整理3D打印技术资料.docx

《整理3D打印技术资料.docx》由会员分享,可在线阅读,更多相关《整理3D打印技术资料.docx(25页珍藏版)》请在冰豆网上搜索。

整理3D打印技术资料

3Dprinting

Formethodsofapplyinga2Dimageona3Dsurface,seepadprinting.Formethodsofprinting2Dparallaxstereogramsthatseem3Dtotheeye,seelenticularprintingandholography.

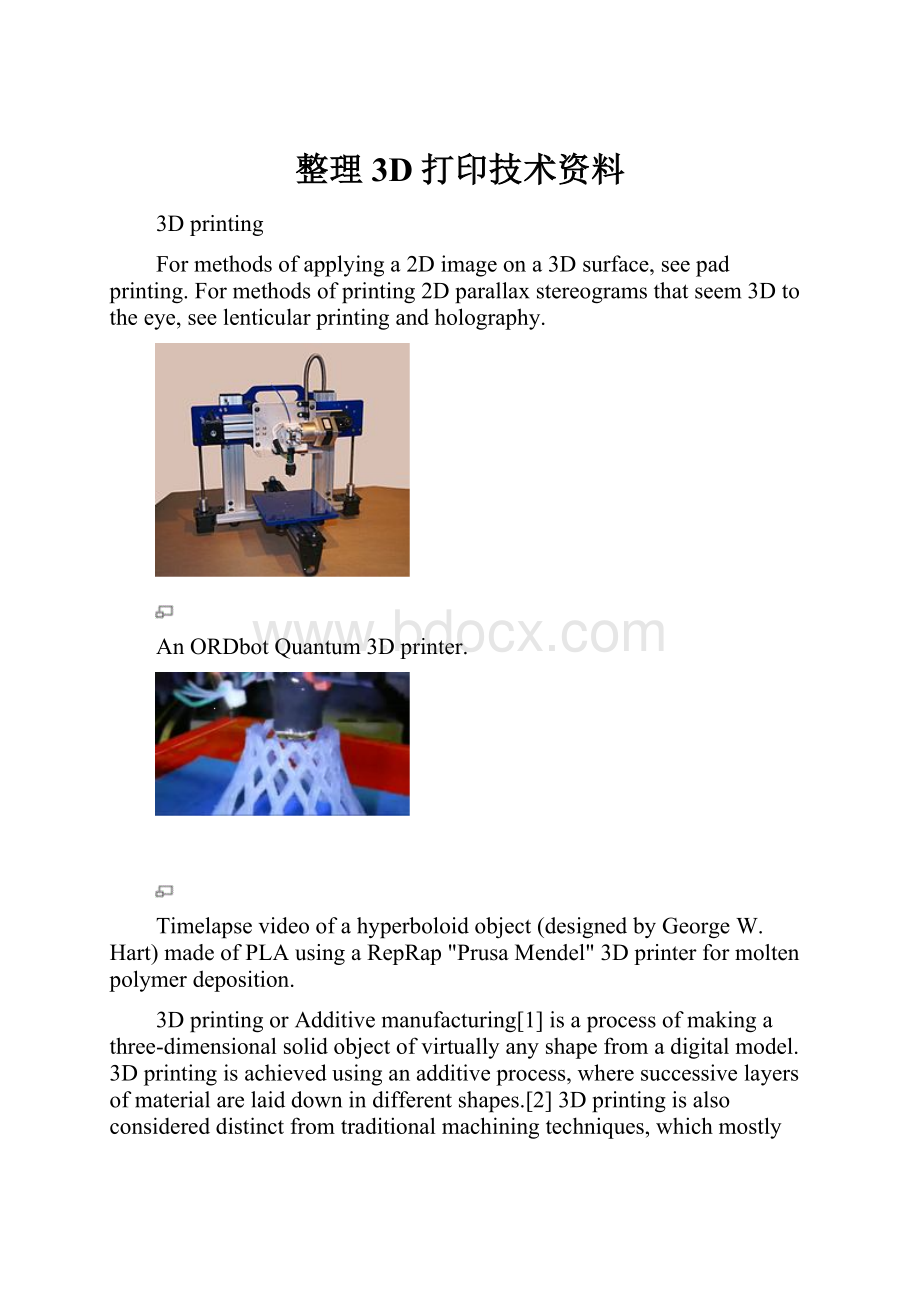

AnORDbotQuantum3Dprinter.

Timelapsevideoofahyperboloidobject(designedbyGeorgeW.Hart)madeofPLAusingaRepRap"PrusaMendel"3Dprinterformoltenpolymerdeposition.

3DprintingorAdditivemanufacturing[1]isaprocessofmakingathree-dimensionalsolidobjectofvirtuallyanyshapefromadigitalmodel.3Dprintingisachievedusinganadditiveprocess,wheresuccessivelayersofmaterialarelaiddownindifferentshapes.[2]3Dprintingisalsoconsidereddistinctfromtraditionalmachiningtechniques,whichmostlyrelyontheremovalofmaterialbymethodssuchascuttingordrilling(subtractiveprocesses).

