化学工程与工艺专业英语课后答案.docx

《化学工程与工艺专业英语课后答案.docx》由会员分享,可在线阅读,更多相关《化学工程与工艺专业英语课后答案.docx(18页珍藏版)》请在冰豆网上搜索。

化学工程与工艺专业英语课后答案

KeytoExercise

Unit1ChemicalIndustries

1.theIndustrialRevolution

2.organicchemicals

3.thecontactprocess

4.theHaberprocess

5.syntheticpolymers

6.intermediates

7.artificialfertilizers

8.pesticides

9.syntheticfibers

10.pharmaceutical

11.researchanddevelopment

12.petrochemical

13.computers

14.capitalintensive

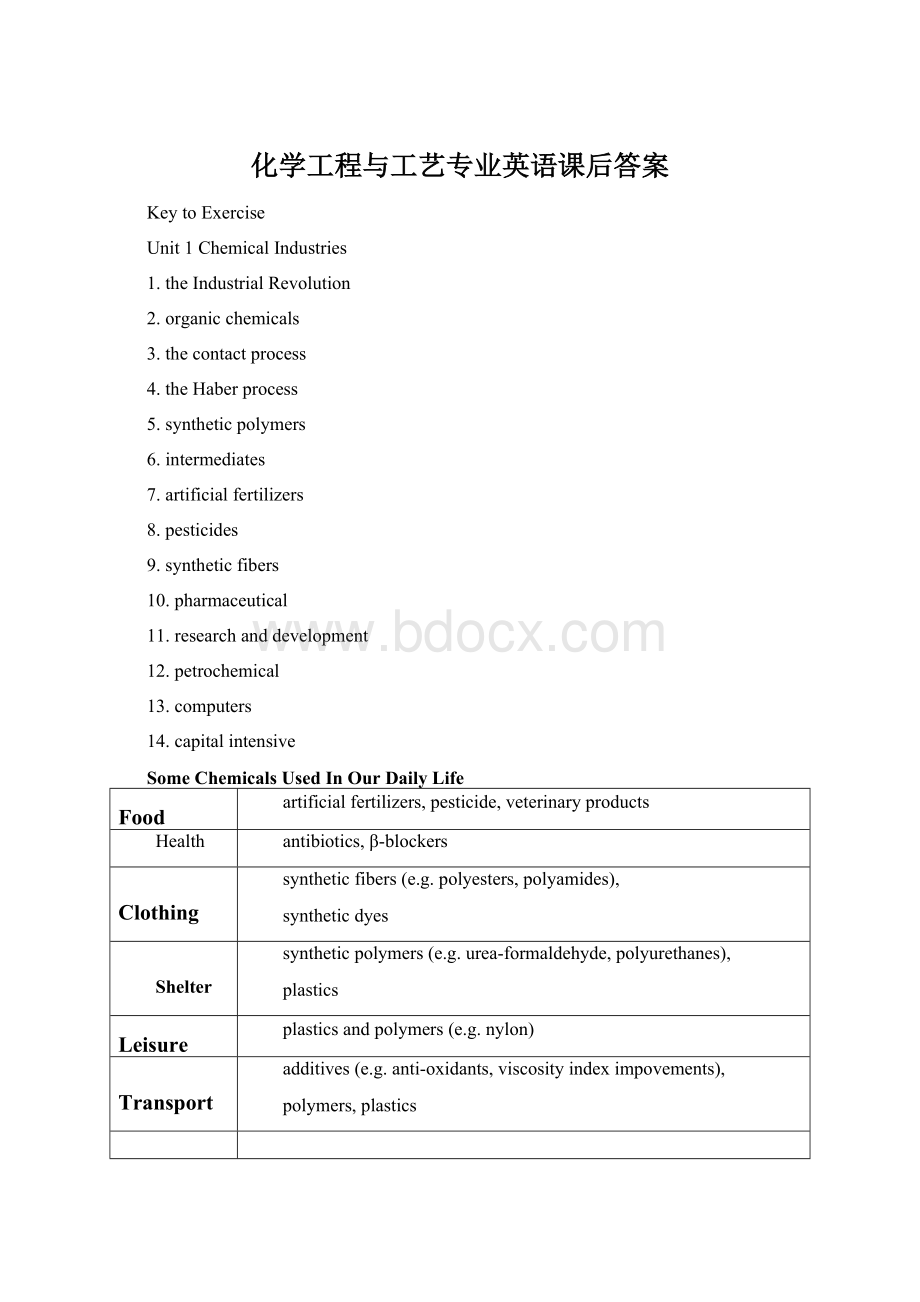

SomeChemicalsUsedInOurDailyLife

Food

artificialfertilizers,pesticide,veterinaryproducts

Health

antibiotics,β-blockers

Clothing

syntheticfibers(e.g.polyesters,polyamides),

syntheticdyes

Shelter

syntheticpolymers(e.g.urea-formaldehyde,polyurethanes),

plastics

Leisure

plasticsandpolymers(e.g.nylon)

Transport

additives(e.g.anti-oxidants,viscosityindeximpovements),

polymers,plastics

Unit2ResearchandDevelopment

1.R&D

2.ideasandknowledge

3.processandproducts

4.fundamental

5.applied

6.productdevelopment

7.existingproduct

8.pilotplant

9.aemergingcase

10.environmentalimpact

11.energycost

12.technicalsupport

13.processimprovement

14.effluenttreatment

15.pharmaceutical

16.sufficientlypure

17.Reaction

18.unreactedmaterial

19.by-products

20.theproductspecification

21.Productstorage

Unit3TypicalActivitiesofChemicalEngineers

1.Mechanical

2.electrical

3.civil

4.scale-up

5.commercial-size

6.reactors

7.distillationcolumns

8.pumps

9.controlandinstrumentation

10.mathematics

11.industry

12.academia

13.steam

14.coolingwater

15.aneconomical

16.toimprove

17.P&IDrawings

