IAI电缸控制器MCEPC学习摘抄.docx

《IAI电缸控制器MCEPC学习摘抄.docx》由会员分享,可在线阅读,更多相关《IAI电缸控制器MCEPC学习摘抄.docx(43页珍藏版)》请在冰豆网上搜索。

IAI电缸控制器MCEPC学习摘抄

Caution:

MakesuretoturnthepowertothecontrollerOFFwheninsertingorremovingthe

connectorthatconnectsthePCsoftwareorteachingpendanttothecontroller.(Fortouchpanelteaching(CON-PTA,TB-01),insertionandremovaloftheactivelineisavailable.)InsertingorremovingtheconnectorwhilethepoweristurnedONcausesacontrollerfailure.在断开电脑或示教器与控制器的连接时,请将电断掉。

2.2OperationPatternSelected

2.2.1OutlineforOperationPatterns

PIOtypeMSEPunitsprovide6varyingpatternsofPIOoperation.FieldbustypeMSEPunits.provide6varyingmodesoffieldbusoperation.Selectanappropriatepatternorfieldbusmode

baseduponyourapplicationrequirements.SeeSection3Operationforthedetailsoftheoperationpatterns.(Note)SettingcanbedoneonlytoOperationPattern6ofthefieldbustypeforMSEP-LC.

看到第37页

第83页:

OperationofMSEP-C

(Note)Referto3.2forMPEP-LCType

3.1.1BasicOperationMethods

Therearetwotypesofmethodsforoperation,onetocontrolwithPIOandtheothertocontrol

witfieldbus.Checkthemodelcodeindicatedonthemodelcodecardattachedonthefront

panelofthebodytoseewhichmethodshouldbeappliedforyourproduct.[RefertoSection

1.1.5]

OperationModeAvailableinFieldbusType。

6typesofoperationmodesareavailabletoselectfrom.Explainedbelowistheoutline.

[BasicOperationSteps]

[1]EstablishthedriverparameterswithusingateachingtoolsuchasPCsoftware.

1)IfusingSEPI/OModeintheoperationmodes[refertothenextpage],settheoperationpatternintheinitialsetting.[Referto3.1.2fordetails.]

2)Establishsuchsettingsasthezone(ParameterNo.21to24)andthesoftlimit(ParameterNo.15)consideringthesystemtobeused.[Refertochapter5I/OParameterfordetails.]

[2]InitialSetting[Referto3.1.2and3.9.]

EstablishthesettingssuchastheslaveaddressesforthefieldnetworkusingGatewayParameterSettingTool.Setoperationmodesforalltheconnectedaxes.设置从站地址。

1)EstablishthesettingsbyfollowingthestepsstatedinSection3.1.2.

2)Setthegatewayparametersconsideringthesystemtobeused.Establishsuchsettingsaswhethertousethecalendarfunction(clocksetting)andthespeedunitchangeduringDirectIndicationMode.

[3]SettingofPositionData[Referto3.3.](Note)SettingisnotnecessaryforDirectIndicationMode.针对Z-Bearing项目不需要这一步设置。

Settheinformationsuchasthetargetpositionandspeedtobeusedinthepositiondata.

[4]FieldNetworkSettings[Referto3.4.1and3.4.2.]AssignMSEPasthePLC(MasterUnit).将MSEP分配给PLC主站。

[RefertotheinstructionmanualsofthemasterunitandPLC.]

[5]LinktoNetwork

1)SettheoperationmodesettingswitchonthefrontpanelofMSEPtoAUTOside,andrebootthepower.(FieldnetworklinebecomesvalidbysettingtheswitchtoAUTO)将模式开关切换到自动,同时重新上电。

2)OncethelinkwiththePLC(MasterUnit)isestablished(Note1),turnONMONsignalinthegatewaycontrolsignals(Note2).WhileMONSignalisON,controlfromfieldnetworkisavailable.

Note1ConfirmthecommunicationisestablishedinnormalconditionbyreferringtoDisplayofFieldNetworkLEDsshowninthesectionofNameandFunctionofEachComponentinearlierpagesofthismanual.

Note2Referto3.4.3GatewayControlSignals.

[6]OperationControlwithEachOperationMode[Referto3.4.4to3.5.]

1)Sendtheinformationofthetargetposition,speed,acceleration/deceleration,etc.fromPLC(MasterUnit)toMSEP.

2)Theactuatorfollowsthereceivedinformationofthetargetposition,speed,acceleration/deceleration,etc.toperformapositioningatthespecificcoordinates.

3)Confirmthestatusofpositioningcomplete.

第一步,初始化设置。

主要设置控制器的控制类型。

InitialSetting

Forthiscontroller,itisnecessarytohavetheinitialsettingandGatewayoperationmodesetting

doneintheaxesonebyone.对轴逐个进行网关操作模式设置。

TheinitialsettingistobeperformedusingRCPCSoftware(Note)ortouchpanelteaching(TB-01,CON-PTA(Note)).AndtheoperationmodeistobesetusingGatewayParameterSettingTool(Ver.1.1.0.0orlater).(Note)用GatewayParameterSettingTool对网关参数进行设置。

SeetheinstructionmanualsoftheRCPCsoftwareandthetouchpanelteachingfortheapplicableversion.Shownbelowistheprocessforthesetup.Followtheinstructiontoconductthesettingproperly.

