压缩空气储罐计算书ASMEU钢印.docx

《压缩空气储罐计算书ASMEU钢印.docx》由会员分享,可在线阅读,更多相关《压缩空气储罐计算书ASMEU钢印.docx(40页珍藏版)》请在冰豆网上搜索。

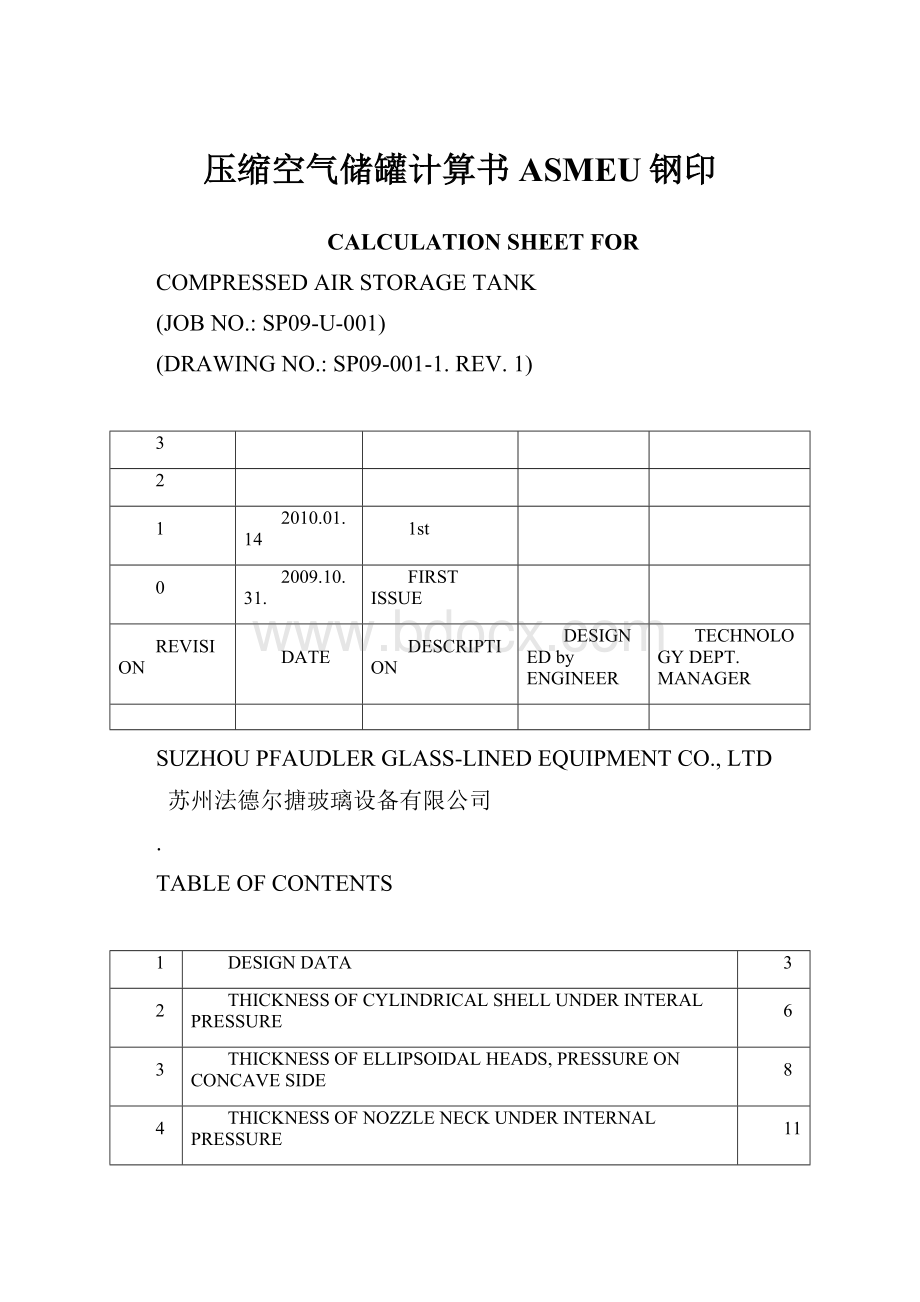

压缩空气储罐计算书ASMEU钢印

CALCULATIONSHEETFOR

COMPRESSEDAIRSTORAGETANK

(JOBNO.:

SP09-U-001)

(DRAWINGNO.:

SP09-001-1.REV.1)

3

2

1

2010.01.14

1st

0

2009.10.31.

