基于CATIA的大型飞机起落架建模与分析热能与动力工程专业毕业设计毕业论文Word文件下载.docx

《基于CATIA的大型飞机起落架建模与分析热能与动力工程专业毕业设计毕业论文Word文件下载.docx》由会员分享,可在线阅读,更多相关《基于CATIA的大型飞机起落架建模与分析热能与动力工程专业毕业设计毕业论文Word文件下载.docx(47页珍藏版)》请在冰豆网上搜索。

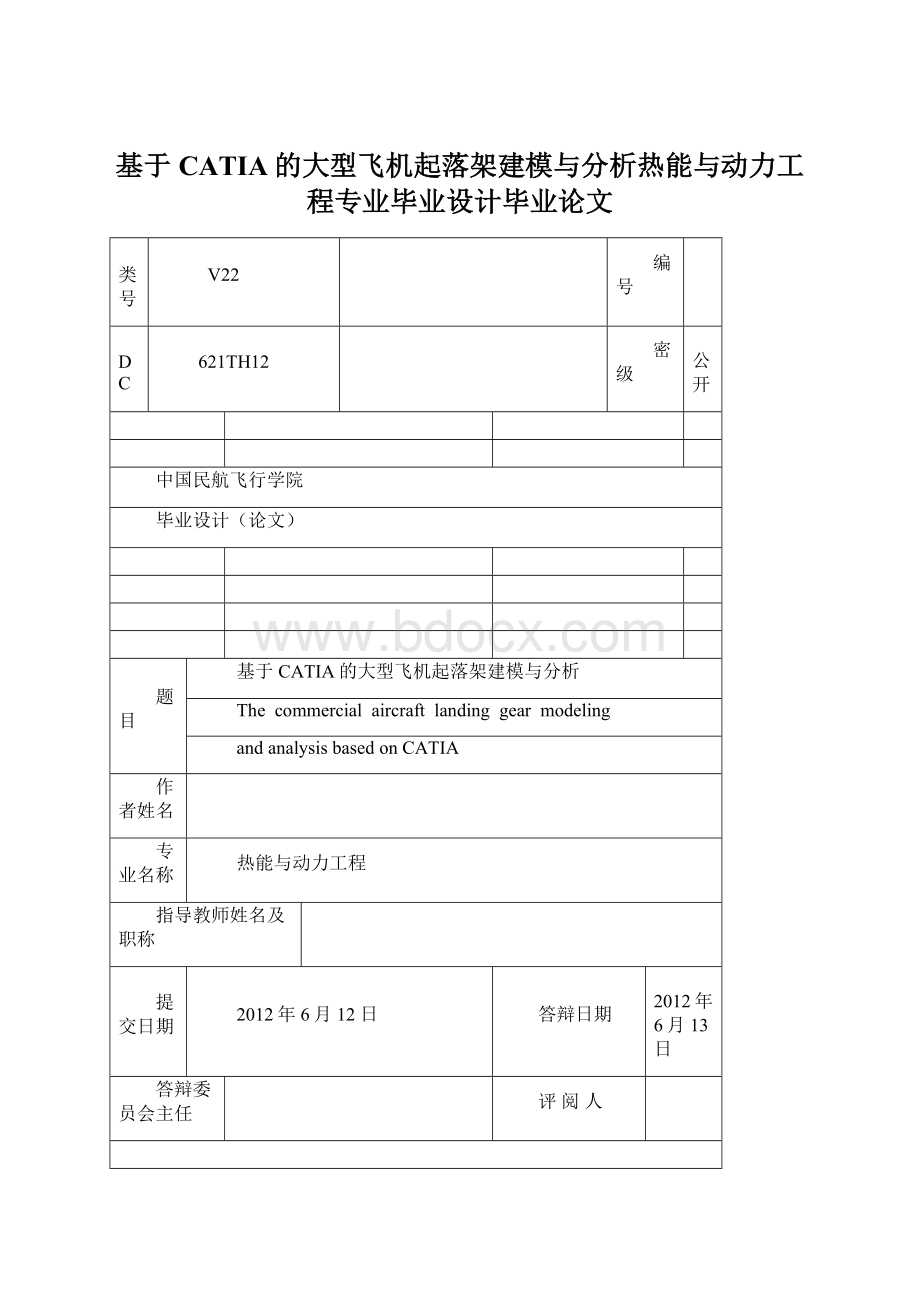

公开

中国民航飞行学院

毕业设计(论文)