18.EquipmentSpecificationSheets

19.Construction

20.capacityandperformance

21.bottlenecks

22.TechnicalSales

23.neworimproved

24.engineeringmethods

25.configurations

Unit4SourcesofChemicals

1.inorganicchemicals

2.derivefrom

3.petrochemicalprocesses

4.Metallicores

5.extractionprocess

6.non-renewableresource

7.renewablesources

8.energysource

9.fermentationprocess

10.selective

11.rawmaterial

12.separationandpurification

13.foodindustry

14.tobewetted

15.Keytosuccess

16.Crushingandgrinding

17.Sieving

18.Stirringandbubbling

19.Surfaceactiveagents

20.Overflowing

Unit5BasicChemicals

1.Ethylene

2.aceticacid

3.Polymerization

4.Polyvinylacetate

5.Emulsionpaint

High-volumesector

Low-volumesector

Productionscale

tenstohundredsofthousandstonsperyear

tenstoafewthousandstonsperyear

Products/aplant

singleproduct

multi-products

Operationmanner

continuous

batch

Priceorprofit

fairlycheap

veryprofitable

Usage

intermediates

end-products

Challenges

reduceddemand,

environmentpollution

Productsinthesector

sulphuricacid,

phosphorus-containingcompounds,

nitrogen-containingcompounds,

chlor-alkali,

petrochemicals,

commoditypolymers

agrochemicals,

dyestuffs,

pharmaceuticals,

specialitypolymers

Unit6Chlor-AlkaliandRelatedProcesses

1.Ammonia

2.ammoniaabsorber

3.NaCl&NH4OH

4.Carbondioxide

5.NH4Cl

6.Rotarydrier

7.LightNa2CO3

8.Water

Product

Rawmaterial

Majorstepsor

Principalreactions

Uses

Soda-ash

brine,

limestone

ammoniating,

carbonating,

precipitating,

filtering,

drying,

calcining

rawmaterialfor

glassmaking,

sodiumsilicate;

