英文文献整理.docx

《英文文献整理.docx》由会员分享,可在线阅读,更多相关《英文文献整理.docx(52页珍藏版)》请在冰豆网上搜索。

英文文献整理

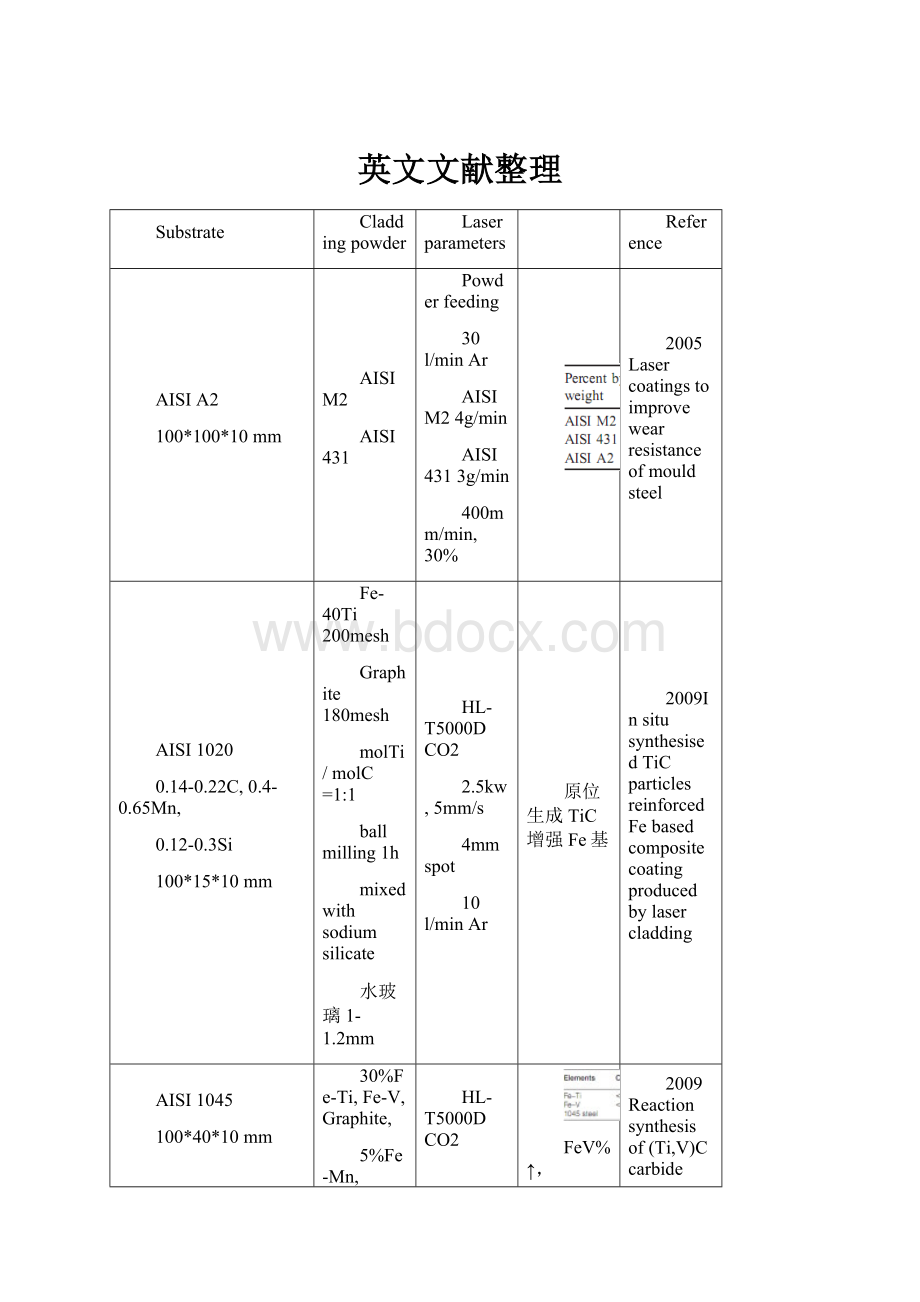

Substrate

Claddingpowder

Laserparameters

Reference

AISIA2

100*100*10mm

AISIM2

AISI431

Powderfeeding

30l/minAr

AISIM24g/min

AISI4313g/min

400mm/min,30%

2005Lasercoatingstoimprovewearresistanceofmouldsteel

AISI1020

0.14-0.22C,0.4-0.65Mn,

0.12-0.3Si

100*15*10mm

Fe-40Ti200mesh

Graphite180mesh

molTi/molC=1:

1

ballmilling1h

mixedwithsodiumsilicate

水玻璃1-1.2mm

HL-T5000DCO2

2.5kw,5mm/s

4mmspot

10l/minAr

原位生成TiC增强Fe基

2009InsitusynthesisedTiCparticlesreinforcedFebasedcompositecoatingproducedbylasercladding