Makesurethepower,systemI/OconnectorwiresandoperationmodesettingswitchareinMANU

conditionwhenhavingthesettingdone.上述操作在手动模式下进行。

连接MSEP和电脑时用什么电缆?

大概在第90页左右开始对设置进行说明。

第二步:

设置每个轴的操作模式(控制类型)

Clickonablankcelland“*”showsup.“*”markmeansthatanoperationmodeisselected

foreachaxis.Selectanoperationmode[refertotopinChapter3]for2axesinaunit.Ifclickingonacell,“*”showsupfor2axestogether.Ifclickingacellshowing“*”,themarkturnsto“(*)”.“(*)”

meansitisareservedaxis,whichistobesetwhennotusingeventhoughtheactuatorisconnected.

Ifclickingonacellwith“(*)”markforthereservedaxesshownonthetwoaxes,thecellturnsbacktoblank.(Note)Evenifthetotalnumberoftheusedaxesisanoddnumber,makethelastaxisin

reservationtogetanevennumber.

第107页:

3.3SettingofPositionData

2)Position[mm]·················Itisthecoordinatevalueforpositioning.Inputthepositionfromthe

homeposition.

3)Speed[mm/s]·················Setthespeedintheoperation.Donotattempttoinputavaluemorethanthemaximumspeed[refertothecautionnotebelow]orminimumspeed(Note1).(Note1)Theminimumspeeddiffersdependingonthetypeoftheactuator.RefertothevaluesstatedintheChapter7appendixorthefollowingforthecalculation.Minimumspeed[mm/s]=Leadlength[mm]/No.ofEncoderPluses/0.001[s]

4)PressingForce[%]·········Setavalueotherthan0hereandthepressingoperationisavailable.Setapressingtorque(limitcurrentvalue)in%.Thesettingrangediffersdependingontheactuator.Refertotheinstructionmanualofeachactuatororthesectionforpressingforceandcurrentlimitintheappendixforthedetails.Ifthevalueissetto0,thenormalpositioningoperationisperformed.

ThespeedforthepressingoperationissetinParameterNo.7.Ifthesettingof3)islowerthanthepressingspeed,thepressingprocesswillbeconductedwiththespeedof3).

5)PressingWidth[mm]······Setthewidthforthepressingoperation.Theamountofthepressingwidthinfrontofthemovementtargetposition(forwardendandbackwardend)isthepointtostart

pressingoperation.

8)Energy-SavingSetting···Setthisto1(effective)andtheservoisturnedOFFautomaticallyin

acertaintimeafterthepositioningiscompletedforpowersaving.ThetimesettingistobeconductedinParameterNo.10AutomaticServo-OFFDelayTime,andthetimesettingcanbeselectedfrom1to9999[sec.].

Caution:

•NoretainingtorqueisprovidedinautomaticservoOFF.Paysufficientattentiontothesettingbecausetheactuatormaybemovedbyexternalforceappliedtoit.

•DonotusetheautomaticservoOFFinpressing.Ifused,thepressingforceislost.

•AutomaticServoOFFwouldnotfunctionintheoperationwithteachingmodeofPCsoftware.

