电动葫芦起重机参数英文.docx

《电动葫芦起重机参数英文.docx》由会员分享,可在线阅读,更多相关《电动葫芦起重机参数英文.docx(6页珍藏版)》请在冰豆网上搜索。

电动葫芦起重机参数英文

电动葫芦起重机参数(英文)

————————————————————————————————作者:

————————————————————————————————日期:

3.15HoistingEquipment

3.15.1Scopeofsupplyanddesignparameters

1.Thetenderershouldbeaccordingtotherequirementsonprovidetheequipmenttheengineeringneeded,includingthetravelmechanismandhoistingequipment,suchas:

mainframe,motor,electricalblock,wirecable,fixedpart,accessories,matchedelectriccableetc.,itshouldbeguaranteedthedesign,manufacture,check,inspectionandsoonofabovementionedequipmentshouldcomplythecoderequirement;meanwhilethetenderershouldprovidecorrespondingsiteservice,includingtheinstallationguidanceandadjustmentofthehoistingequipment.

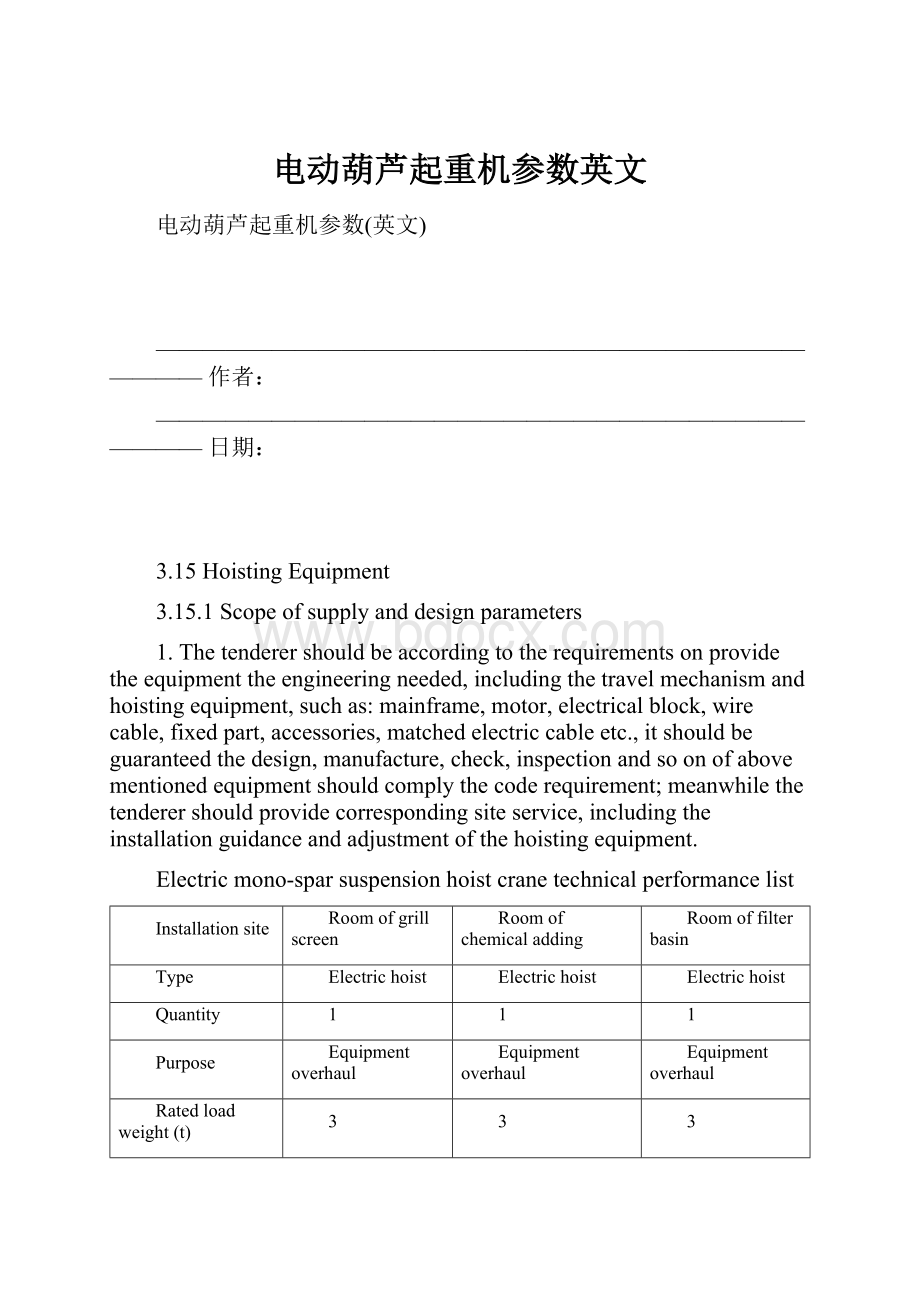

Electricmono-sparsuspensionhoistcranetechnicalperformancelist

Installationsite

Roomofgrillscreen

Roomofchemicaladding

Roomoffilterbasin

Type

Electrichoist

Electrichoist

Electrichoist

Quantity

1

1

1

Purpose

Equipmentoverhaul

Equipmentoverhaul

Equipmentoverhaul

Ratedloadweight(t)

3

3

3

Hoistingheight(m)

12

6

12

Modeofoperation

Groundoperation

Groundoperation

Groundoperation

3.15.2TechnicalRequirements

1.Inordertoguaranteethestandardizationoftheproductsontheaspectsofoperation,maintenanceandspareparts,requiringalltheequipmentandcomponentofsametypeshouldbetheproductsofthesamemanufactureraspossible.Alltheelectric-drivehoistingequipmentshouldsetpowerswitchontheground.

2.Allequipmentandproductshouldhaveperformanceinspectionbeforeexworks;thetenderershouldprovidethefollowing:

exworksproductcertificateofinspection,approvedcertificateforproduct,productinstruction,packinglist,andlistofaccessoriesandspareparts.

3.Alltheelectricdrivingdeviceofthehoistingequipmentshouldbecompletematchedbythehoistingequipmentmanufacturer,tomakeitformcompletehoistingequipment.

3.15.2Materialtobesubmitted

Thetenderershouldsubmitthefollowinginformation,butnotlimitedtothefollowing:

(1)Theconcernedtechnicaldataandelectricschematicdiagramofelectricmachineandelectricity;

(2)Installationinstruction,equipmentoperationandservicemanual;

(3)Qualificationcertificateofmanufacturerandachievement;

(4)Biddingtechnicalitydescription(design,structure,materialetc.)andsampleediting;

(5)Manufacturingandqualityassurancemeasures;

(6)Debugginganddetectionrequirementbeforetest-run;

(7)Submittingfiveuserscertificatesofsuccessfuloperationrunningdomesticallyinrecentfiveyears;

(8)ThehoistingequipmentmanufacturinglicenseissuedbyDomesticLaborDepartment;

3.15.3Basicrequirements

1.Referencestandards

Thedesign,manufacture,inspection,packaging,transportationandinstallationprocessoftheproductshouldbeconsistentwithISO,IECinternationalstandardsandtheequivalentstandardssuchasGB,JB,JIS,DIN,ANCI,etc.(Thesestandardsshouldbetheupdatedstandardsthatarenotbeinvalidated))

2.Othertechnicalrequirements

(1)Thehoistingequipmentsuppliedbythetenderershouldincludetheelectricmono-sparsuspensionhoistcrane,electricalblockandtheconcernedaccessoriesforconnection.

(2)Thecompleteelectricmotorandthespeedreducershouldbesuppliedbythemanufacturerintheformofcompleteandmatching.

(3)Theequipmentfailurefreeoperationtimeshouldnotbelessthan10,000hours;theelectricapparatus’servicelifeshouldnotbelessthan3years,thespeedreducerandbearingservicelifeshouldbe10years,thecoatingserviceshouldbeover5years;thecompletemachineservicelifeshouldbemorethan25years.

(4)Anti-corrosionofequipment:

thesurfacede-rustinggradeofallcarbonsteelcomponentsshouldcomplywiththeSa2.5gradestandardstipulatedinGB8923-88

(5)Themanufacturershouldprovide1setspecialtoolsandsparepartsfortheequipmentinstallationandmaintenance.

(6)NameplateandLabel

ItshouldbefastenedforAllequipmentwiththestainlesssteelnameplateoffollowingtechnicalspecificationcontents:

Number,Model,Power,maintechnicalparameter,weight,manufacturer,dateofmanufactureetc.