AISI1045

100*40*10mm

30%Fe-Ti,Fe-V,Graphite,

5%Fe-Mn,3%Fe-Si,5%CaF

molV/molTi=0,0.5,1,1.2

ballmilledunderAr

HL-T5000DCO2

2.5kw,5mm/s

3mmspot

33%,powderfeed350mg/s

10l/minAr

FeV%↑,TiC+(Ti,V)C→VC+(Ti,V)C多相颗粒增强Fe基

2009Reactionsynthesisof(Ti,V)CcarbidereinforcedFebasedsurfacecompositecoatingbylasercladding

参考文献

AISI1045

100*40*10mm

Fe-25-30Ti,Fe-45-50V,Graphite,

<74μm

HL-T5000DCO2

2.5kw,5mm/s

3mmspot

33%

10l/minAr

TiC+(Ti,V)C增强Fe基

2010MicrostructureandwearpropertiesofinsitumultiplecarbidesreinforcedFebasedsurfacecompositecoatingproducedbylasercladding

AISI1045

100*40*10mm

Fe-25-30Ti,Fe-65-75Mo,Graphite,0-5-10-15%Fe-Mo

<74μm

1.2mm

HL-T5000DCO2

2.5kw,5mm/s

3mmspot

33%

10l/minAr

TiC+(Ti,V)C增强Fe基

AISI1020

50*20*10mm

砂纸研磨-丙酮清洗-预置粉末

Fe38Ni30Si16B14V2(at.%)

纯单相粉末混合100-200目+水玻璃

1mm

HL-T5000CO2

三步:

(1)2kw,5mm/s

3mmspot

(2)2.5kw,10mm/s

(3)4.8kw,5mm/s

2mmspot

15l/minAr

(Ti,Mo)C增强Fe基

2009MicrostructureandwearpropertiesoflasercladFebasedamorphouscompositecoatings

Mildsteel

20*20*10mm

316L(45~60μm)

+5%/20%SiC(25-40μm)

700,800,900,1000w

3.5~7.5mm/s

60mg/s

6l/minAr

316L-5%SiC250-340VHNSiC+Cr2C3

316L-20%SiC450-800VHNSiC+Cr2C3+Fe2Si

316Lstainlesssteel155VHN

700w,7.5mm/s

2009StudiesonDirectlasercladdingofSiCdispersedAISI316LStainlessSteel

316stainlesssteel

316L(-45~+15μm)

+20-33-50vol.%ceramics

WC10Ni(-45~+15μm)

Cr3C2(-45~+5μm)

Al(-45~+5μm)

1-2kw

0.15-0.3g/s

N2

Fe-C-Cr-Ni-M(W,Moetc.)-

Y(CeO,Ti,Netc.)

Ni,N:

lowertheMstemperatureandsubsequentlytopromotetheformationofretainedaustenite.CeO,Ti,V:

refineandspheroidizecarbidesintheinterdendriticregion.StrongcarbideformingelementsCr,W,Mo:

promoteformationofdispersedparticlesresultingfrominsitureactionsduringthelasercladdingprocess.

2012Alloydesign,microstructuralcharacteristics,strengthandtoughnesspropertiesofFe-basedlaser-cladlayer

Mildsteel

Fe-Ni-Si-B-Nb

+2%Mo,1.5%W,2%Y

Fe32Ni32Si16B18Nb2,Fe31Ni31Si18B18Nb2,Fe30Ni30Si20B18Nb2

CO2

非晶、纳米晶

2012FormationandperformanceofanFe-basedamorphous-nanocrystallinecompositecoatingbylasercladdingandremelting

A3mildsteel

50*40*20mm

300目砂纸研磨—丙酮超声波清洗—热喷涂50μm厚Ni层—预置50%高碳铁铬粉

(8.7C,68Cr,balanceFe)+

50%(V+C)100~320目,

球磨2h混合-粘接剂预置1mm-70°C2h烘干

5kwCO2

2.5kw,2.5mm/s

6*1.5mmspot

17%

10l/minAr

VC–Cr7C3ceramiccoating1000HV—matrix150HV

Usinghigh-carbonferrochromepowdertoproducetheCr7C3,thecladiscontinuousandsmooth,withfewdefectsandexcellentbondingwiththesteelsubstrate.Inthecontrast,usingchromiumpowder,thecladexhibitsalargenumberofporosities,roughsurfaceandweakbondinglasercoatingduetouncontrolledCSreaction.

