实用文档risk assessment pouch line.docx

《实用文档risk assessment pouch line.docx》由会员分享,可在线阅读,更多相关《实用文档risk assessment pouch line.docx(61页珍藏版)》请在冰豆网上搜索。

实用文档riskassessmentpouchline

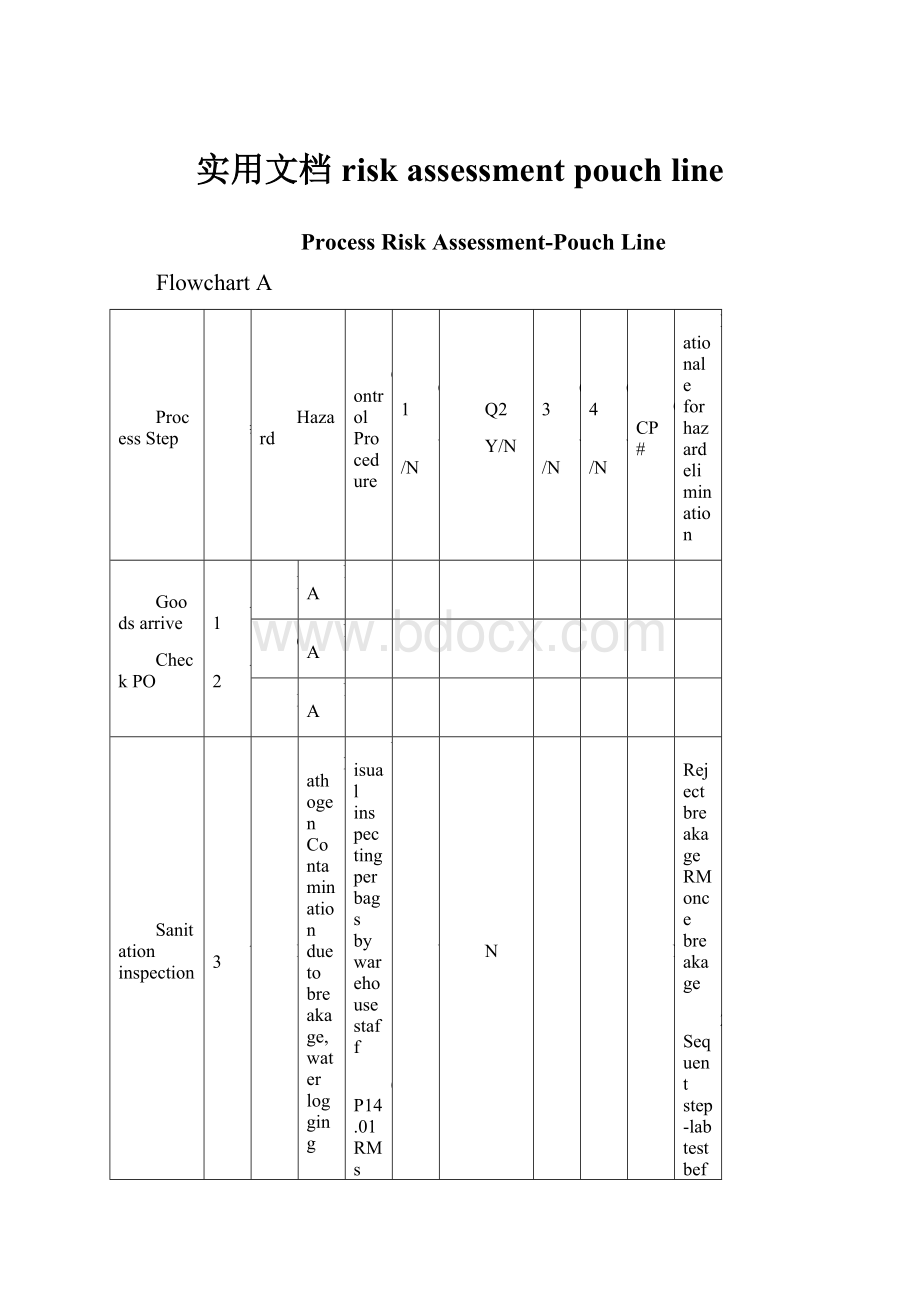

ProcessRiskAssessment-PouchLine

FlowchartA

ProcessStep

#

Hazard

ControlProcedure

Q1

Y/N

Q2

Y/N

Q3

Y/N

Q4

Y/N

CCP#

Rationaleforhazardelimination

Goodsarrive

CheckPO

A1

A2

M

NA

C

NA

P

NA

Sanitationinspection

A3

M

pathogenContaminationduetobreakage,waterlogging

Visualinspectingperbagsbywarehousestaff

(P14.01RMsreceiptstorageandrelease)

Y

N

N

1RejectbreakageRMoncebreakage

2Sequentstep-labtestbeforeusecaneliminatethehazardtoanacceptablelevel

C

ChemicalContaminationduetovehicletransportedchemicalortreatedbychemical

1Visualinspecting,flappingandsmellingperbagsbywarehousestaff

2checkvehiclesanitationandodorcondition

3signtransportqualityagreementwithRMsuppliers,whichrequestRMvehiclesanitationcomplyingwithfoodsafetyrequirement

(P14.01RMsreceipt,storageandrelease)

Y

Y

N

Y

N

Controlprocedurecanmakesuretheeliminatethehazards.

