中英文文献翻译液压传动系统设计与计算文档格式.docx

《中英文文献翻译液压传动系统设计与计算文档格式.docx》由会员分享,可在线阅读,更多相关《中英文文献翻译液压传动系统设计与计算文档格式.docx(23页珍藏版)》请在冰豆网上搜索。

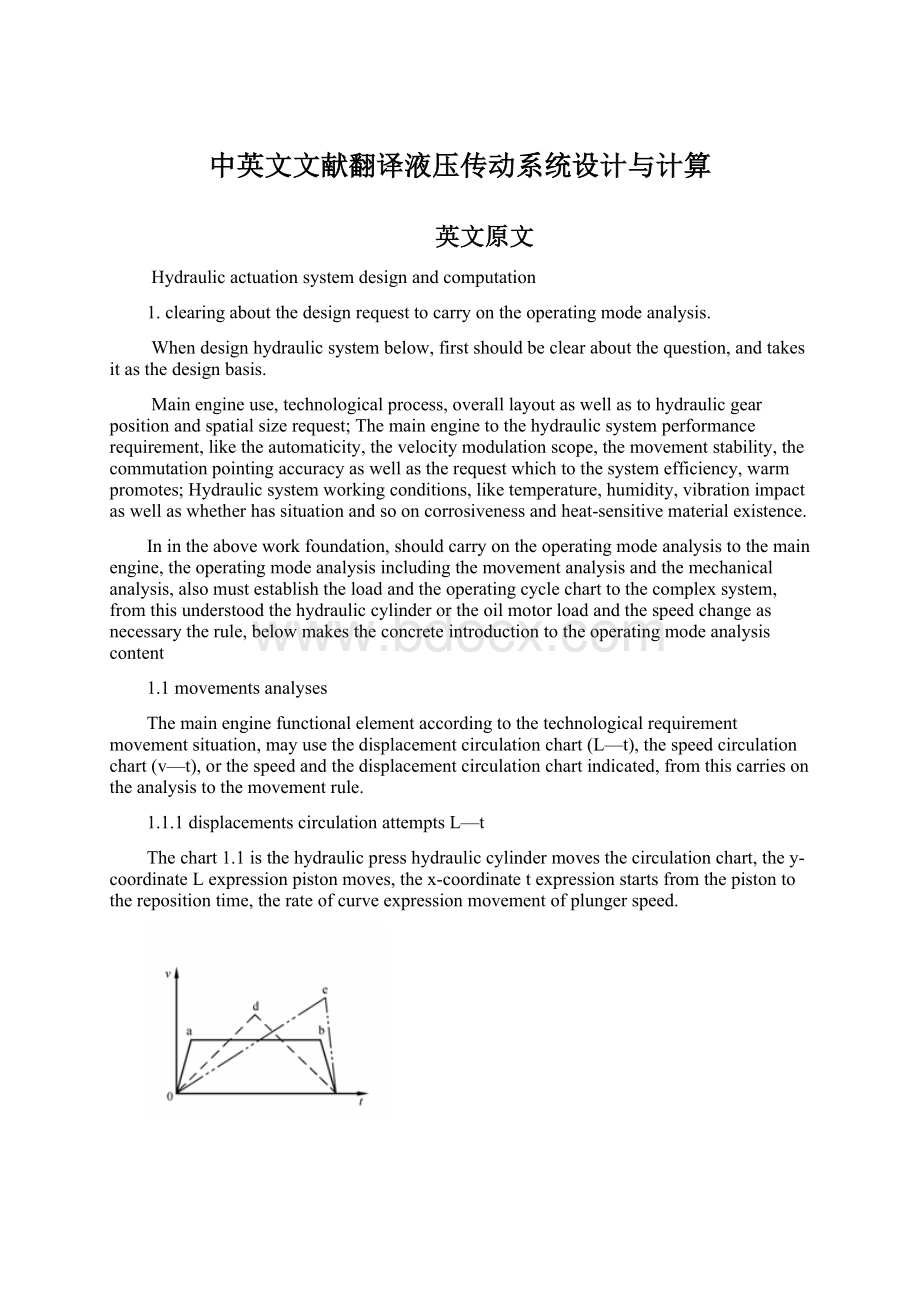

Chart1.1displacementscirculationchart

1.1.2speedscirculationchartv—t(orv—L)