A3Dprinterisalimitedtypeofindustrialrobotthatiscapableofcarryingoutanadditiveprocessundercomputercontrol.

While3Dprintingtechnologyhasbeenaroundsincethe1980s,itwasnotuntiltheearly2010sthattheprintersbecamewidelyavailablecommercially.[3]Thefirstworking3Dprinterwascreatedin1984byChuckHullof3DSystemsCorp.[4]Sincethestartofthe21stcenturytherehasbeenalargegrowthinthesalesofthesemachines,andtheirpricehasdroppedsubstantially.[5]AccordingtoWohlersAssociates,aconsultancy,themarketfor3Dprintersandserviceswasworth$2.2 billionworldwidein2012,up29%from2011.[6]

The3Dprintingtechnologyisusedforbothprototypinganddistributedmanufacturingwithapplicationsinarchitecture,construction(AEC),industrialdesign,automotive,aerospace,military,engineering,civilengineering,dentalandmedicalindustries,biotech(humantissuereplacement),fashion,footwear,jewelry,eyewear,education,geographicinformationsystems,food,andmanyotherfields.Onestudyhasfound[7]thatopensource3Dprintingcouldbecomeamassmarketitembecausedomestic3Dprinterscanoffsettheircapitalcostsbyenablingconsumerstoavoidcostsassociatedwithpurchasingcommonhouseholdobjects.[8]

Terminology

Thetermadditivemanufacturingreferstotechnologiesthatcreateobjectsthroughsequentiallayering.Objectsthataremanufacturedadditivelycanbeusedanywherethroughouttheproductlifecycle,frompre-production(i.e.rapidprototyping)tofull-scaleproduction(i.e.rapidmanufacturing),inadditiontotoolingapplicationsandpost-productioncustomization.[9]

Inmanufacturing,andmachininginparticular,subtractivemethodsreferstomoretraditionalmethods.Thetermsubtractivemanufacturingisaretronymdevelopedinrecentyearstodistinguishitfromneweradditivemanufacturingtechniques.Althoughfabricationhasincludedmethodsthatareessentially"additive"forcenturies(suchasjoiningplates,sheets,forgings,androlledworkviariveting,screwing,forgewelding,ornewerkindsofwelding),itdidnotincludetheinformationtechnologycomponentofmodel-baseddefinition.Machining(generatingexactshapeswithhighprecision)hastypicallybeensubtractive,fromfilingandturningtomilling,drillingandgrinding.[9]

ThetermstereolithographywasdefinedbyCharlesW.Hullasa"systemforgeneratingthree-dimensionalobjectsbycreatingacross-sectionalpatternoftheobjecttobeformed"—ina1984patent.[10][11]

Generalprinciples

3Dmodelslicing.

Printing

Toperformaprint,themachinereadsthedesignfromanSTLfileandlaysdownsuccessivelayersofliquid,powder,paperorsheetmaterialtobuildthemodelfromaseriesofcrosssections.Theselayers,whichcorrespondtothevirtualcrosssectionsfromtheCADmodel,arejoinedorautomaticallyfusedtocreatethefinalshape.Theprimaryadvantageofthistechniqueisitsabilitytocreatealmostanyshapeorgeometricfeature.

PrinterresolutiondescribeslayerthicknessandX-Yresolutionindpi(dotsperinch),[citationneeded]ormicrometers.Typicallayerthicknessisaround100?

?

m(250 DPI),althoughsomemachinessuchastheObjetConnexseriesand3DSystems'ProJetseriescanprintlayersasthinas16?

?

m(1,600 DPI).[12]X-Yresolutioniscomparabletothatoflaserprinters.Theparticles(3Ddots)arearound50to100?

?

m(510to250 DPI)indiameter.

Constructionofamodelwithcontemporarymethodscantakeanywherefromseveralhourstoseveraldays,dependingonthemethodusedandthesizeandcomplexityofthemodel.Additivesystemscantypicallyreducethistimetoafewhours,althoughitvarieswidelydependingonthetypeofmachineusedandthesizeandnumberofmodelsbeingproducedsimultaneously.

Traditionaltechniqueslikeinjectionmoldingcanbelessexpensiveformanufacturingpolymerproductsinhighquantities,butadditivemanufacturingcanbefaster,moreflexibleandlessexpensivewhenproducingrelativelysmallquantitiesofparts.3Dprintersgivedesignersandconceptdevelopmentteamstheabilitytoproducepartsandconceptmodelsusingadesktopsizeprinter.

Finishing

Thoughtheprinter-producedresolutionissufficientformanyapplications,printingaslightlyoversizedversionofthedesiredobjectinstandardresolutionandthenremovingmaterialwithahigher-resolutionsubtractiveprocesscanachievegreaterprecision.[citationneeded]

Someadditivemanufacturingtechniquesarecapableofusingmultiplematerialsinthecourseofconstructingparts.Someareabletoprintinmultiplecolorsandcolorcombinationssimultaneously.Somealsoutilizesupportswhenbuilding.Supportsareremovableordissolvableuponcompletionoftheprint,andareusedtosupportoverhangingfeaturesduringconstruction.

