砂轮英语.docx

《砂轮英语.docx》由会员分享,可在线阅读,更多相关《砂轮英语.docx(9页珍藏版)》请在冰豆网上搜索。

砂轮英语

Literaturereview

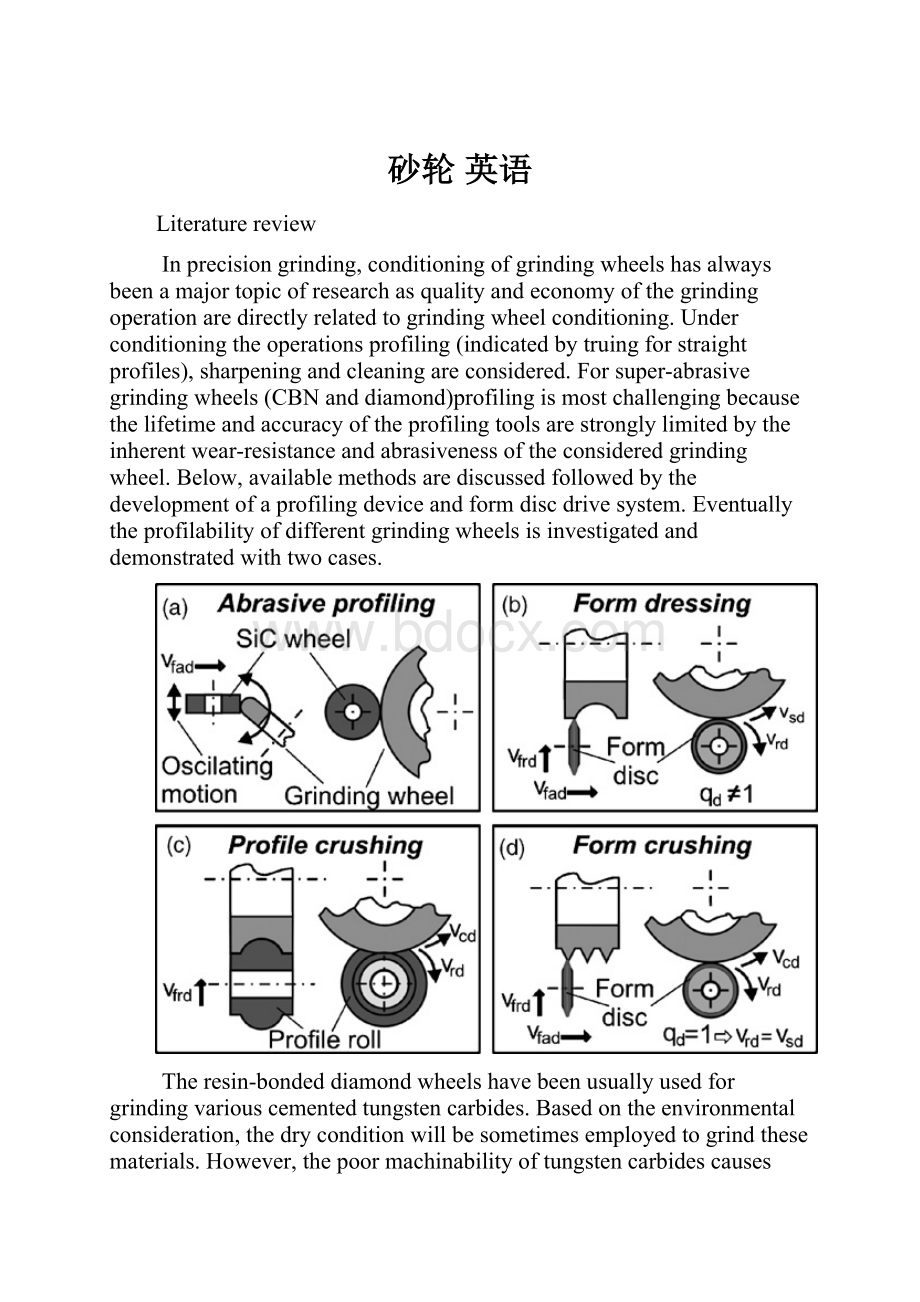

Inprecisiongrinding,conditioningofgrindingwheelshasalwaysbeenamajortopicofresearchasqualityandeconomyofthegrindingoperationaredirectlyrelatedtogrindingwheelconditioning.Underconditioningtheoperationsprofiling(indicatedbytruingforstraightprofiles),sharpeningandcleaningareconsidered.Forsuper-abrasivegrindingwheels(CBNanddiamond)profilingismostchallengingbecausethelifetimeandaccuracyoftheprofilingtoolsarestronglylimitedbytheinherentwear-resistanceandabrasivenessoftheconsideredgrindingwheel.Below,availablemethodsarediscussedfollowedbythedevelopmentofaprofilingdeviceandformdiscdrivesystem.Eventuallytheprofilabilityofdifferentgrindingwheelsisinvestigatedanddemonstratedwithtwocases.

