Method statament of pipe culvert works.docx

《Method statament of pipe culvert works.docx》由会员分享,可在线阅读,更多相关《Method statament of pipe culvert works.docx(9页珍藏版)》请在冰豆网上搜索。

Methodstatamentofpipeculvertworks

MethodStatementof

PipeCulvertWorks

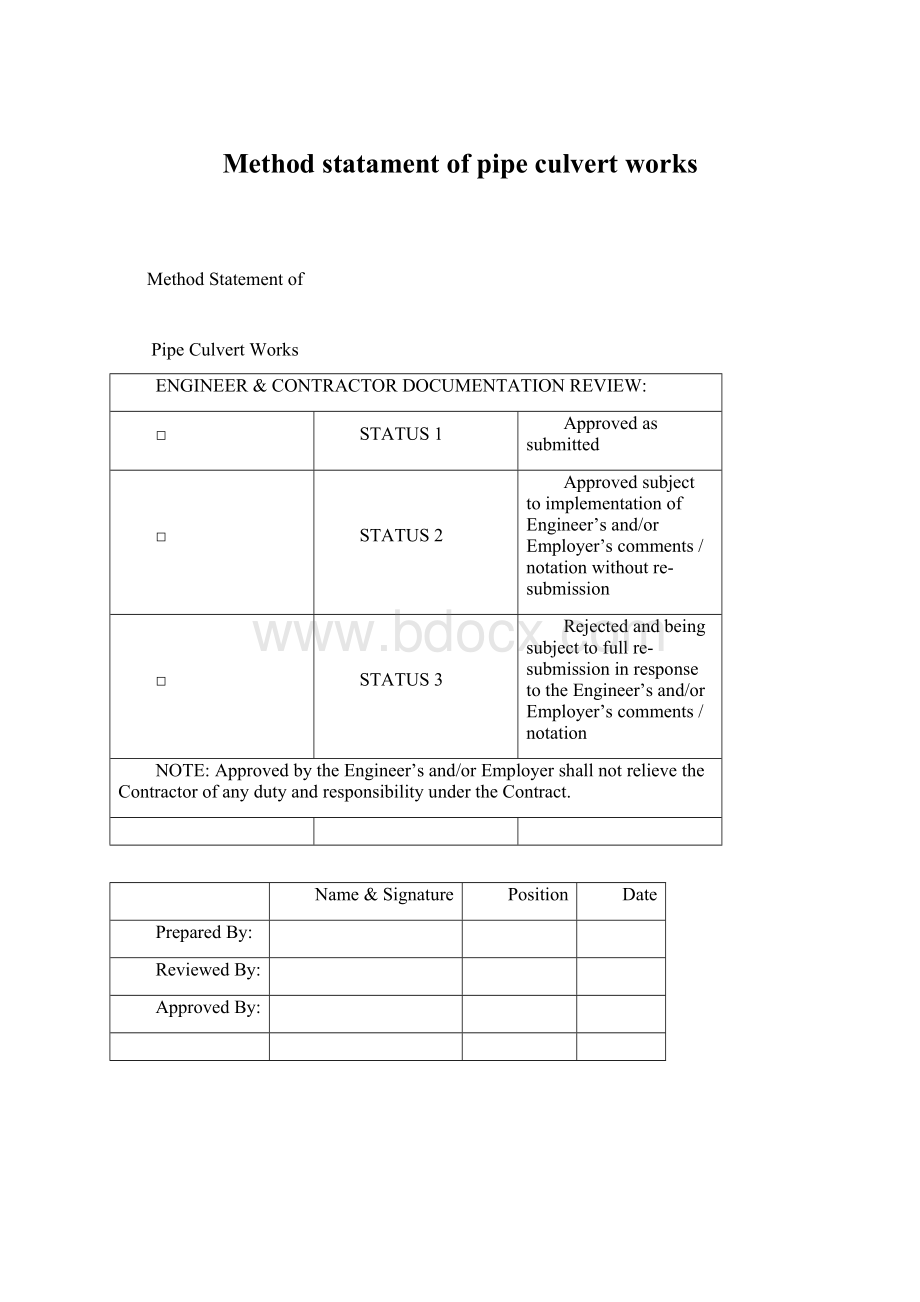

ENGINEER&CONTRACTORDOCUMENTATIONREVIEW:

□

STATUS1

Approvedassubmitted

□

STATUS2

ApprovedsubjecttoimplementationofEngineer’sand/orEmployer’scomments/notationwithoutre-submission

□

STATUS3

Rejectedandbeingsubjecttofullre-submissioninresponsetotheEngineer’sand/orEmployer’scomments/notation

NOTE:

ApprovedbytheEngineer’sand/orEmployershallnotrelievetheContractorofanydutyandresponsibilityundertheContract.

