ch11Flue Gas Desulfurization Systems.docx

《ch11Flue Gas Desulfurization Systems.docx》由会员分享,可在线阅读,更多相关《ch11Flue Gas Desulfurization Systems.docx(18页珍藏版)》请在冰豆网上搜索。

ch11FlueGasDesulfurizationSystems

FlueGasDesulfurizationSystems

TimothyW.DevittP.E.

Vice-President

PEDCoEnvironmental,Inc.

Cincinnati,Ohio

11.1DESCRIPTIONOFCONTROLDEVICE

Fluegasdesulfurization(FGD)istheprocessofremovingsulfuroxides,primarilySO2,fromcombustiongases.InwetprocessFGDsystems,fluegasesarecontactedwithanabsorbentinavesselcalledeitheranabsorberorascrubber.TheSO2reactswiththeabsorbentordissolvesintothesolutiontoproduceaslurryorliquidthatcontainsdissolvedorsolidifiedsulfurcompounds.Inalloperatingsystems,waterisusedtodissolveorsuspendthereactingchemicals,althoughanumberofdryabsorptionsystemsarecurrentlybeingcommercialized.TheadvantagesofdryscrubbingincludepotentialcostandenergysavingsandrelativeeaseofoperationcomparedwithwetFGDsystems.Dryscrubbing,however,requireshigherchemicalconsumptionandmayberestrictedtolow-sulfurcoals.Becausemostofthecommercialdryscrubbinginstallationsareunderconstructionorintheplanningphase,thereisalackofdataonfull-scalesystems.Therefore,thisreviewislimitedtowetFGDsystems.

WetFGDprocessesaregroupedintotwogeneralcategories,regenerableandnonregenerable,dependingonwhetherthesulfurisseparatedfromtheabsorbentaswaste.Nonregenerableprocessesproduceasludgethatrequiresdisposalinanenvironmentallysoundmanner.Regenerableprocessesincludeadditionalstepstoconvertthesulfurintoby-productssuchasliquidsulfurdioxide,sulfuricacid,orelementalsulfur.

SixbasicwetFGDsystemsareusedinthiscountry,primarilytotreatfluegasfromlarge,coal-firedboilers.Ofthese,thelimescrubbing,limestonescrubbing,sodiumcarbonatescrubbing,anddualalkalisystemsareclassifiedasnonregenerable.ThemagnesiumoxidescrubbingandWellman-Lordsystemsareclassifiedasregenerableprocesses.

