运营管理课后习题答案供参考文档格式.docx

《运营管理课后习题答案供参考文档格式.docx》由会员分享,可在线阅读,更多相关《运营管理课后习题答案供参考文档格式.docx(33页珍藏版)》请在冰豆网上搜索。

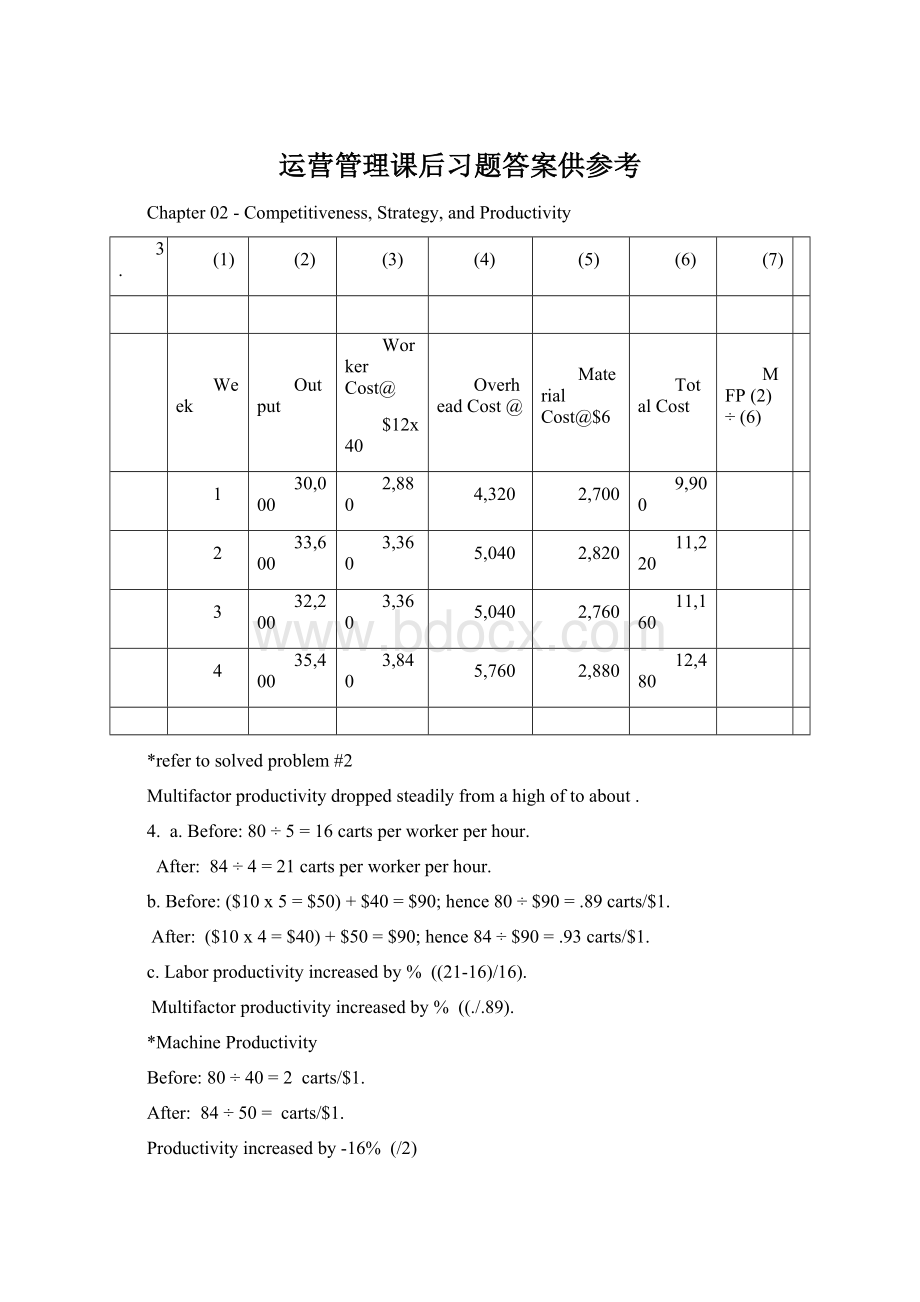

*refertosolvedproblem#2

Multifactorproductivitydroppedsteadilyfromahighoftoabout.