Additiveprocesses

Rapidprototypingworldwide2001[13]

TheAudiRSQwasmadewithrapidprototypingindustrialKUKArobots.

Severaldifferent3Dprintingprocesseshavebeeninventedsincethelate1970s.Theprinterswereoriginallylarge,expensive,andhighlylimitedinwhattheycouldproduce.[14]

Alargenumberofadditiveprocessesarenowavailable.Theydifferinthewaylayersaredepositedtocreatepartsandinthematerialsthatcanbeused.Somemethodsmeltorsoftenmaterialtoproducethelayers,e.g.selectivelasermelting(SLM)ordirectmetallasersintering(DMLS),selectivelasersintering(SLS),fuseddepositionmodeling(FDM),whileotherscureliquidmaterialsusingdifferentsophisticatedtechnologies,e.g.stereolithography(SLA).Withlaminatedobjectmanufacturing(LOM),thinlayersarecuttoshapeandjoinedtogether(e.g.paper,polymer,metal).Eachmethodhasitsownadvantagesanddrawbacks,andsomecompaniesconsequentlyofferachoicebetweenpowderandpolymerforthematerialfromwhichtheobjectisbuilt.[15]Somecompaniesusestandard,off-the-shelfbusinesspaperasthebuildmaterialtoproduceadurableprototype.Themainconsiderationsinchoosingamachinearegenerallyspeed,costofthe3Dprinter,costoftheprintedprototype,andcostandchoiceofmaterialsandcolorcapabilities.[16]

Printersthatworkdirectlywithmetalsareexpensive.Insomecases,however,lessexpensiveprinterscanbeusedtomakeamould,whichisthenusedtomakemetalparts.[17]

Type

Technologies

Materials

Extrusion

Fuseddepositionmodeling(FDM)

Thermoplastics(e.g.PLA,ABS),HDPE,eutecticmetals,ediblematerials,Rubber(Sugru),Modellingclay,Plasticine,RTVsilicone,Porcelain,Metalclay(includingPreciousMetalClay)

Wire

ElectronBeamFreeformFabrication(EBF3)

Almostanymetalalloy

Granular

Directmetallasersintering(DMLS)

Almostanymetalalloy

Electron-beammelting(EBM)

Titaniumalloys

Selectivelasermelting(SLM)

Titaniumalloys,CobaltChromealloys,StainlessSteel,Aluminium

Selectiveheatsintering(SHS)[18]

Thermoplasticpowder

Selectivelasersintering(SLS)

Thermoplastics,metalpowders,ceramicpowders

Powderbedandinkjethead3Dprinting

Plaster-based3Dprinting(PP)

Plaster

Laminated

Laminatedobjectmanufacturing(LOM)

Paper,metalfoil,plasticfilm

Lightpolymerised

Stereolithography(SLA)

photopolymer

DigitalLightProcessing(DLP)

photopolymer

Extrusiondeposition

Fuseddepositionmodeling:

1–nozzleejectingmoltenplastic,2–depositedmaterial(modeledpart),3–controlledmovabletable.

Mainarticle:

Fuseddepositionmodeling

Fuseddepositionmodeling(FDM)wasdevelopedbyS.ScottCrumpinthelate1980sandwascommercializedin1990byStratasys.[19]Withtheexpirationofthepatentonthistechnologythereisnowalargeopen-sourcedevelopmentcommunity,aswellascommercialandDIYvariants,whichutilizethistypeof3Dprinter.Thishasledtoatwoordersofmagnitudepricedropsincethistechnology'screation.

Infuseddepositionmodelingthemodelorpartisproducedbyextrudingsmallbeadsofmaterialwhichhardenimmediatelytoformlayers.Athermoplasticfilamentormetalwirethatiswoundonacoilisunreeledtosupplymaterialtoanextrusionnozzlehead.Thenozzleheadheatsthematerialandturnstheflowonandoff.Typicallysteppermotorsorservomotorsareemployedtomovetheextrusionheadandadjusttheflowandtheheadcanbemovedinbothhorizontalandverticaldirections.Controlofthismechanismistypicallydonebyacomputer-aidedmanufacturing(CAM)softwarepackagerunningonamicrocontroller.

Variouspolymersareused,includingacrylonitrilebutadienestyrene(ABS),polycarbonate(PC),polylacticacid(PLA),highdensitypolyethylene(HDPE),PC/ABS,andpolyphenylsulfone(PPSU).Ingeneralthepolymerisintheformofafilament,fabricatedfromvirginresins.Multipleprojectsintheopen-sourcecommunityexistthatareaimedatprocessingpost-consumerplasticwasteintofilament.Theseinvolvemachin