seawater killing1.docx

《seawater killing1.docx》由会员分享,可在线阅读,更多相关《seawater killing1.docx(10页珍藏版)》请在冰豆网上搜索。

seawaterkilling1

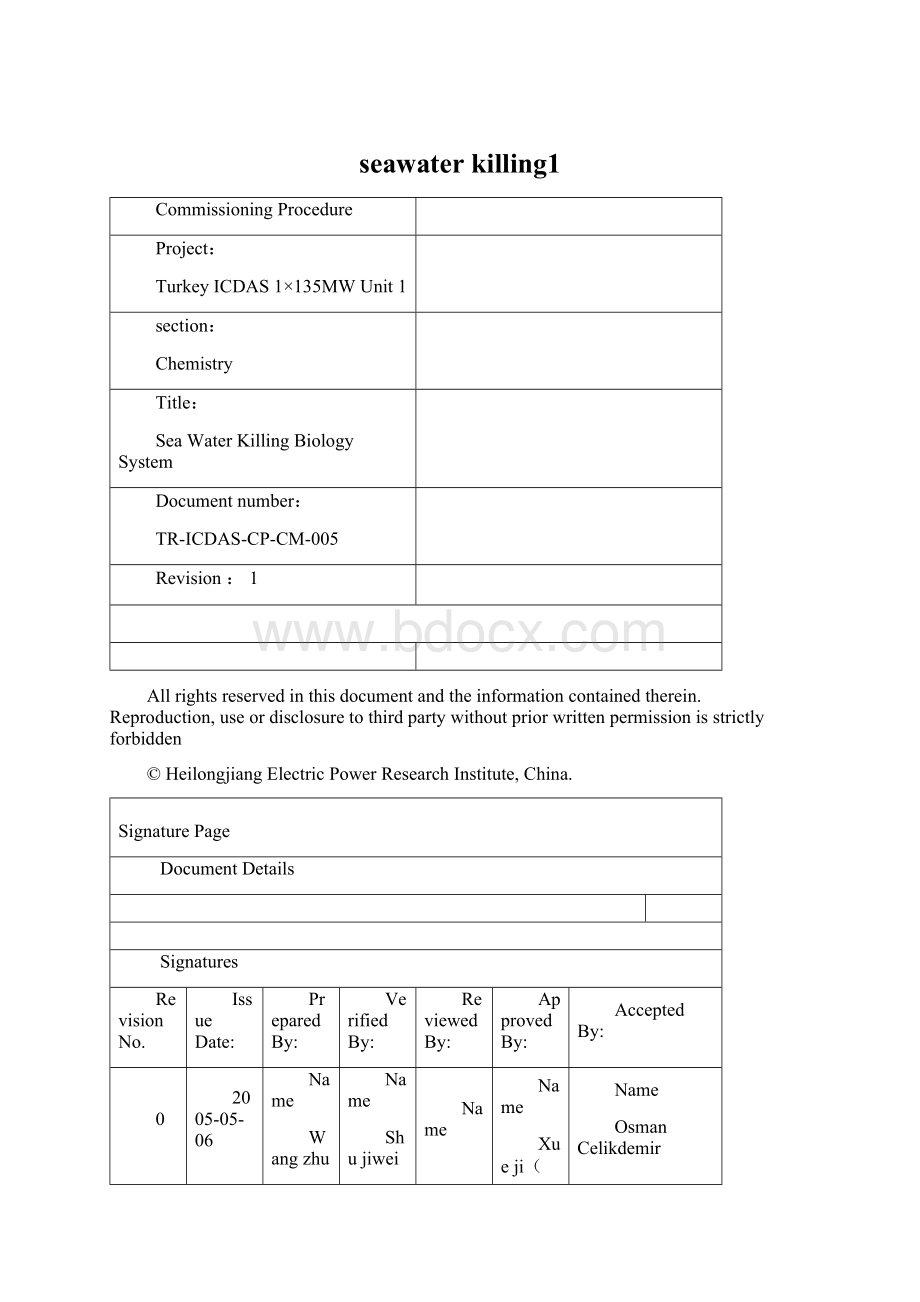

CommissioningProcedure

Project:

TurkeyICDAS1×135MWUnit1

section:

Chemistry

Title:

SeaWaterKillingBiologySystem

Documentnumber:

TR-ICDAS-CP-CM-005

Revision:

1

Allrightsreservedinthisdocumentandtheinformationcontainedtherein.Reproduction,useordisclosuretothirdpartywithoutpriorwrittenpermissionisstrictlyforbidden

©HeilongjiangElectricPowerResearchInstitute,China.

SignaturePage

DocumentDetails

Signatures

RevisionNo.

