哈工大机械原理大作业凸轮16号Word文件下载.docx

《哈工大机械原理大作业凸轮16号Word文件下载.docx》由会员分享,可在线阅读,更多相关《哈工大机械原理大作业凸轮16号Word文件下载.docx(18页珍藏版)》请在冰豆网上搜索。

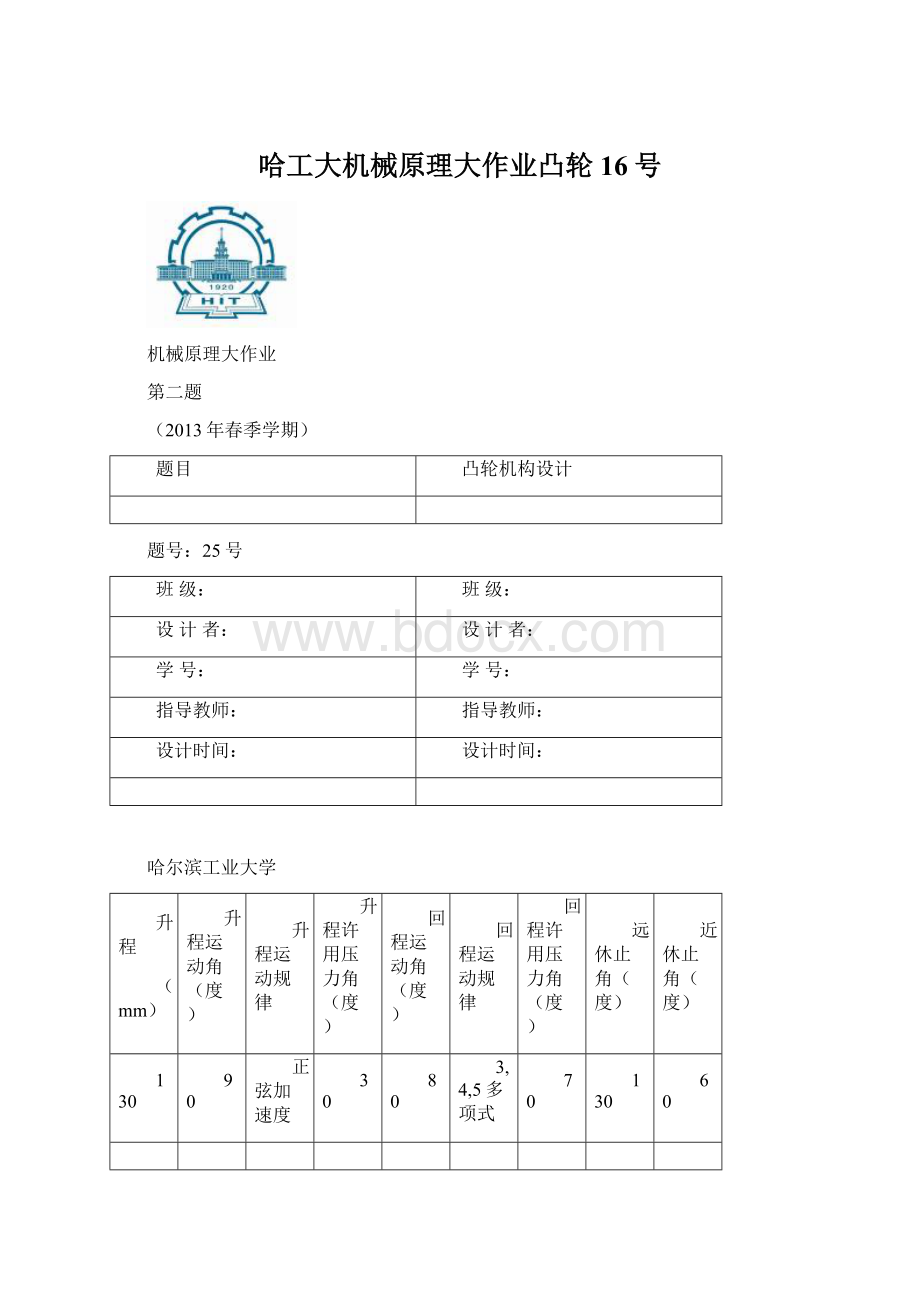

回程运动规律

回程许用压力角(度)

远休止角(度)

近休止角(度)

130

90

正弦加速度

30

80

3,4,5多项式

70

60

1、凸轮推程方程为:

2、回程方程为:

3、以上是推程和回程的运动方程,在远休止角以及近休止角处,位移不变,速度、加速度都为“0”,根据以上方程组在matlab中编程输出结果,绘制曲线如下:

4、用matlab编写程序算出凸轮推杆的位移、速度、加速度曲线,并绘制出ds/dfi—s线图

程序如下:

symsfi;

%定义推杆运动分段函数(0<

fi<

pi/2)

s1=130*(2*fi/pi-(sin(4*fi)/2/pi));

v1=(260/pi)*(1-cos(4*fi));

a1=(8*130/pi)*sin(4*fi);

d1=diff(s1,fi);

k1=0:

pi/90:

pi/2;

s1=subs(s1,fi,k1);

v1=subs(v1,fi,k1);

a1=subs(a1,fi,k1);

d1=subs(d1,fi,k1);