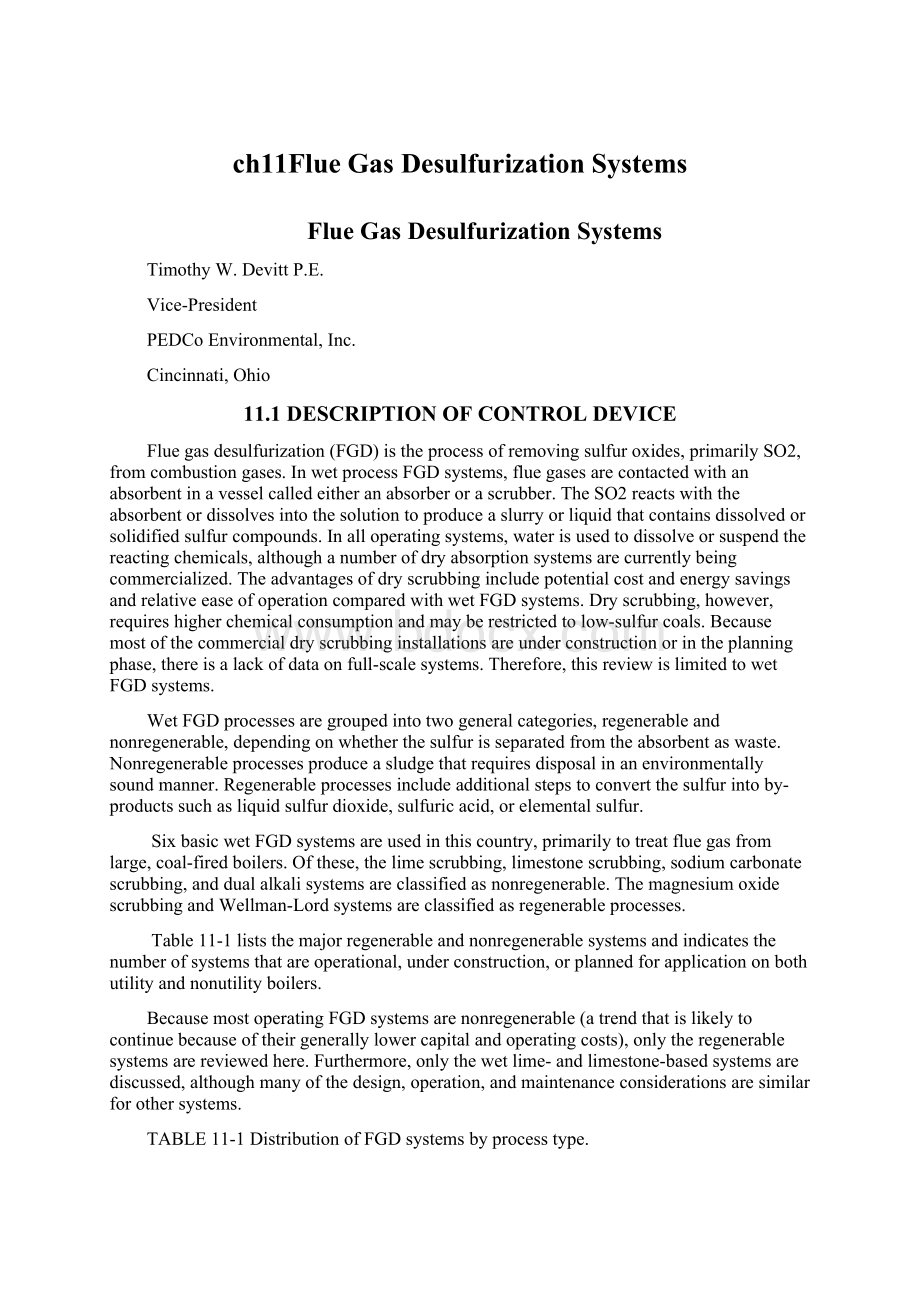

Table11-1liststhemajorregenerableandnonregenerablesystemsandindicatesthenumberofsystemsthatareoperational,underconstruction,orplannedforapplicationonbothutilityandnonutilityboilers.

BecausemostoperatingFGDsystemsarenonregenerable(atrendthatislikelytocontinuebecauseoftheirgenerallylowercapitalandoperatingcosts),onlytheregenerablesystemsarereviewedhere.Furthermore,onlythewetlime-andlimestone-basedsystemsarediscussed,althoughmanyofthedesign,operation,andmaintenanceconsiderationsaresimilarforothersystems.

TABLE11-1DistributionofFGDsystemsbyprocesstype.

Process

UTILITYBOILERFGDCAPACITY(MW)1.2

Process

INDUSTRIALBOILERFGDCAPACITY(SCFM)3.4

Operational

UnderConstruction

Planned

Total

Operational

UnderConstructionPlanned

Total

Aqueouscarbonate/spraydrying

100

100

Ammonia

164,000

154,000

318,000

Citrate

605

605

Caustic

211,000

211,000

Dualalkali

1,201

842

2,043

Causticwastestream

665,000

665,000

Lime

8,801

2,060

6,841

17,702

Citrate

142,0005

142,0005

Limestone

11,437

7,637

17,254

36,328

Dualalkali

1,480,000

1,480,000

Limestone/alkalineflyash

1,480

1,480

Dualalkali(concentrated)