4.a.Before:

80÷

5=16cartsperworkerperhour.

After:

84÷

4=21cartsperworkerperhour.

b.Before:

($10x5=$50)+$40=$90;

hence80÷

$90=.89carts/$1.

After:

($10x4=$40)+$50=$90;

hence84÷

$90=.93carts/$1.

c.Laborproductivityincreasedby%((21-16)/16).

Multifactorproductivityincreasedby%((./.89).

*MachineProductivity

Before:

40=2carts/$1.

After:

50=carts/$1.

Productivityincreasedby-16%(/2)

Chapter03-ProductandServiceDesign

6.StepsforMakingCashWithdrawalfromanATM

1.InsertCard:

MagneticStripShouldbeFacingDown

2.WatchScreenforInstructions

3.SelectTransactionOptions:

1)Deposit

2)Withdrawal

3)Transfer

4)Other

4.EnterInformation:

1)PINNumber

2)SelectaTransactionandAccount

3)EnterAmountofTransaction

5.Deposit/Withdrawal:

1)Deposit—placeinanenvelope(whichyou’llfindnearorintheATM)andinsertitintothedepositslot

2)Withdrawal—liftthe“WithdrawalDoor,”beingcarefultoremoveallcash

6.Removecardandreceipt(whichservesasthetransactionrecord)

8.

Technical

Requirements

Ingredients

Handling

Preparation

CustomerRequirements

Taste

√

Appearance

Texture/consistency

Chapter04-StrategicCapacityPlanningforProductsandServices

2.

Actualoutput=.8(Effectivecapacity)

Effectivecapacity=.5(Designcapacity)

Actualoutput=(.5)(.8)(Effectivecapacity)

Actualoutput=(.4)(Designcapacity)

Actualoutput=8jobs

Utilization=.4

10.a.Given:

10hrs.or600min.ofoperatingtimeperday.

250daysx600min.=150,000min.peryearoperatingtime.

Totalprocessingtimebymachine

Product

A

B

C

48,000

64,000

32,000

36,000

24,000

60,000

Total

186,000

208,000

122,000

Youwouldhavetobuytwo“A”machinesatatotalcostof$80,000,ortwo“B”machinesatatotalcostof$60,000,orone“C”machineat$80,000.

b.Totalcostforeachtypeofmachine:

A

(2):

186,000min÷

60=3,100hrs.x$10=$31,000+$80,000=$111,000

B

(2):

208,000÷

60=3,hrs.x$11=$38,133+$60,000=$98,133

C

(1):

122,000÷

60=2,hrs.x$12=$24,400+$80,000=$104,400

Buy2Bs—thesehavethelowesttotalcost.

Chapter05-ProcessSelectionandFacilityLayout

3.

Desiredoutput=4

Operatingtime=56minutes

Task

#ofFollowingtasks

PositionalWeight

23

20

18

D

25

E

F

29

G

24

H

14

I

5

a.Firstrule:

mostfollowers.Secondrule:

largestpositionalweight.

AssemblyLineBalancingTable(CT=14)

WorkStation

TaskTime

TimeRemaining

FeasibletasksRemaining

9

A,D,G

6

B,G

–

II

7

B,E

III

10

IV

b.Firstrule:

Largestpositionalweight.

AssemblyLineBalancingTable(CT=14)

8

A,E

B,E

c.

4.

a.l.

2.MinimumCt=minutes

Followingtasks

a

b

c

d

e

f

g

h

Eligible

Assign

IdleTime

b,c,e,(tie)

f,g

3.

4.

b.1.

