ISO26262 安全案例Safety Case.docx

《ISO26262 安全案例Safety Case.docx》由会员分享,可在线阅读,更多相关《ISO26262 安全案例Safety Case.docx(9页珍藏版)》请在冰豆网上搜索。

ISO26262安全案例SafetyCase

SafetyCase

1

TableofContents

2

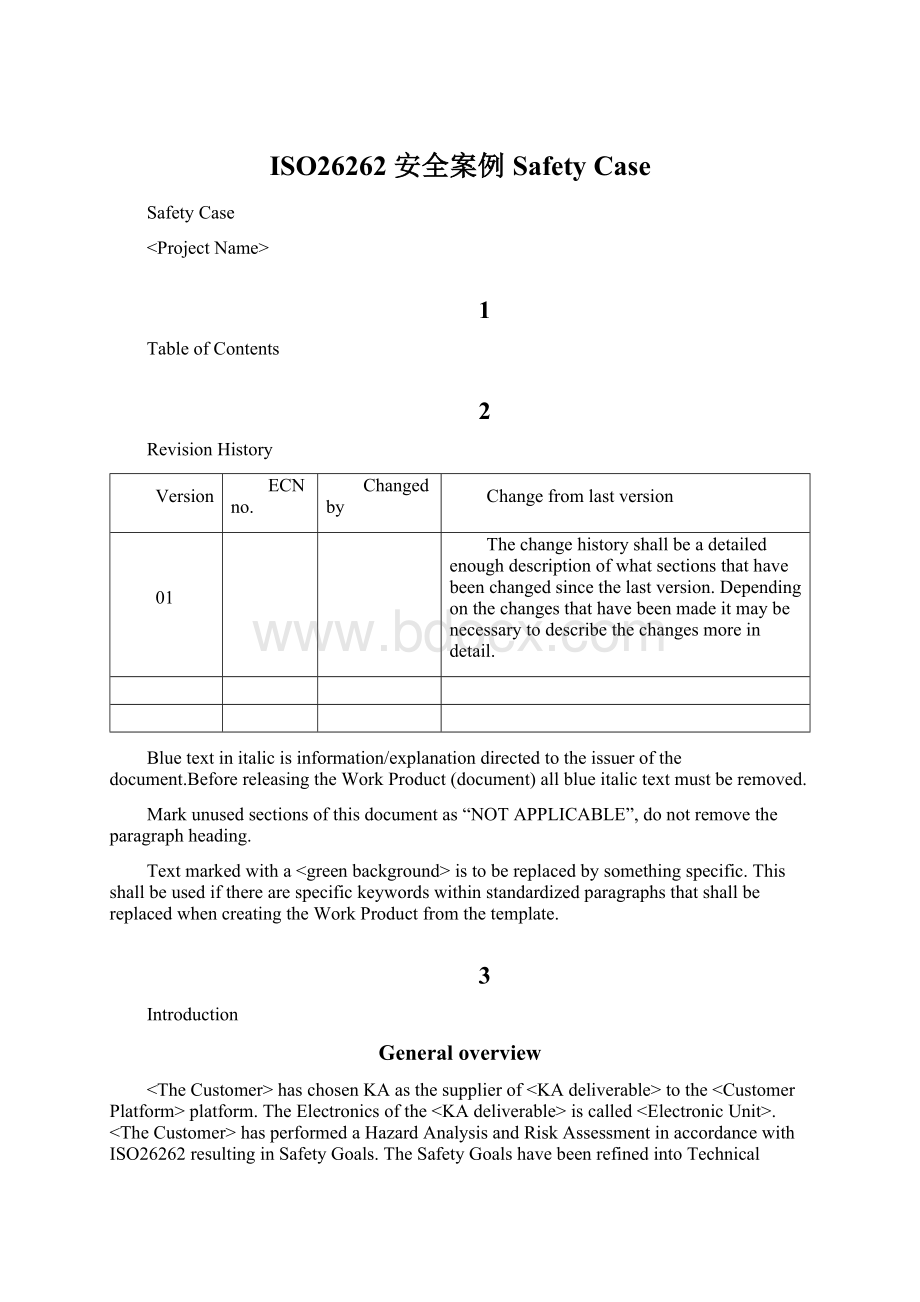

RevisionHistory

Version

ECNno.

Changedby

Changefromlastversion

01

Thechangehistoryshallbeadetailedenoughdescriptionofwhatsectionsthathavebeenchangedsincethelastversion.Dependingonthechangesthathavebeenmadeitmaybenecessarytodescribethechangesmoreindetail.

Bluetextinitalicisinformation/explanationdirectedtotheissuerofthedocument.BeforereleasingtheWorkProduct(document)allblueitalictextmustberemoved.

Markunusedsectionsofthisdocumentas“NOTAPPLICABLE”,donotremovetheparagraphheading.