FIRSTISSUE

REVISION

DATE

DESCRIPTION

DESIGNEDbyENGINEER

TECHNOLOGYDEPT.MANAGER

SUZHOUPFAUDLERGLASS-LINEDEQUIPMENTCO.,LTD

苏州法德尔搪玻璃设备有限公司

.

TABLEOFCONTENTS

1

DESIGNDATA

3

2

THICKNESSOFCYLINDRICALSHELLUNDERINTERALPRESSURE

6

3

THICKNESSOFELLIPSOIDALHEADS,PRESSUREONCONCAVESIDE

8

4

THICKNESSOFNOZZLENECKUNDERINTERNALPRESSURE

11

5

MAX.ALLOWABLEWORKINGPRESSURE

21

6

HYDROSTATICTESTPRESSUREANDTEMPERATURE

22

7

REINFORCEMENTFOROPENINGS

23

8

STRENGTHCALCULATIONSFORNOZZLEATTACHMENTWELDSFORPRESSURELOADING

26

9

CHECKTHEADEQUACYOFTHEATTACHMENTWELDSATOPENINGS

27

10

CHECKFLANGETONOZZLENECKWELDS

29

11

DESIGNOFSUPPORTINGLEGS

30

12

THECALCULATIONOFLIFTINGLUG

32

13

PRESSURE-TEMPERATURERATINGFORASMEFLANGE

34

14

CHECKFORPOSTWELDHEATTREATMENT

35

15

EVALUATIONOFIMPACTTESTREQUIREMENT

36

1.DESIGNDATA:

(1)

APPLICABLECODE

CUSTOMERSPECIFICATION

ASMESEC.ⅧDIV.12007EDITIONAND2009ADDENDA.

DOC.NO.DC-09-1/Rev0

(2)

DESIGNPRESSURE

INTERNAL1.3MPa

(3)

DESIGNTEMPERATURE

50℃

(4)

TYPEOFJOINTSOFCATEGORIESAANDB

TYPENO.1

(5)

RADIOGRAPHY

SPOTperUW-11(b)

(6)

JOINTEFFICIENCY

SHELL:

0.85,HEAD:

0.85,SHEELtoHEAD:

0.85

(7)

CORROSIONALLOWANCE

1mm.

(8)

MATERIAL

SHELL&HEAD:

SA-516MGr.485

NOZZLE:

SA-106Gr.B

FLANGE:

SA-105M

SUPPORTLEGS:

20(GB/T8163-2008)

SUPPORTPLATE:

SA-285MGr.C

LUG:

SA-516MGr.485

(9)

MAX.ALLOWABLESTRESSATDESIGNTEMPERATURE

SA-285MGr.C:

108MPaat50℃

SA-105M:

138MPaat50℃

SA-106Gr.B:

118MPaat50℃

SA-516MGr.485:

138MPaat50℃

(10)

HEADTYPE

2:

1StandardEllipsoidalHead

(11)

TANKCAPACITY

1.5m3

(12)

SERVICEFLUID

COMPRESSEDAIR(nolethal)

(13)

MIN.SERVICETEMPERATURE

-10℃

(14)

THELOADINGCONSIDEREDINDESIGNING

SEETABLE1-1

(15)

TANKDIMENSIONS

SEEFIG.1-1

TABLE1-1LOADINGCONSIDEREDINDESIGNING

Item

Description

Yes

No

1

Internalpressure

[√]

[]

2

Externalpressure

[]

[√]

3

Weightofvessel

[√]

[]

4

Weightofnormalcontentsunderoperationconditions

[]

[√]

5

Weightofnormalcontentsundertestconditions

[√]

[]

6

Superimposedstaticreactionsfromweightofattachedequipment

[]

[√]

7

Theattachmentsofinternals

[]

[√]

8

Theattachmentsofvesselsupports(skirt,legs,saddlesetc.)