asanalkali

Chlorine

brine

2Na++2Cl-+2H2O→NaOH+Cl2+H2

aswaterpurification,bleachingofwoodpulp;productionof

vinylchloride,solvents,inorganicchlorine-containingproducts

Causticsoda

brine

2Na++2Cl-+2H2O→NaOH+Cl2+H2

forpaper-making,manufactureofinorganicchemicals,

synthesesoforganicchemicals,

productionofaluminaandsoap

Sulfuricacid

elementalsulphur

S+O2→SO2

SO2+O2→SO3

SO3+H2O→H2SO4

feedstockforfertilizers;productionofethanol,hydrofluoricacid,aluminumsulphates

Unit7Ammonia,NitricAcidandUrea

1.kineticallyinert

2.someironcompounds

3.exothermic

4.conversion

5.areasonablespeed

6.lowerpressures

7.highertemperatures

8.capital

9.energy

10.steamreforming

11.carbonmonoxide

12.secondaryreformer

13.theshiftreaction

14.methane

15.3:

1

1787

C.Berthollet

discoversthecompositionofammonia

1903

FritzHaber

synthesizesammonia

1909

FritzHaber

drivestheoptimumreactionconditions

1909-1914

C.Bosch,A.Mittasch

scale-uptheprocess

1913

inBASF

buildapilotplant

1919

FritzHaber

receivestheNobleprice

1920s

inBritainandAmerica

IntroducetheHaberprocess

1931

C.Bosch

receivestheNobleprice

Unit8PetroleumProcessing

1.organicchemicals

2.H:

Cratios

3.hightemperaturecarbonization

4.crudetar

5.pyrolysis

6.poorselectivity

7.consumptionofhydrogen

8.thepilotstage

9.surfaceandunderground

10.fluidizedbed

11.Biotechnology

12.sulfurspecies

Unit9Polymers

Abbreviation

Nameofpolymer

LDPE

Lowdensitypolyethylene

低密度聚乙烯

HDPE

Highdensitypolyethylene

高密度聚乙烯

LLDPE

Linearlowdensitypolyethylene

线性低密度聚乙烯

PETorPBT

Polyethyleneterephthalate(PET)

Polybutyleneterephthalate(PBT)

聚对苯二甲酸乙二醇酯

聚对苯二甲酸丁二醇酯

PVC

Polyvinylchloride

聚氯乙烯

PS

Polystyrene

聚苯乙烯

POM

Polyoxymethylene

聚甲醛

PP

Polypropylene

聚丙烯

PC

Polycarbonate

聚碳酸酯

PPO

Polyphenyleneoxide

聚苯醚

PTFE

polytetrafluoroethylene

聚四氟乙烯

PF

phenol-formaldehyderesins

酚醛树脂

PMMA

poly(methylmethacrylate)

聚甲基丙烯酸甲酯

UF

urea-formaldehyderesins

脲醛树脂

Nameofpolymer

CompanyorInventor

Yearintroduced

Phenol-formaldehyderesin

Baekland

1909

Urea-formaldehyderesin

1929

Alkydresin

late1920s

Poly(styrene-butadiene)

Germany

Poly(acrylonitrile-butadiene)

Germany

Poly(vinylchloride)

Germany

Polystyrene

Germany

polyethylene

ICI

1938

Nylon

Dupont

1941

Polyacrylonitrile

Dupont

1948

Terylene

ICI

1949

Epoxyresins

Dupont

1955

polypropylene

Montecatini

1956

LLDPE

late1970s

Unit10WhatIsChemicalEngineering

Microscale(≤10-3m)

●Atomicandmolecularstudiesofcatalysts

●Chemicalprocessinginthemanufactureofintegratedcircuits

●Studiesofthedynamicsofsuspensionsandmicrostructuredfluids

Mesoscale(10-3-102m)