题目

基于CATIA的大型飞机起落架建模与分析

Thecommercialaircraftlandinggearmodeling

andanalysisbasedonCATIA

作者姓名

专业名称

热能与动力工程

指导教师姓名及职称

提交日期

2012年6月12日

答辩日期

2012年6月13日

答辩委员会主任

评阅人

20

12

年

6

月

日

基于CATIA的大型飞机起落架建模与分析

学生:

指导教师:

摘要

本文首先总结了飞机起落架的发展历史、收放系统及各种结构形式,简单的列举了一些由起落架故障引发的事故。

然后介绍了下CATIAV5的特点、应用、基本操作、各种工作界面、零部件设计、装配设计、运动仿真、及较高层次的应用。

在进行三维建模之前,首先,从一些官方数据上确定起落架的类型,以及一些基本的数据。

然后进行简化,省略掉液压管、电线、以及刹车等部件,再将其分为外筒、活塞杆、主支柱、斜支柱、轮轴、扭力臂和机轮等部分。

确定每一部分的具体数据,连接形式,以及运动方式。

然后从草图工作台入手,对各个部分进行零部件设计及建模,并且展示出建模步骤。

然后将各个部件导入装配设计工作台,进行组装,添加结构约束。

下一步对组装好的部件进行接合,进行数字样机收放演示。

在本文的最后,总结各种不足和待改进之处,并且对CATIA建模的优缺点进行总结及展望。

关键词:

起落架,CATIA,结构设计,数字样机

ABSTRACT

Thedevelopmenthistoryofthelandinggearandallkindsofstructureformandretractionsystemaresummarized.Andsomeaccidentcausebylandinggeararelisted.ThenthebasicknowledgeofCATIAV5ascovered,fromtheapplicationcharacteristicstoitsuserinterfaceandallkindsofworkbench.Before3Dmodeling,firstofall,someofficialdatatodeterminethetypeoflandinggeariscollected,andsomebasicdataisalsocollected.ThenHubcap,Cylinder,Dragbrace,Torquearm,Collarandtirearemodeledbysimplified.Thedataofeachpartoftheconcrete,connectingforms,andlocomotionarebecorrected.Thenfromthesketchofthevariouspartsofthepartsaremodeled.ThenextstepismartialingeachpartsandDMU.Atthelast,allkindsofdeficiencyandstayforimprovementaresummarized,andtheadvantagesofCATIAmodelingareprospected.

KeyWords:

Landinggear,CATIA,structuraldesign,DMU

Content

Chapter1Reviews

Landinggearisanimportantpartoftheplane.It’sthemaincomponentfortheplaneongroundparking,rollout,takeoff,andlanding.Itcanloadtheweightoftheplaneandabsorbimpactenergy.Theplanelandinggearmajorfunctionsforaircraftinthestationarystateunderthegravityandtheimpactofthetakeoffandlanding,controllingtheplaneonthegroundmotion.Thereisawiderangeofplanelandinggearmodel,sothesecausethelandinggeardesigndifficult,processingdocumentcomplicated,andmaintainabilitylowmaintenancerate.Itcostalongtimefrommodelingtoprocessingcycle,theseleadtothedescendingoftheproductionefficiency.Toliftingtheplanelandinggearpartsproductionefficiency,theprojecthasputforwardfastofparameterizedmodelingandofparameterizedmodelingcanalsobeusedinotherparts.CATIA(ComputerAidedTri-DimensionalInterfaceApplication)isthemodelingsoftwaretobuildupathree-dimensionalmodeloftheplatform