2.Assigna,b,c,d,andetostation1:

minutes[noidletime]

Assignf,g,andhtostation2:

minutes

3.

4.

7.

Chapter06-WorkDesignandMeasurement

Element

PR

OT

NT

AFjob

ST

.90

.46

.414

.476

.85

.83

.913

Total

A=24+10+14=48minutesper4hours

9.

a.

.955

.56

.588

.676

b.

c.e=.01minutes

Chapter07-LocationPlanningandAnalysis

1.

Factor

Localbank

Steelmill

Foodwarehouse

Publicschool

1.

Convenienceforcustomers

L

M–H

2.

Attractivenessofbuilding

M

Nearnesstorawmaterials

4.

Largeamountsofpower

5.

Pollutioncontrols

6.

Laborcostandavailability

Transportationcosts

Constructioncosts

Location(a)

Location(b)

4.

Weight

BusinessServices

2/9

18/9

10/9

CommunityServices

1/9

7/9

6/9

RealEstateCost

3/9

8/9

ConstructionCosts

12/9

CostofLiving

4/9

Taxes

5/9

Transportation

6

7

8

6/9

7/9

8/9

39

44

45

53/9

55/9

54/9

Eachfactorhasaweightof1/7.

CompositeScores

BorCisthebestandAisleastdesirable.

b.

BusinessServicesandConstructionCostsbothhaveaweightof2/9;

theotherfactorseachhaveaweightof1/9.

5x+2x+2x=1⇒x=1/9

c.

BisthebestfollowedbyCandthenA.

Location

x

y

4

Totals

=

∑xi

=

∑yi

n

Hence,thecenterofgravityisat(5,4)andthereforetheoptimallocation.

Chapter08-ManagementofQuality

Checksheet

WorkType

Frequency

LubeandOil

12

Brakes

Tires

Battery

Transmission

30

Pareto

.

Therunchartsseemstoshowapatternoferrorspossiblylinkedtobreaktimesortheendoftheshift.Perhapsworkersarebecomingfatigued.Ifso,perhapstwo10minutebreaksinthemorningandagainintheafternooninsteadofone20minutebreakcouldreducesomeerrors.Also,errorsareoccurringduringthelastfewminutesbeforenoonandtheendoftheshift,andthoseperiodsshouldalsobegivenmanagement’sattention.

Chapter9-QualityControl

Sample

Mean

Range

MeanChart:

±

A2

=±

UCL=,LCL=

RangeChart:

UCL=D4

==

LCL=D3

=0=0

[Bothchartssuggesttheprocessisincontrol:

Neitherhasanypointsoutsidethelimits.]

6.n=200ControlLimits=

Thus,UCLis.0234andLCLbecomes0.

Sincen=200,thefractionrepresentedbyeachdatapointishalftheamountshown..,1defective=.005,2defectives=.01,etc.

Sample10istoolarge.

7.

Controllimits:

UCLis,LCLbecomes0.

Allvaluesarewithinthelimits.

14.LetUSL=UpperSpecificationLimit,LSL=LowerSpecificationLimit,

=Processmean,σ=Processstandarddeviation

ForprocessH:

ForprocessK:

Assumingtheminimumacceptable

is,since<

theprocessisnotcapable.

ForprocessT:

Since=,theprocessiscapable.

Chapter10-AggregatePlanningandMasterScheduling

7.a.Nobacklogsareallowed

Period

Mar.

Apr.

May

Jun.

July

Aug.

Sep.

Forecast

50

55

60

40

51

350

Regular

280

Overtime

Subcontract

19

Output-Forecast

–4

–3

Inventory

Beginning

Ending

Average

Backlog

Costs:

Regular

3,200

22,400

Overtime

960

360

6,120

Subcontract

420

1,680

2,660

Inventory

15

70

4,440

4,180

4,600

5,840

3,575

4,175

31,250

b.Levelstrategy

56

–5

–10

–1

.5

Ba