MI设计规范文档格式.docx

《MI设计规范文档格式.docx》由会员分享,可在线阅读,更多相关《MI设计规范文档格式.docx(13页珍藏版)》请在冰豆网上搜索。

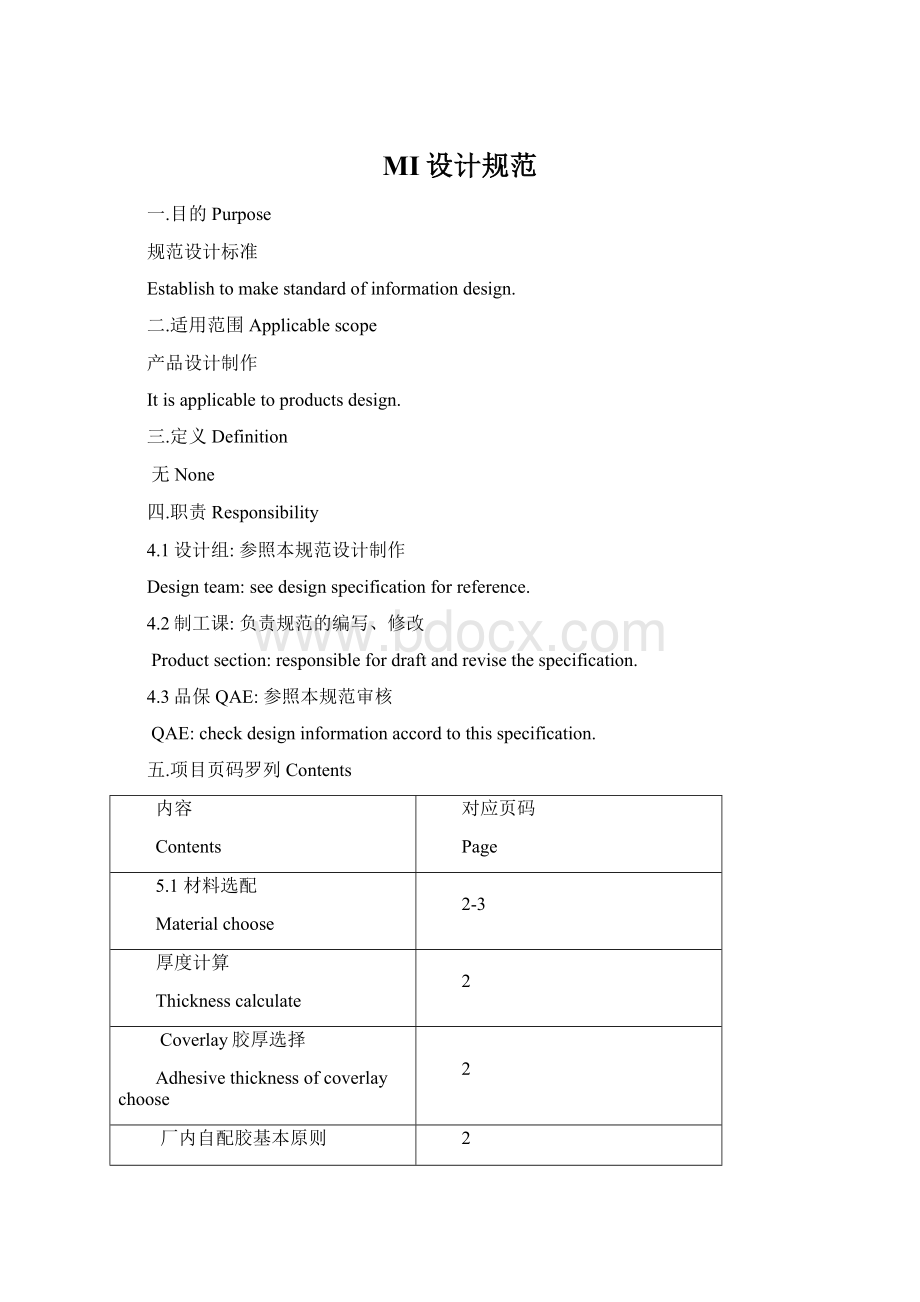

内容

Contents

对应页码

Page

5.1材料选配

Materialchoose

2-3

厚度计算

Thicknesscalculate

2

Coverlay胶厚选择

Adhesivethicknessofcoverlaychoose

厂内自配胶基本原则

Matchingprincipleofadhesivebythecompany

材料选配

Materialchoose

3

5.2流程定义

Manufacturingprocess

3-7

基本流程定义

Mainprocess

3-5

流程注意事项定义

Notestopayattention

5-7

5.3资料图纸制作

Drawingmaking

7-11

流程单备注内容

NotesinMI

7-8

图纸资料制作

Drawinginformationmaking

8-11

5.4检查项目

Checkitem

附件一

MIChecklist

六.内容Contents

6.1材料选配Materialchoose

6.1.1厚度计算Thicknesscalculate

6.1.1.1FPC厚度公差±

0.03mm(Min±

0.02mm);

ThethicknesstoleranceofFPCis±

0.02mm).