1.1Themeaningofthisresearch

Thereliabilityofthelandinggearplaysanimportantroletothesafetyoftheaircraft,thestructureandappearanceofthelandinggearalsodecidestheeconomyoftheaircraft.Andthereliabilityofthelandinggearisbyitsoriginaldesignprogramofthescienceandengineeringanalysis.Soitisagreatsignificancetoresearchthemodelingofthelandinggear.Thisreportstartatcivilaviationmaintenanceengineeringprofessionalcharacteristics,andcombiningwith3Dtechnologythroughtothelandinggearofthemodelingandfiniteelementanalysis,simulationthestressofthelandinggearintherealsituation,estimatedthefailure,loadingoftheimportantpartssuchashydrauliccomponents.Itplaysavitalsignificancetofaultpredictionofaircraftstructure.

1.2ThehistoryofCATIA

CATIAstartedasanin-housedevelopmentin1977byFrenchaircraftmanufacturerAvionsMarcelDassault,atthattimecustomeroftheCAD/CAMCADsoftwaretodevelopDassault'

sMiragefighterjet,thenwasadoptedintheaerospace,automotive,shipbuilding,andotherindustries.

InitiallynamedCATI(ConceptionAssisté

eTridimensionnelleInteractive—FrenchforInteractiveAidedThree-dimensionalDesign)—itwasrenamedCATIAin1981,whenDassaultcreatedasubsidiarytodevelopandsellthesoftware,andsignedanon-exclusivedistributionagreementwithIBM.

In1984,theBoeingCompanychoseCATIAV3asitsmain3DCADtool,becomingitslargestcustomer.In1988,CATIAV3wasportedfrommainframecomputerstoUNIX.In1990,GeneralDynamicsElectricBoatCorpchoseCATIAasitsmain3DCADtool,todesigntheU.S.Navy'

sVirginiaclasssubmarine.

In1992,CADAMwaspurchasedfromIBMandthenextyearCATIACADAMV4waspublished.In1996,itwasportedfromonetofourUnixoperatingsystems,includingIBMAIX,SiliconGraphicsIRIX,SunMicrosystemsSunOS,andHewlett-PackardHP-UX.

In1998,V5wasreleased,whichwasanentirelyrewrittenversionofCATIA,withsupportforUNIX,WindowsNTandWindowsXPsince2001.

In2008,DassaultannouncedandreleasedCATIAV6.WhiletheservercanrunonMicrosoftWindows,LinuxorAIX,clientsupportforanyoperatingsystemotherthanMicrosoftWindowsisdropped.[5]InNovember2010,DassaultlaunchedCatiaV6R2011x,thelatestreleaseofitsPLM2.0platformwhilestillcontinuingtosupportandimproveitsCatiaV5software.InJune2011,DassaultlaunchedV6R2012.

Commonlyreferredtoasa3D-ProductLifecycleManagementsoftwaresuite,CATIAsupportsmultiplestagesofproductdevelopment(CAx),fromconceptualization,design(CAD),manufacturing(CAM),andengineering(CAE).CATIAfacilitatescollaborativeengineeringacrossdisciplines,includingsurfacing&

shapedesign,mechanicalengineering,equipmentandsystemsengineering.CATIAprovidesasuiteofsurfacing,reverseengineering,andvisualizationsolutionstocreate,modify,andvalidatecomplexinnovativeshapes.Fromsubdivision,styling,andClassAsurfacestomechanicalfunctionalsurfaces.CATIAenablesthecreationof3Dparts,from3Dsketches,sheetmetal,composites,andmolded,forgedortoolingpartsuptothedefinitionofmechanicalassemblies.Itprovidestoolstocompleteproductdefinition,includingfunctionaltolerances,aswellaskinematicsdefinition.CATIAfacilitatesthedesignofelectronic,electricalaswellasdistributedsystemssuchasfluidandHVACsystems,allthewaytotheproductionofdocumentationformanufacturing.