489,070

512,000

1,001,070

Lime/alkalineflyash

2,613

1,400

4,013

Dualalkali(dilute)

233,400

233,400

Lime/limestone

20

475

495

Lime

40,000

30,000

70,000

Lime/spraydrying

110

1,060

1,813

2,983

Lime/spraydrying

72,700

72,700

Magnesiumoxide

724

724

Limestone

55,000

55,000

Sodiumcarbonate

925

330

1,900

3,155

Sodiumcarbonate

2,467,000

504,500

2,971,500

Sodiumcarbonate/spraydrying

440

440

Sodiumhydroxide

1,140,300

12,000

1,152,300

WellmanLord

1,540

534

2,074

Sulf-xscore

10,000

10,000

Processnotselected

6,650

6,650

Processnotselected

124,000

124,000

Total

28,187

14,285

35,775

78,247

Total

5,464,770

3,041,200

8,505,970

1M.Smith,etal.,EPAUtilityFGDSurvey:

October-December1980.Vol.1.EPA-600/7-81-012a,PEDCoEnvironmental,Cincinnati,Ohio,October1979.2Capacitiesarereportedasequivalentscrubbedcapacity(ESC);thesummationofeffectivescrubbedfluegasinequivalentMWbasedonthepercentofthefluegasscrubbedbytheFGDsystem(s).3J.Tuttle,etal.,EPAIndustrialBoilerFGDSurvey:

FirstQuarter1979.EPA-600/7-79-067b,PEDCoEnvironmental,Cincinnati,Ohio,April1979.4Forapproximatecomparisonpurposes1MWmaybeconsidered≈3000scfm.5ThecitrateprocessFGDsystemonSt.JoeZinc’sG.F.Weatonunitwasincludedinboththeutilityandindustrialreportsinceitsuppliespowertotheutilitygridaswellassteamfortheindustrialplant.Thisunitshouldbedeletedfromoneortheothersectionswhenestimatingtotalprocesscapacitiesfortheindustrial-utilitymarketplaceasawhole.

TheLimeScrubbingProcess

Thefirststepoftheprocessispreparationofalimeslurry.Lime(CaO)isreactedwithwaterinaslaker[]石灰消和器toproduceaslurryofcalciumhydroxide[Ca(OH)2]andwater,accordingtothefollowingreaction:

CaO+H2O→Ca(OH)2+heat.Thismaterialisdiluted[]无力的,冲淡的withrecycledwatertoproduceascrubberslurrycontainingabout15to20%solids.

Thelimeslurryisaddedataregulatedratetoarecycletankthatcontainsthescrubbingslurry.Largepumpscirculatethescrubbingslurrythroughthescrubberorabsorbervessel.Intheabsorber,theslurrydropletsarebroughtintocontactwiththefluegascontainingSO2,andtheSO2passesfromthegasintothedropletsdrivenbyaconcentrationgradient.ThedissolvedSO2reactswithcalciumfromthelimeaccordingtothefollowingreactions:

Ca(OH)2(s)↔Ca(OH)2(aq)↔Ca

+2OH‾

2OH‾+CO2↔CO

+H2O

CO

+CO2+H2O↔2HCO

Ca2++CO

↔CaCO3

CaCO3(s)↔CaCO3(aq)↔Ca2++CO

SO2(g)↔SO2(aq)+H2O↔H++HSO

HSO

↔H++SO

Ca2++SO

↔CaSO3(aq)

Ca2++SO

+1/2H2O↔CaSO3•1/2H2O(s)