2013MicrostructureandwearbehavioroflasercladdingVC–Cr7C3ceramiccoatingonsteelsubstrate

AISI1020

120*40*10mm

Surfacegroove

100*20*1.5mm

Fe/Cr/Mo,

Fe/Cr/Si3N4,

Fe/Cr/Mo/Si3N4(120,10,3,0.6μm)

喷砂-填充粉末

CO2

2.5kw,750mm/min

8mmspot

33%

12l/minAr

Mo:

increasetheresistanceofstainlesssteels(SSs)tolocalizedcorrosioninchloride-containingmedia.

N:

enhancemechanicalpropertiesandcorrosionresistance,especiallylocalizedcorrosion,comparedwithconventionalausteniticSS

不锈钢粉末

1995MicrostructureandelectrochemicalbehavioroflasercladdedFe-Cr-Mo-Si-Nsurfacealloysoncarbonsteel

中碳钢

80*35*10mm

Fe-Cr-Ni-B-Si+5,15,20%Ni

Fe66Cr20Nil0B2Si2

1mm

CO2

2kw,4mm/s

5mmspot

50%

12l/minAr

1996EffectofNicontentoncrackingsusceptibilityandmicrostructureoflaser-cladFe-Cr-Ni-B-Sialloy

中碳钢

80*35*10mm

Fe-Cr-Ni-B-Si+Ni/Mo/Co

5,10,15,20,25,30%

Fe66Cr20Nil0B2Si2

1mm

CO2

2kw,5mm/s

5mmspot

50%

1999Crackingsusceptibilityofalaser-cladlayerasrelatedtothemeltingpropertiesofthecladdingalloy

80*35*10cm

Self-fluxingFe-based

+0,1,2,3,4Hf

Fe66Cr20Nil0B2Si2

1mm

CO2

2kw,2-8mm/s

5mmspot

50%

Thelowestcracksusceptibilitypointis0.9%wt.Hfinthecladlayeralloy.Forgasshielding,theburninglossofHfisveryserious.+3.0%wt.Hfinthecladalloypowders.Forvacuumprotection,+1.0%wt.Hfincladalloypowders.

Hf:

细化铁基合金提高强度、降低热裂性,但易氧化需保护

图1真空保护装置

2000VacuumlasercladdingandeffectofHfonthecrackingsusceptibilityandthemicrostructureofFe–Cr–Nilaser-cladlayer

中碳钢

80*35*10mm

Self-fluxingFe-based

+0,5,10,15,20Co

Fe66Cr20Nil0B2Si2

1mm

Ni:

可降低热裂倾向,但降低硬度

Co>15%,裂纹消失

ahypoeutecticstructurecanefficientlypreventfromcrackinginlasercladdinglayers.

2001EffectsofCoonthecrackingsusceptibilityandthemicrostructureofFe-Cr-Nilaser-cladlayer

SAE103

0.2%C碳钢

25*15*15cm

ASTMS31254stainlesssteel

<44μm

95°C1h烘干

CO2

2.1~2.4kw,5mm/s

5mmspot

0.1g/s

50%

2.5l/minN2

1997LasercladdingofASTMS31254stainlesssteelonaplaincarbonsteelsubstrate

5CrMnMo

10*4*1.5cm

880°C20min奥氏体化-油冷-560°C60min回火

Fe,Cr,W,Ni,C10:

5:

1:

1:

1

690°C1h时效

3kwCO2

2kw,16mm/s

3mmspot

0.3g/s

50%

2.5l/minN2

Coating:

730μmmax,860HV,6%稀释率

Hightemperaturetemperingat963KpromotedtheprecipitationofvariouscarbidesfromnonequilibriumausteniteandtheevolutionofM7C3carbides.insitucarbidetransformationoccurredofM7C3toM23C6andM6C.

1999NonequilibriummicrostructuresandtheirevolutioninaFe–Cr–W–Ni–Clasercladcoating

5CrMnMo

10*4*1.5cm

Fe,0.52C,1.21Cr,1.18Mn,0.33Mo,

..

..

Cr:

thepredominantcarbideformer,animportantalloyingelementinthematrix.

W:

thesecondaryhardeningcarbideformer,providesadditionalstrengthtothematrix.

Ni:

stabilizethef.c.c.structureasanintrinsictoughnessenhancerduringservice

二次硬化:

690°C时效,1140HV0.2peak

1999Rapidlysolidifiednonequilibriummicrostructureandphasetransformationoflaser-synthesizediron-basedalloycoating

AISI1045

40*30*20mm

Fe-Co-Ni-Zr-Si-B

Fe57Co8Ni8Zr10Si4B13(at.%)6~44μm混合粉末

丙酮预置1.3mm

10kwCO2

7.5kw,50mm/s

3.5mmspot

Ar

涂层最大厚度1.2mm,硬度1270HV

Thesupercooledliquidregion,_Txandthereducedamorphous-formingtemperature,Tg_Tmare62Kand0.61

2001Fe-basedthickamorphous-alloycoatingbylasercladding

1Cr18Ni9Ti

40*20*5mm

Fe-B,150μm,1085°C,6.15

Fe-C,150μm,1502°C,7.15

B4C,B76%,dissociatedC50μm,2450°C,2.52

中国厂家

球磨20min

FeTi+20,25,30wt.%B4C

200目砂纸研磨-丙酮清洗-聚苯乙烯溶液粘接剂预置

1mm

5kwCO2

1.5~3kw,2.5

4~12mm/s6

1.5~3.5mmspot3

30-50%

Ar

17.6Cr,9.42Ni,0.68Ti,1.32Mn,0.53Si,0.082C,Febalance.