CATIAcanbeappliedtoawidevarietyofindustries,fromaerospaceanddefense,automotive,andindustrialequipment,tohightech,shipbuilding,consumergoods,plantdesign,consumerpackagedgoods,lifesciences,architectureandconstruction,processpowerandpetroleum,andservices.CATIAV4,CATIAV5,Pro/ENGINEER,NX(formerlyUnigraphics),andSolidWorksarethedominantsystems.

Chapter2Overviewthelandinggear

2.1Definitionoflandinggear

Theundercarriageorlandinggearinaviationisthestructurethatsupportsanaircraftonthegroundandallowsittotaxi,takeoffandland.Typicallywheelsareused,butskids,skis,floatsoracombinationoftheseandotherelementscanbedeployed,dependingonthesurface.

Aircraftdesignersofthe1920sknewthatreducingdragonanairplaneinflightwasimportanttoimprovingspeedandfuelefficiency,aswellasmaneuverabilityandcontrollability.Buttheystillhadrelativelylittleunderstandingofwhatactuallycauseddragonairplanes.Variousstructuresobviouslycauseddrag,buttheyhadfirsttoidentifythemostimportantsourcesbeforetheycouldaddressthem.

In1927,theNationalAdvisoryCommitteeforAeronautics(NACA)openeditsnewPropellerResearchTunnel(PRT)atLangleyMemorialAeronauticalLaboratoryinVirginia.ThePRTwasaverylargewindtunnelforthetime,withadiameterof20feet(6.1meters).Itwasdesignedtoallowthetestingofanentireairplanefuselagewithengineandpropeller,asopposedtosimplyapartofanairplaneorascalemodel.NACAaeronauticalengineerssuspectedthattheaircraftlandinggearcontributedtomuchofthedragofanairplane,andthePRTwasthefirstwindtunnelthatwouldallowthemtotestthis.

Landinggearconsistsofthewheelsthatstickoutbelowthefuselagesothatanairplanecanrolldowntherunwayduringlandingandtakeoff.Inearlyaircraft,theywerefixedinanopenpositionsothattheyprotrudedatalltimes,evenwhiletheplanewasflyingandnowhereneartheground.TestsinthePRTimmediatelydemonstratedthatlandinggearcontributedupto40percentoffuselagedrag,whichshockedtheresearchers.Theyrealizedthatreducingthedragproducedbythelandinggearwouldsignificantlyimprovetheperformanceoftheairplaneinflight.

Therewereseveralwaystoreducethedragofthelandinggear.Thetwomostobviousmethodsweretoeitherretractthelandinggearinsidetheaircraftorredesignafixedlandinggearsothatitproducedlessdragwhilestillprotrudingbelowanaircraft.

Retractinglandinggearwerenotacompletelynewideainthe1920s.J.W.Wartin'

sKitten,builtin1917,hadretractablegear(butcouldnotactuallyfly).TheDaytonWrightRB-1(Figure2-1)of1920andtheVervilleSperryR-3of1922alsohadretractablegear.Buttheseaircraftwereraritiesandmostairplaneshadfixedlandinggearattheendofmetalstrutsbecausetheywereeasytodesign,strong,andrelativelylightweight.

Figure2-1AircraftRB-1

Whendesigninganaircraft,engineershavealwayshadtoaddressfiveconflictingrequirements.Theseare:

performance,weight,cost,reliability,andmaintenance.Thebestsolutiontotheperformancerequirementwastopullthelandinggearcompletelyinsidethefuselageandcoverthemover,presentingasmoothsurfacethatproducednodrag.Butwhileidealfromaperformancestandpoint,thisapproachaffectedalloftheotherrequirementsatweighedmore,costmore,waslessreliable,andre