Textmarkedwithaistobereplacedbysomethingspecific.ThisshallbeusediftherearespecifickeywordswithinstandardizedparagraphsthatshallbereplacedwhencreatingtheWorkProductfromthetemplate.

3

Introduction

Generaloverview

haschosenKAasthesupplieroftotheplatform.TheElectronicsoftheiscalled.hasperformedaHazardAnalysisandRiskAssessmentinaccordancewithISO26262resultinginSafetyGoals.TheSafetyGoalshavebeenrefinedintoTechnicalSafetyRequirementsallocatedtothe.ThehighestASILoftheseSafetyRequirementsisASIL.

ThesafetyresponsibilitiesarefurtherdetailedintheKA-DevelopmentInterfaceAgreement,DIA,ref[R11].

KAwillhavetoensurethattheProduction,OperationandServiceoftheaswellastheshallsatisfytherequirementsofISO26262atalevelthatcorrespondswiththehighestASILallocated.

KAisresponsiblefortheoverallTechnicalSafetyofthecompleteaswellasthe.

Aboutthisdocument

ThisdocumentcontainstheSafetyCasefortheinthe.TheSafetyCaseconstitutestheargumentationwhytheisfreefromunreasonableriskinaccordancewiththeAutomotiveFunctionalSafetyStandardISO26262ref[R1],[R2],[R3],[R4],[R5],[R6],[R7],[R8],[R9],[R10].

TheSafetyWorkProductsanddocumentslistedintheSafetyCaseareconsideredwiththerespectivetailoringthathasbeendoneintheSafetyPlan,ref[R12].

Abbreviations

Abbreviation

KA

XXAutomotive

N/A

NotApplicable

TBC

ToBeConfirmed

TBD

ToBeDefined

4

References

Ref

Id

Issue

DocumentName

[R1]

ISO26262:

1

2011

Vocabulary

[R2]

ISO26262:

2

2011

Managementoffunctionalsafety

[R3]

ISO26262:

3

2011

Conceptphase

[R4]

ISO26262:

4

2011

Productdevelopmentatthesystemlevel

[R5]

ISO26262:

5

2011

Productdevelopmentatthehardwarelevel

[R6]

ISO26262:

6

2011

Productdevelopmentatthesoftwarelevel

[R7]

ISO26262:

7

2011

Productionandoperation

[R8]

ISO26262:

8

2011

Supportingprocesses

[R9]

ISO26262:

9

2011

AutomotiveSafetyIntegrityLevel(ASIL)-orientedandsafety-orientedanalyses

[R10]

ISO26262:

10

2012

GuidelineonISO26262

[R11]

KA-DevelopmentInterfaceAgreement(DIA)

[R12]

SafetyPlan

[R13]

5

StatementofSafety

KAherebystatethattheisfreefromunreasonableriskwithrespectto“MalfunctioningbehaviorofE/Esafety-relatedsystems”.ThatisbasedonthatISO26262,ref[R1],[R2],[R3],[R4],[R5],[R6],[R7],[R8],[R9],[R10],hasbeenappliedduringthedevelopmentoftheandduringtheplanningoftheproduction.Thisclaimisbuiltonthestatementsprovidedinthisdocument.

ThisdocumentconstitutestheSafetyCasefortheinthe.

6OverviewofCreatedFunctionalSafetyWorkProducts

ThefollowingtablelistsalltheWorkProductsdevelopedinaccordancewiththeProjectSafetyPlan,ref,andthestatusofeachWorkProduct.

WorkProduct

Documenttitle

Documentid&latestreviewedrevision

ReviewProtocolid&revision

WorkProductStatus(OK,CondOK,NOK)

(WP-X:

X.X.X)

7

Deviations

Listalldeviationsfromtheplannedbaselinehere,togetherwithasummaryoftheriskthatthedeviationresultsin.

8

FunctionalSafetyManagement

OverallSafetyManagement

SafetyCulture

StatethesafetycultureinKA.DescribehowKAfocusesonsafetyinrelationtoothertasksandmilestonesintheproject.ProvideanargumentforthatKAhasanadequateattitudetowardssafetyissues.

OrganizationSpecificrulesandprocessestocomplywithISO26262

DescribetherulesandtheframeworkforhandlingISO26262relatedtasks.

QualityManagement

KAiscertifiedaccordingtoISO/TS16949.

SafetyManagementduringtheConceptPhaseandtheProductDevelopment

DescribetheprojectorganizationbrieflyandprovideareferencetoallSafetyRelatedRoles,theirappointmentsandthesafetybackground/competenceofthepersonshavingthoseroles.

SafetyManagementaftertheItem’sReleaseforProduction

Describehowthesafetymanagementwillbeorganisedafterthestartofproductionandtheclosureofthedevelopmentproject.

