Finite Element Analysis Report for Drying Raw Mill new.docx

《Finite Element Analysis Report for Drying Raw Mill new.docx》由会员分享,可在线阅读,更多相关《Finite Element Analysis Report for Drying Raw Mill new.docx(13页珍藏版)》请在冰豆网上搜索。

FiniteElementAnalysisReportforDryingRawMillnew

FiniteElementAnalysisReportforDryingRawMill

1.Introduction

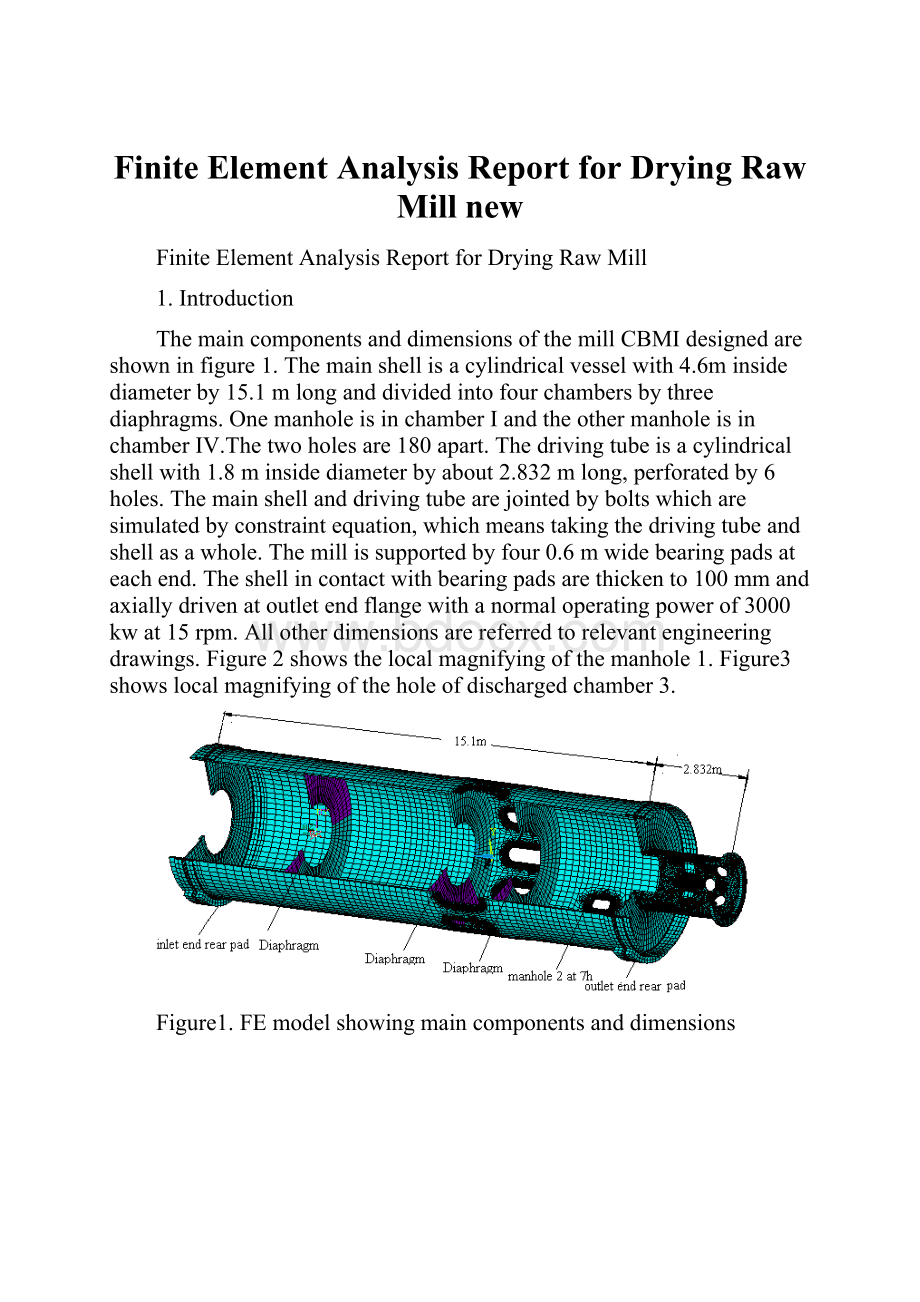

ThemaincomponentsanddimensionsofthemillCBMIdesignedareshowninfigure1.Themainshellisacylindricalvesselwith4.6minsidediameterby15.1mlonganddividedintofourchambersbythreediaphragms.OnemanholeisinchamberIandtheothermanholeisinchamberⅣ.Thetwoholesare180apart.Thedrivingtubeisacylindricalshellwith1.8minsidediameterbyabout2.832mlong,perforatedby6holes.Themainshellanddrivingtubearejointedbyboltswhicharesimulatedbyconstraintequation,whichmeanstakingthedrivingtubeandshellasawhole.Themillissupportedbyfour0.6mwidebearingpadsateachend.Theshellincontactwithbearingpadsarethickento100mmandaxiallydrivenatoutletendflangewithanormaloperatingpowerof3000kwat15rpm.Allotherdimensionsarereferredtorelevantengineeringdrawings.Figure2showsthelocalmagnifyingofthemanhole1.Figure3showslocalmagnifyingoftheholeofdischargedchamber3.

Figure1.FEmodelshowingmaincomponentsanddimensions

Figure2.localmagnifyingofthemanhole1

Figure3.localmagnifyingoftheholeofdischargedchamber3

2.Boundaryconditions

3-Dstructureelementandquadraticshellelementareusedtomodelthemill.

2.1Drivingtorqueandoffsetload

AdrivingtorqueT=1910000N.mwhichcorrespondstoabout3000kwat15rpmisappliedbycircumferentialforcesonendflange.Aloadof200736.3kginternalballsandmaterialisappliedasadditionalmassonbottompartofmainshellandoffsettotheleftasillustratedinfigure4.TheangularpositionsofAandBareapproximately-1800and-600respectively,foundbytrialanderrorsoastocounterbalancetheappliedadditionalmass.

Figure4.Drivingtorqueandoffsetload

