baseline.docx

《baseline.docx》由会员分享,可在线阅读,更多相关《baseline.docx(16页珍藏版)》请在冰豆网上搜索。

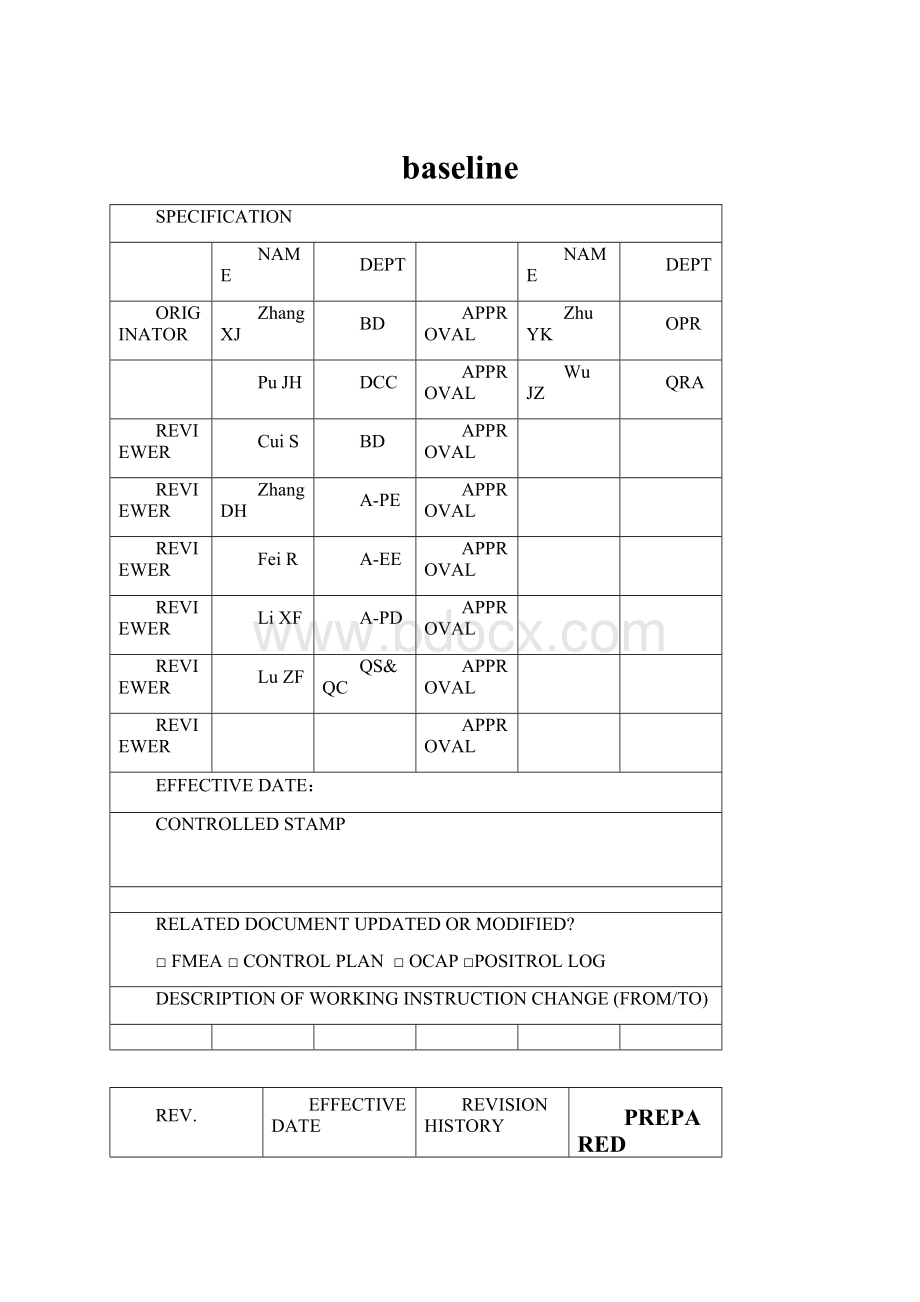

baseline

SPECIFICATION

NAME

DEPT

NAME

DEPT

ORIGINATOR

ZhangXJ

BD

APPROVAL

ZhuYK

OPR

PuJH

DCC

APPROVAL

WuJZ

QRA

REVIEWER

CuiS

BD

APPROVAL

REVIEWER

ZhangDH

A-PE

APPROVAL

REVIEWER

FeiR

A-EE

APPROVAL

REVIEWER

LiXF

A-PD

APPROVAL

REVIEWER

LuZF

QS&QC

APPROVAL

REVIEWER

APPROVAL

EFFECTIVEDATE:

CONTROLLEDSTAMP

RELATEDDOCUMENTUPDATEDORMODIFIED?