Intheprojectthehydrauliccylindermovementcharacteristicmayinduceisthreekindoftypes.Thechart1.2isthreekindoftypeshydrauliccylindersv—tchart,thefirstkindoflikechart1.2centersolidlinesshow,thehydrauliccylinderstartstomaketheuniformacceleratedmotion,thenuniformmotion,

Chart1.2speedscirculationchart

Finallyuniformretardedmotiontoendpoint;

Thesecondkind,thehydrauliccylinderprecedingpartlymakestheuniformacceleratedmotionintheoveralltravellingschedule,inanotheronepartlymakestheuniformretardedmotion,alsotheaccelerationvalueisequal;

Thethirdkind,thehydrauliccylinderonemostabovemakestheuniformacceleratedmotionintheoveralltravellingschedulebyasmalleracceleration,thenuniformdeceleratestothetravellingscheduleendpoint.V—tchartthreevelocitycurve,notonlyclearlyhasindicatedthreekindoftypeshydrauliccylindersmovementrule,alsoindirectlyhasindicatedthreekindofoperatingmodesdynamicperformance.

1.2mechanicalanalyses

1.2.1hydrauliccylindersloadsanddutycyclechart

1.2.1.1hydrauliccylindersloadstrengthcomputations

Whentheoperatingmechanismmakesthestraightreciprocatingmotion,thehydrauliccylindermustovercometheloadiscomposedbysixparts

(1.1)

Intheformula:

FcInordertoresistancetocutting;

FfInordertofrictiondrag;

FiForinertiaresistance;

FgForgravity;

FmInordertosealtheresistance;

FbInordertodraintheoiltheresistance.

1.2.1.2hydrauliccylinderscycleofmotionvariousstagesoverallloadstrength

Thehydrauliccylindercycleofmotionvariousstagesoverallloadstrengthcomputation,generallyincludesthestartacceleration,quicklyenters,thelaborenters,quicklydrawsback,deceleratesappliesthebrakeandsoonseveralstages,eachstageoverallloadstrengthhasthedifference.

(1)startstheaccelerationperiod:

Bynowthehydrauliccylinderorthepistonwereinfromstaticenoughtostartsandacceleratestothecertainspeed,itsoverallloadstrengthincludingguiderailfrictionforce,packingassemblyfrictionforce(accordingtocylindermechanicalefficiencyηm=0.9computation),gravityandsoonitem,namely:

(1.2)

(2)faststage:

(1.3)

(3)thelaborentersthestage:

(1.4)(4)decelerates:

(1.5)

Tothesimplehydraulicsystem,theabovecomputationprocessmaysimplify.Forexampleusesthesingleproportioningpumptosupplytheoil,onlymustcalculatethelabortoenterthestagetheoverallloadstrength,ifthesimplesystemusesthelimitingpressuretypevariabledisplacementpumporapairofassociationpumpsfortheoil,thenonlymustcalculatethefaststageandthelaborentersthestagetheoverallloadstrength.

1.2.2oilmotorsload

Whentheoperatingmechanismmakestherotarymotion,theoilmotormustovercometheoutsideloadis:

(1.6)

1.2.2.1operatingdutiesmomentofforceMe.Theoperatingdutymomentofforceispossiblyadefinitevalue,alsopossiblyasnecessarychanges,shouldcarryontheconcreteanalysisaccordingtothemachineworkingcondition.

1.2.2.2frictionmoments.Inordertorevolvethepartjournalplacefrictionmoment,itsformulais:

(1.7)

Gisrevolvesthepartweight(N);

Fistherubbingfactor,whenthestartforthefactor,afterthestartformovestherubbingfactor;

Risthejournalradius(m).

1.2.2.3momentofinertiaMi.Themomentofinertiawhichinordertorevolvethepartaccelerationordecelerateswhenproduces,itsformulais:

(1.8)

εIstheangleacceleration(r/s2);

istheaccelerationordeceleratesthetime(s);

Jisrevolvesthepartrotationinertia(

),

Inordertorotatetheparttheflywheeleffect(

).

