FMEA 中英文范本汇总Word文件下载.docx

《FMEA 中英文范本汇总Word文件下载.docx》由会员分享,可在线阅读,更多相关《FMEA 中英文范本汇总Word文件下载.docx(34页珍藏版)》请在冰豆网上搜索。

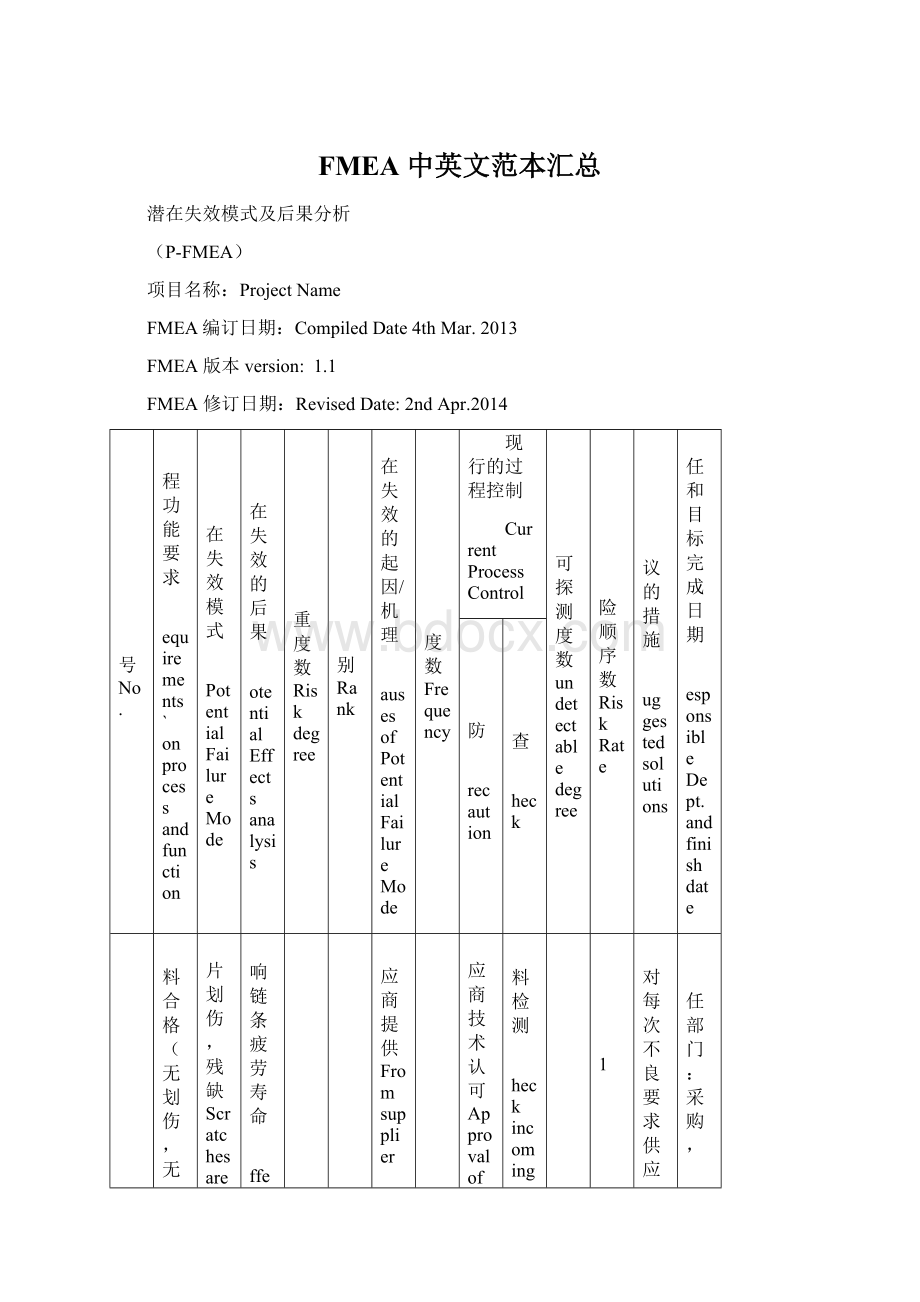

CurrentProcessControl

不可探测度数undetectabledegree

风险顺序数RiskRate

建议的措施

Suggestedsolutions

责任和目标完成日期

ResponsibleDept.andfinishdate

预防

Precaution

检查

Check

1

物料合格(无划伤,无残缺,无歪孔大小头,Materialsarequalified(Noscratches,nocrippleparts,andnounqualifiedshapeandsize)