6.1.1.2FPC+PI补强厚度公差±

0.05mm(Min±

0.03mm);

ThethicknesstoleranceofFPCandPIstiffeneris±

0.03mm).

6.1.1.3FPC+FR4补强厚度公差±

0.1mm;

ThethicknesstoleranceofFPCandFR4is±

0.1mm.

6.1.1.4FPC+钢片补强厚度公差±

ThethicknesstoleranceofFPCandsteelsheetis±

6.1.1.5FPC+背胶厚度公差±

0.05mm;

ThethicknesstoleranceofFPCandtapeis±

0.05mm.

6.1.1.6厚度计算须考虑镀铜厚度,计算时取值单面镀铜厚0.6mil;

Takethethicknessofcopperplatingintoaccountwhencalculate,andchoosethesingleplatingthicknessof0.6mil.

6.1.1.7厚度计算时,Coverlay须扣除溢胶厚度,溢胶量依其胶厚的40%计算;

Deducttheresinthickness(40%oftheadhesivethickness)ofcoverlaywhencalculate.

6.1.1.8背胶厚度为不包括离形纸厚;

Thetapethicknessdoesn’tincludethethicknessofreleasepaper.

6.1.2基材搭配Coverlay之基本原则Principleofmainmaterialmatchcoverlay

6.1.2.1单面板1/3oZ&

1/2oZ铜基材,CoverlayAD厚度可选择0.6mil&

1mil;

Single-side1/3oZ&

1/2oZcoppermatchCoverlayAD0.6mil&

1mil;

6.1.2.2双面板1/3oZ&

1/2oZ铜基材,CoverlayAD厚度可选择1mil;

Double-side1/3oZ&

1/2oZcoppermatchCoverlayAD1mil;

6.1.2.3单,双面板1oZ铜基材,CoverlayAD厚度可选择1mil&

1.4mil;

Singleanddouble-side1oZcoppermatchesCoverlayAD1mil&

1.4mil;

6.1.3厂内自配胶基本原则Matchingprincipleofadhesivebythecompany

6.1.3.1FR4配胶是将胶布于FR4上;

FR4:

GelatinizeontheFR4.

6.1.3.2PET配胶通常为感压胶;

PET:

choosethepressuresensitiveadhesive.

6.1.3.3自配PI补强选材原则;

纯PI+带胶PI+纯胶,不可使用两种带胶PI直接叠成;

PIstiffener:

purePI+PIwithadhesive+pureadhesive,nottochoosetwoPIwithadhesiveatthesametime.

6.1.4材料选配基本原则Principleofmaterialchoose

6.1.4.1压合板接着使用之纯胶应尽量使用1mil之厚度;

Choosetheadhesivethicknessof1milforlaminateboard.

6.1.4.2有动态绕折或屈曲要求之FPC必须使用RA铜;

ChooseRAcopperforflexibleboard.

6.1.4.3线宽线距小于4mil,基材尽量使用薄铜,1/2oZ或1/3oZ铜基材;

Choosethethincopperof1/2oZor1/3oZfortheL/W&

L/Sunder4mil.

6.1.4.4无特殊指定情况下,插拔手指背面补强配PI补强;

ChoosePIstiffeneronbottomoftheinsertfingerunlessspecified.

6.1.4.5无特殊指定情况下,Connector背面补强配FR4补强;

ChooseFR4stiffeneronbottomoftheConnectorunlessspecified.

6.1.4.6无特殊指定情况下,BGA背面补强配钢片补强;

ChooseSTEELSHEETonbottomoftheBGAunlessspecified.

6.1.4.7副材贴合后需过SMT高温焊接之FPC,胶系的使用须考虑是否耐高温;

ChoosethehotresistadhesiveifitneedsSMTaftertacking.

6.1.4.8钢片补强有接地要求(电阻<

1欧姆),建议采用CBF-300热固胶膜+SUS304NST钢片;

ChoosetheCBF-300thermalsettingadhesive+SUS304NSTsteelsheetifthesteelsheetneedstolinktoearth.

