塔器施工方案TowerWord格式文档下载.docx

《塔器施工方案TowerWord格式文档下载.docx》由会员分享,可在线阅读,更多相关《塔器施工方案TowerWord格式文档下载.docx(12页珍藏版)》请在冰豆网上搜索。

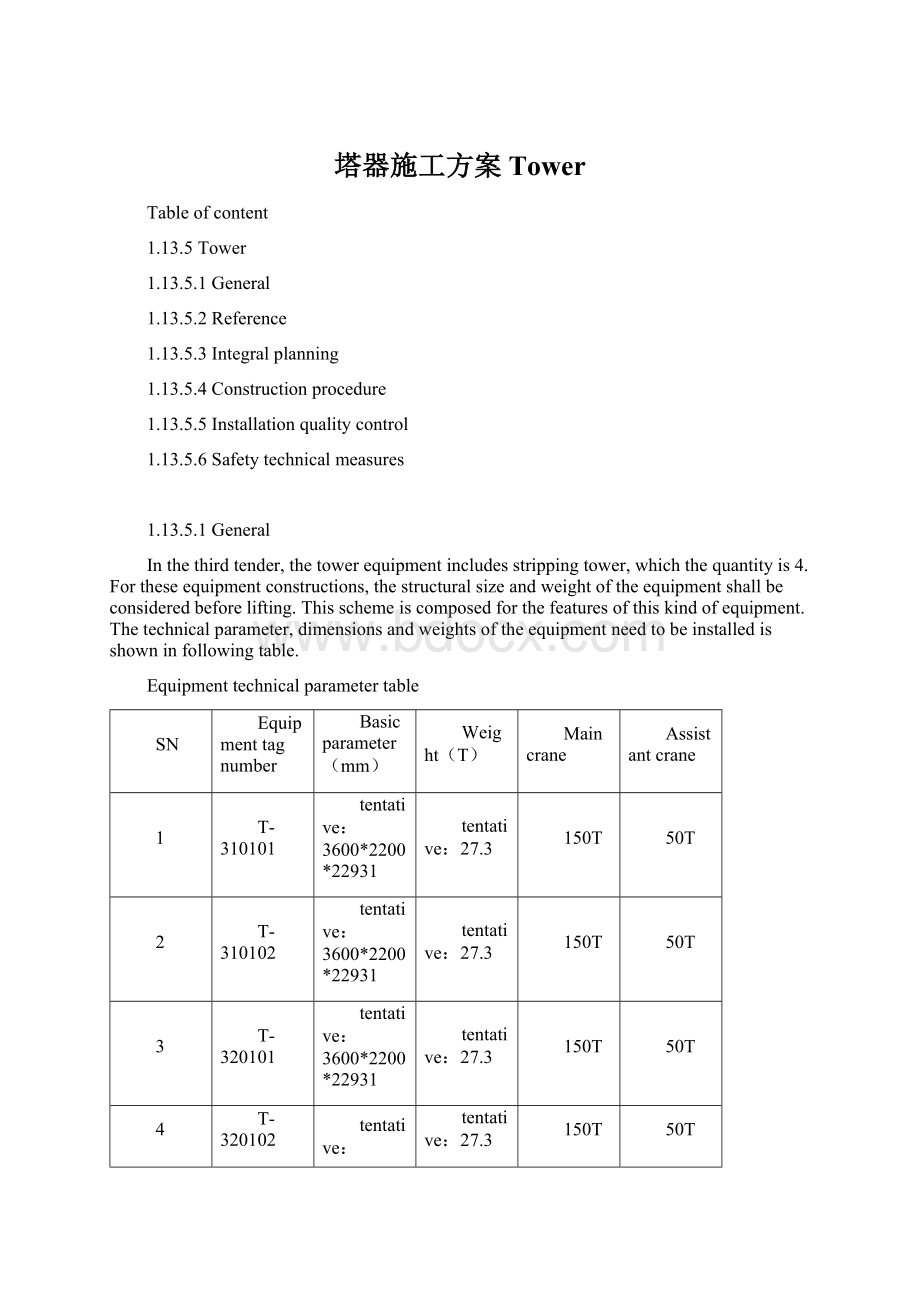

SN

Equipmenttagnumber

Basicparameter(mm)

Weight(T)

Maincrane

Assistantcrane

1

T-310101

tentative:

3600*2200*22931

27.3

150T

50T

2

T-310102

3

T-320101

4

T-320102

Craneselecting:

Maincrane:

QY150V633,operationrange:

10m,mainderrick:

34m,ratedload:

39t,loadratio:

69%

Assistantcrane:

QY50V633,operationrange:

5m,mainderrick:

10.7m,ratedload:

28t.