链片划伤,残缺Scratchesareonthelinkplates,orlinkplatesarecripple

影响链条疲劳寿命

Affectchainfatiguelife

7

供应商提供Fromsupplier

3

供应商技术认可Approvalofsupplier’stechnology

来料检测

Checkincomingmaterials

21

针对每次不良要求供应商提列不良原因,改善对策,DW对其效果验证Foreachdefectedissues,suppliershouldfindoutthecause,andcomeupwiththesolutions.DWwillexamtheeffects

责任部门:

采购,质量

日期:

即日起ResponsibleDept.:

purchasingDept.andQC

FinishDate:

Fromnowon.

链片歪孔,大小头LP’sholeisunqualified,orsizeofLP’sheadisunqualified

影响链条装配Affectassemblingprocess

6

2

12

小轴切面不良Breakingareaofpinisdefected.

倒角面不合格Defectedchamfer

5

15

小轴R角锋利Pin’sR-angleistoosharp

链片产生毛坯BurswillhappenonLP

18

频度数Frequency

风险顺序数RiskRate

包装辅料合格Qualifiedpackagematerials

尺寸不合格

Unqualifiedsize

产品不能正常包装Productscannotbepackagedbythestandardsway

-设计错误

-供应商提供错误

Wrongdesignversion

Wrongdeliveryfromsupplier

4

包材尺寸规格书变更后及时通知辅料检验员Ifthepackagesizeischanged,inspectorofpackagematerialsshouldbeinformedintime

检验员依据包材尺寸规格书检测

InspectorwillchecktheincomingmaterialsbasedonthePackageSizeProcedure.

60

版面印刷错误,印刷不清晰Wrongprintversion,orfaintversion

客户投诉

Customercomplaints

-供应商提供Fromsupplier

所有彩盒版面进行标准化Regularallofthecolorfulboxversion

检验员依据标准版面检测Inspectorwilldotheinspectionbasedonthestandards

84

Requirementsonprocessandfunction

潜在失效的后果

PotentialEffectsanalysis

不可探测度数UnknownRate

建议的措施Suggestedsolutions

责任和目标完成日期ResponsibleDept.andfinishdate

预防Precaution

检查Check

物料储存Materialsstorage

零件生锈Componentsarerusted

影响生产效率,增加生产成本Affectproductionefficiency

储存时间太长

Storematerialsforlongtime

按照Fi-Fo原则发放物料DeliverymaterialsbasedonFi-Foprinciples

Inspectionontheincomingmaterials

首件检测

Inspectiononthefirstproducts

彩盒褪色Colorinbox,willfade

顾客不满意Customerdissatisfaction

储存过程中没遮光

Lightisnotshelteredfromduringthestorageprocess.

使用遮光布覆盖彩盒

Colorfulboxesshouldbepreventedfromlightbythecovercloth

包装前检测

Doinspectionbeforepackage

14

物料发放Materialsdelivery

发错物料Wrongmaterialdelivery

链条拆解,浪费零件和工时

Needtodisassemblechain.Componentsandlaborwillbewasted.

8

1.作业员为新员工

Freshoperator

2.零件标签丢失

Lackofcomponentslabel

3.零件标签与料架标签不一致

Componentslabelisinconsistentwithmaterialshelflabel

-发料前确认实际物料是否跟标签一致

Beforedelivery,Confirmmateriallabelisright

-首件检测

Do100%inspectiononthefirstproduct

-仓库盘点

Physicalinventory

CurrentProcessControl

预防Precaution

检查

Check

打组距

AssembleRL

内节偏低

Bearingareaislowerthanstandards

影响客户安装,跳齿,啮合不畅Haveabadaffectiononcustomer’sassemblingprocess

布斯压平撞子,引导撞子安装偏低Bushingbringspressuretopunchtooling.Ortheinstallationlocationofleadingpunchtoolingislowerthanstandards

-量具定期校验

Doinspectiononfirstproduct

Doroutinecalibrationonmeasurementtooling.

自主检测:

4pcs/次/2H

Frequencyforworkerstodotheinspection4pcs/time/2H

QC巡检:

4pcs/次/4H

FrequencyforQCtodotheinspection

4pcs/time/4H

布斯嵌合力偏低Pushoutforceislowerthanstandards

链条拉脱Chainelongation

10

▲

布斯孔径偏小,RLP孔径偏小

DiameterofbushingandRLP’sholeissmaller

-嵌合力机定期校验

Doroutineinspectiononthepushoutforcemachine

2pcs/次/4H

2pcs/time/4H

20

装配连接Assemblingandconnecting

外节偏高

Heightofouterlinkishigherthanstandards

链条安装后跳齿,啮合不畅Afterassembling,chaincannotfixwithgearwell.