[√]

[]

9

Theattachmentsofliftinglugs

[√]

[]

10

Cyclicanddynamicreactionsduetopressure

[]

[√]

11

Cyclicanddynamicreactionsduetothermalvariations

[]

[√]

12

Cyclicanddynamicreactionsduetoequipmentmountedonthevessel

[]

[√]

13

Cyclicanddynamicreactionsduetomechanicalloadings

[]

[√]

14

Windreactions

[]

[√]

15

Snowreactions

[]

[√]

16

Seismicreactions

[]

[√]

17

Impactreactions,suchasthoseduetofluidshock

[]

[√]

18

Temperaturegradients

[]

[√]

19

Differentialthermalexpansion

[]

[√]

20

Abnormalpressure,suchasthosecausedbydeflagration

[]

[√]

21

Testpressureandcoincidentstaticheadactingduringthetest

(SeeUG-99)

[√]

[]

LISTOFNOZZLES

f

1

DN40

Class150S.O.RF

DRAIN

SA-106Gr.B

e

1

DN450

Class150S.O.RF

MANHOLE

SA-516MGr.485

d

1

DN40

Class150S.O.RF

SAFETYVALVE

SA-106Gr.B

c

1

DN15

Class150S.O.RF

PRESSUREGAUGE

SA-106Gr.B

b

1

DN50

Class150S.O.RF

AIROUTLET

SA-106Gr.B

a

1

DN50

Class150S.O.RF

AIRINLET

SA-106Gr.B

NOZZLENO.

Q’TY

SIZE

TYPE

DESCRIPTION

REMARKS

Note:

Boltholesofflangesshallstraddlecenterlineofthetank.

FIG.1-1BriefDrawingofShell

2.THICKNESSOFCYLINDRICALSHELLUNDERINTERNALPRESSURE

ASMESEC.ⅧDIV.1UG-27

●

Part

:

Shell

●

Designpressure

P(MPa)

:

1.3

●

Designtemperature

(℃)

:

50

●

Material

:

SA-516MGr.485

●

Maximumallowablestressvalueatdesigntemperature

Sd(MPa)

:

138

●

Maximumallowablestressvalueattesttemperature

St(MPa)

:

138

●

Heighttopointunderconsideration

H(m)

:

1.900

●

Densityoftestmedium(water)attesttemperature

ρ(kg/m3)

:

1000

●

TypeofweldedjointsinTABLEUW-12

:

TypeNo.

(1)

●

Radiographicexamination

:

SPOT

PerUW-11(b)

●

Jointefficiency(specifiedinUW-12)

E

:

0.85

●

Corrosionallowance(designatedbycustomer)

C(mm)

:

1.0

●

Nominalshellthickness

tn(mm)

10

●

Insideradiuscorroded

R(mm)

:

501

●

Finalcenterlineradius

Rf(mm)

:

505

●

Originalcenterlineradius(specifiedinUCS-79)

Ro(mm)

:

∞(Infinity)

(1)Requiredminimumshellthicknessexcludingallowance(circumferentialstress)

0.385SE=0.385×138×0.85=45.16>PaccordingtoUG-27(b)&(c)

(a)Fordesigncondition

(b)Forhydrostatictestcondition

(2)Designthickness

Requiredminimumshellthicknessincludingallowance

t=max(tmin1,tmin2)+C=5.67+1.0=6.67mm

(3)Providedthickness

Nominalthickness(mm)10>tOK

(4)CheckminimumrequiredthicknessforparagraphUG-16(b)(4)

Minimumthicknessrequired(includingcorrosionallowance):

2.5+1=3.5mm,nominalthicknessis10mm>3.5mm,OK

(5)CheckextremefiberelongationforparagraphUCS-79

Maximumallowablefiberelongationwithoutpostweldheattreatmentisbasedonthefollowingformula:

Forsinglecurvature

NoneoftheconditionsinUCS-79(1~5)apply,sonoheattreatmentaftercoldformingneedtoapply.

3.

THICKNESSOFELLIPSOIDALHEAD,PRESSUREONCONCAVESIDE

ASMESEC.ⅧDIV.1UG-32

●Part

:

heads

●Designpressure

P(MPa)

:

1.3

●Designtemperature

(℃)

:

50

●Material

:

SA-516MGr.485

●Maximumallowablestressvalueatdesigntemperature

Sd(MPa)

:

138

●Maximumallowablestressvalueattesttemperature

St(MPa)

:

138

●Heighttopointunderconsideration(bottomhead)

H(m)

:

2.190

●Heighttopointunderconsideration(tophead)

H(m)

:

0.400

●Densityoftestmediumattesttemperature

ρ(kg/m3)

:

1000

●TypeofweldedjointsinTABLEUW-12

:

Seamless

●Radiographicexamination(A)

:

N.A

●Weldjoiningheadstoshell

:

TypeNo.