1towerequipmentlistanddatasheetsuppliedinbiddocument

2overalllayoutplanningforplantarea

3Parameterperformancesheetofcrane

4Relevantstandardandspecification

1.13.5.3Integralplanning

1Arrangetheliftingsequencefortheequipmentaccordingtotheactualsituationatsite.

2Onpremiseofensuringthereliableliftingworkandreasonableprocess,unloadingandliftingshallbedoneinonetimewithprocessofusinglargecrane“liftingbysinglecraneandhoisttailbyassistantcrane”.

3Sincetheconstructiondrawingisnotdetailed.Weassumethemaincraneforthisequipmentis150tcranetruckandtheassistantcraneis50tcranetruck.Theequipmentwillbeliftedbyassistanceofdeliveringtailbyassistancecranetoerecttheequipmentandthenliftitintopositionbymaincrane.Toensuretheequipmentcanspinsmoothlyduringliftedbymaincraneandbeforeerection,thebalancebeamshallbeusedtoensuretheliftingcanbecarriedoutsuccessfully.

1Foundationrecheckacceptance

●Whendeliveringthefoundation,themeasurementshallberecorded.Theelevationdatumlineandvertical,horizontalcenterlineofthefoundationshallbedrawnonthefoundationclearly.Coordinateaxisshallbemarkedonthebuildingandthefoundationforimportantequipmentshallhavesubsideobservationpoint.

●Carryoutappearanceinspectiontothefoundation.Itshallbefreeofdefectsuchascrack,honeycomb,void,barereinforcingetc.

●Recheckthesize,position,elevationofthefoundationaspercivilworkfoundationdiagramandtechnicaldocumentoftheequipment.Theallowabletoleranceshallcomplytotheregulationofthefollowingtable.Theacceptanceresultshallbesignedbycivilworkunitrepresentative,constructionunitrepresentative,supervision,installationunit.

●Thefollowingworkshallbecarriedouttothefoundationbeforeinstallationofequipment:

Forthefoundationsurfaceneedsecondarygrouting,thepittedsurfaceshallbeshoveledandthesurfaceshallbefreeofoilortentorium.

Thefoundationsurfacewheretheshimplateisinstalledshallbeevenoutandthelevelallowabletoleranceis2mm/m.

Thesundriessuchasgravel,soilandpondingintheboltholemustbecleanedout.

Allowabletoleranceforequipmentfoundationsizeandposition

Itemname

Allowabletolerance(mm)

foundationcoordinateposition(horizontalandverticalaxis)

±

20

elevationfordifferentplaneoffoundation

+0,-20

planedimensionofthefoundation

planedimensionoftheboss

-20

Depressiondimension

+20

levelnessofupperplaneofthefoundation

5/m,Wholelength10

5

verticaltolerance

5/m,Wholeheight20

6

embeddedanchorblot

elevation(top)

+20,-0

Centerdistance(atrootandtop)

7

reservedanchorblothole

centerposition

10

Depth

verticalityoftheholewall(Wholedepth)

8

embeddedplate

elevation

2Basicrequirementsforshimplateinstallation

●Theprincipleforshimplatelayoutis:

setonegrouponeachsideoftheanchorboltandmaketheshimplateclosetotheanchorboltascloseaspossible.Whentheintervalbetweenanchorboltsislessthan300mm,amainshimplategroupcanbesetatsamesideofeachanchorbolt.Theadjacentshimplatecanbedeterminedaccordingtotheactualsituationofweight,substratestructuretypeandloaddistributionoftheequipmentanditisnormallyapproximateto500mm.Thetypeoftheshimplateshallbefinalizedaccordingtothesituationofweight,substrateshapeanddimensionofequipment.

●Theshimplateshallbeflat,freeofscale,overlapetc.Theslopefinishoftheinclinedshimplateshallbenolessthan▽3andtheinclinationisnormallybetween1/20~1/10.

●Theinclinedshimplateshallbeusedinpairs.Whenitisformingagroupwithflatshimplate,normallythelayersisnomorethan4.Thethinplateshallbetweentheinclinedshimplateandthethickflatshimplate.Theheightoftheshimplatesgroupisnormally30-70mm.