Eachkindmaylookup<

MachinedesignHandbook>

Accordingtothetype(1.6),separatelyfiguresouttheoilmotorinaoperatingcyclevariousstagesloadsize,thenmaydrawuptheoilmotorthedutycyclechart

2determinationshydraulicsystemmainparameter

2.1hydrauliccylindersdesigncalculations

2.1.1initiallydecidesthehydrauliccylinderworkingpressure

Inthehydrauliccylinderworkingpressuremainbasiscycleofmotionvariousstagesbiggestoverallloadstrengthdetermined,inadditionbelow,butalsoneedstoconsiderthefactor:

2.1.1.1eachkindofequipmentdifferentcharacteristicandusesituation.

2.1.1.2considerationseconomiesandtheweightfactor,thepressureelectslowly,thenpartsizebig,theweightisheavy;

Thepressurechooseshighsomewhat,thenpartsizesmall,theweightislight,buttothepartmanufactureprecision,thesealingpropertyrequestshigh.

Therefore,thehydrauliccylinderworkingpressurechoicehastwoways:

One,electsaccordingtothemechanicaltype;

Two,accordingtocutstheloadtoelect.

Ifthetable2.1,thetable2.2shows.

Thetable2.1pressestheloadtochoosetheexecutionfiletheworkingpressure

Load

/N

<5000

500~10000

10000~20000

20000~30000

30000~50000

>50000

Workingpressure

/MPa

≤0.8~1

1.5~2

2.5~3

3~4

4~5

>5

Thetable2.2pressesthemechanicaltypetochoosetheexecutionfiletheworkingpressure

Mechanicaltype

Enginebed

Farmmachinery

Projectmachinery

Grinder

Aggregatemachine-tool

DragonGatedigsthebed

Broachingmachine

a≤2

3~5

≤8

8~10

10~16

20~32

2.2oilmotorsdesigncalculation

2.2.1computationsoilmotordisplacement

Underoilmotordisplacementaccordingtothetypedecidedthat,

(2.1)

Tistheoilmotorloadmomentofforce(N·

m);

Foroilmotorimportandexportpressuredifference(n/m3);

istheoilmotormechanicalefficiency,thecommongearandtheplungermotortakes0.9~0.95,theleafblademotortakes0.8~0.9.

2.2.2computationsoilmotorneedsthecurrentcapacityoilmotorthemaximumcurrentcapacity

(2.2)

istheoilmotordisplacement(m3/r);

istheoilmotorhighestrotationalspeed(r/s).

3hydraulicpressurepartschoice

3.1hydraulicpumpsdeterminationswithneedthepowerthecomputation

3.1.1.1determinesthehydraulicpumpthebiggestworkingpressure.Thehydraulicpressurepumpingstationmusttheworkingpressuredetermination,mainlyactsaccordingtothehydrauliccylinderintheoperatingcyclevariousstagestohavemosttremendouspressurep1,inadditiontheoilpumplosesSigmaDeltaptheoilmouthtothecylinderplacealwayspressureΣΔp,namely

(3.1)

loses,thepipelineincludingtheoilaftertheflowvalveandotherpartslocalpressuresalongtheregulationlossandsoon,beforesystempipelinedesign,mayactaccordingtothesimilarsystemexperiencetoestimate,commonpipelinesimplethrottlevalvevelocitymodulationsystemΣΔpis(2~5)×

105Pa,withthevelocitymodulationvalveandpipelinecomplexsystem

is(5~15)×

105Pa,

alsomayonlyconsiderflowsaftervariouscontrolvalvespressureloss,butignoresthecircuitryalongtheregulationloss,variousvalvesratedpressurelosesmaysearchesfromthehydraulicpressureparthandbookortheproductsample,Alsomayrefertothetable1.3selections

Thetable3.1iscommonlyused,thelowpressureeachkindofvalvepressureloses(Δpn)

Valve

Δpn(×

105Pa)

Cone-wayvalve

0.3~0.5

3~8

Crossvalve

1.5~3

2~3

3.1.2determinesthehydraulicpumpcurrentcapacityqB

Pumpsthecurrentcapacity

basisfunctionalelementoperatingcyclemustthemaximumcurrentcapacity

andthesystemdivulgesthedetermination

3.1.2.1Atthesametimewhenmorethanhydrauliccylindersmovement,thehydraulicp