%pi/2<

=fi<

11*pi/9

k2=pi/2:

11*pi/9;

s2=130;

v2=0;

a2=0;

%11*pi/9<

=fi<

5*pi/3

t2=9*(fi-(pi/2)-(13*pi/18))/4/pi;

s3=130*(1-(10*t2^3)+(15*t2^4)-(6*t2^5));

v3=-(30*130*9/4/pi)*t2^2*(1-2*t2+t2^2);

a3=-(60*130*81/16/pi/pi)*t2*(1-3*t2+2*t2^2);

d3=diff(s3,fi);

k3=11*pi/9:

5*pi/3;

s3=subs(s3,fi,k3);

v3=subs(v3,fi,k3);

a3=subs(a3,fi,k3);

d3=subs(d3,fi,k3);

%5*pi/3<

=fi<

2*pi

k4=5*pi/3:

2*pi;

s4=0;

v4=0;

a4=0;

%画函数曲线(推杆位移)

plot(k1,s1);

holdon

plot(k2,s2);

plot(k3,s3);

plot(k4,s4);

title('

推杆位移曲线'

);

xlabel('

x角度fi(rad)'

),ylabel('

y位移s(mm)'

holdoff

pause

%推杆速度

plot(k1,v1);

plot(k2,v2);

plot(k3,v3);

plot(k4,v4);

推杆速度曲线'

y速度v(mm/s)'

%推杆加速度

plot(k1,a1);

plot(k2,a2);

plot(k3,a3);

plot(k4,a4);

推杆加速度曲线'

y加速度a(mm/s^2)'

%ds/dfi-s线图

plot(d1,s1);

plot(0,130);

plot(d3,s3);

plot(0,0);

ds/dfi-s线图'

xds/dfi'

ys(fi)'

推杆位移曲线

先由推程到远休止,到回程,再到近休止;

推杆速度曲线:

推杆速度在推程阶段先增大后减小,在回程阶段速度也是先增大后减小,

在远休止、近休止处速度都为“0”;

推杆加速度曲线:

推杆加速度在推程阶段先增大后减小,再反向增大后减小,在回程阶段速度也是先增大后减小,再反向增大后减小;

在远休止、近休止处加速度都为“0”;

ds/dfi—s线图:

按许用压力角[30度]、[70度],确定凸轮机构的基本尺寸:

根据此图可以确定一个合适的基圆半径,和一个合适的偏心距;

取

ro=200mm,e=50mm

凸轮理论轮廓线matlab编程及生成图线如下:

%理论轮廓线

ro=200;

e=50;

so=sqrt(ro^2-e^2);

x1=(so+s1)*cos(fi)-(e*sin(fi));

y1=(so+s1)*sin(fi)+(e*cos(fi));

x1=subs(x1,fi,k1);

y1=subs(y1,fi,k1);

x2=(so+s2)*cos(fi)-(e*sin(fi));

y2=(so+s2)*sin(fi)+(e*cos(fi));

x2=subs(x2,fi,k2);

y2=subs(y2,fi,k2);

x3=(so+s3)*cos(fi)-(e*sin(fi));

y3=(so+s3)*sin(fi)+(e*cos(fi));

x3=subs(x3,fi,k3);

y3=subs(y3,fi,k3);

x4=(so+s4)*cos(fi)-(e*sin(fi));

y4=(so+s4)*sin(fi)+(e*cos(fi));

x4=subs(x4,fi,k4);

y4=subs(y4,fi,k4);

%绘制凸轮理论轮廓线

plot(x1,y1);

plot(x2,y2);

plot(x3,y3);

plot(x4,y4);

凸轮理论轮廓线'

x(mm)'

y(mm)'

凸轮理论轮廓线图

该图谱显示的为凸轮的理论轮廓线,即利用反转法时,滚子中心划过的轨迹

凸轮实际轮廓线生成matlab编程如下

确定滚子半径为r1=30mm

%实际轮廓线

dx1=diff(x1,fi);

dy1=diff(y1,fi);

X1=x1-(10*dy1/sqrt(dx1^2+dy1^2));

Y1=y1+(10*dx1/sqrt(dx1^2+dy1^2));

X1=subs(X1,fi,k1);

Y1=subs(Y1,fi,k1);

dx2=diff(x2,fi);

dy2=diff(y2,fi);

X2=x2-(10*dy2/sqrt(dx2^2+dy2^2));

Y2=y2+(10*dx2/sqrt(dx2^2+dy2^2));

X2=subs(X2,fi,k2);

Y2=subs(Y2,fi,k2);

dx3=diff(x3,fi);

dy3=diff(y3,fi);

X3=x3-(10*dy3/sqrt(dx3^2+dy1^2));

Y3=y3+(10*dx3/sqrt(dx3^2+dy1^2));

X3=subs(X3,fi,k3);