2001FormationofTiB2whiskersinlasercladFe–Ti–Bcoatings

退火A36mildsteel

(0.25-0.28C;0.6-/1.2Mn)

Fe,Al

1h球磨混合Fe-20Al

1,2,4,6g/min

2003CladdingofFe-aluminidecoatingonmildsteelusingpulsedlaserassistedpowderdeposition

中碳钢

25*15*11mm

去脂:

丙酮-酒精清洗

Fe-basedpowder74-100μm

(Fe-Si-Ni-Mo-C-B,清华大学)

+Re2O3,CaF2

+2.4%Zr

有机溶剂粘接预置粉末0.7mm室温干燥4h

3kwCO2

1.5kw

4mmspot

单道:

5mm/s

多道:

5,5.83,6.33,6.33mm/sreduceheataccumulation

25%

Ar

ZrC选择原因

insituZrC0.7-reinforcedcompositecoating

1000-1200HV

2003MicrostructurecharacteristicsofZrC-reinforcedcompositecoatingproducedbylasercladding

50Fe,15Cu,15Fe3P<60μm20Ni<5μm

Nd:

YAG

Theadditionofameltingpointloweringadditive,e.g.Fe3PorCu3Pisfavorableinmakingtheprocessmoreenergyefficient.Forinstance,pureFehasameltingpointof1538˚C,butafteralloyingwithsomesmallamountofPthiscanbeloweredto1048˚C[7].ThedissolutionofPinFealsohasthebenefitofloweringthesurfacetensionofthemelt[8,9].Thislowersthetendencytoformballsaftermeltingandthusenhancesthesurfacequalityanddensity.PlowerstheoxidationrateoftheCuandFepowderparticles&increaseinhardness.Niisaddedforitsmarkedstrengtheningeffectalthoughitstoxicitymakesitanunpopularmaterial.

2004Selectivelasermeltingofiron-basedpowder

中碳钢

Ø40*10mm

Fe–Ni–Cr–Mn–Si+0.2,0.3,0.4%C

Fe95.5–Ni1.5–Cr1–Mn1–Si1

CO2

3.5kw

4mmspot

3,6mm/s

33%

Ar

Comparedwiththedesigningprincipleof‘‘highcarboncontentandeutecticstructure’’,thatof‘‘lowcarboncontentandperitecticstructure’’isbetter.

2005EffectofcarboncontentonthemicrostructureandthecrackingsusceptibilityofFe-basedlaser-cladlayer

AISI1010

150*75*5mm

退火态,喷砂

Fe-B-C,Fe-B-Si,Fe-B-C-Si-Al-C

94Fe4B2C,75Fe15B10Siand

78Fe10BC9Si2Al1C(wt.%)

溅射100μm厚粉末

2.5kwNd:

YAG

3.5*0.6mmspot

15%

5l/min

AISI1010steel(0.08-0.13C,0.3-0.6Mn,0.04P,0.05S)

Fe-B-C,950HV,耐磨性、耐蚀性最佳

Fe-B-Si,600HV

Fe-B-C-Si-Al-C,1150-1200HV

Substrate:

260HV

2006LasersurfacecladdingofFe–B–C,Fe–B–SiandFe–BC–Si–Al–Conplaincarbonsteel

1Cr13马氏体不锈钢Fe-13.4Cr-0.9Si

-0.08C

30*25*3cm

Fe-Cr-Ni–Mo-Si-Nb-N-C

Fe-15.2Cr-5.1Ni,Fe-15.7Cr-7.1Ni

2kwCO2

1.3kw

3mmspot

5mm/s

10g/min

35%

Ar

Ni含量的影响

铁基粉末优点

2007EffectofasmallincreaseintheNicontentonthepropertiesofalasersurfacecladFe-basedalloy

热轧siliconsteel

Fe-1.25Si-0.23Mn-0.28Al-0.005C

50*15*2.65mm

Fe-80%Si(1:

4)

50-75μm

喷砂-预置

TheSicontentsareabout5.8wt%and6.5wt%inthesingle-trackandmulti-trackcladdingzones,respectively.

单道1150HV,多道980HV

20