□FMEA□CONTROLPLAN□OCAP□POSITROLLOG

DESCRIPTIONOFWORKINGINSTRUCTIONCHANGE(FROM/TO)

REV.

EFFECTIVEDATE

REVISIONHISTORY

PREPARED

AA

Newrelease

ZhagnXJ

CONTENTS

1.PURPOSE目的

2.SCOPE范围

3.REFERENCEDOCUMENTS参考文件

4.DEFINITION定义

5.RESPONSIBILITY职责和权限

6.APPLIEDEQUIPMENT适用设备

7.PROCEDURE程序内容

8.SAFETYANDENVIRONMENT安全与环保

9.RECORD记录

10.ATTACHMENT附录

1PURPOSE目的

Toprovidebase-lineflowforQFNpackageassemblyandtodefinebasicrequirementsforQFNpackageproductioninANST.

为ANST生产的QFN封装件加工提供基本流程图,定义QFN封装件加工生产的基本要求。

2SCOPE范围

ThisspecificationshallbeappliedtoANSTQFNproducts.

本规范适用于ANST封装的QFN封装件产品。

3REFERENCEDOCUMENTS参考文件

3.1QFNControlPlan

QFN控制计划S-CP-BD-002

3.2AnstCONTROLPLANFORINCOMINGINSPECTIONMATERIALS

安盛来料检验的控制计划S-CP-IQA-001

3.3ESDControlProcedureESD控制标准S-QAP-ESD-040

3.4EnvironmentControlProcedure环境控制程序S-QAP-ENV-008

3.5ProcessControlProcedure工艺控制程序S-PEP-GEN-029

3.6CalibrationProcedure校准程序S-QAP-CAL-017

3.7CorrectiveandPreventiveActionProcedure纠正和预防措施程序S-QAP-QS-021

3.8Non-conformingMaterialControlProcedure不合格材料控制程序S-QAP-IQA-023

3.9RecordControlProcedure记录控制程序S-QAP-QS-002

3.10CustomerSpecification/RequirementReviewProcedure客户规范要求评审规定S-QAW-QS-004

3.11NonconformingProductControlProcedure不合格品管理程序S-QAP-QC-019

4DEFINITIONS定义

4.1BD(BisinessDevelopmentdapartment)业务发展部

4.2QA(QualityAssurancedepartment):

质量部

4.3PROD(Productiondepartment):

生产部

4.4PE(ProcessEngineeringDepartment):

工艺工程部

4.5IQA(IncomingQualityAssurance):

进料质量检验

4.6PC(PlanControl):

生产计划.

4.7PDC(ProductDistributionCenter):

产品发货中心

5RESPONSIBILITY职责和权限

5.1ProductionDepartment生产部

Productiondepartmentisresponsibleforperformingtheproductionoperationbasedonthedocumentedprocedureandensureproductsafetyduringproduction.

生产部负责根据文件规定的过程进行生产并保证产品在生产中的安全。

5.2PlanDepartment企划部

Kittingroomclerkisresponsibleforreceivingthewafersandcheckingthedevice,quantity,lotnumberwithlabelinboxandshippinginformation.

圆片库人员负责接收原片,并根据盒子上的标签和运输信息检查Device,数量,批量号.

5.3PDC(ProductDistributionCenter):

产品发货中心

PDCdepartmenthasresponsibilitytoassurethehandling,storageandshippingandtomaintainproductsqualitybyrequiredmannersforthefinishedproductswhichismovedfrommanufacturingarea.

产品发货中心确保在管理,储存及运输中保证产品数量与从生产部送来的产品数量一致.

5.4QualityAssuranceDepartment质量部

TheQAdepartmentperformsmonitoring,inspectionandtesttoensuretheconformityoftheprocessandproductaccordingtothespecifiedrequirements.IQAperformsincominginspectionofmaterials.

质量部门负责监控,检查和测试确保过程和产品符合所规定的要求.IQA对材料进行进货检查.

5.5ProcessEngineeringDepartment工艺工程部

TheProcessEngineer'sresponsibilitytosupportR&Dandupdateperiodically.

工艺工程师负责支持研发并定时更新.