IssueDate:

PreparedBy:

VerifiedBy:

ReviewedBy:

ApprovedBy:

AcceptedBy:

0

2005-05-06

Name

Wangzhu

Signature

Name

Shujiwei

Signature

Name

Jiachangge

Signature

Name

Xueji(CMEC)

Gaoyunda(HPCC3)

Signature

Name

OsmanCelikdemir

(ICDAS)

Signature

1

2005-06-23

Name

Wangzhu

Signature

Name

Shujiwei

Signature

Name

Jiachangge

Signature

Name

Xueji(CMEC)

Gaoyunda(HPCC3)

Signature

Name

OsmanCelikdemir

(ICDAS)

Signature

RevisionSummary

Rev.0Initialissue

Rev.1RevisedaccordingtoICDAScomments.

TableofContents

1Objective5

2Scopeofwork5

3Acceptancecriteria5

4References5

5Prerequisites5

6Precautions6

7Testequipmentandmaterials6

8Procedure6

9VerificationandPostRequisites9

10Attachment10

1Objective

Forpreventthemicro-organismgrowthinthecirculatingwatersystem,onesetofseawaterkillingbiologysystemisprovided.Thefeedpointisatwaterintakeandinletwaterroom.Theequipmentisintheseawatertreatmentroomneartheseawaterpumphouse.

Theinstallationofelectrolyzingseawaterproducesavailablechlorinebyutilizingspecialelectrodes.

2Scopeofwork

Includingthecommissioningofautomaticfilter,electrolysisgroup,dosingsystem,cleaningsystemandsoon.

Sodiumhypochloridegenerationsystemisasfollows:

Seawater→seawaterpump→automaticfilter→electrolysisgroup→Sodiumhypochloridesolutiontank→dosingpump→user.

Cleaningsystemofsodiumhypochloridegeneratorisasfollows:

Acidcleaningtank→Acidcleaningpump→electrolysisgroup→Acidcleaningtank

3Acceptancecriteria

№

Checkitems

Results

1

Methodandconcentrationofdosingsodiumhypochlorite:

1)Additcontinuouslywithaconcentrationof0.5ppm;or

2)Addittwiceadaywithaconcentrationof3ppm,for1heachtime.

□

2

Thecapacityofthesodiumhypochloriteis2×10kg/h.

□

4References

4.1Seawaterkillingbiologysystemdiagram(№:

F356S-H0501-01)

4.2SeawaterelectrochlorinationoperationandmaintenanceManual

5Prerequisites

5.1Civilworkandinstallationworkofseawaterkillingbiologysystemhasbeencompletedinaccordancewithsystemdiagram.

5.2Electricalequipments,i.e.switchboard,console,indictoranalysis,I&Cmeasurementhas

beeninstalledandchecked,ensureoperationflexibility.

5.3Servicewatersystemshouldbeputinservicenormally.

5.4Communicationandlightinsiteareallready,ifnot,thetemporarymeasureshouldbetaken,workingpassageareunblocked,temporaryequipmentswhichusedininstallingperiodshouldberemoved.

5.5Analyticalreagentandanalyzerareallready.

5.6Recorderpaperusedincommissioningareallready.

5.7Electricalpersonnel,I&Cpersonnelanderectorshouldbeonshift,soastodealwithdrawbackduringcommissioning.

5.8Watersamplingsystemshallbeinstalledattheoutletofcondenserbeforethewaterisdischargedintothesea.

5.9Drainchannelaroundacidtankforwaterusedtocleanspilledacid&itsconnectiontotheexistingdrainage.

5.10Carbonsteelplatecoversofdrainagechannelmustbechangedwithacidproofplate.

5.11Acidintheacidtankwillbesenttoaacidproofcontainerwhichwillbedischargedonceinamonthto#3wastewaterbasin.

5.12Theladderwhichattheacidcleaningtankmustbeacidproofmaterial.

6Precautions

6.1Personnelwhoattendcommissioningshouldstudysafetyguideforchemicalandelectric,refertosection*ofsafetymanual.

6.2Electricequipment,chemicalsshouldbetakenchargebyskilledperson.

6.3Providedsomefirefightingequipments.

6.4Electricswitchesandelectricequipmentshouldhaveevidencesign.

6.5Personnelwhoattendcommissioningshouldbefamiliarwithsystem,preventfromimproperoperation.

6.6Necessaryindividualprotectivemeasureshouldbetaken.

7Testequipmentandmaterials

Preparedanalyzersandchemicalsasfollows:

Someanalyticalreagentsforexamplepotassiumdichromate,sodiumthiosulfateandsoon.