CaSO3+H+↔Ca2++HSO

H++HCO

↔H2CO3↔CO2(g)+H2O

CaSO3•1/2H2O+3/2H2O+1/2O2↔CaSO4•2H2O

Thesereactionstakeplacetosomeextentineverytimescrubbingsystem;similarreactionsoccurinlimestonesystems.Suchfactorsasionicconcentrations,pH,temperature,andretentiontimeinthereactiontankinfluencethespeedandcompletenessofthevariousreactions.Theneteffect,however,isremovalofSO2fromthefluegas,depletionofcalciumhydroxideintheslurry,andgenerationofinsolublecalciumsulfiteandcalciumsulfate.Thecalciumionsusedinthereactionsarereplenishedbydissociationofcalciumhydroxide.Theuseofaninsolublealkalinereagentistheprimarydifferencebetweenthelimeandlimestoneslurryscrubbingsystemsandtheso-calledclearsolutionscrubbers(e.g.,doublealkaliscrubbers),wherethepredominantreactivealkali(sodium)ismoresoluble.

Forcingmostofthesulfite/sulfateprecipitationtooccurinthereactiontankrequiresacertainamountofretentiontimetopermittheslurrytoreachchemicalequilibriumbeforeitisrecirculatedtothescrubber.Forthispurpose,areactiontank,sometimesanintegralpartofthescrubbervessel,isusuallysizedwitharetentiontimeofbetween5and10minutes.

Thecalciumsulfiteandcalciumsulfatethatareformedinthereactiontankmustberemovedfromthesystem.Thisisaccomplishedbybleedingastreamfromtherecirculatingslurrytoathickenerorclarifier.Thecalciumsulfiteandsulfatesettleoutandareremovedfromtheunderflowoftheclarifierinaslurryofabout30%solids.Theoverflow,aclearliquidoflessthan1%solids,isbroughtbacktothesystemforreuseintheprocess.Thesludgefromtheunderflowisdisposedofbyoneofseveralmeans.

Onemethodofdisposalistopumpthesludgetoapond.Inthiscasethesludgeispumpedfromthethickenerunderflow(oroccasionallydirectlyfromthereactiontank)toalargepond,wherethesolidssettle.Clearwaterisrecycledfromthepond,asnecessary,tokeepthepondfromoverflowing.Returnofallthisclearliquorfromthepondtotheprocessiscalleda“closed-loop”operation.

Anothermethodofdisposalistodewaterthesludgeinavacuumfilter,chemicallystabilizeitbytheuseofgenericorproprietaryprocesses,anddisposeofitinalandfill[]n.垃圾掩埋法,垃圾.Whenvacuumfiltrationisused,thefiltrateisreturnedtothesystemtocreateclosed-loopoperation.

TheLimestoneScrubbingProcess

Limestoneslurrypreparationistheonlystepthatissignificantlydifferentfromthelimescrubbingprocess.Lumpsizelimestoneispulverized[]v.研磨成粉to-200to–300meshinaballmillandslurriedwithwater.ThefinesizeisneededbecausedissolutionofCaCO3isaslowreaction,theratebeingdirectlyrelatedtotheparticlesurfaceareaandthereforetotheparticlesize.Forfurtherlimestonedissolution,thescrubbingslurryismaintainedatanacidicpH,incontrasttolime-basedsystems,inwhichscrubbingslurryisslightlyalkaline.Theoverallprocessreactionsarethesameasforthelimeslurryscrubbingprocess,exceptthereactantspeciesisCaCO3,notCa(OH)2.

Figure11-1illustratesatypicallimestoneprocess.Thelimeprocessissimilarexceptalimeslakerreplacestheballmillofthelimestoneprocess.

OtherwetprocessFGDsystemsoperatesimilarly.TheSO2isscrubbedfromthegasesinacontactor,andreactionproductsareremovedinaseparatevessel.Severalexcellenttextsandreportsareavailablethatdescribethevarioussystems,theirchemistry,andstatusofcommercialization;thesearelistedinSection11.8.

11.2DESIGNPROCEDURES

Propersystemdesigniscrucial[]极重要的tosuccessfuloperationofanFGDsystem.Althoughthisistrueforallairpollutioncontrolsystems,itisespeciallyimportantforFGDsystems.Incontrasttom