BisinessDevelopmentdapartment业务发展部

BDhasresponsibilitytoconstituteinitialbaselineaboutnewPackageinRD

业务发展部负责新开发封装形式baseline的初步制定

6APPLIEDEQUIPMENT适用设备

Refertopara,technicalspecifications.参考的技术规范

7PROCEDURES程序内容

7.1Base-lineprocessflow基本工艺流程图

Manufacturingstep

Inspection/Test

QAgate

Judgement

Processflow

RESP

SpecNo

Remark

DieAttach

WaferMounting

Backgrinding

WaferSawing

Waferreceiving

WaferIQC

Accept

2ndOpticalQCgate

Reject

2ndOpticalinspection

PostDieAttachCure

WireBonding

Accept

3RDOpticalQCgate

Reject

3RDOpticalinspection

Molding

PostMoldCure

PC

IQA

PROD

PROD

PROD

QA

PROD

PROD

PROD

PROD

PROD

QA

PROD

PROD

PROD

S-PLW-PC-001

S-QAW-IQA-001

S-PES-BG-011

S-PES-WS-008

S-PES-WS-007

S-QAW-WS-001

S-PES-WS-003

S-PES-DA-008

S-PEW-DA-009

S-PES-WB-008

S-QAW-WB-004

S-PES-WB-001

S-PES-MD-001

S-PEW-MD-014

Note#1

Note#2

Note#4

Note#3

Note#2

Note#5

Note#6

Processflow

RESP

SpecNo

Remark

Marking

Y

N

Testing

EVIQClotsaccept

ExternalVisualInspection

Singulation

PROD

PROD

PROD

QA

PROD

S-PES-MK-001

S-PES-EVI-001

S-QAW-EVI-001

Note7#

Note8#

NOTE1>Iffail,IQAshallinformcustomerservicedept.andcustomerservicedept.shouldinformcustomerand

waitfortheirdisposition.

当检查失败,IQA应该通知客户服务部,客户服务部必须通知客户并等候处理.

NOTE2>100%inspectionshallbeprocessedwhenonlyQAgateinspectionfail.

当QAgate检查失败时,生产部必须进行100%检查。

NOTE3>PleasecleaningitbyPLASMAbeforewirebonding.

在键合之前需要进行PLASMA清洗

NOTE4>PleasemarkingthedifferenNooneveryleadframebeforediebonding,thenrecordthestripNoonthepaperattachafterT-CARD,anddo“X”atrejectappeddixone.

在装片时,每条引线框上标上不同的号码,并在随件单后面附的不良品记录纸上记录该条的号码,并在不良品位置上画“X”,见附录一.

NOTE5>Allrejectproductneedbedone“X”accordingtorejectrecordingpaper,puttingrejectstripontopside.

全部不良品根据不良品记录单使用特制网格板对位打“X”,不良电路放在最上层。

NOTE6>UsingpressuremagazinedoPMC,putoneslatsecludeevery10strips,andonemagazineonlycancontain30strips,andput30kgweightslatonthetop.

塑封后固化采用施压弹匣,每隔10条放入一块铁板,一个弹匣只能放30条框架,最上层放置8~10kg的金属块。

NOTE7>Usingtailor-madetabletoolingonmanuallasermarkingMC,precisionisveryimportant.

打印使用专用的定位钉台面在手动激光打印机生产,控制精度

NOTE8>OperatorwipeofftapebeforeSawing,theninputittoFOLmagazine.

切割前作业员手动撕除LF上的贴膜,然后将产品插入前道料盒,放入机器生产.

7.2TECHNICALSPECIFICATIONS技术规范

7.2.1AvailableRawmaterial原材料清单

(1)

工序

原材料

备品号/型号

供应商

PROCESS

RAWMAT’L

PART#/MODELNAME

SUPPLIER

BackGrinding

BackGrindTape

SB-205SI-R2

MITSUI

WaferMount

MountTape

SPV-224

Nitto

HAE-1503L

日立化成

DieSawing

SawBlade

SD3500-N1-70AA

DISCO

ZH05-SD2000-N1-110-DD

DISCO

104F27HDDD

DISCO

J1440-Q300

Kulicke&Soffa

J1030-Q300

Kulicke&Soffa

KH5-1635

DISCO

203027HCDC

DISCO

203027HCBB

DISCO

S1435

Kulicke&Soffa

DieAttach

Epoxy

QMI519/QMI168

Henkel

8290

Ablestik

LeadFrame

QFN系列

ASM/三星/QPL/三井

WireBonding

GoldWire

20um~50um

贺利氏,达博,康强

Molding

Compound

CEL9200M(φ16*

HITACHI

CEL9220HF13(φ16*

HITACHI

Singulation

Blade

58x40

三菱/DISCO/ITI

7.2.2AvailableProcessEquipment现有加工设备

(1)