8Commissioningprocedure

8.1Inspectionofsingleequipment

8.1.1Inspectionofmotor-operatedvalve

Serialnumber

Description

Checkitems

Results

10QJA11

/AT001/10UPQ0000

Automaticfilterdrainagemotor-operatedvalve

Normaloperation

□

8.1.2Inspectionofpumps

Serialnumber

Description

Checkitems

Results

10QJA21/AP001/10UPQ0000

#1seawaterpump

Normalstartupandstop

□

10QJA22

/AP001/10UPQ0000

#2seawaterpump

Normalstartupandstop

□

10QJA51

/BN001/10UPQ0000

#1dosingpump

Normalstartupandstop

□

10QJA52

/BN001/10UPQ0000

#2dosingpump

Normalstartupandstop

□

10QJA70

/AP001/10UPQ0000

#1acidcleaningpump

Normalstartupandstop

□

10QJA51

/AN001/10UPQ0000

#1blower

Normalstartupandstop

□

10QJA52

/AN001/10UPQ0000

#2blower

Normalstartupandstop

□

8.1.3InspectionofI&Cequipment

№

Description

Checkitems

Results

1

Differentialpressureswitchofautomaticfilter

Feedbackcorrectly

□

2

DifferentialpressureswitchofYtypefilter

Feedbackcorrectly

□

3

Pressureswitchof#1electrolyergroupinlet

Feedbackcorrectly

□

4

Pressureswitchof#2electrolyergroupinlet

Feedbackcorrectly

□

5

Flowswitchof#1electrolyergroupinlet

Feedbackcorrectly

□

6

Flowswitchof#2electrolyergroupinlet

Feedbackcorrectly

□

7

Temperatureswitchof#1electrolyergroupoutlet

Feedbackcorrectly

□

8

Temperatureswitchof#2electrolyergroupoutlet

Feedbackcorrectly

□

9

Levelswitchofsodiumhypochloritesolutiontank

Feedbackcorrectly

□

10

Fanswitchofsodiumhypochloritesolutiontank

Feedbackcorrectly

□

11

Directamperemeterof#1rectifieroutput

Meterindicatecorrectly

□

12

Directamperemeterof#2rectifieroutput

Meterindicatecorrectly

□

13

Directvoltagemeterof#1rectifieroutput

Meterindicatecorrectly

□

14

Directvoltagemeterof#2rectifieroutput

Meterindicatecorrectly

□

15

Temperatureof#1electrolyergroupoutletsolution

Meterindicatecorrectly

□

16

Temperatureof#2electrolyergroupoutletsolution

Meterindicatecorrectly

□

17

Inletseawaterflowratemeterof#1electrolyergroup

Meterindicatecorrectly

□

18

Inletseawaterflowratemeterof#2electrolyergroup

Meterindicatecorrectly

□

19

Flowratemeterofdosingpumpoutlet

Meterindicatecorrectly

□

20

Levelofsodiumhypochloritetank

Meterindicatecorrectly

□

8.1.4Sequencecontrolandalarmtest

№

Items

Results

1

Automaticfilterhighdifferentialpressurealarmandself-backwash

□

2

Pressurehighalarmof#1electrolyergroupinletandstopsystem

□

3

Pressurehighalarmof#2electrolyergroupinletandstopsystem

□

4

Flowratelowalarmof#1electrolyergroupinletandstop#1rectifier

□

5

Flowratelowalarmof#2electrolyergroupinletandstop#2rectifier

□

6

Temperaturehighalarmof#1electrolyergroupoutlet

□

7

Temperaturehighalarmof#2electrolyergroupoutlet

□

8

Levelhighalarmofsodiumhypochloritesolutiontank

□

9

Levellowalarmofsodiumhypochloritesolutiontankandstopdosingpump

□

8.1.5Inspectionlistsofseawaterkillingbiologysystempriortocommissioning

№

Checkitems

Results

1

Constructionofsystemiscompletedandaccordwithdesigndiagram

□

2

Singleequipmentcommissioningofallofpumps,valveandblowerarecompleted

□

3

PutI&Cequipmentrelatedtosysteminservice,indicatecorrectly

□

4

Recirculatingcoolingwatersystemoperatenormal

□

5

Systemisflushedanddrainagewaterisclear.

8.2Startupprocedure

№

Step

Checkitems

Results

1

Systemoperationbymanual

1

Startup#1blower

Normaloperation

□

2

Puttheself-cleaningfilterinservice

Normaloperation

□

3

Startup#1seawaterpump

Normaloperation

□

4

Afterabout1minute,putrectifierequipmentinservice

Normaloperation

□

5

Levelofsodiumhypochloritereachtointermediate,startup#1dosingpump

Systemoperatenormal

□

6

Startupthesecondsetofsystemasmentionedsteps

□

2

Systemshutdownbymanual

1

Adjusttheknob“Current”to“0”thenstoptherectifier

□

2

Stoptheseawaterpump

□

3

Stopthedosingpump

□

4

Stoptheblowerafter5minutes

□

3

Systemoperationbyautomaticmode

□

4

Systemshutdownbyautomaticmode

□

5

Duringnormaloperation,controlresidualchloridecontentofoutletcondenserabout0.1mg/L,relationbetweenresidualchloride&dosageshallbedeterminedbydaily/weeklycheckingforayear.Calibrationcurvewillbesuppliedtotheowner.

□

6

Integratedtrialrunofsystemandsupervisesystemoperation

Refertosection3

□

9VerificationandPostRequisites

9.1Verification

1

Allworkcompleted.

□

2

Workareacleanedup.

□

3

Alldatarecorded.

□

4

Resultsmeetacceptancecriteria.

□

5

Workrequestsignedoff.

□

9.2DeficienciesIdentified

9.3ImprovementsifRequired

10Attachment

N/A