第113页对报文结构做了简单的说明

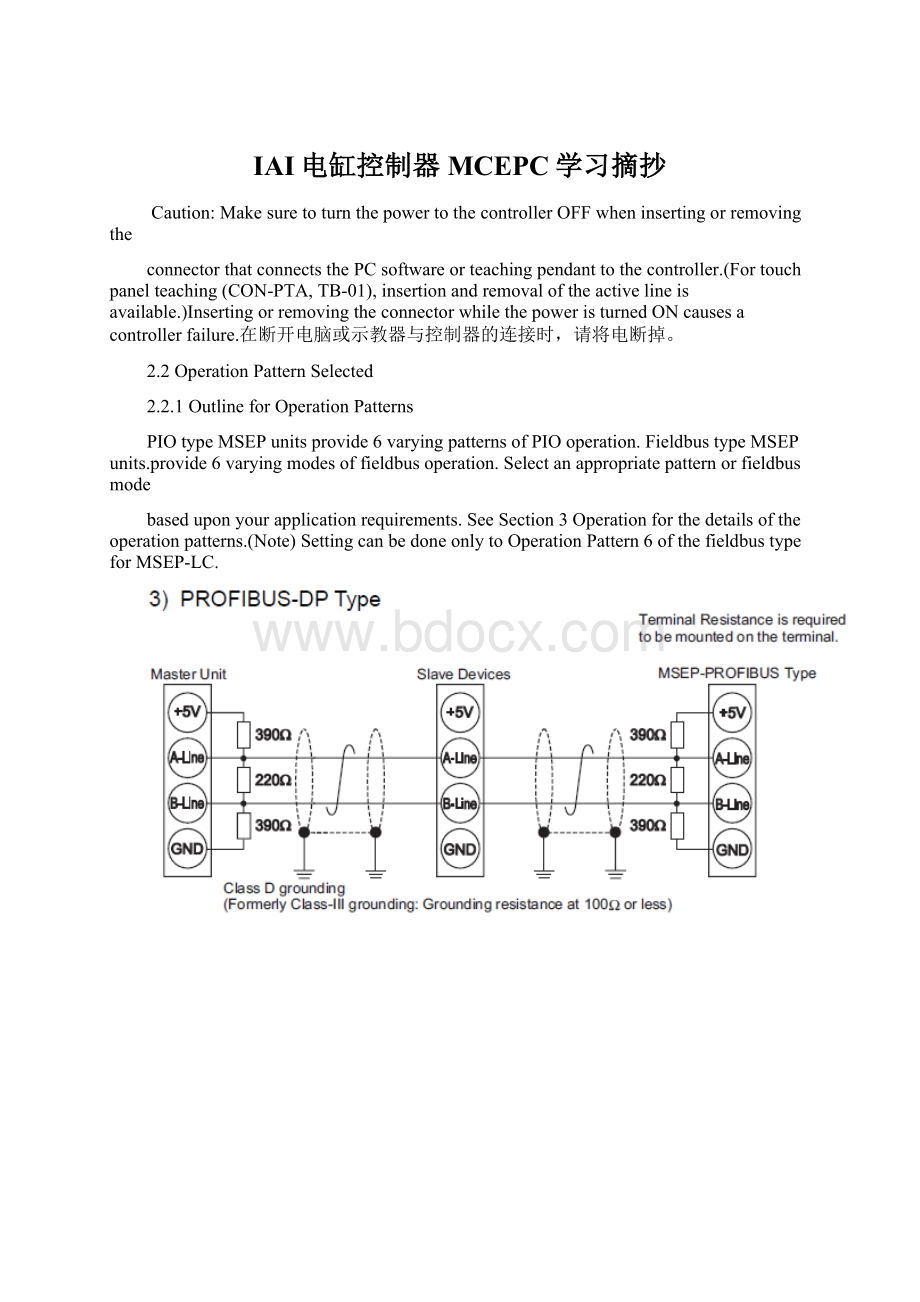

3)PROFIBUS-DP,EtherNet/IP,EtherCAT

3.4.2ExampleforeachFieldbusAddressMap

[CombinationExample4]WhennumberofSimpleDirectModeaxesis0andnumberof

DirectIndicationMode8(nisthetopnodeaddressforeachPLCinputandoutputbetween

MSEPandPLC)

3.4.3GatewayControlSignals(incommonforalloperationmodesforMSEP-C)

WhenoperatingthesystemwithFieldbus,theaxesarecontrolledviaGatewayofMSEP.The

top2wordsofinputandoutputineachoperationmodearethesignalsGatewaycontroland

statusmonitoring.

3.4.5ControlSignalsforDirectIndicationMode

Thisisanoperationmodetoindicatedirectlywithvaluesforthetargetposition,positioning

width,speed,acceleration/decelerationandpressingcurrent.Setavaluetoeachinputandoutputdataregister.Settotheparameterswhenusingthezonesignals.ThemainfunctionsofROBOCylindercapabletocontrolinthismodeareasdescribedinthefollowingtable.

(2)InputandOutputSignalAssignmentforeachAxisTheI/Osignalsforeachaxisconsistsof8-wordforeachI/Obitregister.位寄存器

●ThecontrolsignalsandstatussignalsareON/OFFsignalsinunitsofbit.

●Forthetargetpositionandcurrentposition,2-word(32-bit)binarydataisavailableandvalues

from-999999to+999999(unit:

0.01mm)canbeused.Negativenumbersaretobedealtwith

two’scomplement.

Caution:

Setthepositiondataintherangeofthesoftstroke(0toeffectivestrokelength)oftheactuator.

Setthepositioningwidth.Thepositioningwidthisexpressedusing2-word(32bits)binarydata.Thefiguresfrom0to+999999(Unit:

0.01mm)canbesetinPLC.

●Thecommandspeedisexpressedusing1-word(16bits)binarydata.Thefiguresfrom1to

+65535(Unit:

1.0mm/secor0.1mm/sec)canbesetinPLC.Achangeoftheunitistobe

conductedonGatewayParameterSettingTool.

●TheAcceleration/Decelerationisexpressedusing1-word(16bits)binarydata.Thefigures

from1to300(Unit:

0.01G)canbesetinPLC.

●Thepressingcurrentlimitvalueisexpressedusing1-word(16bits)binarydata.Thefigures

from0to100%(0toFFH)canbesetinPLC.

Caution:

Havethesettingwithvaluesavailableintherangeofforspeed,acceleration/decelerationandpressingcurrentoftheactuator.(Refertothecatalogorinstructionmanualoftheactuator.)

Otherwise,itmaycauseanabnormalconditionoftheservooramalfunctionoftheactuatorsuchasthealarmcodes0A3“PositionCommandInformationDataError”,0C0“ExcessActualSpe