80万吨无回收焦化方案Word格式文档下载.docx

《80万吨无回收焦化方案Word格式文档下载.docx》由会员分享,可在线阅读,更多相关《80万吨无回收焦化方案Word格式文档下载.docx(14页珍藏版)》请在冰豆网上搜索。

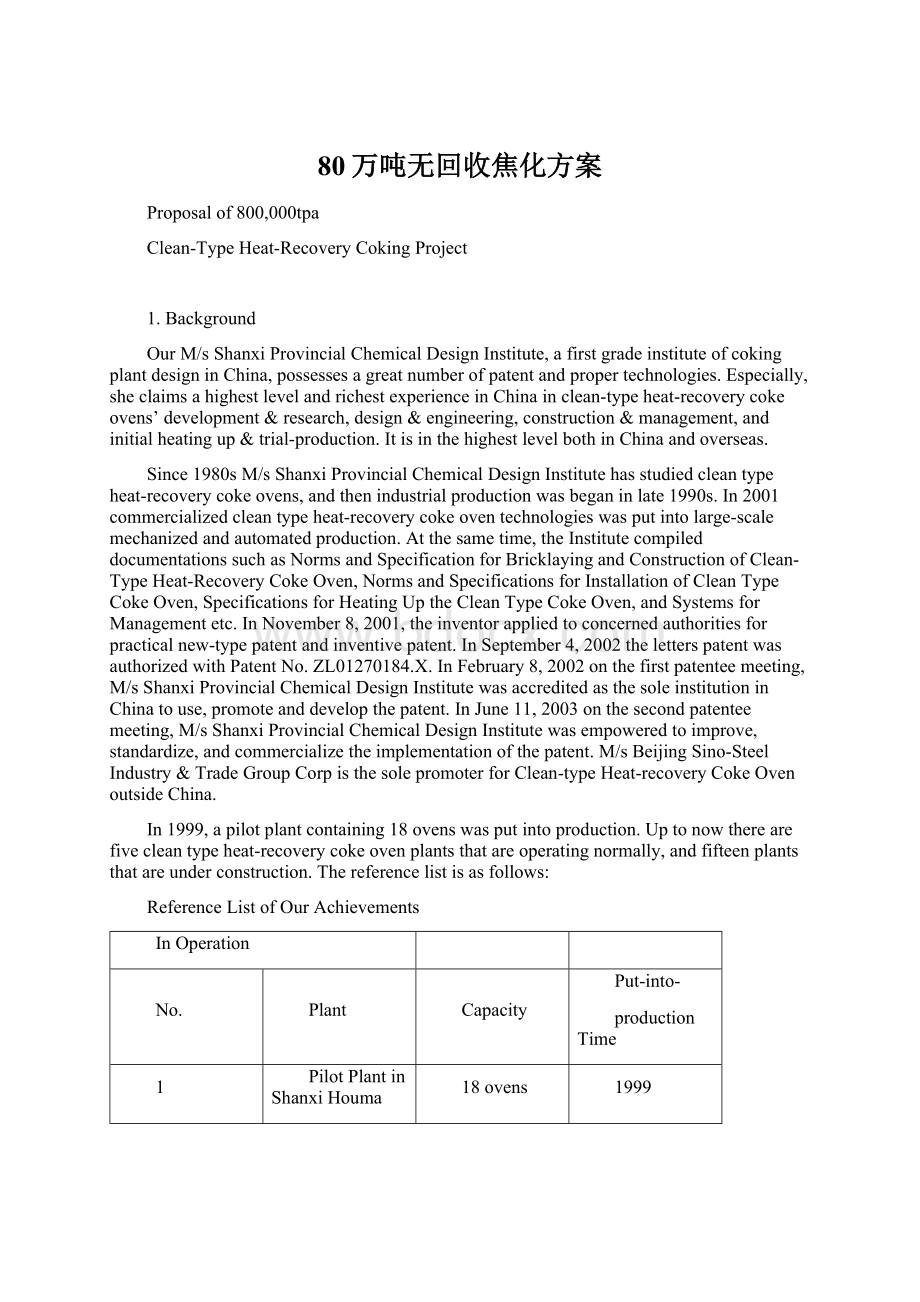

In1999,apilotplantcontaining18ovenswasputintoproduction.Uptonowtherearefivecleantypeheat-recoverycokeovenplantsthatareoperatingnormally,andfifteenplantsthatareunderconstruction.Thereferencelistisasfollows:

ReferenceListofOurAchievements

InOperation

No.