Figure5Modelof8supportpads

2.2Linermasses

7559kgforheadlineratinletend,7942kgforheadlineratoutletend,14782.56kgforshelllinerinchamberI,38088kgforshelllinerinchamberⅡ,10760kgforshelllinerinchamberⅢ,22954kgforshelllinerinchamberⅣareappliedasadditionaldistributedmassofcorrespondingcomponents(headplatesandmainshell).

2.3Diaphragm

16402kgweightfordiaphragmbetweenchamberIandⅡ,8201kgweightforthetwodiaphragmsrespectivelyindischargedchamberⅢ,alltheweightsareappliedasdistributedmassofanannularplateusingverysmallYoung'smodulussothatthediaphragmdoesnotcontributetothestiffnessoftheshell.

2.4Drivingtubeandshellmasses

12399kgfordrivingtube(SeedrawingNO.BMRaCD46.3.7),122683kgforshell(SeedrawingNO.BMRaCD4685/35.3.4),alloftheweightswillbecalculatedbydefiningdenseofthematerialthroughANSYSsystem,andultimatelyappliedtothemodel.

2.5Support

Thecontactmodelisintroducedtosimulatethefrictionlesscontactbetweenshellringsandthe200mmthicksupportpads.Radialreactionsillustrateinfigure5.

Totally,12modelsarestudied,eachoneforeveryhourpositioninaccordingtothepositionofpads,andonlyimportantandcriticalresultsarereportedbelow.

3.Resultanalysis

3.1Resultsforforcesandstressesonpads

Asillustratedinfigure5andthroughcontactmodelsimulation,

=551380,

=592676,

=666763N,

=964697N,

=581772N,

=557564N,

=581077N,

=948661N,finallytheverticalreactiontotallyequalsto4697300N(about479.36tons).

With0.2mthickplatesforpads,themaximumVonMisesstressis7.57MPa(figure6).Foranyotherthicknessofpads,byfunction

=

inMPaandtinmeter,basedonthefactthatbendingstressinplatesisinverselyproportionaltothesquareofitsthickness(

=

).Usingtheyieldstrength185MPaofthepadsmaterialandsafetyfactor2,thefunctiongivesthethicknessofpadsis57mm.

Figure6ThemaximumVonMisesstressinpads

Padshaveasafetyfactorgreaterthan2whiletheyarestrongerthan57mmthickplate.