Theresin-bondeddiamondwheelshavebeenusuallyusedforgrindingvariouscementedtungstencarbides.Basedontheenvironmentalconsideration,thedryconditionwillbesometimesemployedtogrindthesematerials.However,thepoormachinabilityoftungstencarbidescausesdifficultiesindrygrinding.Especiallyinadrymachiningprocess,allthegrindingpowerisdissipatedasheatinthegrindingzone,attheinterfacebetweenthewheelandtheworkpiece.Thisheatcausesthewheelandworkpiecetemperaturestorise,whichmaycausethermaldamage.Undersuchacondition,increasingmaterialremovalratesandobtaininghigh-qualitysurfaceswouldbelimited.

Inordertoimprovethemachinabilityoftungstencarbidesinadrygrindingprocess,manystudieshavebeenconducted.TorranceandMetzgerstatedthatindrygrindingofcarbide,theresultingpredominantmodeofwheelwearisheatrelated.Furthermore,thewheellossinwetgrindingismainlymechanicalwear,andthegrindingratioincreaseswithincreaseofthewheelspeed.Inaddition,Metzgerindicatedthatfrequencyofthewheel/workpieceentryimpactsduringgrindingofcementedtungstencarbidewouldacceleratediamondwheelwear.Thedropingrindingratiocanreachvaluesashighas70%inreciprocatingfacegrindingwithresinbondwheels.

Forbestresultsindrygrindingcementedcarbides,thefollowingguidelinesareadopted:

(1)alowwheelspeedofaround18m/s;

(2)alowtablespeedof2–3m/min;(3)alowdepthofcutinthe0.01–0.05mmrange;(4)reductionintheareaofcontact.

Furthermore,intheselectionanduseofwheelsoperatedunderadrycondition,metallicadditivesandlubricantswouldbeaddedintotheresinbond,whichfacilitatesthedispersionofheatandthereductionoffrictioninthecontactzone.Besides,theirregularmetalcladdiamondparticleswiththemoderatestrengtharealsorecommendedtoimproveheatdissipationandretentionintheresinbond.Inturnthesebenefitsresultinincreasedtoollifeandenhancedperformance.

Eventhoughseveralstudiesontheperformanceofthediamondwheelsinthegrindingofcarbideshadbeeninvestigated.However,studiesrelatingtheeffectsofthefilleroftheresinbondonthedrygrindingoftungstencarbidearelittlereported.Inthispaper,theeffectsofseveralfillersoftheresin-bondeddiamondwheelontheperformanceofdrygrindingoftungstencarbidearestudied.

AnewkinddiamondgrindingwheelwithAl-basedbondingagentwaspreparedinthispaper.Theinfluenceofsinteringtemperaturetotherelativedensity,hardnessandservicelifeofdiamondgrindingwheelswithAlSnTi,AlSnTiNiCo,AlSnTiNiandAlSnNiCobondingagentwasstudied.Themicrostructureofdifferentbondingagentsinteredatdifferenttemperaturewasobserved.TheservicelifeoftheAl-basedgrindingwheelswascomparedwithCu-basedorresin-basedones.TheresultsshowedthattheAlSnTiNiCoisthebestcompositionsysteminthisresearch.Thebestsinteringtemperatureis300?

C.Thesamplehasahighrelativedensityaftersinteredat300C.TheretentionofAl-basedbondingagenttodiamondgritisstrong.TheservicelifeofthisAlbaseddiamondgrindingwheelisaboutthreetimesaslongasthatofresin-bondedgrindingwheel.

AnewkindofgrindingwheelhasbeenfabricatedwithAlbasedbondingagent.TheoptimalsystemofAl-basedagentinthisresearchisAlSnTiNiCo.Relativedensity,hardnesshardnessandservicelifeofAl-baseddiamondtoolsareeffectivelyinfluencedbysinteringtemperature.FortheseAl-basedsystems,theoptimalsinteringtemperatureisabout300C.ThegrindingeffectofceramictilesquaredbyAl-basewheelisasgoodasthatbyresin-basedwheel.TheservicelifeofAl-basedgrindingwheelisthreetimesaslongasthatoftheresinbased.

Epoxyresinshavebeencommercializedfor50years.Therearethousandsofepoxiesavailableinthemarkets.Thebasicpropertiesofepoxyresinscanbemodifiedinmanyways:

byblendingofdifferentresins,byselectionofcuringagentsandbytheuseofmodifiersandfillers.Theepoxyresinshaveexhibitedgoodthermalproperties,chemicalresistanceandelectricinsulationthroughacross-linkingreactionwithacuringagentthatmakesthetwo-dimensionalepoxystructurechangetothethree-dimensionalnetworkstructure.Thesepropertiesofcuredepoxiesalldependonthestructuresofcuringagentsandepoxyresin.

