斗轮堆取料机使用说明书正文英文.docx

《斗轮堆取料机使用说明书正文英文.docx》由会员分享,可在线阅读,更多相关《斗轮堆取料机使用说明书正文英文.docx(50页珍藏版)》请在冰豆网上搜索。

斗轮堆取料机使用说明书正文英文

Chapter1Summary

DQ500/1000·35boombucket-wheelstackerreclaimer(BWSR)isakindoflarge,continuousandhighefficientbulkcargoandgranularmaterialstackingandreclaimingequipment,developed,designedandmanufacturedbyChangchunGeneratingEquipmentCo.,Ltd,ChinaforBotswanaMorupuleB4X150MWPowerStationproject.

This“operationinstruction”includesnecessarydataandexplanationoftheequipment.Maincontentsareasfollows:

performanceoftheequipmentandtechnicalparameter,equipmentstructure,operatingmodeandcharacteristic,operatingregulations,safeoperatingregulationandmaintenanceaswellasserviceetc.oftheequipment.Thereareinterlockingprotectionbetweenlongtraveldrive,luff,bucketwheeldriveandboomconveyoretctransmissionpart(detailedinformationrefertotheinstructionineachChapter/Section).Operatormustread“Operationinstruction”carefullyandmasterdailyoperationandmaintenancebeforestartingtowork;ifoperation,maintenanceisimproper,notonlycanreducetheservicelifeofequipment,butalsocancausetheaccident.

