轮胎外观缺陷分析.docx

《轮胎外观缺陷分析.docx》由会员分享,可在线阅读,更多相关《轮胎外观缺陷分析.docx(21页珍藏版)》请在冰豆网上搜索。

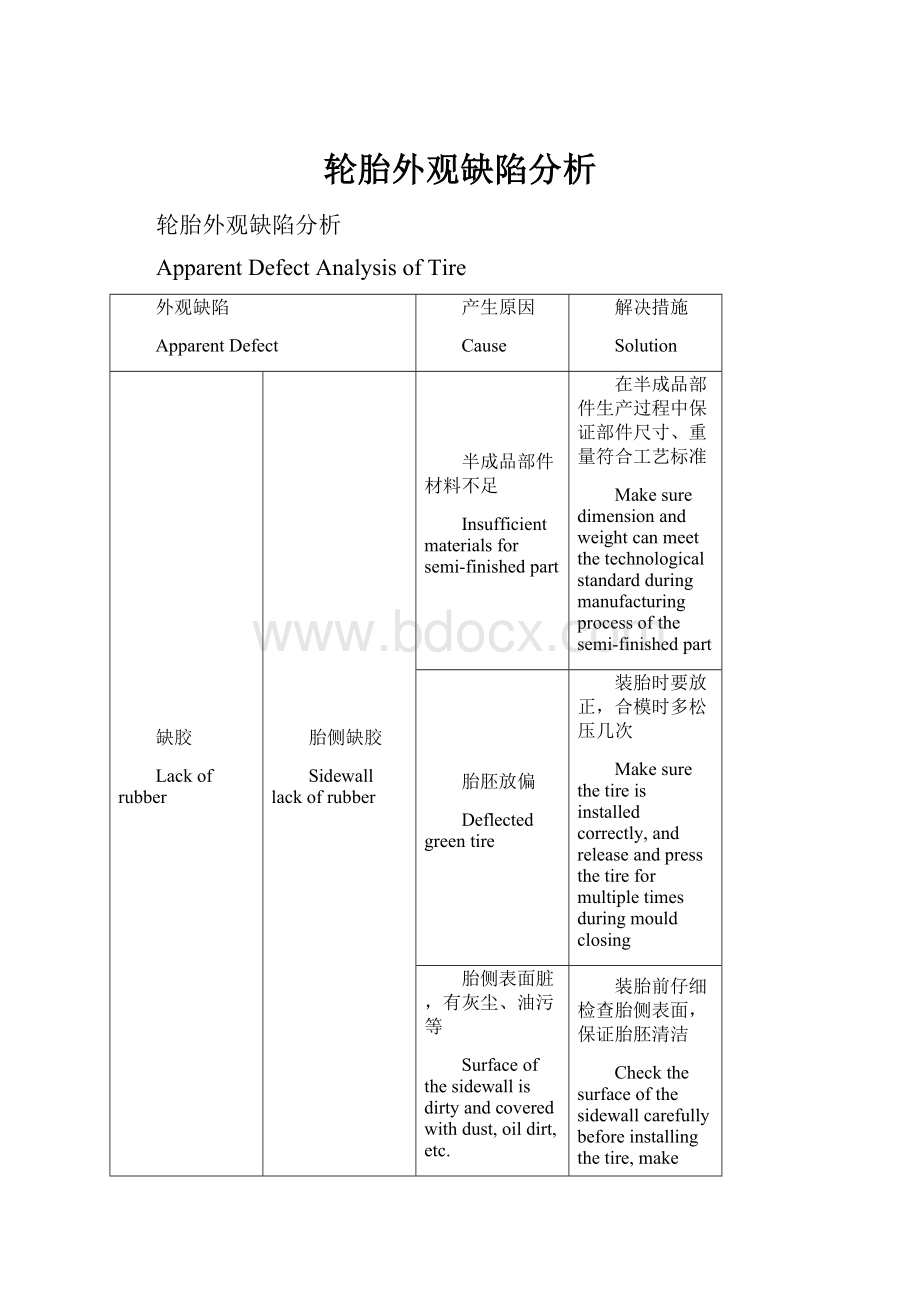

轮胎外观缺陷分析

轮胎外观缺陷分析

ApparentDefectAnalysisofTire

外观缺陷

ApparentDefect

产生原因

Cause

解决措施

Solution

缺胶

Lackofrubber

胎侧缺胶

Sidewalllackofrubber

半成品部件材料不足

Insufficientmaterialsforsemi-finishedpart

在半成品部件生产过程中保证部件尺寸、重量符合工艺标准

Makesuredimensionandweightcanmeetthetechnologicalstandardduringmanufacturingprocessofthesemi-finishedpart

胎胚放偏

Deflectedgreentire

装胎时要放正,合模时多松压几次

Makesurethetireisinstalledcorrectly,andreleaseandpressthetireformultipletimesduringmouldclosing

胎侧表面脏,有灰尘、油污等

Surfaceofthesidewallisdirtyandcoveredwithdust,oildirt,etc.