●Improvingtherateandcapacityofseparationsequipment

●Designofinjectionmoldingequipmenttoproducecarbumpersmadefrompolymers

●Designingfeedbackcontrolsystemsforbioreactors

Macroscale(>10m)

●Operabilityanalysisandcontrolsystemsynthesisforanentirechemicalplant

●Mathematicalmodelingoftransportandchemicalreactionsofcombustion-generatedairpollutants

●Manipulatingapetroleumreservoirduringenhancedoilrecoverythroughremotesensingofprocessdata,developmentanduseofdynamicmodelsofundergroundinteractions,andselectiveinjectionofchemicalstoimproveefficiencyofrecovery

Course

Coursecontent

ScienceandMath.

Chemistry,Physics,Biology,MaterialScience,Mathematics,ComputerInstruction

ChemicalEngineering

Thermodynamics,Kinetics,Catalysis,

RectorDesignandAnalysis,UnitOperations,ProcessControl,ChemicalEngineeringLaboratories,Design/Economics

Otherengineering

ElectricalEngineering,Mechanics,EngineeringDrawing

HumanitiesandSocialscience

Understandtheoriginsofone’sowncultureaswellasthatofothers

Unit12WhatDoWeMeanbyTransportPhenomena?

1.density

2.viscosity

3.tubediameter

4.Reynolds

5.Eddies

6.laminarflow

7.turbulentflow

8.velocityfluctuations

9.solidsurface

10.idealfluids

11.viscosity

12.Prandtl

13.fluiddynamics

Unit13UnitOperationsinChemicalEngineering

1.physical

2.unitoperations

3.identical

4.A.D.Little

5.fluidflow

6.membraneseparation

7.crystallization

8.filtration

9.materialbalance

10.equilibriumstagemodel

11.Hydrocyclones

12.Filtration

13.Gravity

14.Vaccum

Unit14DistillationOperations

1.relativevolatilities

2.contactingtrays

3.reboiler

4.anoverheadcondenser

5.reflux

6.plates

7.packing

8.strippingsection

9.rectifyingsection

10.energy-inputrequirement

11.overallthermodynamicefficiency

12.trayefficiencies

13.Batchoperation

14.composition

15.arectifyingbatch

Sieveplate

Bubble-capplates

Valveplates

Cost

1

3

2

Capacity

3

1

2

Operatingrange

3

1

2

Efficiency

same

same

Same

Pressuredrop

1

3

2

1<2<3

Unit15SolventExtraction,LeachingandAdsorption

1.aliquidsolvent

2.solubilities

3.leaching

4.distillation

5.extract

6.raffinate

7.countercurrent

8.afluid

9.adsorbedphase

10.400,000

11.originalcondition

12.totalpressure

13.equivalentnumbers

14.H+orOH–

15.regenerant

16.processflowrates

17.deteriorationofperformance

18.closelysimilar

19.stationaryphase

20.mobilephase

21.distributioncoefficients

22.selectivemembranes

23.synthetic

24.ambienttemperature

25.ultrafiltration

26.reverseosmosis(RO).

Unit16Evaporation,CrystallizationandDrying

1.concentratesolutions

2.solids

3.circulation

4.viscosity

5.heatsensitivity

6.heattransfersurfaces

7.thelongtube

8.multiple-effectevaporators

9.vacuum

10.condensers

11.supersaturation

12.circulationpump

13.heatexchanger

14.swirlbreaker

15.circulatingpipe

16.product

17.non-condensablegas

18.barometriccondenser

Dryertype

Generalfeatures

Application

Traydryers

Batchoperation,

Closecontrolofdryingconditionsandproductinventory

Dryingvaluableproducts

Conveyordryers

Continuouscirculation,

Highdryingrates,

Goodproduct-quality,

Highthermalefficiencies,

Highinitialandmaintenancecost

Dryingmaterialsthatformabedwithanopenstructure

Rotarydryer

Continuousoperation,

Highthroughput,

Highthermalefficiency,

Lowcapitalcostandl