Name&Signature

Position

Date

PreparedBy:

ReviewedBy:

ApprovedBy:

Section

CONTENTS

Page

1.0

Purposeofmethodstatement

1

2.0

ScopeofWorks

1

3.0

Documentstobereferredinthismethodstatement

1

4.0

Responsibilitiesforactivitiesdescribedwithinmethodstatement

1

5.0

ResourcestobeusedfortheWorks

2

5.1Manpower

2

5.2Plant&Equipments

2

6.0

Detailedmethodofcarryingoutthismethodstatement

3

7.0

Inspectionplan

5

8.0

Health&SafetyConsiderations

5

8.1Generalsafetyissues

5

8.2EmergencyArrangement

5

9.0

EnvironmentalConsiderations

6

10.0

Recorddocumentationand/oroutput(s)whichconfirmcompletionofmethodstatement.

6

11.0

Training

6

12.0

Appendices

7

AppendixA

-

RiskAssessment

AppendixB

-

ToolBoxTalk

AppendixC

-

InspectionPlan

AppendixD

-

RICF

1.0Purposeofmethodstatement

Thismethodstatementismadeinordertocontrolthetechnologyandmanagementeffectively,andservesasaguidelineforthepipeculvertworksthatfromGerehuto9mileroad.

2.0ScopeofWorks

ThismethodstatementisapplicabletothepipeculvertprefabricationandinstallationofGerehuto9mileroadengineering.

Pipeculvertsshallbemadeintheprecastyardandtransportedtothesiteforinstallation.

3.0Documentstobereferencedwiththemethodstatement

1)MRS004

2)MRS51

3)AS1289

4)Specificationsforroadandbridgeworks—August1995

5)ProposedGerehuCasiocircleto9-mileroadgeotechnicalinvestigationreport

6)Contractspecification

7)Constructiondrawing

8)ProjectQualityPlan(PQP)

9)ProjectSafetyPlan(PSP)

10)ProjectEnvironmentalPlan(PEP)

11)InspectionPlan(IP)

4.0Responsibilitiesforactivitiesdescribedwithinmethodstatement

4.1TheresponsibilitiesoftheConstructionManager

TheConstructionManagerwillberesponsibleforthecoordinationworkin-betweentherelatedparties,machinerydeployment,andtoensuretheconstructionquality,safetyandenvironmentalstandardtoachievetherequirementsofthemethodstatementandthetechnicalspecifications.

4.2TheresponsibilitiesoftheSiteEngineer

TheSiteEngineer’sresponsibilityistomakedetailedtechnicalclarificationandgivetechnicalguidancetothepersonnelwhomareonthesiteoftheconstruction.

4.3TheresponsibilitiesoftheSurveyor

Intheprocessofinstallingthepipeculvert,theSurveyorshouldberesponsiblefortheculverts’centrelinelayout,andtocontroltheelevationofpipeculvert.

4.4TheresponsibilitiesoftheMaterialEngineer

TheMaterialEngineerwillberesponsibleforthecompliancetestonthebackfillingmaterialsandthedesignofconcreteforreinforcedconcretepipeculvert.

4.5TheresponsibilitiesoftheSupervisor

TheSupervisorwillberesponsibleforthepreparationworkonthesite,andcarryoutthemanagementworkaccordingtotheconstructionschedulesandplans.

5.0Resourcestobeusedfortheworks

5.1Materials/TechnicalInformation

NO.

MATERIALDESIGNATION

QUANTITY

1

Concrete

1057m3³

2

Steel

42t

3

Sandcushion

300m3³

5.2ManPower

NO.

POSITION

NATIONALITY

AMOUNT

1

Supervisor

China

1

2

Excavatoroperator

China

1

3

Dumptruckdriver

PNG

1

4

Rolleroperator

PNG

1

5

Craneoperator

China

1

6

Concretemixertruckdriver

PNG

1

7

Labour

PNG

5

5.3Plant&Equipments

NO.

MACHINERY

MODEL

FUNCTION

1

Excavator

EC300

1

3

Dumptruck

15t

1

4

Crane

25T

1

5

Concretemixertruck

8m2

1

6

Roller

XL180J

1

7

Flatvibrationrammer

HZD115

2

8

Thefrogvibrationrammer

HW40

2

6.0Detailedmethodofcarryingoutthismethodstatement

6.1Sequenceofworks

6.1.1Sequenceofprecastreinforcedconcretepipeculvert

6.1.2Sequenceofprecastreinforcedpipeculvertinstallation

6.2Detailedmethodofprecastconcretepipeculvert

6.2.1Thepreparationofprecast

Priortoprecast,theworkershallcleanuptheareathathasbeingusedtoprecasttheconcretepipeculvert.Watershallbeaddedasrequiredtoavoidmoistureloss.Andweneedfabricatethecolumncageswithφ6cold-rolledribbedmildsteelbarsasperthedesign.Forpipeculvertunderφ600mmorbetweenφ600mm-φ1000mm,columncagesshallbefabricatedwithsinglelayerofsteelbarmesh,anddoublelayersteelbarmeshshallbeengagedandwellfixedforpipeculvertoverφ1000mm.Beforethecageisputtedintheformwork,weshouldmakesurethattheformworkhasbeencleanedandtheformworkhasbeencoveredbyreleaseagent.Thenweputthespacerblockinthecage,andmakesurethatthesteelbarhasenoughthicknessprotectivelayers.