●Whentheshimplateisdirectlyplacedonthefoundation(embeddedplate),thecontactwiththefoundation(embeddedplate)shallbeeven.Thecontactproportionshallbenolessthan80%.Theallowabletolerancefortheflatnessofthetopofflatshimplateshallbe2mm/m.Checkwithcooperationoflevelrulerandlevelertomakesuretheelevationoftopofeachgroupofshimplatecanmatchtheactualinstallationelevationofequipmentbottom.

●Aftertheleveling,theshimplategroupshallexpose10-30mmfromthefoundation.Fortheshimplategroupsonbothsidesofanchorbolts,thelengthextendedintoequipmentfoundationbyeachpieceofshimplateshallbemorethantheanchorboltsandensuretheequipmentfoundationcanbeforcedevenly.Ifthecontactwidthbetweenfoundationbottomandtheshimplateisnotenough,theplacingpositionoftheshimplateshallensurethefoundationcanbelocatedonthemiddleofthebearingsurfaceoftheshimplategroup.

●Aftertheequipmentisleveled,alignedwithshimplates,knockwithhammertocheckthetightnessoftheshimplategroupsandthereshallbenoloose.Checktheclearancebetweentheshimplatesandbetweentheshimplateandthefoundationbottomwithfeelergaugeof0.05mm.Thesumofthelengthwhichthegaugestickintofrombothsidesonthesamesectionoftheshimplateshallbenomorethan1/3ofthelength(width)oftheshimplate.Spotweldingbetweenlayersshallbecarriedoutatthebothsidesoftheshimplategroupsafterqualified.Theshimplateandtheequipmentfoundationshallnotbewelded.

Foundationshimplatesfortowerequipmentlayout

(Canbeadjustedaccordingtheintervaloftheboltsproperly)

3Openboxauditandmanagement

Aftertheequipmentandmaterialsarrivestheconstructionfield,theconstructionunitshallorganizerelevantpersonneltoattendtheopenboxauditaccordingtotheordercontract,packinglistandtechnicaldocuments.Themaincontentisasfollowing:

●Checkthepacksituation,boxnumber,specificationandquantityoftheequipmentandmaterials.

●Thetechnicaldocumentsandspecializedtoolsshallbecomplete,includingassemblydiagram,components,quick-wearpartdiagramandinstallationoperationmanual,manufacturequalification,productioncertification,recordforassembly,testandcommission,packagelistoftheequipment.

●Carryoutappearanceinspectiontotheequipment,partsandcomponentsandcheckthetype,specification,versionandquantityetc.ofthepartsandcomponents.

●Afterinspection,representativesofeachpartywhoattendtheacceptanceshallsigntheinspectionrecord.

●Thepressurevesselsshallbeinspectedaspertherelevantstandardofthepressurevessel.

●Effectiveprotectiveandstoragemeasuresshallbetakenforequipmentandthecomponentstopreventdeformation,damage,rust,ageing,deranged,lostetc.

●Theequipmentincludingelectrical,instrumentsandcomponentswhichisinsuitwiththeequipmentshallbecheckedandacceptedandstorageproperlybyprofessionalperssonel.

●Ifthetowerequipmentisdeliveredinparts,itshallbeassembledonthegroundforliftingintegrally.

4Checkbeforelifting

●TheschemeissubmittedandapprovedbyCOMPANY

●Thecraneisstoppedatsiteandthesundriesiscleanedandthegroundiscompacted.

●Thematerialsandmachineryforliftingiscomplete.

●Thefoundationoftheequipmentisqualifiedwithcheckandacceptance.

●Thetechnicaldisclosureisalreadydonefortheliftingpersonnel.

5Trylifting

Thespecializedworkerandpersonnelineachpostisinposition.Sundriesintowerarecleaned.Eachbearingpartistiedfirmlyandthepositioniscorrect.Thetowershallbeseparatedfromunrelatedparts.Afterensuringnomistake,thegeneralcommandershallsendordertotrylifting.Slowlyliftthetowerto100mmabovegroundandcarryoutoverallcheck.

6Formallifting

Aftercontinuoustwicenormaltryinglifting,theformalliftingcanbecarriedout.Duringlifting,adjusttheangleofthederrickfrequentlytopreventhittingthederrickanddamagetheequipment.Ensuretheequipmentisverticalbeforeliftingintopositionforconvenienceofpositioning,levelingandalignment.Thepositioningoftheequipmentshallbeslow,stabletopreventthedamagetotheanchorboltsscrewspread.

7Mainstepsoflifting

●Thecraneposition,equipmentlayoutandbaseboardforcraneapproachshallbesetaccordingtothe