(7)MaterialandProcess

Allmaterialsmustbethehighqualitymaterialwithindicatedgradeandspecies,theseshouldbethenewestmaterialusedbythemanufacturer,nottherejectedintodisuse,andthemanufacturingprocessshouldbethecontemporaryoptimalitycriteria.

(8)Thetenderershouldbeinchargetoguidetheinstallationoftheequipment,toaccomplishthedebuggingworkoftheequipmentwithintheperiodstipulatedbytheconstructionparty.

3.15.4Structuralrequirements

(1)TravelingMechanismBody

Thebodyisrigidstructure,forbiddenanyabnormalbend.

Thetravelingmechanismdrivingreliesontheelectricmotorthroughspeedreducertodrivethetrolley’sdrivingshaft.

Themono-sparbodyshouldhavearollerstabilizer,topreventthetravelingmechanismfrominclineduringoperation.

Thematerialofthetravelingmechanismwheelissteelrollingorforgedsteelheattreated;thehardnessofthetreadofthewheelshouldbeat200Brinellatleast.

Afterrefiningprocessandburnishing,thewheelaxlematerialcanassemblytheinnerbearingwasher.

Whenusingtherotationaxis,thewheelshouldinstallthecontractorandkey,orinstallthekeyonly.

Allthegearsarespiraltooth,straighttoothorherringbonetooth,thegearwheelismanufacturedofsteelrollingorcastiron,andprocessittobe20°pressureintermeshingangle.

Thebearingistheradialandthrust,doublebank,angularcontactballbearing,orthedoublebankthrusttyperollerbearing.Beforeinstallationthebearingshouldbelubricationandsealing;thebrakeofthetravelingmechanismshouldbeassembledaccordingtothestipulatedworkinggrade,thetravelingmechanismshouldbematchedwithrippledamper

(2)Electricalblock

Themachinepartsoftheelectricalblockarecomposedbythewindingdrum,drivingequipment,loadbox,hook,steelcable,pulleyandbrake.

Whenthehookisatthelowestposition,onwindingdrumthereareatleast2loopofsteelcable.

Thewindingdrumsizeandsteelcablelengthshouldbeconfirmedaccordingtothedesigndrawings.

Theloadboxadoptstheenclosedtypetohaveinterferenceprevention.

Thesteelcableshouldhaveenoughflexibilityandtoughness.

Thereshouldbeenoughtoughness,whenoverload,beforefailurethehookshouldbewithenoughdegreeoffreedom.

Underratedload,thehookcanturn360°.

Thecraneshouldbematchedwithelectricbrakeandmechanicalbraking,itcanbeadjustedsoastocompensatewear-out.

(3)PowerEquipment

Thecranemanufacturershouldinstalltheelectricdeviceonthecraneincludingtheelectricmotor,electricmotorstarter,suspensioncontrolandconduitetc.

Theelectricmotorissquirrelcagetype,undertheconditionoffullload,withlowstartcurrentandhighstarttorque.EachphaseoftheACelectricmotorshouldhaveoverloadrelay.

Therailconductorshouldbetrolleylinetype.Asthedeviationofdesignedvoltageofthebuildingsystemis5%,thetrackandtravelingmechanismconductorfrommotortrackpowersupplyofcontrolcranetooperationthedeviationis10%.

Theslidingconductoriscomposedbygalvanizedsteelstripencapsulatedintheinsulationmaterialbox,therelayisslideblockstylewithpressingoutspring.

Thehoistershouldbeequippedwithcontrollerofmomentarycontactbutton,wheneveranyelectriccableisinpower-cut,itcanstopalltheelectricmotorsuntilre-operation.Eachelectricmotorshouldbeequippedwithlow-voltageprotection.

Thetravelingmechanismshouldhaveslowstartdevice.

Thehoistershouldbeequippedwiththecontroller,thecontrollershouldbehungdownbyelectriccable,onthecontrollertherearestop/startbuttonsforhoister,axletrack,travelingmechanismcontrolling.

(4)SafetyFactor

Thesafetyfactorofthehoisteris1.2timesofthenominalload,theultimateloadtestshouldbedonebeforeexworks,andthetestreportandrecordshouldbesubmitted.Thehoister’sfault-freetimeshouldbe5yearswithoutmaintenance;theservicelifeshouldbe40years.

3.15.5Maincomponentsandmaterials

Mainbeam:

carbonsteelQ235A

Roadwheel:

caststeelZG55

Fastener:

stainlesssteel1Cr18Ni9Ti