P

Foreignmatterscontaminationduetobreakage

Visualinspecting,flappingperbagsbywarehousestaff

(P14.01RMsreceipt,storageandrelease)

Y

N

N

1RejectbreakageRMoncebreakage

Metaldetection

M

NA

C

NA

P

MetalfragmentsfromRMandpackage

1detectionlimits:

Fe1.8mm,SUS2.5mm,SS2.5mm

2allRMaredetectedbeforeusing

3periodicallytestingdetectorsensitivitywhenstartup,onceper2hours,detectioncodechange,maintenanceandendup

4segregatethoseabnormalRM

5re-detectsegregatingRM,ifdetectoralarmed,informQStodispose

Y

Y

Y

N

1.IPQAinspectmetaldetectortwicepershift,forkliftdriverinspectitonetimepertwohours

2.vendorverifyandmaintenancemetaldetectoreveryyear

3.Willcontinuouslydetectmetalfragmentsbymagnetfixedinsubsequentprocess(dumping,vibrantsieve)

Re-pileup

EstablishLot

Affixthesmalllabel

AffixpalletIDlabel

Putuprack

Receivereport

EntryinBPCs

A4

A5

A6

A7

A8

A9

A10

M

NA

C

NA

P

NA

ProcessStep

#

Hazard

ControlProcedure

Q1

Y/N

Q2

Y/N

Q3

Y/N

Q4

Y/N

CCP#

Rationaleforhazardelimination

QS(MI)sample

A11

M

pathogencontaminationduetoincorrectorinsanitationsampling

Strictwithasepsistechnique

Samplinginlaminarflow

(P9.14RMsamplingandreleaseprocedure)

Y

Y

N

Y

N

1Samplingareaasahighhygieneonenvironmenthygienemonitorprocedure,labswabbingtesteveryweek

2LabdoublecheckMIsample

C

NA

P

Metalfragmentsduetobreakageofsamplingknife

1useuneasybreakoffknife

2checkknifeintegritybeforesampling

(P9.14RMsamplingandreleaseprocedure)

Y

Y

Y

N

1knifebreakingoffhavenotbeenoccurredincompanyhistory

2Sequentstepsuchasmagneticandvibratesievecaneliminatemetalfragmentsoncesamplingknifebreakoff

CIQtest

A12

M

NA

C

NA

P

NA

QCinspection

COAreview

A13

M

RefertoRMhazardanalysis

C

P

Release

A14

M

NA

C

NA

P

NA

Storage

(Sanitation&check)

A15

M

Pathogencontaminationduetoineffectivepestcontrolandinsects/mice/rodentsinfestedinwarehouse

1SanitationinspectionweeklyonMay-NovansemimonthlyonDec-Apr

(P8.11Pestcontrol)

2Inspectioneveryday

(P14.06warehousesanitationprocedure)

Y

Y

Y

N

1pesticideandpestcontrolvendormustbevaluatedandcertificated

2currentMSDS(materialsafetydatasheet)forpesticideandfumigantsissetup

3effectofpestcontrolhavebeenvalidatedandachievedMJNrequirement

C

Pesticidecontaminationduetounapprovedpesticideorincorrectpractice

1approvedpestcontrolvendor

2pestkillerhavequalificationcertification

3approvedpesticide

4Pesticideusagecontrolsuchasscope,quantity,productdate,expirationdate,rateofapplicationandstorage

5goodpracticeofsprayingpesticideandfumigating

6internalemployeemonitorallprocessofsprayingpesticideandfumigating

Y

N

N

1pesticideandpestcontrolvendormustbevaluatedandcertificated

2currentMSDS(materialsafetydatasheet)forpesticideandfumigantsissetup

3effectofpestcontrolhavebeenvalidatedandachievedMJNrequirement

P

NA

ProcessStep

#

Hazard

ControlProcedure

Q1

Y/N

Q2

Y/N

Q3

Y/N

Q4

Y/N

CCP#

Rationaleforhazardelimination

Reject

Segregateandlabelreject

WO

Returtovendor

Unqualified

Segregateandlabelonhold

Retest

RUD

A16

A17

A18A19A20

A21

A22

A23

M

NA

C

NA

P

NA

FlowchartB

ProcessStep

#

Hazard

ControlProcedure

Q1

Y/N

Q2

Y/N

Q3

Y/N

Q4

Y/N

CCP#

Rationaleforhazardelimination

Receiveshoporder

OBIanddocument

Takeoutrack

cleaning

B1

B2

B2-1

B2-2

M

NA

C

NA

P

NA

Pickup

Doublecheck

(Checkingredientandquantityvs.shoporder)