1.1Briefintroductionoftheequipment

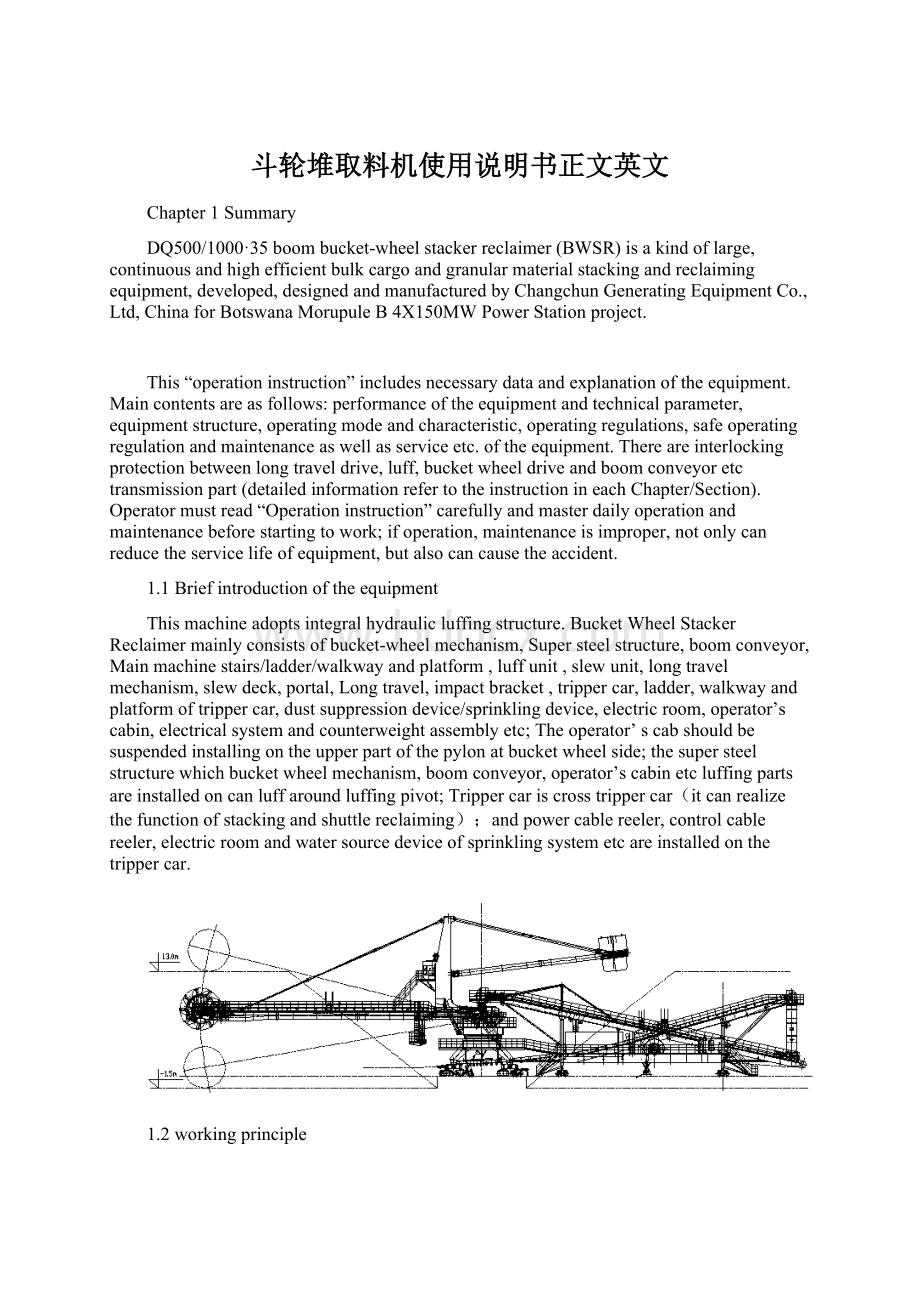

Thismachineadoptsintegralhydraulicluffingstructure.BucketWheelStackerReclaimermainlyconsistsofbucket-wheelmechanism,Supersteelstructure,boomconveyor,Mainmachinestairs/ladder/walkwayandplatform,luffunit,slewunit,longtravelmechanism,slewdeck,portal,Longtravel,impactbracket,trippercar,ladder,walkwayandplatformoftrippercar,dustsuppressiondevice/sprinklingdevice,electricroom,operator’scabin,electricalsystemandcounterweightassemblyetc;Theoperator’scabshouldbesuspendedinstallingontheupperpartofthepylonatbucketwheelside;thesupersteelstructurewhichbucketwheelmechanism,boomconveyor,operator’scabinetcluffingpartsareinstalledoncanluffaroundluffingpivot;Trippercariscrosstrippercar(itcanrealizethefunctionofstackingandshuttlereclaiming);andpowercablereeler,controlcablereeler,electricroomandwatersourcedeviceofsprinklingsystemetcareinstalledonthetrippercar.

1.2workingprinciple

Thisequipmentisselectedtousemanual,manualinterlockedandsemi-automaticforstackingandreclaimingoperation.

1.2.1Duringstackingoperation,thematerialtransferredfromauxiliarytripper(yard-conveyor)willbedeliveredtotransferchutethroughprimarytrippercarandheadparthopperofthetrippercar;-thendeliveredtoboomconveyor,atlaststackingontostockpiles.Boomconveyor’sluffingcanrealizehigh&lowlevelstacking;Bucketwheelboomslewingcanreachleft-rightstockyardandstockyardwidthstacking,LongTravelDrivecanrealizestackingalongthetracklength.

1.2.2Reclaimingoperationiscarriedoutaccordingtolayerreclaimingprocessaswellasbevelreclaimingifnecessary.Thecoalwillbeexcavatedandreclaimedbythebucket(bucketwheelmechanism),anddeliveredtoboomconveyor.Thentransferchuteviayardconveyoroutput.Bucketwheelboomluffingcanrealizehigh&lowlevelreclaiming;Bucketwheelboomslewingcanreachleft-rightstockyardandstockyardwidthreclaiming.

Forbiddentoreclaimthematerialonlydependingonlongtravel.