Plant

Capacity

Put-into-

productionTime

1

PilotPlantinShanxiHouma

18ovens

1999

2

TaiYuanGangyuanCokingCo.

400,000tpa

July,2003

3

ShanxiFenyangWenfengCokingCo.

500,000tpa

June,2003

4

ShanxiGaopingXingaoCokingCo.

August,2003

5

ShanxiLvliangFuliCokingCo.

March,2003

6

ShanxiZhongyangYaolongCoal&

CokingCo.

200,000tpa

November,2003

UnderConstruction

EstimatedCommissioningTime

TaiyuanLoufanWanguangCoal&

CokeCo.

300,000tpa

May,2004

TaiyuanLoufanLiminCoal&

November,2004

ShanxiLishiLiangyuCokingCo.

February,2004

ShanxiLishiShuangfuCoal&

ShanxiLinxianXinminCokingCo.

August,2004

ShanxiFenyangLongquanFoundryCokeCo.

April,2004

7

ShanxiLanxianFengdaCoking&

MetallurgyCo.

8

ShanxiQinxinCoal&

PowerCo.

600,000tpa

October,2004

9

ShanxiQinshuiQinmaoCoal&

10

ShanxiLuxinCoalGasCo.

11

ShanxiCokingCoalGroupCorp.

800,000tpa

12

HunanLoudiXingxingCokingCo.

June,2004

13

ShandongTsingdaoIron&

SteelCo.

March,2004

14

JiangsuZhuxiIron&

15

ShandongShunxinCokeCo.

2.

Profileof800,000tpaCleanTypeHeat-RecoveryCokingPlant

Theproposalincludescoalreceivingfromtransferhouse,coalhandling,coalstocking,coalpreparing,coking,screening,cokecrushing,stocking,transferringtostockhouseandsuitableutilities.Fourgradesofcoalareusedtopreparethecoalblend.Inthecoalyard,forkliftisusedtotransportcoalintocoalreceivingpit,whichissuccessivelyblendedinblendingbunker,andpulverizedbycounterhammeringpulverizer.

Thecoaliscokedinclean-typeheat-recoverymechanizedcokeovenstypedQRD-2000withstamp-chargingprocess.Withsilicabricksastherefractoryoftheirmainbodies,thecokeovensadopthighaluminabricksaspartoftherefractoryofovenhead,andfireclaybricksandordinaryredbricksaspartoftherefractoryofovenbottomandovenroof.Theplantconsistsof128ovensof8batteries,eachcontaining16ovens,andself-adjustingsuctiondevices.Thecokeisscreenedto3gradesasperthecustomer’srequirements.Spaceisprearrangedfora2x12MWpowerplantutilizingthewasteheatfromthecokeovens.Thewholedesignwasfeaturedbyadvancementintechnology,security&

reliability,economy&

applicability,andcleannessinproduction.

3.QRDClean-typeHeatRecoveryMechanizedCokeOvenwithStamp-chargedProcess

QRDclean-typeheatrecoverymechanizedcokeovenswithstamp-chargedprocess,with8batteriesof128ovens,arearrangedintwolines.Eachlineconsistsof4batterieswitharatedcapacityof300,000tpa.Thewholeplantcanbeeitherputintoproductionwithaentirecapacityi.e.800,000tpaorstartwithhalfratedcapacityi.e.300,000tpa.

3.1BriefDescriptionofStructureofCokeOven

QRDclean-typeheatrecoverymechanizedcokeoveniscomposedofcarbonizationchamberroof,bottom,mainwall,sidegateandironcomponentstoprotectthecokeoven.

3.1.1OvenRoof

TheRoofisofarchtype.Topreventcokefrommelting,adjustableprimaryairinletsareevenlyinstalledinthearch,whichformawaste-gas-protectinglayerbetweenthecoalandburningzoneontheovenroof.