9

MainSafetyArgumentation

TechnicalSafetyConcept

Overview

Provideanoverviewofthesafetyrelatedmechanismsintheproduct.

SafetyArchitecture

DescribetheTechnicalSafetyArchitecturehere,includingthederivationoftheTechnicalSafetyRequirementsontheSystemLevel.

Referencestomoredetailedinformation

Referenceadditionalinformationsuchasspecificationsandrequirements.

HardwareSafetyRequirements

Overview

Inthissection,describehowHardwareSafetyRequirementshavebeenderivedfromTechnicalSafetyRequirementsontheSystemLevel.Alsodescribehowtheyhavebeenreviewedforcorrectnessandhowtheyhavebeenverified.

Referencestomoredetailedinformation

Referenceadditionalinformationsuchasspecificationsandrequirements.

SoftwareSafetyRequirements

Overview

Inthissection,describehowSoftwareSafetyRequirementshavebeenderivedfromTechnicalSafetyRequirementsontheSystemLevel.Alsodescribehowtheyhavebeenreviewedforcorrectnessandhowtheyhavebeenverified.

Referencestomoredetailedinformation

Referenceadditionalinformationsuchasspecificationsandrequirements.

Verification&Validation

SummaryofSafetyRequirements’verification

Summarizetheverificationofthesafetyrequirements.

ElectronicUnitSafetyTesting

ElectronicUnitSystemSafetyTestResults

SummarizethetestresultsfromtheSafetyTestingonSystemLevelinthissection.

ElectronicUnitHardwareSafetyTestResults

SummarizethetestresultsfromtheHardwareSafetyTestinginthissection.

ElectronicUnitSoftwareSafetyTestResults

SummarizethetestresultsfromtheSoftwareSafetyTestinginthissection.

SafetyRequirementsReviewResults

IncasesomeSafetyRequirementsareverifiedbyreview,summarizethereviewresultsinthissection.

Qualificationtesting

Functionaltestingoncompleteassemblylevel(mechanicalandelectronical)

Summarizethetestingonthecompleteassemblylevel,combiningbothmechanicalandelectronicalsystemsinthissection.

EMCtesting

SummarizetheEMCtestingonthecompleteassemblylevel,combiningbothmechanicalandelectronicalsystemsinthissection.

Environmentaltesting

Summarizetheenvironmentaltestingonthecompleteassemblylevel,combiningbothmechanicalandelectronicalsystemsinthissection.

SafetyAnalyses

Methods&Results

Describeanddetailtheresultsfromthesafetyanalysesaswellasthemethodsthathavebeenused.

HardwareMetrics

SummarizetheHardwareMetricsfromtheFMEDAinthissection.

10SupportingArgumentation

KAhasanextensiveprocesstoensurequality,timingandsafetyduringtheentireproductdevelopment.

TheKAproductdevelopmentprocessiscalledKBD,“KnowledgeBasedDevelopment”.ItisdescribedbyasetofpagesontheKAIntranet,inthesection“XXAutomotiveManagementSystem”,visualizingtheprocessphasesandstepsinagraphicalway.

Production

ProductionPlan&ProductionControlPlan

DescribehowtheProductionPlanandProductionControlPlanhandlesafetycriticaltasksandhowfaultsthatcanbesafetyrelatedarehandledwhenfoundduringtheproduction.

Operation,ServiceandDecommissioning

Operation

Describehowtheenduserdocumentationrelayssafetyrelatedinformationtotheenduserwhereapplicable.Ifenduserdocumentationisomitted,argueforwhythatisacceptable.

Service

Describethelimitationsforserviceinordertonotbreachsafetycompatibility.

Decommissioning

Ifthereareanyspecialconsiderationsforthesafedecommissioningoftheproduct,describehowthatinformationisrelayedtothepersonnellresponsibleforsuchtasks.

FieldMonitoring

DescribetheKAfieldmonitoringprocessusedintheproject.

RequirementsManagement

Describehowrequirementsarehandledintheproject.Ifapplicable,referencetheKARequirementsManagementprocess.

ConfigurationManagement

ReferencetheKAConfigurationManagementProcess.

ChangeManagement

ReferencetheKAChangeManagementProcess.

Verification

Seesection9.4.

Documentation

ArguethatanadequateamountofSafetyDocumentationhasbeenperformed,referencetheSafetyPlanandstateifalllisteddocumentationhasbeenperformed.

ConfidenceintheUseofSoftwareTools

ArguethatallsoftwareusedduringallphaseshavebeenassignedaToolImpactLevelandthatalltoolsthathavebeenidentifiedaspossiblyaffectingthesafetyalsohavebeenclassifiedandverifiedfortheirintendeduse.

Referencethereportfromtheanalysisoftheconfidenceinthesoftwaretools.

QualificationofSoftwareComponents

Ifre-useofSoftwareComponents