftprobablyonarbitrarydirection10~20mm.Distancebetweeneyeletboltsandfoundationalholewall,andbetweenlowendofeyeletboltandholebottom,mustbenotlessthan15cm.Dimensionofeyeletboltreserveholerefertotable1.

Table1Eyeletboltholedimensiononcrosssection

Boltspecification

Foundationalholedimensions

Square

Circle

M12

80×80

Φ100

M16

90×90

Φ110

M20

100×100

Φ120

M24

120×120

Φ140

M30

140×140

Φ160

M36

150×150

Φ170

M42

160×160

Φ180

M48

170×170

Φ190

M56

180×180

Φ200

M64

190×190

Φ220

(3)Thereshouldbenosundryarticleandwaterineyeletboltsholes.Beforeinstalling,shouldcoverthemtoavertanysundryarticlefallin.

(4)Foundationoveralldimensionsshouldbeinspected,anditselevationsrelativetofactorybuildingandotherequipmentsshouldfitdesign.

(5)Inordertoadjust(heightofequipment)byfittingspacesthatbetweenfoundationandmachinerybaseplate,therefore,foundationelevationshouldbelower30~50mmthanbasesurfaceofequipment.

(6)Inordertogetintegrativecombinationbetweensecondpourandformerfoundation,therefore,shouldshovelsurfacethatwillbetosecondpourandletthembecomepockmarks(pitdiametermaybe30~50mm),distancebetweenpitseachothermayusuallybeabout150mm.Shovelupnotchesontheirbordersoffoundation.

(7)Foundationtreatment

(a)Shovelitandcutdownbyflatshovelwhenelevationistoohigher,shoveluppockmarksandpatchingpourbyformergradeofconcretewhenitistoolower.

(b)Ifeyeletboltsdrift,mayextendreserveholes,orbakeandmanifesteyeletboltsasdullredandcorrectthem.

1.2Centermarkingboards

Whenfoundationhasbeeninspectedandfitrequirements,accordingtodrawings,whichhavebeenmeasuredmillandhavebeenaltered,thenmayfixcenter-markingboardsinfoundation.(Note:

usingthesamemeasuringtool).

Centermarkingboardsareusuallymadefromsteelrail.I-steelorchannelbeam(channelbar),theirdimensionsabout(150~200mm)×(30~60mm).Fixeddurablytheminfoundation,thenmarkoutcenterpoints,punchverysmallholesbypuncher(orbytheodolite).Theseholesareregardedasbasesofobtainingthepositionsofequipmentforinstallation.

1.3Datumpoints

Datumpointsareregardedasstandardbasesofelevationsforinstallation,tomeasureuptheirelevationsagainst“zeropointofplantdistrict”,andmakemarksonthem.

Datumpointsareusuallymadeofrivets,andweldupapieceof50mm×50mm,thickness10mmofsteelplatesontheheadsofrivets,orwelduptwopiecesof50mmlong,havebeenbentofscrewysteel.Theyareburiedinpredeterminedarea.Alsodatumpointsmaybespotweldedonrelevantreinforcedsteelbar.

1.4Drawinglinesonbase

Therequirementsofdrawinglinesonbaseshouldbeasfollowing:

(1)Distancebetweentwocrosswisecenterlinesonbaseoftwomainbearingitserrorshouldbenotabove1/10ofmillexpansionmoreovershouldbenotabove2mm.

(2)Thepositionoflengthwisecenterlinethatisindicatedbycentermarkingboard,ascomparedtodrawings,theirdisplacementshouldbenotabove±3mm.

(3)Millcenterlinemustparallelseverelytocenterlineoftransmissionshaft,itserrorshouldbenotabove±0.5mm.

(4)Diagonallinesofadjacentbasesshouldbemeasured,andadjustthembeingequaleachother,toobtainappearing90°betweencrosswisecenterlineandlengthwisecenterlineeachother.

1.5Hangcenterline

Thepurposesofhangingcenterlinearetocheck(positional)relationsofeveryparteachotherininstalling.

(1)Tocheckthedistancebetweentwoactualcenterlinesofmainbearingsonbaseplates,andthepositionofcenterpointofmarkingboardbycentermarkingboards.

(2)Tochecktheverticaldistancebetweenmillshellcenterlineandtransmissionshaftcenterline,andtheverticaldistancebetweenthemotorcenterlineandtransmissionshaftcenterlinebycentermarkingboards.

(3)Tocheckthepositionsoftheeyeletboltsholesshouldfitdrawing.

(II)Installingofeyeletbolts

(1)Eyeletboltsshouldhavebeencleaneddownoilstainsandrust,andsmeargreaseonscrewthreadsmakeantirust.Beforeinstallingshouldavertstrictlyforeignmattersfallinbaseholes.

(2)Eyeletboltsshouldbeperpendicularinthebaseholes,theirperpendicularlytolerancesare5/10000.

(3)Belowthenutwhichisontheeyeletboltshouldaddwashermoreovercheckdeviceshouldbeusedforlockingthem.(lockingnutspringwasher)

(4)Theorderoftighteneyeletboltsshouldbeginatcent