Thermalpropertiesdifferencesbetweenrigidrodtetramethylbiphenyl(TMBP)andflexiblediglycidylethersofbisphenolA(DGEBA)epoxieswerestudiedusingmodifieddifferentialscanningcalorimeter(MDSC),thermogravimetricanalyzer(TGA)anddynamicmechanicalanalyzer(DMA)techniques.Theseepoxieswerecuredwithphthalicanhydride(PA)andphenolicresin(PF5110),respectively.ThePF5110-curedepoxyhasbetterthermalpropertiesthanthePA-curedepoxywithahigherglasstransitiontemperature(Tg)andahigherdecompositiontemperature.ThegoodthermalpropertiesofthePF5110-curedepoxyareduetotherigidPF5110structureonthecuredepoxy.DGEBAepoxyhasahigherdecompositiontemperaturethantherigidrodepoxywhentheyarecuredwithPF5110.But,inthePAcuringsystem,rigidrodepoxyhasabetterthermalstability.Thesetwodifferentresultsareduetothedifferentstructuresofcuringagents.

Phenolicthermosettingmaterialswerethefirstmajorplasticmaterialusedbyindustry.Theyarestillamongthemostwidelyusedthermosetsbecausetheyaresomeofthelowest-costengineeringmaterialonacost-per-volumebasis.Phenolicsareformedfromthecondensationofpolymerizationreactionbetweenphenolandformaldehyde.Thecondensationreactionforphenolicscanbecarriedoutundertwodifferentconditions,resultingintwodifferentintermediatematerials.Oneoftheintermediatesiscalledresolesandtheothernovolacs.

Intheearlierstudyaboutpolymernetworkofphenolicandepoxiesresinsmixedwithlinseedoil,onlyPhencat15wasusedasthecatalystforthephenolicresin.Inthisstudy,Phencat382andUH(aureahydrochloridesolutionbasedona1:

1moleratioofurea:

hydrochloricacid32%)willbeusedascatalyststostudytheireffectsonthepolymernetworkofphenolicandepoxyresinsmixedwithepoxidizedlinseedoil(ELO)(58%).Theeffectofeachoneofthesecatalystsonthecuringandthepropertiesoftheformednetworkwereinvestigated.ItwasdiscoveredthatPhencat382wasthebestcatalystforthecomposites.ItwasalsodiscoveredthatELOcanplayitsroleasplasticiserintheblendsofepoxyandphenolicresinsanddoesimprovetheflexuralstrengthandothermechanicalpropertiesofthepreparedresins.

Thestoragemodulus,flexuralmodulus,stressatpeakandglasstransitiontemperaturedecreasedwithincreasingpercentagebyweightofELOaddedirrespectiveofthecatalystsused,whilethestrainyieldincreased.Thecross-linkdensitydecreasedwiththeincreasingamountofELOintheresins.Thebestpropertieswereobtainedforthe80/20epoxy/phenolicresinblendsafterpost-curingfor4h.

Imidazolewithvariousmolecularweightspoly(ethyleneglycol)s,includingPEG1000,PEG2000,andPEG5000,wasblendedandevaluatedasthermallatentcatalystsforthepolymerizationofdiglycidyletherofbisphenolA(DGEBA)underliquid–liquidorliquid–solidtwophasesystems.ThethermallatencyandstoragestabilitypropertiesofDGEBAresincuredby1–5wt%ofmolecularweightimidazole/PEGcomplexesweremeasuredbyviscometer,differentialscanningcalorimetry(DSC),andTGA.

Basedontheviscosity–shearrateresults,wefoundthe1–3wt%amountofimidazole/PEGsshowedthebetterthermallatencyinthethermalpolymerizationsystem.Fromthecureactivationenergyandtheviscosity–storagetimeofthesecomplexcatalysts,theorderofthermallylatentactivitywasimidazole/PEG1000

(2)>imidazole/PEG5000(4)>imidazole/PEG2000(3)>imidazole.Concerningtheglasstransitiontemperature(Tg),theuseofimidazole/PEGcomplexcatalystsprovidedcompleteornearcompletecuringsystemsinthetemperaturerangeabout150.8C.

Togetabetterunderstandingofthecuringprocessofmulti-componentthermosetsdifferentialscanningcalorimetric(DSC)andtemperaturemodulatedDSC(TMDSC)measurementswereperformedduringisothermalcuringofsemi-interpenetratingpolymernetworks(semi-IPNs)withamountsof10or20wt.%oflinearpolymerandofthecorrespondingpurenetworksattemperaturesbetween333and393K.ThenetworkcomponentconsistsofdiglycidyletherofbisphenolA(DGEBA)cross-linkedwithdiaminodiphenylmethane(DDM)andthelinearpolymercomponentispolysulfone(PSn)orpolyethersulfone(PES).Thecuringtimedependenceofconversionwasestimatedfromtimedependentheatflowmeasurementsduringisothermalcuring.Thecuringkineticsisdiscussedintheframeworkofdifferentmodels

takingintoaccountthecatalyticeffectsandtheinfluenceofdif