6.2.2Precastpipeculvert

Afterweputtedthecageintheformwork,usedgantrycranemadethemintheposition.Andthenaddharshconcretetothesteelformwork.Asthemachinerevolves,harshconcreteiscontinuouslyaddeduntilthewallsofthetubereachtherequiredthickness.Thewallsofthetubearetobefullycompactedbeforethespeedofthemachineisgraduallytransferredto1200revolutionsp/min.Themachineshallbeathighrevolutionfor5mins-7minsuntilthewallofthetubeisinacompactedstate.Oncethepipeculvertiscompleted,itwillbehungintoasteampool.

6.2.3Curing

Beforetheremovaloftheformwork,thepipeculvertshallbeinasteamcuringprocessforfourhours.

6.2.4Test

Finishedalltheprecastworksweneeddosometesttocheckthequalityoftheculvert,thesetestswillbecarriedoutaccordingwiththeAS/NZS4058:

2007orasdirectedbytheengineer.

6.3Detailedmethodofpipeculvertinstallation

6.3.1Settingout

Thesiteshallbesurveyedtosetthelimitsofexcavationandculvertcentrelineasperthedrawings.Thetemporarybenchmarkshallbesetuptocontroltheelevationofpipeculvert.

6.3.2Drainage

Afterthefieldinvestigation,partofculvertsshallbedrainedoffwatertoreducetheinfluenceofwaterflowingthroughtheconstructedpipeculvert.

6.3.3Excavation

Theexcavationofthefoundationforpipeculvertsshallbedoneaccordingtothelimitsofthesettingout.WhenMechanicalexcavationtothedesignelevationabove10~20cm,artificialexcavationshallbecarriedouttoavoidoverexcavation.Thewidthofthefoundationshallbejustsufficienttopermitsatisfactoryjointingofthepipeandtheminimumwidthofthetrenchtobeconstructedforapipeculvertshallnotbelessthantheexternalpipediameterplus600mm.Duringtheprocessofexcavation,thesurveyshalluselevelstocontroltheelevationofthepipeculvert.Ifconstructionislaunchedduringtherainyseason,oneormoresumpsshallbedugwithinthefoundationpit,usingwaterpumptodrainwateroutfromthescopeofthefoundationpit.

Digtodesignelevation,Basalbearingcapacityshallbecarriedout.Ifbasalbearingcapacitycannotmeetthedesigndemand,lessthan150kpa,quotesupervisionengineeranddisposeasdirectivebytheengineer.

6.3.4Basetrimming

75mmthickofsandshallbelaidatthebottomofthefoundationbeforethelayingoftheculvert.Andatrenchneedstobedugmanuallyinthefoundationbedtolayaculvert.Theconstructionofthetrenchshallbeconstructedaccordingtothelengthandwidthoftheculvert.

6.3.5Layingofpipeculvert

Thelayingofthepipesshallbeginattheoutletendofthebarrelwiththesocketendsupstreamandspigotendsdownstream.Theendsofeachlengthofpipeshallbecarefullybuttedtogethertoprovideacontinuouslystraightbarrel.

Wherethereismorethanonepipethatformstheculvert,thepipesshallbespacedasperthedrawings.

6.3.6Pipejointing

Whenjointing,thetrenchshallbedryandthejointsshallbecleanedandwettedbeforesealingwithmortar.ThemortarshallbekeptdampuntiltheEngineerapprovesbackfillingtoproceed.Internaljointsofpipesmorethanlmetreindiametershallnotbemortareduntilafterbackfillingiscomplete.Wherethereislessthan1meterofpipe,thejointshallbesealedwithmortarbeforebackfillingiscompleted.Allexcessmortarshallberemovedfrominsidethepipe.

6.3.7Headwallsandwingwalls

Theexcavationoftheheadwallsorwindwallsshallbesetoutasperthedrawing.Thefoundationshallbeexcavatedandormanuallydugfollowedbyconcreteplacement.Theconcreteplacementiscarriedoutuponthecompletionofexcavationtothebottomofthefoundationaccordingtothedesignelevation.

Theconcreteshallbedoneinlayeredcastingduetheheightoftheheadwallandwindwall.Iftheformworkisabove2m,scaffoldingshallbeinstalledonbothsidesofthefoundationtoensurethesafetyoftheconstruction.

6.3.8Backfilling

Thebackfillingofthebasetopandbothsidewallsoftheculverttrenchshallbebackfilledwithsand,withlayerslaidsymmetricallyaccordingtothedesignandspecificationrequirements.Eachlayershallnotexceed150mmwiththecompactiondegreeoftheembankmentontheplatformnotlessthan90%.Thebackfillingmaterialshallbethoroughlyrammedandtamped.

Thesub-gradetopshallbebackfill