装胎前仔细检查胎侧表面,保证胎胚清洁

Checkthesurfaceofthesidewallcarefullybeforeinstallingthetire,makesurethegreentireisclean

部件停放时间过长,影响表面黏性和流动性

Parthasbeenplacedforalongtime,andthesurfacestickinessandfluidityareaffected

胎胚必须按先后顺序及时硫化

Thegreentiresshouldbecuredsequentiallyintime

胎侧有气泡

Sidewallhasbubbles

刺破后压实、压平

Piercethebubbles,thencompactandflattenthesidewall

模型内积水

Mouldisinternallyprovidedwithaccumulatedwater

装胎前模具吹干、吹净,保证模具清洁,气孔流畅

Dryandcleanthemouldbyblowingbeforeinstallingthetire,makesurethemouldisclean,andtheairholesaresmooth

模具跑气孔位置不当

Incorrectpositionsofmouldairholes

增加跑气孔

Increasethenumberofairholes

硫化压力、温度过低

Curingpressureandtemperaturearetoolow

提高硫化温度、压力,保证硫化温度、压力分布均匀,使之符合工艺规定

Improvethecuringtemperatureandpressure,makesurethevulcanizationtemperatureandpressureareevenlydistributed,soastomeetthetechnologicalregulations

胶囊夹盘泄漏

Bladderchuckisleaked

重新上夹盘

Reinstallthechuck

胎圈缺胶

Beadlackofrubber

胎圈部位排气孔堵塞

Exhaustholesinthebeadareblocked

保证模具清洁、气孔流畅

Makesurethemouldisclean,andtheexhaustholesaresmooth

气密层、耐磨胶厚度或宽度不够

Thicknessorwidthoftheinnerlinerandthewearrubberisinsufficient

保证气密层、耐磨胶厚度或宽度稳定、达标

Makesurethicknessorwidthoftheinnerlinerandthewearrubbercanmeetthestandard

帘布宽度过小,硫化时帘布拉伸,钢丝圈局部上抽,造成该部位胶料不足

Widthoftextilecordistoosmall,thecordfabricwillbetensionedduringcuring,beadwillbepulledupwardspartially,namely,therubbercompoundatthatportionwillbeinsufficient

保证帘布宽度稳定、达标

Makesurethewidthofthecordfabricisstableandcanmeetthestandard

钢丝圈反包不实

Beadisturnedupweakly

成型反包压实

Formashape,turnitup,andcompactit

钢丝圈直径过大,钢丝圈底部相应部位需要更多的胶料来填充

Diameterofthebeadistoolarge,andcorrespondingportionsatthebottomofthebeadneedtobefilledwithmorerubbercompounds

保证钢丝圈直径稳定、达标

Makesurethediameterofthebeadisstableandcanmeetthestandard

其余相应同胎侧缺胶

Othercorrespondingsidewallslackofrubber

其余相应同胎侧缺胶

Othercorrespondingsidewallslackofrubber

杂质

Impurities

胎胚表面粘有油污,硫化时脱落,轮胎表面有杂质印痕

Surfaceofthegreentirehasoildirtandwillbefallenoffduringcuring,surfaceofthetirehasimpuritymarks

强化员工责任心,严格落实互检查工作,出现油污必须用汽油等挥发剂处理控制后再生产

Strengthenthesenseofresponsibilityofthestaff,strictlyimplementthemutualinspectionoperation,andusepropellant,suchasgasoline,toprocessandcontroloildirtbeforeproduction

胶料或者胎胚在搬运过程中有落地现象,导致粘有杂物

Rubbercompoundorgreentireisfallentothegroundduringhandling,therefore,therubbercompoundorthegreentireiscoveredwithimpurities