Chapter2Performanceofthemachineandmaintechnicalparameter

1Typeofequipment

DQ500/1000.35type,itmeans:

35-slewingradius(thedistancefrombucketwheel

centertoslewingcenteroftheequipmentis35m);

1000--stackingcapacity1000tons/hour;

500--reclaimingcapacity500tons/hour;

Q……reclaiming;

D……stacking。

2Naturalconditionofthecoalyard

Coalyardtype:

shuttlingtypelayout

Coaldensity:

0.85~1t/m3

Heightofstockpile:

13mabovetherail,

and1.5mbelowtherail

3Mainparameterofequipment

Ratedcapacity:

Stackingcapacity:

1000t/h

Reclaimingcapacity:

500t/h

a.Longtravel

Travelingspeed:

Operatingspeed:

7m/min;

Commissioningspeed:

30m/min

Wheelbaseandwheelgauge:

7mx7m

Motorpower:

4x11kW

Reducertype:

FH127GDV160M4BM/HF

Outputrpm.ofreducer:

14.45r/min

Braketype:

withthegearbox

Railclamptype:

TZT-J100

Limitswitchofanchordevice:

XCKS141H29

b.Slewunit

Slewingradius:

35m

Slewingspeed:

0.02~0.12r/min

Slewingangle:

stackingangle:

±110°

reclaimingangle:

±110°

Motortype:

Y2-200L-8

Motorpower:

15kW

Reducertype:

PHF062+KF107AD6

Transmissionratioofreducer:

i=774.4

Braketype:

YWZ9-200/E23

c.Bucket-wheelmechanism

Reclaimingcapacity:

500t/h

Outerdiameterofbucket-wheel:

Φ5200mm

rpmofbucket-wheel6.5r/min

Bucketcapacity:

0.2m3

Bucketquantity:

9nos.

Drivingdeviceparameter:

Motortype:

Y225M-4

Motorpower:

45kW

Reducertype:

P2HF052+MC2RLS03

Transmissionratioofreducer:

i=226.86

Limitedtorquefluidcouplingtype:

YOXA450

d.Luffunit

Luffingangle:

Luffup12.04°,Luffdown11.87°

Luffingspeed:

3~5m/min(atthecenterofbucket-wheel)

Typeofhydrauliccylinder:

250MP5

Hydrauliccylinderform:

doubleactingcylinder

Ratedworkingpressure:

16Mpa

e.Boomconveyor

Lengthofboomconveyor:

36.83m

Conveyingcapacity:

1500t/h

Beltwidthxbeltspeed:

1200mmx3.15m/s

Idlerdiameter:

φ133mm

Troughangleoftheilder:

35°

Takeuptype:

Heavybobtakeup

Drivingdeviceparameter:

Motortype:

Y280S-4

Motorpower:

75kW

Reducertype:

MC3RLHF05+1FAN

Transmissionratioofreducer:

i=20.22

Limitedtorquefluidcouplingtype:

YOXⅡZ-450

Braketype:

YWZ-300/45

Longitudinalsplitingprotectionswitchtype:

HFZL-K

Dualdirectionpullingwireswitchtype:

KLT2-Ⅰ

Misalliancedetectingswitchtype:

FPK-12-30

Speedsensortype:

SJK-B-Ⅲ

boomconveyormaterialflowdetectingswitchtype:

LJ-Ⅲ

f..Dustsuppressionsystem/Sprinklingsystem

Watertankvolume:

10m3

Pumptype40DL6.2-11.8X7

Flowofthepump:

6.2m3/h

Deliverylift:

82.6m

Typeofmotorequippedwithpump:

Y132S1-4

Motorpower:

5.5kW

Rotationalspeedofmotor:

1450r/min

Liquidlevelrelay:

UQK-02

Electromagneticvalve:

ZCLF-20

Waterpressureenteringintowatertank:

0.1~0.2MPa

g.Powercablereeler

Cablespecification:

F-3PNCT3x35+1x16mm2

Cablecrossdimensions:

91.6mmx31mm

Cablereelertype:

T1C-[J2D-4]x2(right)

h.Controlcablereeler

Cablespecification:

F-3PNCT-30x2.5+2Gmm2

Cablecrossdimensions:

82.8mmx23.7mm

Cablereelertype:

T1C-[J3K37]x1(left)

i.Transferchute

ElectricalthrustorMT300500Ⅲ-60

JammingdetectorLD-X

j.Trippercarguidechutedevice

lockingpreventiondeviceZFB-6

blockagedetectorLD-X

k.Limitedswitch

Anti-collisiondeviceofboomrack:

FKLT2-I

OtherlimitedswitchesXCKS141H29

Note:

Otherlimitswitchesmeanboomrackluffinglimitedposition,slewingangle,slewingluffandterminallimitedpositionofLongtravel.

l.Detectiondevice

Detectiondevicefortravelingdistance:

XCC1406PR01Ktyperotaryencoder

Detectiondeviceforslewingangle:

XCC2506PS81KBtyperotaryencoder

Detectiondeviceforluffingangle:

XCC2506PS81KBtyperotaryencoder

Detectiondeviceforstockpilelevel:

20-39typeincliningswitch.

Chapter3Equipmentstructure

Section1:

GeneralStructure

Theequipment(seedetailsingeneralarrangementdrawingDQ9912.0ST)consistsofbucket-wheelmechanism,supersteelstructure,boomconveyor,mainladderplatform,luffinghydraulicdevice,portal,supportpivot,slewdeck,transferchute,slewingmechanism,limitedswitchdevice,detectiondevice,longtravel,centrallubricationsystem,powercablereelerdevice,controlcablereelerdevice,trippercar,impactbracket,ladderplatformoftrippercar,dustsuppression/sprinklingsystem,electricroom,electricalsystem,operator’scabin,nameplate,counterweightassembly,foundationallayout,loadandsoon.

Superstructureofmainmachineisanintegralstructurewhichconsistsofboomrack,pylon,counterweightboomandfrontandbackbracing,allpartswillbeconnectedbypinrollwhichfixedbyblock.Headpartisbucket-wheelmechanism;backpartiscounterweightassemblywhichcanadjustthebalanceofsuperstructure.Superstructureisfixedonslewdeckbysupportpivot,theupperpartofthesupportpivot(bearingbody)willbeweldedwiththelowerplaneofthepylon;thelowerpartofthesupportpivot(supportingblock)willbeweldedwiththeupperplaneoftheSlewdeck.Thecompletedstructurecanwagglearoundthesupportpivotpoint,Hydrauliccylinderwhichliebetweenslewdeckandpylonactscanachieveintegralluffofsuperstructure.Slewsupportbearingismountedbetweenupperandlowerpedestalring,upperpedestalringsupportstheslewdeck,andlowerpedestalringisfixedontheportal.Slewdrivingdeviceisfixedontheslewdeck,andthroughoutputaxispinionofslewingreducer,thespurpinionismeshedwithbiggearringwhichisfixedunderthebearingoflowerpedestalring,whichshalltransmitupperstructuretorotatearoundslewcenter.Pivotoftravelingmechanismisweldedwithsupportlegofportal.Sincesuchstructureadoptsintegralmachineluffstructuraltype,ithaslessconnectingjoints,lessservices,andhighsecurity.

Section2:

Detailedstructureofunitandoperatingfeatures

1Bucket-wheelmechanism

1.1Structure

Bucket-wheelmechanismmainlyconsistsofbucketwheeldrivedevice,ringchute,bucketwheelbody,bucketwheelshaft,bucket,slidingchuteandguidechutedeviceetc.Bucketwheeldrivedeviceconsistsofmotor,gearbox/reducer,blockanddrivegearetc.;throughmotor-gearboxtransmittedtobucketwheelshaft.Sobucketwheelbodycanbedrivenbybucketwheeldrivedevice,andcanbecarriedoutreclaimingoperation.

Totalninebucketswithbucketteetharefixedonbucketwheelbody(bucketteethshouldbedetachable)bypinrollsandpins,Bucketwheelmechanismconsistsofthem.Bucketwheelbodyiscelllesstype,inorderto