Y3=subs(Y3,fi,k3);

dx4=diff(x4,fi);

dy4=diff(y4,fi);

X4=x4-(10*dy4/sqrt(dx4^2+dy4^2));

Y4=y4+(10*dx4/sqrt(dx4^2+dy4^2));

X4=subs(X4,fi,k4);

Y4=subs(Y4,fi,k4);

plot(X1,Y1);

plot(X2,Y2);

plot(X3,Y3);

plot(X4,Y4);

凸轮实际轮廓线'

disp(X1);

disp(X2);

disp(X3);

disp(X4);

disp(Y1);

disp(Y2);

disp(Y3);

disp(Y4);

实际轮廓线的x,y坐标输出值:

(1)推程,x:

183.9667182.1953180.2313178.1263175.9311173.6938171.4587169.2647167.1435165.1181163.2012161.3945159.6879158.0603156.4806154.9092153.2997151.6007149.7577147.7146145.4152142.8052139.8335136.4535132.6243128.3121123.4905118.1415112.2554105.830798.874191.399983.429174.989166.112556.836547.201837.252027.032216.58815.9645-4.7954-15.6519-26.5694-37.5178-48.4732

y:

47.500053.929360.371466.827873.306479.820586.387493.026599.7579106.6008113.5733120.6914127.9694135.4197143.0522150.8736158.8862167.0862175.4634183.9996192.6683201.4352210.2579219.0875227.8686236.5418245.0445253.3124261.2819268.8907276.0801282.7958288.9890294.6178299.6473304.0503307.8083310.9110313.3571315.1543316.3188316.8753316.8564316.3012315.2548313.7664

(2)元休止,x:

-48.4732-59.3940-70.2424-81.0052-91.6693-102.2218-112.6497-122.9403-133.0812-143.0599-152.8644-162.4826-171.9028-181.1136-190.1037-198.8623-207.3785-215.6421-223.6429-231.3713-238.8178-245.9733-252.8292-259.3770-265.6088-271.5170-277.0944-282.3342-287.2300-291.7759-295.9663-299.7961-303.2606-306.3557-309.0775-311.4228-313.3886-314.9727-316.1729-316.9880-317.4169-317.4590-317.1144-316.3834-315.2670-313.7664-311.8836-309.6208-306.9807-303.9667-300.5823-296.8317-292.7195-288.2506-283.4305-278.2652-272.7608-266.9240-260.7621-254.2825-247.4931-240.4021-233.0183-225.3505-217.4082-209.2010

y:

313.7664311.8836309.6208306.9807303.9667300.5823296.8317292.7195288.2506283.4305278.2652272.7608266.9240260.7621254.2825247.4931240.4021233.0183225.3505217.4082209.2010200.7390192.0323183.0917173.9281164.5525154.9765145.2116135.2698125.1632114.9042104.505193.978783.337872.595461.764550.858439.890328.873617.82176.7482-4.3336-15.4102-26.4679-37.4934-48.4732-59.3940-70.2424-81.0052-91.6693-102.2218-112.6497-122.9403-133.0812-143.0599-152.8644-162.4826-171.9028-181.1136-190.1037-198.8623-207.3785-215.6421-223.6429-231.3713-238.8178

(3)回程,x:

-211.6366-203.0993-194.2730-185.1069-175.5718-165.6586-155.3762-144.7495-133.8169-122.6285-111.2433-99.7272-88.1505-76.5858-65.1058-53.7807-42.6765-31.8524-21.3589-11.2349-1.50637.816216.737325.276433.464041.336348.929056.272263.388070.292076.995883.510289.847196.0194102.0401107.9200113.6651119.2743124.7368130.0290135.1124

-241.5982-248.8205-255.6198-261.9191-267.6440-272.7245-277.0976-280.7083-283.5115-285.4727-286.5693-286.7907-286.1387-284.6279-282.2849-279.1485-275.2686-270.7065-265.5331-259.8288-253.6819-247.1869-240.4419-233.5447-226.5882-219.6555-212.8154-206.1209-199.6103-193.3094-187.2354-181.3984-175.8029-170.4466-165.3199-160.4038-155.6696-151.0777-146.5776-142.1084-137.5994

(4)近休止,x:

133.1196137.7698142.2522146.5612150.6917154.6386158.3971161.9627165.3308168.4976171.4591174.2117176.7520179.0770181.1838183.0698184.7329186.1708187.3819188.3648189.1181189.6410189.9329189.9934189.8224189.4201188.7871187.9240186.8320185.5124183.9667

-135.5698-130.8415-125.9537-120.9124-115.7238-110.3943-104.9302-99.3383-93.6254-87.7984-81.8644-75.8307-69.7046-63.4936-57.2052-50.8471-44.4271-37.9530-31.4326-24.8739-18.2849-11.6737-5.04821.58358.213214.832921.434528.010034.551441.050747.5000

凸轮实际轮廓线

该图谱经过坐标变换后,得到了滚子边缘包络出的轨迹,即为凸轮的实际轮廓线。