3.1.2OvenBottom

Fourlinkedarchesareusedontheovenbottom.Onthebaseofthearches,adjustablesecondaryairinletsareinstalledtomaketheairevenlydistributedintheflue.Theaircombustswithwastegasforasecondtimeandmakestheovenbottombeheatedevenly.

Thefirechannelsofthemainwallandtheovenbottomcancommunicatewitheachother.Anairlayerisprovidedbetweenthefoundationofthecokeovenandovenbottomtopreventthebaseplatefrombeingoverheated.

3.1.3MainWallofCarbonizationChamber

Evenlyprovidedwithavarietyoffirechannels,themainwallisequippedwithsuction-adjustingfacilities.Theoperationintheovenisundernegativepressure.

3.1.4OvenGate

Thegateisoftwosections.Theupperisfixedandthelowerismovable.Thetwo-sectiondesignisabletopreventsootleakageandreducetheoperativeweightoftheovengate.

Themainmaterialofovengateiscastiron.Thecircleofrefractoryliningishighaluminabrickandthemiddleiscastable.Thereisalsosomesiliciousaluminiumfabric.

3.1.5IronComponents

Thecokeovenisequippedwithironprotectivecomponentsincludingovencolumn,upperandlowerhorizontaltie-rod,verticaltie-rod,springandprotectiveplate.

3.1.6MachinesforCokeOven

Stamp-chargedmachine,coalcharging&

cokepushingcar,quenchingcar.

(1)Stampingmachine

Thestampingmachineisoperatedhydraulically,coalcakeisstampedintwolayersanddurationofstampingtimeis20minutes.

(2)Chargingandpushingcar

CoalchargingprocessisoneofthekeytechnologiesoftheQRD-2000cleantypeheatrecoverymechanizedcokeovenwithstamp-chargedprocess.Thecokeovenischargedsidewise,eachcarbonizationchamberischargedwith45tdrycoalandthechargingprocesscanbefinishedin2minutes.Cantileverboxtypecoalchargingprocessisadopted.Aliftinganddoorsidewiseremovingmechanismcombinedwithcokepushingmechanismisprovidedonthecar,makingthesamecarhavetwofunctionsatthesametime.Thecarismainlycomposedofcoalbox,coalrod,coalboxdrivingmechanism,endbaffle,cokepushingbar,cokepushingbardrivingmechanism,ovendooropeningandclosedevice,supportingwheelandpressingwheel,carframeandthecaroperatingmechanism,etc.Thedrivercabinisprovidedwithairconditioningandthecontroldevicesforcoalchargingandcokepushing.

(3)Cokereceivingandquenchingcar

Thecokereceivingandquenchingcarislocatedatthecokeside,functioningforovendooropeningandclosingaswellascokereceivingandquenching.Itismainlycomposedofovendooropeningandclosingmechanism,horizontalcokereceivingtrough,travelingmechanism,carframeandoperatingroom,etc.Theovendoorsopenandclosehydraulically,thetravelingmechanismisprovidedwithtandemresistancespeedregulatedcontrolsystemandelectromagneticbreakerandnecessaryinterlockdevices.Thedrivercabinisprovidedwithairconditioning.Thecokereceivingtroughisofsteelstructure,withopeningatbothendsandbeinglinedwithheat-resistantcastplate,anditcantravelhorizontallyandtiltforward.

3.1.7Automation

Theheatingtemperatureandthesuctionpressureforeachholeoftheovenareself-adjusting.DCScontrolisadopted.

3.1.8MaterialofOvenBody

Accordingtodifferentconstructiveconditionsandproducts,suchasmetallurgicalcokeandfoundrycoke,variousrefractorybricksareadoptede.g.silicabricks,claybricks,aluminousbricks.

3.2TechnicalFeatures

3.2.1Volumeofthistypeofcokeovenislargeandworkingconditionisclean,whichrepresentthedirectionforthedevelopmentofinternationalcokingtechnology.

3.2.2Environmentalprotectivetechnologiesareadoptedinthecokeovenstructureandoperationprocess,suchascokeovennegative-pressureoperation,horizontalcokereceiving,etc.Nofumeordustemissionoccurduringthewholeprocessofcoalcharging,cokingandcokepushing.Nowastewaterwithharmfulingredientsisproducedduringtheoperationprocess,thuscleanproductionandpollutionfreeworkingenvironmentarerealized.

3.2