6.1.4.9银箔目前有两种规格,SF-PC5000(22um,黑色),SF-PC1000(32um,白色),均可做为防电磁波使用;

Thereare2typesofsilverfoilrecently:

SF-PC5000(22um,black),SF-PC1000(32um,white),ofallareanti-electromagneticwave.

6.1.4.10单面板不可整面印曝光显影型油墨制作,易卷曲;

NottochoosetheLPIforwholepanelprintofsinglesideboard.

6.1.4.11基材搭配Coverlay尽量选用同一供应商;

Choosethesamesupplierofthecopperandcoverlayatonetime.

6.2流程定义DefinitionofManufacturingProcess

6.2.1基本流程定义(只定义出流程中的大站)DefinitionofMainprocess

6.2.1.1单面板基本流程Single-side

开料---钻孔---曝光显影---蚀刻脱膜---贴Coverlay---压制固化---打孔---网印文字---电,化金---加工贴补强---冲型---电测---外形冲型---成检---入库

Shearing–drilling–exposinganddeveloping–etchingandstriping–coverlaytacking–laminatingandsolidifying–targetpunching–silkscreen–Ni/GoldplatingorNi/Goldimmersion–stiffenertacking–punching–electricaltesting–outlinepunching–FQC-warehouse

6.2.1.2纯铜板基本流程Purecopperfoil

开料---钻孔---假贴Base---压制固化---曝光显影---蚀刻脱膜---假贴Coverlay---压制固化---打孔---网印文字---电,化金---加工贴补强---冲型---电测---外形冲型---成检---入库

Shearing–drilling–basecoverlaytacking–laminatingandsolidifying–exposinganddeveloping–etchingandstriping–topsidecoverlaytacking–laminatingandsolidifying–targetpunching–silkscreen-Ni/GoldplatingorNi/Goldimmersion-stiffenertacking–punching–electricaltesting–outlinepunching–FQC-warehouse

6.2.1.3双面板基本流程Double-side

开料---钻孔---沉电铜---曝光显影---蚀刻脱膜---假贴Coverlay---压制固化---打孔---网印文字---电,化金---加工贴补强---冲型---电测---外形冲型---成检---入库

Shearing–drilling–copperplatingorimmersion-exposinganddeveloping–etchingandstriping–coverlaytacking–laminatingandsolidifying–targetpunching–silkscreen–Ni/GoldplatingorNi/Goldimmersion–stiffenertacking–punching–electricaltesting–outlinepunching–FQC-warehouse

6.2.1.4压合板基本流程Laminateboard

开料---一次钻孔---基材压合---二次钻孔---沉电铜---曝光显影---蚀刻脱膜---假贴Coverlay---压制固化---打孔---网印文字---电,化金---加工贴补强---冲型---电测---外形冲型---成检---入库

Shearing–firstdrilling–basefilmtacking–seconddrilling-copperplatingorimmersion-exposinganddeveloping–etchingandstriping–coverlaytacking–laminatingandsolidifying–targetpunching–silkscreen–Ni/GoldplatingorNi/Goldimmersion–stiffenertacking–punching–electricaltesting–outlinepunching–FQC-warehouse

6.2.1.5四层分层板基本流程4-layerboard

开料---一次钻孔---内层基材压合---二次钻孔(内层菲林对位孔)---内层线路曝光显影---内层线路蚀刻脱膜---电测线检---内层Coverlay假贴---压制固化---四层基材压合---打孔(三钻定位孔)---三次钻孔---等离子处理---沉电铜---外层线路曝光显影---外层线路蚀刻脱膜---电测线检---外层Coverlay假贴---压制固化---打孔---网印文字---电,化金---加工贴补强---冲型---电测---外形冲型---成检---入库

Shearing–firstdrilling–innerbasefilmtacking–seconddrilling(innerfilmregistration)–exposinganddevelopingofinnerlayer–etchingandstripingofinnerlayer–electricaltestingofinnerlayer–coverlaytackingofinnerlayer–laminatingandsolidifying–4-layerbasefilmtacking–punching(registrationtooling)–thirddrilling–plasma–copperplatingorimmersion–exposingand

developingofouterlayer–etchingandstripingofouterlayer–electricaltesting–coverlaytackingofouterlayer–laminatingandsolidifying–targetpunching–silkscreen-Ni/GoldplatingorNi/Goldimmersion–stiffenertacking–punching–electricaltesting–outlinepunching–FQC-warehouse

6.2.1.6以上基本流程在Coverlay压制固化前是不可更改,Coverlay压制固化后可根据具体情况适当调整流程

Itcannotbechangetheprocessbeforecoverlaytacking,andcanbeadjusteddependstoactualconditionfortheprocessesaftercoverlaytacking.