加强生产过程现场管理,保证胎胚表面清洁

Strengthenthesitemanagementduringproduction,makesurethesurfaceofthegreentireisclean

胎胚架脏,有杂物

Greentirerackisdirtyandcoveredwithimpurities

加强胎胚架卫生清理,及时清除异物

Strengthenthesanitationandcleaningofthegreentirerack,andremoveforeignobjectsintime

胶料本身有杂物,硫化时露出

Rubbercompoundsareprovidedwithimpurities,andtheimpuritiesareexposedduringcuring

加强对原材料、胶料各类半成品生产时的控制,避免混入杂物,发现杂物及时剔除

Strengthenthecontrolforrawmaterials,rubbercompoundsandsemi-finishedproductsduringproductiontopreventimpuritiesfrommixing,andremovetheimpuritiesintime

装胎前模具内有异物未清除

Foreignobjectsinthemouldarenotremovedbeforeinstallationofthetire

加强硫化自检及清模,保证设备清洁

Strengthenself-inspectionofcuringandmouldcleaning,makesuretheequipmentisclean

圆角

RoundCorner

花纹圆角

PatternedRoundCorner

模具花纹气孔堵或设计不合理、排气不畅

Patternedairholesinthemouldareblockedorthedesignisunreasonable,andtheaircannotbeexhaustedsmoothly

加强模具清洗及气孔疏通,对设计不合理气孔进行改进或追加

Strengthenthecleaningofthemouldanduncloggingoftheairhole,improvetheairholeswithunreasonabledesign,orincreasethenumberofairholes

模具表面粗糙,胶料流动困难

Surfaceofthemouldisrough,therubbercompoundsaredifficulttomove

对模具表面粗糙进行整修,及时淘汰外观不好模具

Repairthemouldwithroughsurface,removeunattractivemouldintime

胎胚胎面粘有油迹或内喷涂液等杂物

Treadofthegreentireiscoveredwithoildirtorisinternallycoveredwithsprayliquid,etc.

保证胎胚表面清洁

Makesurethesurfaceofthegreentireisclean

胶料焦烧时间短、流动性差

Scorchtimeoftherubbercompoundisshort,andtheliquidityispoor

改善胎面胶料流动性能,延长胶料的焦烧时间

Improvetheliquidityofthetreadrubbercompound,prolongthescorchtimeoftherubbercompound

模具表面有油等污物

Surfaceofthemouldiscoveredwithdirt,suchasoil

保证模具清洁

Makesurethemouldisclean

子口圆角

ChaferRoundCorner

胶囊与夹盘涂隔离剂太多,子口部位胶料不能充分模腔

Bladderandchuckarecoveredwithtoomanyseparant,rubbercompoundsatthetirebeadarenotsufficientformouldcavity

隔离剂喷洒适度,不能过多

Sprayseparantproperly

夹盘螺纹未上紧有间隙

Thechuckthreadsarenottightenedandhaveclearance

旋紧夹盘螺纹

Rotatethechuckthreadtightly

子口直径过大,圈口部位胶料不足

Diameterofthetirebeadistoolarge,rubbercompoundsatthetireringareinsufficient

保证子口直径稳定、达标

Makesurethediameterofthetirebeadisstableandcanmeetthestandard

装胎时胎圈定位不正,胎圈部位空隙过大

Thebeadisincorrectlypositionedduringinstallationoftire,andthegapinthebeadistoolarge

装胎时要放正,合模时多松压几次

Makesurethetireisinstalledcorrectly,andreleaseandpressthetireformultipletimesduringmouldclosing

定型高度过高,胶囊与夹盘内压蒸汽泄露

Themoldingheightistoohigh,theinternally-compressedsteaminthebladderandchuckisleaked

确保定型高度合理

Makesurethemoldingheightisreasonable

胎侧或胎圈包布厚度偏小导致子口胶料不足

Theflipperthicknessofsidewallandbeadistoosmall,whichresultsinthefactthattherubbercompoundsattirebeadareinsufficient

保证胎侧或胎圈包布尺寸稳定、达标

Makesuretheflipperthicknessofsidewallorbeadisstableandcanmeetthestandard

气泡

Bubble

胎侧或胎体线表面有杂质或挥发分

Surfaceoftirebodylineorsidewalliscoveredwithimpuritiesorvolatilecomponents

保证半成品部件清洁

Makesurethesemi-finishedpartisclean

胶料各类半成品未压实,有气泡

Semi-finishedproductsmadefromrubbercompoundsarenotcompactedandhavebubbles

胎体线接头处易有泡,必须压实

Thejointoftirebodylinesispronetosufferingfrombubbles,therefore,itshouldbecompacted