工序

设备

备品号/型号

供应商

PROCESS

EQUIPMENT

MODELNAME

MANUFACTURER

BackGrinding

BackGrinder

DFG-83H/6

DISCO

DFG-850

DISCO

MULTI-NANO-3-300

G&N

TapeLaminator

D-304

NELSYSTEM

ATM-1100E

TAKATIRI

TapeRemove

H-304

NELSYSTEM

ATRM-2200

TAKATIRI

WaferMount

WaferMount

M-265

NITTO

SAM-8

TAKATIRI

FM-114

Technovifion

DTMWM1230

DYNATECH

ATM-8100

TAKATORI

DieSawing

WaferSaw

A-WD-100A

TSK

A-WD-10A

TSK

DAD321

DISCO

DFD640

DISCO

DFD641

DISCO

DFD651

DISCO

DFD6340

DISCO

DieAttach

DieBonder

AD828

ASM

PLASMA

Clean

AP-1000

March

WireBonding

WireBonder

ASMEagle60/K&S/UTC1000/2000

ASM/K&S/INKWA

Molding

Automoldsystem

TOWAY-1

TOWA

Marking

Manualmarkingsystem

Manualmarkingsystem

大族

Singulation

Sawmachine

SW5000

SECRON

QualitySpecification产品外观检查规范

No

QFN标准QFNQualitySpecification

1

塑封体裂纹packagecrack

REJ

2

塑封体微隙packagemicrogap

REJ

3

塑封体缺损packagechipout

<**

4

塑封体异物packagestain

正面,其他区域,沾污影响打印必须具备可识别top,otherareaIfthestainonpackagemarkingarea,thenvisionshallbemustcanidentify

5

塑封体弯曲packagebend

6

刮痕scratch

1*,影响打印必须具备可识别1*,ifthescratchonpackagemarkingarea,thenvisionshallbemustcanidentify

7

塑封体尺寸packagesize

长和宽偏差±Thelongandwidewindageis±

8

底部外露小岛粘污bottomexposestheislandtostain

<1/5小岛面积lessthan1/5islandarea

9

切割后引脚尺寸偏差leadsizewindageaftercutting

±(左右或上下引脚长度之差)±(Differenceonleftandrightsidesorupperandlowerleadlength)

10

引脚凹痕leaddent

<

11

连筋残留dambarremain

REJ

12

切割毛刺cuttingburr

<

13

引脚松动\断裂leadbreak

REJ

14

X,Y方向引脚突出leadextrude

<

15

引脚损坏leaddamage

<引脚长度,<引脚宽度lessthanleadlengthandlessthanleadwidth

16

引脚异物leadstain

引脚焊接面不允许有Therecan'tbestainontheleadsurface

17

引脚切断面金属毛刺leadcuttingsurfaceofmetalburr

<引脚间距离的1/2(QFN48(5*5)<引脚间距离的2/3)lessthan1/2ofthedistancebetweenthelead

(QFN48(5*5)lessthan2/3ofthedistancebetweenthelead)

18

切割Z方向毛刺cuttingZdirectionburr

MAX

19

模糊的打印标记(IllegibleMarking)

在规定条件下,裸眼12英寸(30cm)无法辨认的打印标记为模糊的打印标记.

Rejectanymarkingnotclearlyvisibleatadistanceof12inches(30cm)underspecifiedconditionwithnakedeyes.

双重打印标记(DoubleMarking)

由于双重打印标记导致的字迹模糊或可能被误识的都应REJECT(报废).

Rejectanydoublemarkingwhichrenderscharactersillegibleormaybemisjudgedwithanothercharacter.

打印标记方向错误(IncorrectMarkingOrientation)

任何方向错误的打印标记都应REJECT(报废).

Rejectanymarkingwithincorrectorientation.

错误的打印标记(WrongMarking)

打印的内容不符合打印指导书错误打印标记都应REJECT(报废).

Rejectanymarkingnotinaccordancewithmarkinginstruction.

打印标记错位或移位

(MarkingPlacement)

打印内容落在注塑体外,字体压边不完整(报废).

Rejectmarkingoutofthepackagesurfaceortouchtheedge

打印标记倾斜(InclinedMarking)

打印内容倾斜超过10度应REJECT(报废).

Rejectmarkinginclinationmorethan10degree.

打印标记破裂(BrokenMarking)

打印的图标或者字符有断裂处超过其本来印记宽度的应该REJECT(报废).

Rejectmarkinglogoorcharacterwithbrokenareamorethantheoriginalwidthofthemark.

无打印标记(NoMarking)

有遗漏打印标记的器件应