Putuprack

Preparedtouse

B2-4

B2-5

B2-6

B2-7

M

NA

C

NA

P

NA

Pickupmaterial

Takeoffpacking

B3

B4

M

NA

C

NA

P

NA

Outerpackdisinfection

Cleaning

(weighingmaterials)

B5

M

pathogencontaminationduetoinsufficientdisinfectionorincorrectdisinfectpractice

175%alcoholdisinfectouterpacking

ofweighingmaterials

2towelsareprohibittousingrepeat

3makesurewatervaporizedcompletelybeforeweighing

(I14.25-02Outerpackdisinfectionworkinstruction)

Y

N

N

1Outerpackdisinfectionprovedtobeavalidpracticeformicrocontamination

2ATPSwabbingtestthriceperweekandRLU150

3sanitationinspectionperiodically

C

NA

P

NA

ProcessStep

#

Hazard

ControlProcedure

Q1

Y/N

Q2

Y/N

Q3

Y/N

Q4

Y/N

CCP#

Rationaleforhazardelimination

Transferfromwindow

B6

M

NA

C

NA

P

NA

weighing

B7

M

Pathogencontaminationduetobadpersonapracticelorinvalidequipment

GMPandweighingstartupchecklist.

Y

N

N

ControlledbyPrerequisiteprogramGMPandPM,currentprogramcaneliminatethehazardtoanacceptablelevel.

C

Babygrowthdiseaseduetoinsufficientoroverfullfeedingforvitamins,mineralsandirononstageoneproductswhenitisusedasauniquenutrientresource.

Lactoseintoleranceduetolactosecontamination

1checkeachmateriallabelcomplywithmaterialnameandnumber.

2periodicalcheckforbalanceaccuracywhilestartup,formulachangeandatleastonceper2hours.

3podicalcheckforbalanceaccuracywhilestartup,formulachangeandatleastonceper2hours.

4pecialoperatorcheckshoporder.

5roductsequence:

fromnon-lactosetolactose

6fnot,replaceweighinginstruments,cleaningtowelandbalance,sanitizeworktable

Y

Y

N

Y

Y

P

Metalfragmentscomefrombreakageofscissors,scoop,alsonailsandsealingironcircleoffiberbarrel

1useuneasybreakoffscissors,scoops

2checkscissors,scoopsintegritybeforeusing

3iffindscissorsorscoopsbrokeoff,informsupervisorsimmediately,segregatesuspiciousRMandtrace

brokeoffmetalfragment

4notbeatfiberbarrelwithhammer,complywithsuppliersmethodtounseal

Y

Y

Y

N

Sequentstepsuchasmagneticandvibratesievecaneliminatemetalfragmentsoncesamplingknifebreakoff

Fillinform&packing

store

B8B10

M

NA

C

NA

P

NA

FlowchartP

ProcessStep

#

Hazard

ControlProcedure

Q1

Y/N

Q2

Y/N

Q3

Y/N

Q4

Y/N

CCP#

Rationaleforhazardelimination

Check

E1

E3

M

NA

C

NA

P

NA

Premix

E2

M

NA

C

Dystrophiadueto:

1missingbagsofVitamin,minerals,iron,ARAorDHA

2moreresidualsofVitamin,minerals,iron,ARAorDHAinPEpackingwhenmixing.

1checkallRMsagainstshopordertoavoidmisusing

2premixcomplywithshoporder

3bagsoftheseRMSshouldkeepspareroomafterweighingtoavoidhidinginbundlearea

4checkifthereisresidualsofVitamin,minerals,iron,ARAorDHAinPEpackingafterdumpingeverybags

(P11.05operationprocedureforbatchingarea)

Y

Y

N

Y

N

Currentprocedurecaneliminatethehazardtoanacceptablelevel.

P

NA

Stripoutpackaging

P1-2

M

pathogencontaminationduetoSucroseouterpackageinsufficientdisinfection

Sucroseouterpackageisdisinfectedbeforeentrydumpingroombyusing70%alcohol.

Y

N

N

Notasignificantrisk

Disinfectioncaneliminatethehazardtoanacceptablelevel

C

NA

P

Metalfragmentsduetobreakageofunsealing

knife

1checkintegrityofknifepereveryshift

2ifknifebreakoff,immediatelyinformsupervisor,stopproducing,findanddiscovermetalfragmentsinworkingarea

3checkmagneticandvibratesieve

(P7.082knifeusageandcontrolprocedure)

Y

Y

Y

N

1theseprocedurecouldeliminatemetalfragmenthazardtoanacceptablelevel

2notfoundmetalfragmentsinmagneticinfactoryhistory

ProcessStep

#

Hazard

ControlProcedure

Q1

Y/N

Q2

Y/N

Q3

Y/N

Q4

Y/N

CCP#

Rationaleforhazardelimination

Dumping

P2-2

M

pathogencontaminationduetoSucroseouterpackageinsufficientdisinfection

Sucroseouterpackageisdisinfectedbeforeentrydumpingroombyusing70%alcohol.

Y

N

N

Controlledbytheprerequisiteprogram.

Notasignificantrisk

Disinfectioncaneliminatethehazardtoanacceptablelevel

C

NA