6.2.2流程注意事项定义Notestopayattention

6.2.2.1辅助流程定义Definitionofassistantprocess

6.2.2.1.1干膜贴合前使用:

化学清洗;

Beforedryfilmtacking:

chemicaltreatment.

6.2.2.1.2双面板脱膜后进假贴前:

双面磨板处理;

单面板毋须;

Beforecoverlaypre-laminateexceptsingle-side:

brushingtreatmentofbothsides.

6.2.2.1.3黄油丝印前使用:

磨板处理;

Beforeyellowinkprinting:

brushingtreatment.

6.2.2.1.4表面处理前使用:

表面处理喷沙;

Beforesurfacetreatment:

sandspraying.

6.2.2.1.5热固胶系补强贴合前:

板面檫乙醇;

Beforestiffenertackingofthermalsettingadhesive:

wipethesurfacewithalcohol.

6.2.2.1.6BGA板于FQC前:

碱性除油;

BeforeFQCofBGA:

alkalidegreasing.

6.2.2.2流程注意事项Notestopayattention

6.2.2.2.1同时需要电镀Ni~Au和化学Ni~Au两种表面处理流程时,采取先化学Ni~Au,后电镀Ni~Au,即先高温后低温原则;

PuttheNi-AuimmersionbeforetheNi-Auplatingwhentakeuseofthetwoprocessesatthesametime.

6.2.2.2.2同时需要“金”和“锡”两种表面处理时,采取先“金”和“锡”;

PutthegoldplatingbeforeTinplatingwhentakesuseofthegoldandtinplatingatthesametime.

6.2.2.2.3导电银箔或银浆须放置于电镀后制作;

Puttheelectricsilverfoilorsilverpasteaftertheplatingprocess.

6.2.2.2.4需同时贴银箔和印银浆之FPC,须先贴银箔再印银浆;

Putthesilverfoiltackingbeforesilverpasteprintingwhentakeuseofthetwoprocessesatthesametime.

6.2.2.2.5网印文字须排于化金之后;

Putthesilkscreenafterthegoldplatingprocess.

6.2.2.2.6OSP流程须排于电测后,且为整板过OSP;

PuttheOSPprocess(wholepanel)afterelectricaltestingprocess.

6.2.2.2.7打孔流程尽量排于Coverlay压制固化后;

Putthepunchingafterthecoverlaytackingprocess.

6.2.2.2.8针对双面板LPI制作;

Double-sideLPIproduction

a单面开窗阻焊,但需双面印刷黄油时流程:

印刷油墨(无阻焊开窗面)→预烘

→印刷油墨(有阻焊开窗面)→预烘→曝光→后流程

Singlesidesoldermaskopenanddouble-sideyellowinkprinting:

inkprinting(noopen)–prebaks–inkprinting(withopen)–prebaking–exposing-…

b双面开窗阻焊时流程:

正面印刷油墨→预烘→曝光→显影→固化→化学清洗→反面印刷油墨→预烘→曝光→后流程

Double-sideopen:

inkprintingoftopside–prebaking–exposing–developing–solidifying–chemicaltreatment–inkprintingofbottomside–prebaking–exposing-…

6.2.2.2.10针对PI补强的贴合与压制;

PIstiffenertackingandlaminating

a3mil及以下PI补强,流程:

Coverlay假贴后→PI补强假贴→一起压制固化;

3milandunder3mil:

coverlaytacking–PIstiffenertacking–laminatingandsolidifyingtogether.

b3mil以上PI补强,不可与Coverlay一起压制固化,须单独压制固化;

Above3mil:

laminatingandsolidifyingseparately.

6.2.2.2.11钢片补强尽量于外形冲型后,单PCS贴合;

Tackthesteelsheetpiecebypieceafteroutlinepunching.

6.2.2.2.12当钢片于外型冲型前贴合时时流程:

穴拔冲型(钢片贴合处)→贴钢片→外

形冲型(模具须将钢片处挖开);

Tackbeforeoutlinepunching:

punching–steelsheettacking–outlinespunching.

6.2.2.2.130.2mmFR4可条贴后与FPC一起成型;

RouttogetherwithFPCfortheFR4lessthan0.2mm