3.2Maximumstressindrivingtube

Asillustratedinfigure7,"TheVonMisesstressdistributionofdrivingtube"showsthemaximumVonMisesstressis17.6MPa.Consideringthestartuptorque2.5timesgreater,thenthesafetyfactoragainstyieldis200/17.6/2.5=4.54.Figure8showsthemaximumVonMisesstressofdrivingtubehole,whichis4.17MPa,muchsmallerthanthematerialbreakagelimit.

Figure7TheVonMisesstressdistributionofdrivingtube

Figure8TheVonMisesstressdistributionofdrivingtubehole

3.3stressanalysisofmanholes

3.3.1VonMisesstressaroundmanhole

Formanhole1,themaximumstaticVonMisesstressis66.7MPaat4hposition(seeFig9);formanhole2,themaximumstaticVonMisesstressis79.4MPaat4hposition(seeFig10);thesafetyfactorwithrespecttoyieldisf=250/79.4=3.15

Fig9MaximumVonMisesStressaroundmanhole1

Fig10MaximumVonMisesStressaroundmanhole2

3.3.2Fatiguestressaroundmanhole

Formanhole1,theworstprincipalstressrangeoccursontheedgeofshellbetween

maxat4h=68.4Mpaand

minat7h=-12.9Mpa(Fig11-12).Thus,stressrange=68.4-(12.9)=81.3Mpa.SafetyfactorwithrespecttoallowableinfinitelifecategoryAstressaccordingtoAISC:

f=165(Mpa)/(81.3Mpa)=2.02。

Fig11Max.principalstressonmanhole1

Fig12Min.principalstressonmanhole1

Formanhole2,theworstprincipalstressrangeoccursontheedgeofshellbetween

maxat10h=82.1Mpaand

minat2h=-19.7Mpa(Fig13-14).Thus,stressrange=82.1-(19.7)=101.8Mpa.SafetyfactorwithrespecttoallowableinfinitelifecategoryAstressaccordingtoAISC:

f=165(Mpa)/(101.8Mpa)=1.62。

Fig13Max.principalstressonmanhole2

Fig14Min.principalstressonmanhole2

3.4Fatiguestressarounddischargedhole

Forthesymmetricalcharacteristicsoftheholeinthedischargedpart,thisreportjuststudiesoneholewiththesamepositionofmanhole1ofeveryhourposition.

Forthedischargedhole,theworstprincipalstressrangeoccursontheedgeofinsideshellbetween

maxat4h=45.5Mpaand

minat10h=-14.7Mpa(Fig15-16).Thus,stressrange

=45.5-(-14.7)=60.2Mpa.SafetyfactorwithrespecttoallowableinfinitelifecategoryAstressaccordingtoAISC:

=(165Mpa)/(60.2Mpa)=2.74

Fig15Max.principalstressondischargedhole

Fig16Min.principalstressondischargedhole

3.5Fatiguestressof“T”shapebuttjoint

Forthesymmetricalcharacteristicsofsliderring,takeonesideofthe“T”shapebuttjointinthepositionofinletendforexample.Theworstprincipalstressrangeoccursontheedgeofshellbetween

maxat1h=2.35Mpaand

minat3h=-9.5Mpa(Fig17-18).Thus,stressrange

=2.35-(-9.5)=11.85Mpa.SafetyfactorwithrespecttoallowableinfinitelifecategoryAstressaccordingtoAISC:

=(165Mpa)/(11.85Mpa)=13.92

Fig17Max.principalstressof“T”shapebuttjoint

Fig18Min.principalstressof“T”shapebuttjoint

4Generalconlusions

1.Thesafetyfactorwithrespecttoyieldofmanholesandmainshell=3.15whichmeetthestrengthrequirement.

2.Formanhole1,fatiguestressrange=81.3Mpa,safetyfactor=2.02;formanhole2,fatiguestressrange=101.8Mpa,safetyfactor=1.62;fordischargedhole,fatiguestressrange=60.2Mpa,safetyfactor=2.74.For“T”shapebuttjoint,fatiguestressrange=11.85Mpa,safetyfactor=13.92.Thefatiguestrengthofmanholesmeetdesignrequirement.

3.Themaximumstressondrivingtube=17.6Mpa,consideringthestartuptorque2.5timesgreater,safetyfactor=4.54,whicharesafeenough.

4.ThemaximumVonMisesstressofbearingpads=7.57Mpa.ThemaximumVonMisesstressofthecontactsurfaceofsliderring=10.0Mpa.

Inaword,thedesignofmillmeetsstaticandfatiguerequirement.