(1),

SPOTPerUW-11(b)

●Jointefficiency(specifiedinUW-12(d))

E

:

0.85

●Corrosionallowance(designatedbycustomer)

C(mm)

:

1

●Insidediameterofellipsoidalhead(corroded)

D

1002

●Insidesphericalradiusofhemisphericalhead

L(mm)

:

501

●Crownfinalcenterlineradius(specifiedinUG-32(d)andUCS-79)

Rf(mm)

:

905

●Knucklefinalcenterlineradius(specifiedinUG-32(d)andUCS-79)

rf(mm)

:

174.25

●Originalcenterlineradius(specifiedinUCS-79)

R0(mm)

:

∞(Infinity)

(1)

Requiredminimumheadthickness

Withoutjoint,accordingtoUW-12(d),E=0.85,L=0.9D=0.9×1002=901.8mm

ts/L=8.5/901.8=0.0094>0.002accordingtoUG-32(d)

(a)ForthetopheadaccordingtoUG-32(d)

(a-1)fordesigncondition

Requiredminimumheadthicknessexcludingallowancetmin

(b)Forthebottomhead

(b-1)fordesigncondition

Requiredminimumheadthicknessexcludingallowancetmin

(b-2)forhydrostatictestcondition

(Duetosamedimensionforellipsoidalheads,thebottomheadwillbeappliedforcalculation)

(2)Designthickness

Requiredminimumheadthicknessincludingallowance

t=max(tmin1,tmin2,tmin3)+C=5.65+1.0=6.65mm

(3)Providedthickness

Nominalthickness(mm)10

Minimumthicknessafterforming(mm)8.5≥tOK

(4)CheckminimumheadthicknessforhemisphericalheadfromparagraphUG-32(b)&(f)0.665SE=0.665×138×1=91.77MPa>P

Requiredminimumhemisphericalheadthickness

tr=tminh/E=2.36/0.85=2.78mm<8.5mmOK

(5)CheckminimumrequiredthicknessforparagraphUG-16(b)(4)

Minimumthicknessrequired(includingcorrosionallowance):

2.5+1=3.5mm,minimumthicknessafterformingis8.5mm.>3.5mmOK

(6)CheckextremefiberelongationforparagraphUCS-79

Maximumallowablefiberelongationwithoutheattreatmentisbasedonthefollowingformula:

Fordoublecurvature

Crownradiuselongation

Knuckleradiuselongation

NoneoftheconditionslistedinUCS-79(d)

(1)through(5)exist,sonoheattreatmentofheadsaftercoldformingneedtoapplyforSA-516MGr.485(P-NO.1GroupNO.2).

4.

THICKNESSOFNOZZLENECKINTERNALPRESSURE

4-1FORNOZZLEa

ASMESEC.ⅧDIV.1UG-45

●Designpressure

P(MPa)

:

1.3

●Designtemperature

T(℃)

:

50

●Materialofnozzleneck

:

SA-106Gr.B

●Allowablestressofnozzleneckmaterialatdesigntemperature

Sd(MPa)

:

118

●Allowablestressofnozzleneckmaterialattesttemperature

St(MPa)

:

118

●Materialofshell

:

SA-516MGr.485

●Allowablestressofshell(orhead)atdesigntemperature

Ss(MPa)

:

138

●Heighttopointunderconsideration

H(m)

:

1.580

●Densityoftestmediumattesttemperature(water)

ρ(kg/m3)

:

1000

●TypeofweldedjointsofnozzleneckinTABLEUW-12

:

Seamless

●Jointefficiencyofnozzleneck

E

:

1.0

●Corrosionallowance(designatedbycustomer)

C(mm)

:

1

●Outsideradiusofnozzleneck

Ro(mm)

:

30.15

●Nominalthicknessofthestandardwallpipe(B36.10M)

tstd(mm)

:

3.91

●Insideradiusofshellcorroded

Rs(mm)

:

501

(1)Minimumrequiredthicknessofnozzleneckforpar.UG-45(a)

0.385SE=0.385×118×1.00=45.43>P

(a)underdesignconditionAppendix1-1

Requiredminimumthicknessincludingallowance

(b)underhydrostatictestcondition

Requiredminimumthicknessincludingallowance

(2)Minimumrequiredthicknessofshellforpar.UG-45(b)

(1),andUG-16(b)(4),Es=1.00

(3)Minimumthicknessofstandardwallpipeincludingall