胎侧、胎体帘布、胎圈包布、气密层胶等胶料黏性差,导致成型时各部件间存有气体过多

Rubbercompounds,suchassidewall,carcassply,beadchaferandinnerliner,arepoorinstickiness,whichresultsinthefactthatgasbetweenpartsistoomuchduringmolding

保证各工序胶料黏度稳定、达标

Makesurethestickinessofrubbercompoundsineachprocedureisstableandcanmeetthestandard

模具排气不佳

Mouldispoorinexhausting

改进模具结构

Improvethestructureofthemould

硫化温度、压力不达标

Curingtemperatureandpressurecannotmeetthestandard

确保硫化温度、压力稳定、达标

Makesurethecuringtemperatureandpressurearestableandcanmeetthestandard

变形

Deformation

主要出现在出模后抽真空效果差,胶囊拉直所致

Deformationismainlycausedbypoorvacuumingeffectaftermoldstrippingandstraighteningofbladder

对硫化机抽真空进行检查,出现性能下降立即整修

Checkvacuumingofcuringmachine,andrepairitassoonastheperformanceisreduced

由于喷涂不均造成硫化结束后,胎里局部与胶囊脱离困难造成

Tireinsidepartsandbladderaredifficulttobeseparatedduetounevensprayingaftercuring

提高喷涂质量,使表面喷涂均匀

Improvethesprayingquality,andspraythesurfaceevenly

开模时硫化胶囊的影响

Effectoncuringbladderduringmouldopening

确保开模时内压为零

Makesuretheinternalpressureiszeroduringmouldopening

硫化胶囊老化,胎圈区周向膨胀不均一

Thecuringbladderisaged,expansionatthebeadareaisuneven

装胎前检查胶囊质量,确保有问题的及时更换

Checkthequalityofthebladderbeforeinstallingthetire,andreplacethedefectivebladderintime

硫化定型压力不足,导致胶料不能合理流动

Thecuringmoldingpressureisinsufficient,whichresultsinthefactthattherubbercompoundcannotflowreasonably

确保硫化定型压力稳定、达标

Makesurethecuringmoldingpressurearestableandcanmeetthestandard

硫化装模时对胎胚子口部位的机械损伤

Thechaferatthegreentireismechanicallydamagedduringcuringmouldfilling

正确、适度地装模,严禁远距离扔、甩

Carryoutmouldfillingcorrectlyandappropriately,donotthroworswingthemouldremotely

开模高度过高

Mouldopeningheightistoohigh

根据不同规格设定不同开模高度

Setdifferentmouldopeningheightsaccordingtodifferentspecifications

轮胎轨道运输时挤压变形

Tireisdeformedbysqueezingduringtracktransportation

保证运输轨道畅通

Makesurethetransportationtrackisunblocked

胎圈露线

ExposedCordinBead

胎胚子口直径过小,硫化装模时夹盘挤压子口材料严重

Diameterofgreentirebeadistoosmall,andthematerialatthetirebeadisseriouslysqueezedbythechuckduringcuringmouldfilling

保证子口直径稳定、达标

Makesurethediameterofthetirebeadisstableandcanmeetthestandard

成型机头宽度偏小

Thebuildingdrumwidthisrelativelysmall

调整施工标准

Adjusttheconstructionstandard

装胎高度过低或硫化定型尺寸过大。

胎胚子口处夹盘非正常接触,外压作用下胶料非正常流动将钢丝暴露出来

Themouldfillingheightistooloworthecuringmoldingdimensionistoolarge.Thechuckatthegreentiretirebeadisabnormallycontacted,therubbercompoundsaredrivenbytheexternalpressureabnormallytoexposethesteelwire

确保定型高度、尺寸适度

Makesurethemoldingheightanddimensionareappropriate

装胎时间过长,子口包胶在模具上停留时间过久,子口包胶发软流失,引起胎圈露线

Thetimeformouldfillingistoolong,thetirebeadrubbercoatinghasbeenreservedonthemouldfortoolong,andthetirebeadrubbercoatingissoftenedanddrained,whichresultsinthefactthatthecordinbeadisexposed

及时硫化,及时卸胎

Carryoutcuringintime,andremovethetireintime