压规格模安装偏高Theinstallationlocationofassemblingtoolingishigherthanstandards

-外节高度检测

-量具定期校验Doinspectiononfirstproduct

Doroutinecalibrationonmeasurementtooling.

自动化全检

外节偏低

Heightofouterlinkislowerthanstandards

紧目Tightjoints

压规格模具偏低Theinstallationlocationofassemblingtoolingislowerthanstandards

-紧目检测

Doinspectiononheightofouterlink

小轴凸出不均Headextensionofpinsarenotstable.

安装不畅Affectassemblingprocess

小轴长度不合格unqualifiedpinlength

10pcs/次/4H

8pcs/次/4H

自动化全检Frequencyforworkerstodotheinspection10pcs/time/4H

8pcs/time/4H

Automatic100%inspection

小轴嵌合力偏低

Lowerpushoutforceofpin

链条拉脱

Chainelongation

P外径偏小,PLP孔径偏大Pin’sdiameterissmallerthanstandards,PLP’sholeisbiggerthanstandards.

-嵌合力机定期校验Doinspe343ctiononfirstproduct

Doroutinecalibrationonpushoutforcemachine

装配连接Assemblingandconnecting

缺零件(布斯,罗拉)Lackofcomponents(Bushingandroller)

链条使用过程中拉断chainwillbebrokenduringtheusageprocess

有异物卡到布斯,罗拉下料筒里面Thereissomethingleftinbushingandroller’sinnerside

确保每次倒料时包装袋口没有碎丝,及料里面没有异物Confirmthereisnoimpuritywhenaddingmaterials

作业前操作员查看物料里面是否有异物

Operatorshouldcheckwhetherthereisimpuritymixedintomaterials

外片重叠在一侧DoublePLPononeside

客户不能正常装配Chaincannotbeassembled

-组装时链条上侧多压一个外片OnemorePLPisassembledduringtheassemblingprocess

-链条重新修整时多压一个外片OnemorePLPisassembledduringtherepairingprocess

-

-链条休整后的零件及时清理Clearpartsfromrepairingprocessintime

-外节自动化全检

-重整后的链条重新过检包线100%inspectionshouldbedoneonouterlinkautomatically.

Aftertherepairingprocess,chainshouldbeinspectedagain.

过油

Lubrication

油品到期未更换Donotchangethelubricationoilwhenitisoutexpirationdate

影响链条寿命Affectthechainservicelife

油品使用时间未记录Donothaveagoodtimerecord

生产前QC抽检Beforelubrication,QCwillinspecttheoilquality

生产记录油品使用时间后,QC签字确认QCwillinspectandsignthetimerecord

16

整直Preload

整直受力不够Thepreloadforceisnotenough

初期伸长量大Theelongationamountwillbemoreatthefirststage

链条未张紧Tensileforceisnotenoughtomakechainbeelongated

增加限位感应器来控制行程

Addoffsettinginductortocontroltheoffsetting

通过1次/天检测感应器是否正常运作Checktheinductor1timeeverydaytoseeifitworkswell

切断Cutting

长度不合格

Cuttinglengthisunqualified

无法安装或跳齿,啮合不畅Cannotassembleorchaincannotfitwithgearwell.

链片节距不合格,小轴外径不合格Unqualifiedpitchandpindiameter

Inspectthefirstproduct

-长度台定期校验

Doroutinecalibrationonlength

-长度检测使用首件比对Dolengthmeasurementbyusingthefirstproducts

FrequencyfortheQCinspectortodotheinspection2pcs/time/4H

切断机外片数目设定错误Wrongsettingnumberofbreakingmachine

9

铆钉Riveting

小轴倒角面偏小Pinchamfersideissmallerthanstandards

链条拉脱Chainwillbeelongated

油压及油压行程偏小Theoffsettingofoilhydraulicsystemislowerthanstandards

Inspectthefirstproduct

-量具定期校验

Calibratethemeasurementmachineinroutinetime

-外观自主检测

Appearanceinspection

FrequencyofInspectiondonebyworks

8pcs/次/2H

8pcs/time/2H

FrequencyofinspectiondonebyQCinspector8pcs/次/4H

8pcs/